BLDC motors are composed of three primary parts:

- Rotor: The rotating part, typically embedded with permanent magnets.

- Stator: The stationary part that contains the motor windings.

- Electronic Controller: Manages the commutation by switching current direction in the stator windings.

Types of Brushless DC Motors

Brushless DC motors can be categorized based on their construction and commutation methods:

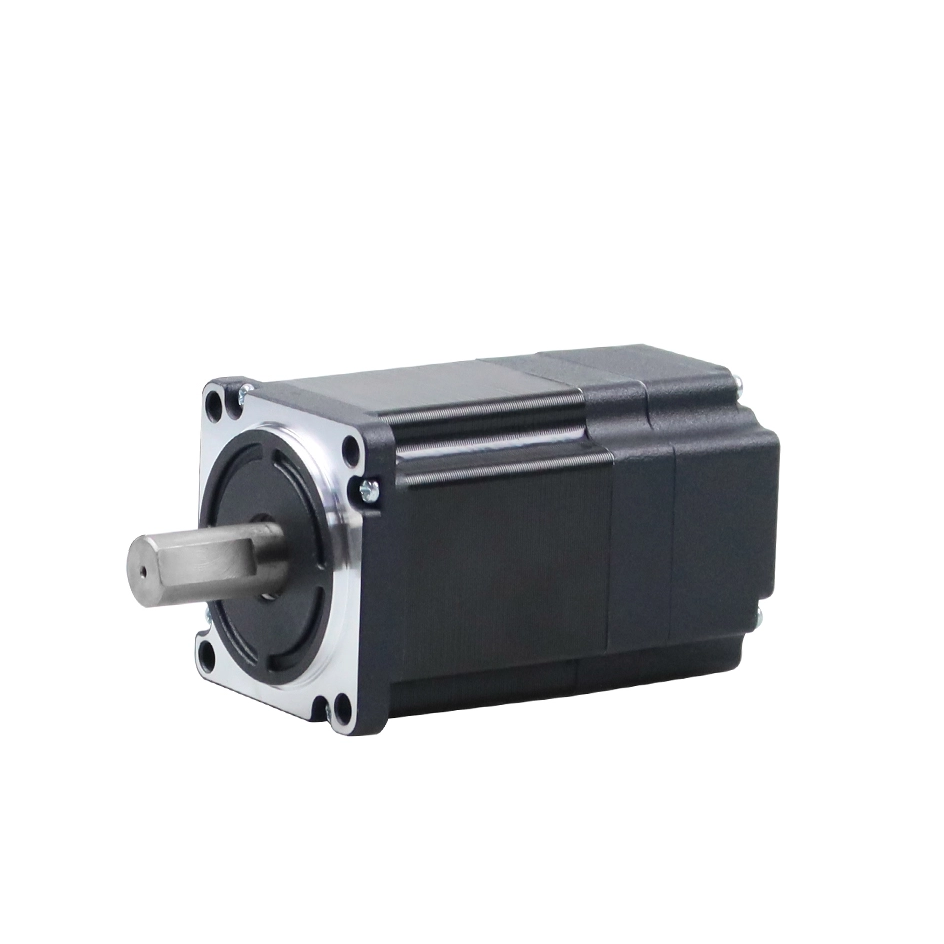

1. Inner Rotor BLDC Motors

In this design, the rotor is located inside the stator. Inner rotor motors are known for their high torque and are commonly used in industrial applications.

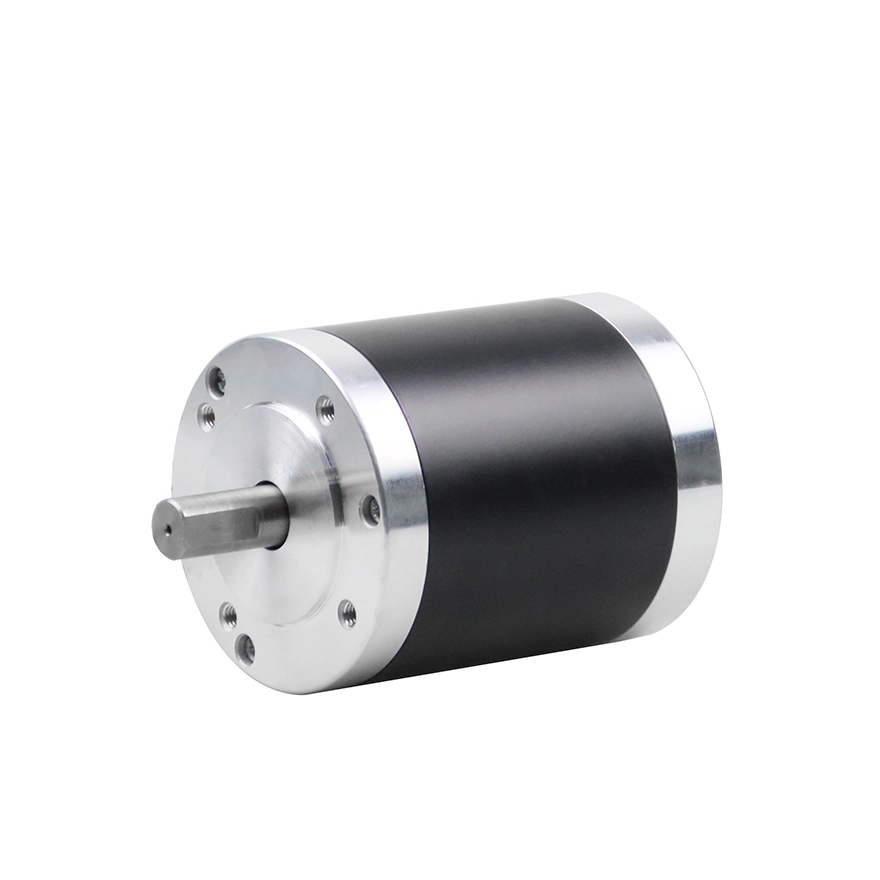

2. Outer Rotor BLDC Motors

Here, the rotor is positioned outside the stator, resulting in a compact design with high inertia. These are popular in applications like drones and small appliances.

3. Sensor-Based BLDC Motors

Equipped with sensors (e.g., Hall-effect sensors), these motors provide precise feedback on rotor position, ensuring accurate control.

4. Sensorless BLDC Motors

Sensorless motors rely on back-EMF (Electromotive Force) to determine rotor position. They are more affordable and used in cost-sensitive applications like fans and pumps.

How Does a Brushless DC Motor Work?

The operation of a brushless DC motor is based on the interaction between the magnetic field of the stator windings and the permanent magnets of the rotor. Unlike brushed motors, where brushes physically transfer electricity to the rotor, BLDC motors rely on an electronic controller to generate a rotating magnetic field.

Steps in BLDC Motor Operation:

- Electronic Commutation: The controller alternates current flow between different windings, creating a rotating magnetic field.

- Rotor Alignment: The magnetic field of the rotor aligns with the stator's magnetic field, causing rotation.

- Sensor Feedback: Sensors such as Hall-effect sensors detect rotor position, ensuring precise commutation.

This seamless process ensures higher efficiency and reduced wear, making BLDC motors ideal for demanding applications.

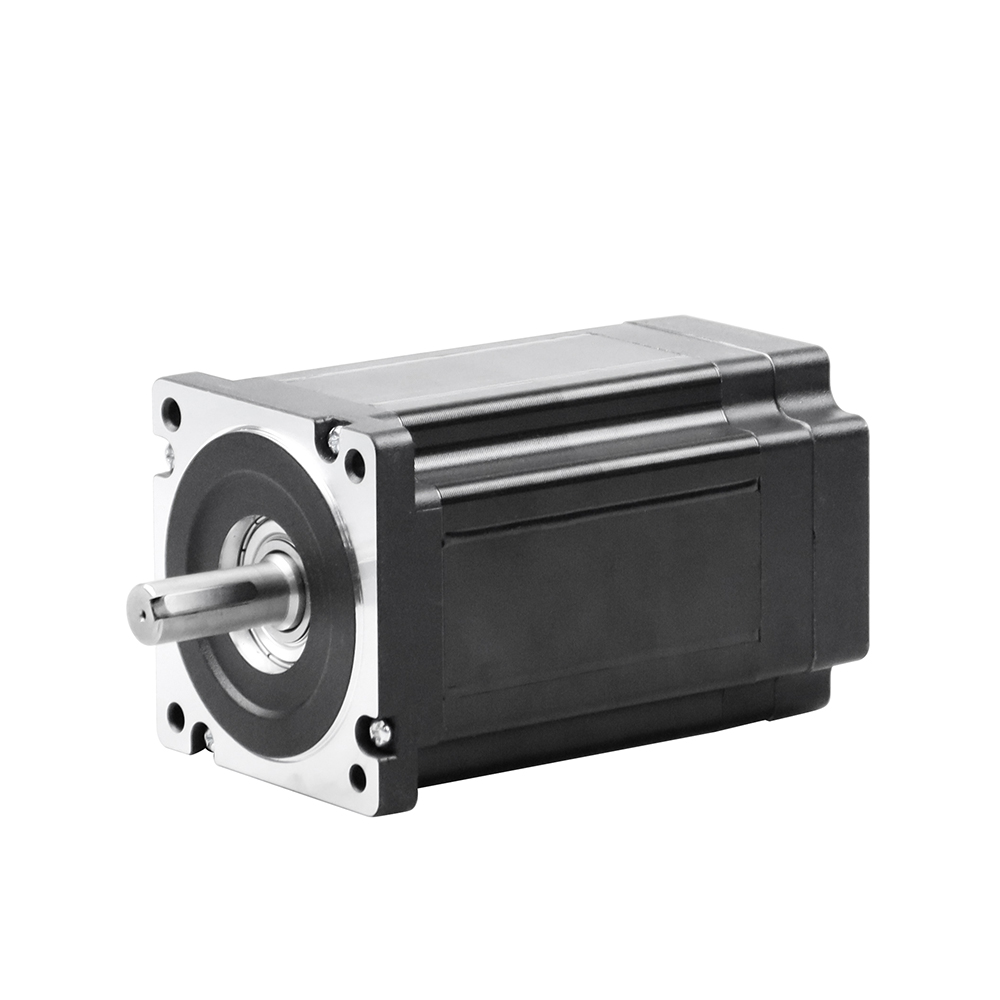

BesFoc Brushless DC Motors has the following main advantages:

(1) With good mechanical characteristics and regulating characteristics, can replace the DC brush motor speed regulation, frequency conversion motor speed regulation, induction motor plus reducer speed regulation.

(2) Can run at low speed and high power, save the reducer, and directly drive the large load.

(3) It has many advantages of the traditional DC brush motor, but also eliminates the brush and collector ring structure.

(4) Excellent torque performance, medium, and low-speed torque performance start torque is large, start current is small.

(5) Step-less speed regulation, wide speed range, strong overload capacity.

(6) Small volume, light weight, large output.

(7) Soft start, soft stop, and good braking characteristics can leave out the original mechanical or electromagnetic device.

(8) The motor itself has no excitation loss and brush loss, high efficiency, and a good comprehensive power-saving effect.

(9) High reliability, good stability, strong adaptability, and simple repair and maintenance.

(10) Vibration resistance, low noise, small vibration, smooth operation, and long life.

(11) No spark, especially suitable for public places, anti-interference, good safety performance.

Brushless dc motor application:

1. Automotive Industry

2. Consumer Electronics

3. Industrial Automation

4. Medical Devices

5. Aerospace and Drones

Key Considerations When Choosing a BLDC Motor

When selecting a brushless DC motor for a specific application, it is essential to evaluate the following factors:

Torque and Speed Requirements

Power Efficiency

Size and Weight Constraints

Environmental Conditions

Cost vs. Performance

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català