FAQs of Customized Stepper Motor

1. What is a Stepper Motor and where is it commonly used?

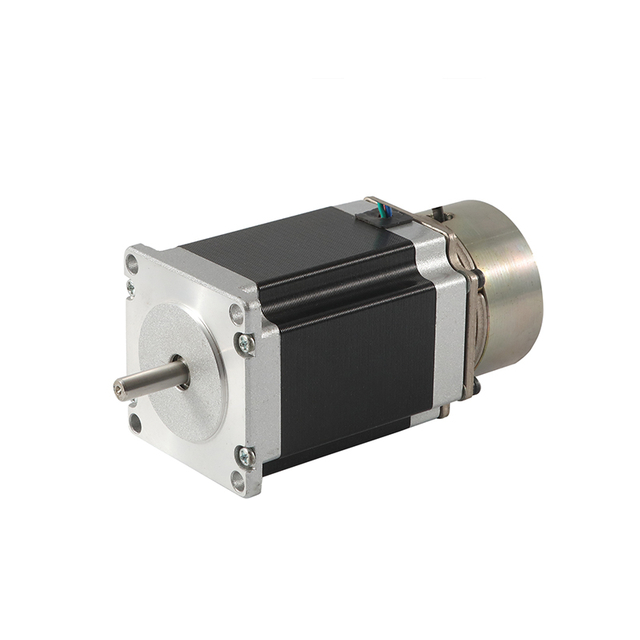

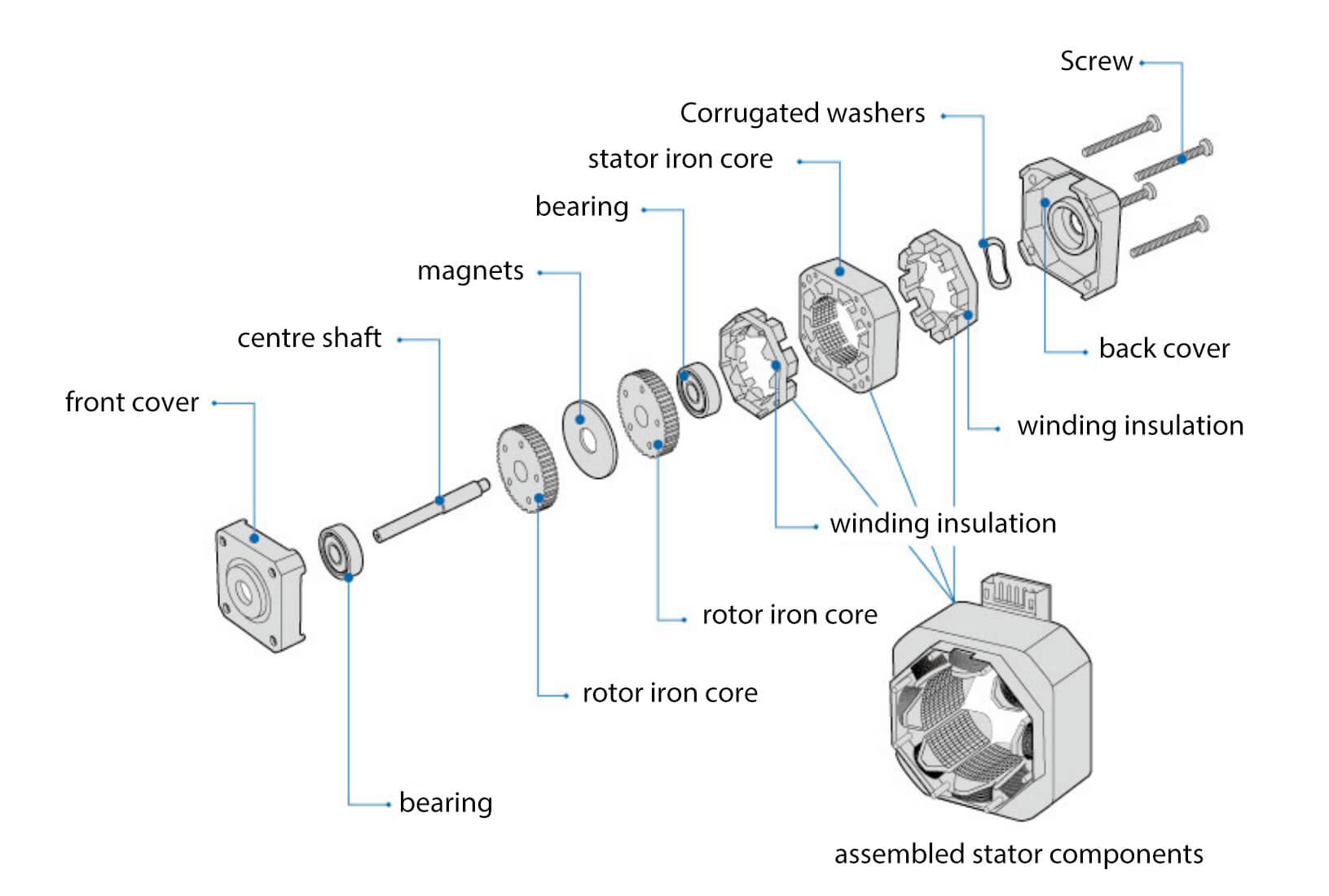

A Stepper Motor is an electromechanical device that moves in precise steps making it ideal for applications like 3D printers, CNC machines, robotics, medical equipment and industrial automation systems.

2. What are the main performance advantages of Besfoc Stepper Motors?

Besfoc Stepper Motors offer high precision, strong torque at low speeds, efficient electromagnetic design and smooth motion with reduced vibration.

3. How can a Stepper Motor improve motion control accuracy?

Stepper Motors convert digital pulses into fixed increments of movement allowing precise position control repeatability and reliable step tracking.

4. What does OEM ODM Customized service mean for a Besfoc Stepper Motor?

OEM ODM Customized service means Besfoc can tailor Stepper Motors based on customer specifications including shaft size, mounting details, torque and special features.

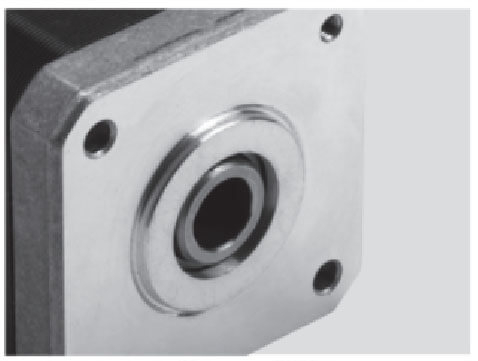

5. What customization options are available for Besfoc Stepper Motors?

Customizable options include sealed motors, special shafts, encoders, brakes, gearboxes, lead length and termination connectors.

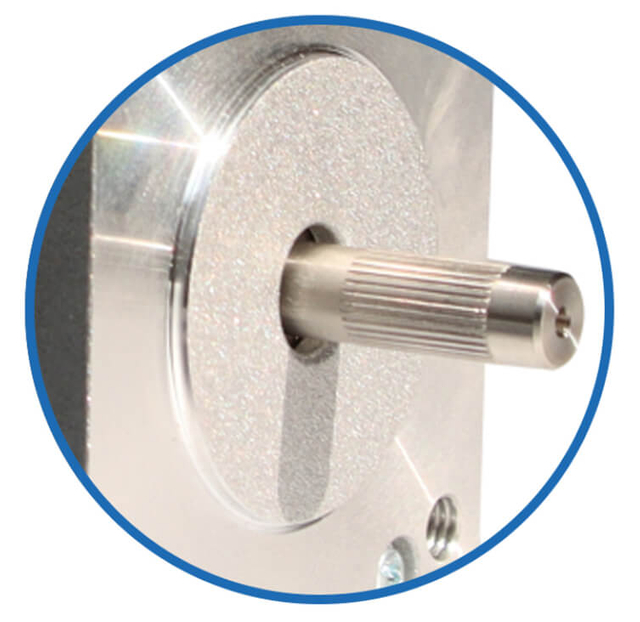

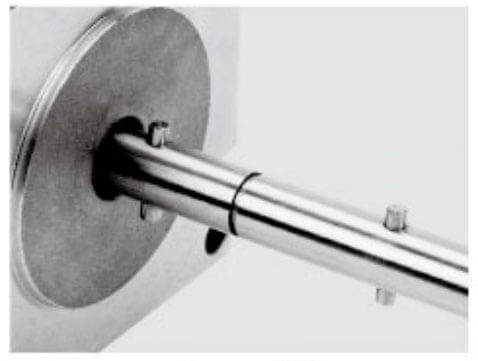

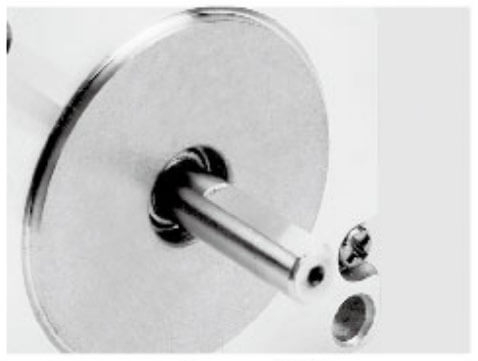

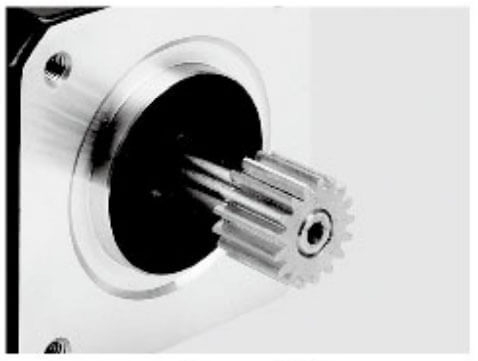

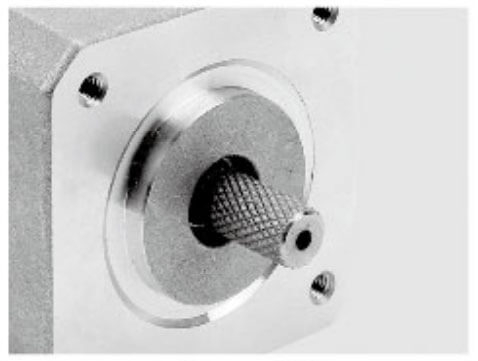

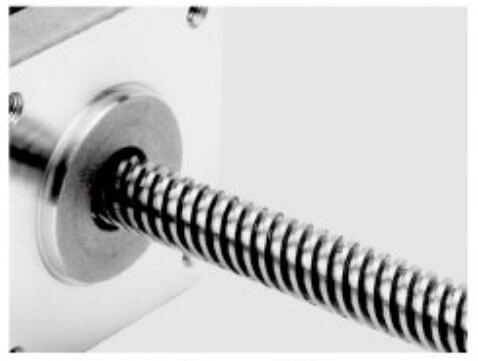

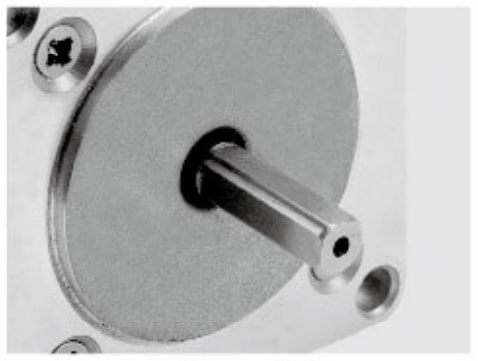

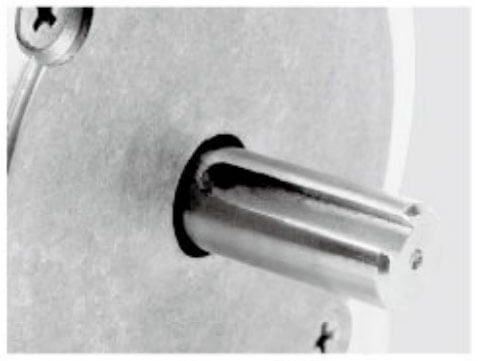

6. How does Besfoc support Stepper Motor shaft customization?

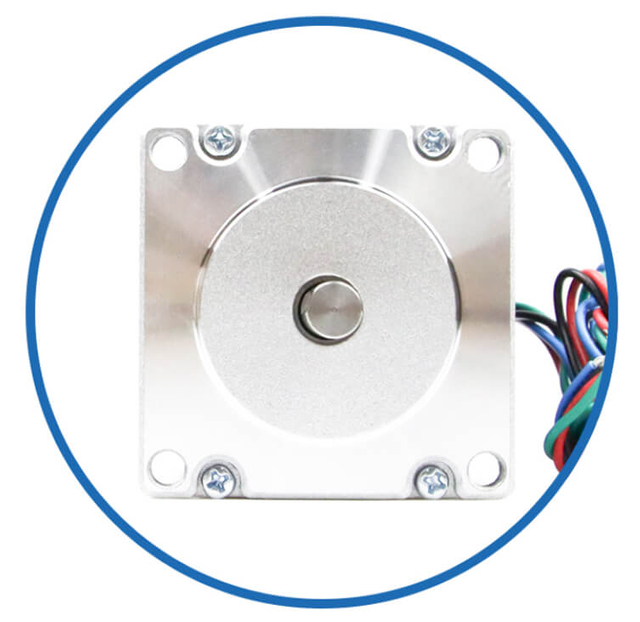

Customers can request different shaft types including hollow shafts, double D shafts, keyway shafts and threaded shafts based on their mechanical needs.

7. Can Besfoc customize Stepper Motors for integrated systems?

Yes Besfoc can provide integrated systems combining Stepper Motors with drivers, encoders and other components per customer design.

8. Why would a customer choose a customized Stepper Motor over a standard motor?

A customized Stepper Motor can fit precise system requirements, improve performance and reduce integration time and cost.

9. Does Besfoc offer Stepper Motor customization for harsh environments?

Yes Besfoc can tailor Stepper Motors with sealed or rugged designs for dusty or moisture exposed industrial environments.

10. How experienced is Besfoc in manufacturing Stepper Motors and customized products?

Besfoc has more than 10 years of manufacturing experience with a skilled R D team and global exports to major markets.

11. How quickly can Besfoc deliver customized Stepper Motor samples?

Besfoc can often deliver customized Stepper Motor samples within about 7 days to accelerate development cycles.

12. What certifications ensure the quality of Besfoc Stepper Motors?

Besfoc Stepper Motors and manufacturing processes are backed by certifications such as CE, RoHS, Reach and ISO9001 quality standards.

13. Can Besfoc customize Stepper Motor electrical parameters like current or voltage?

Yes OEM ODM Customized services allow customers to specify current, voltage and electrical parameters to align with their system needs.

14. Are encoders available as an option in Besfoc Stepper Motors?

Encoders can be added to Stepper Motors to provide feedback which improves motion control and accuracy.

15. What sizes of Stepper Motors can Besfoc manufacture?

Besfoc manufactures various Stepper Motor sizes including common NEMA frame sizes to match torque and mounting requirements.

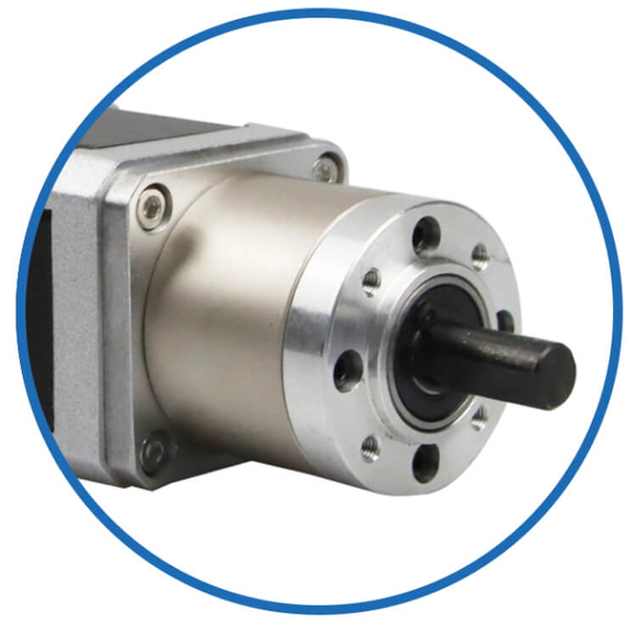

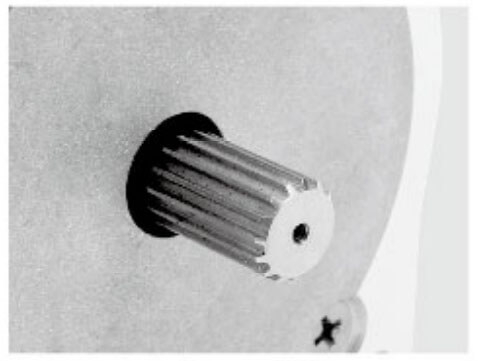

16. Can Besfoc Stepper Motors be customized with a gearbox?

Yes Besfoc offers gearbox options to increase output torque and lower speed when required for specific applications.

17. What kind of technical support does Besfoc provide for customized Stepper Motors?

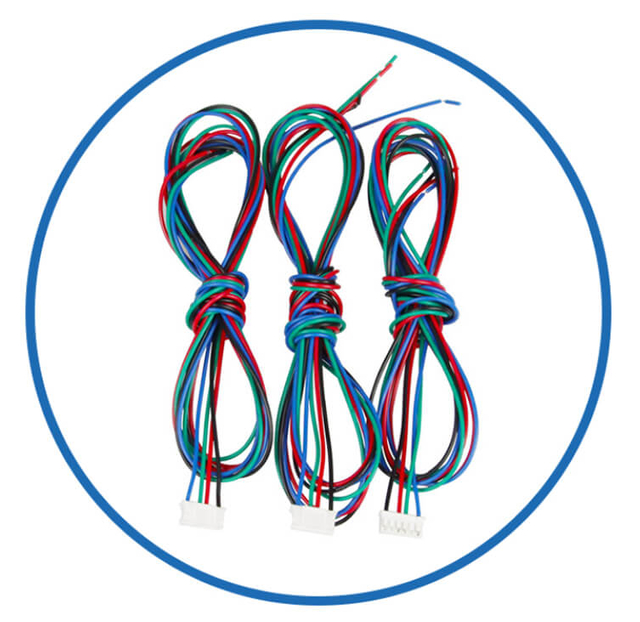

Besfoc provides technical support including application advice, wiring guidance and performance optimization during integration.

18. How does customized lead length benefit Stepper Motor integration?

Custom lead lengths and termination options help simplify wiring and match customer harness designs.

19. Can Besfoc provide sealed Stepper Motors for clean or outdoor environments?

Yes sealed Stepper Motors with ingress protection can be provided to ensure longevity and stable operation in harsh environments.

20. How does Besfoc manage mass production for customized Stepper Motors?

With large scale facilities producing millions of motors annually and a streamlined supply chain Besfoc delivers quality customized Stepper Motors efficiently.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català