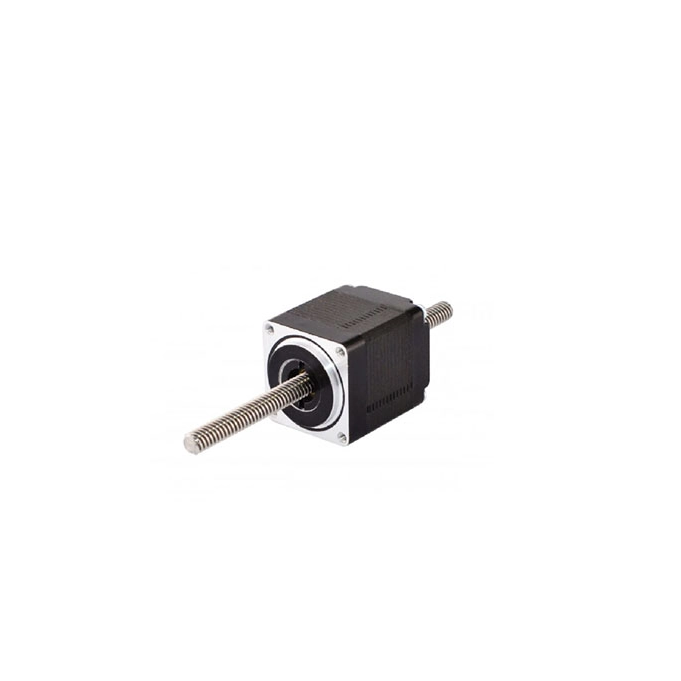

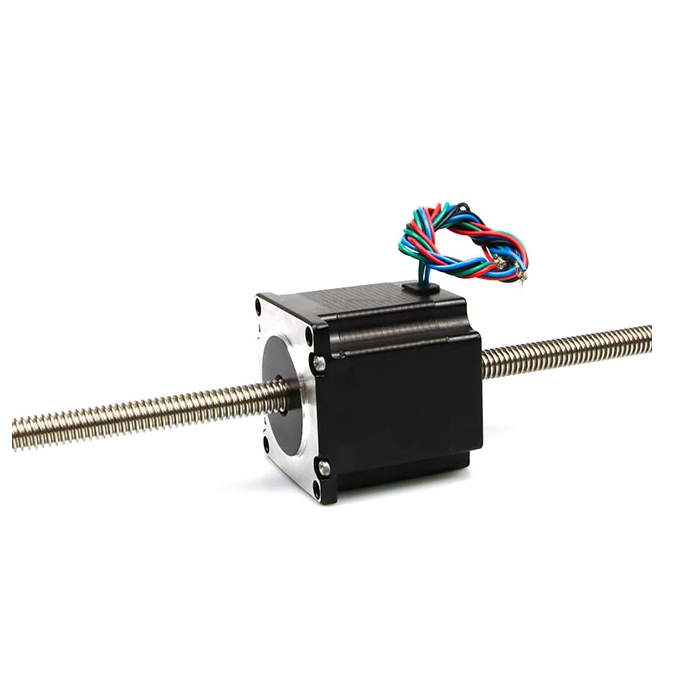

FAQs of Customized Non Captive Linear Stepper Motor

1. What is a linear Stepper Motor and how does a non captive linear stepper motor work?

A linear Stepper Motor converts pulse signals into controlled linear motion and a non captive linear stepper motor uses a free moving nut on the lead screw for flexible and smooth straight line movement.

2. What are the main advantages of a non captive linear stepper motor compared to other linear actuators?

Non captive linear stepper motors offer smooth motion, reduced backlash, greater flexibility, high efficiency and a simple design that is cost effective.

3. Why would a customer choose a non captive linear stepper motor for automation systems?

Customers choose them for precise linear motion tasks in robotics, CNC machines, 3D printing and laboratory systems where reliable straight line movement is needed.

4. What sizes of non captive linear stepper motors are available from Besfoc?

Besfoc offers non captive linear stepper motors in NEMA 8, NEMA 11, NEMA 14, NEMA 17 and NEMA 23 sizes with various body lengths and screw leads.

5. What customization options are available for a linear Stepper Motor through OEM ODM Customized services?

OEM ODM Customized options include selecting screw lead and length, body dimensions, shaft and connector types, encoder, brake or integrated driver options.

6. Can Besfoc support custom screw lead and stroke specifications for non captive linear stepper motors?

Yes Besfoc can tailor screw lead values and stroke distances to meet unique movement requirements through OEM ODM Customized design.

7. Are encoders available as an option on non captive linear stepper motors?

Yes customers can request optional encoders to provide position feedback for more precise control.

8. How does the free moving nut design benefit non captive linear stepper motors?

The free nut allows for longer travel distances without housing constraints and provides more adaptable movement for various load configurations.

9. Can non captive linear stepper motors be configured with brakes or gearboxes?

Yes OEM ODM Customized services can add brakes or gearboxes to enhance load control and stopping accuracy.

10. What torque performance can Besfoc non captive linear stepper motors deliver?

Depending on size and configuration, these motors can deliver holding torque from a few N·cm up to several N·m suitable for heavier linear applications.

11. Are non captive linear stepper motors suitable for long travel strokes?

Yes the design supports long travel strokes and high precision linear motion ideal for longer range positioning.

12. Can Besfoc customize electrical parameters like current or phase count for linear Stepper Motors?

Yes OEM ODM Customized services allow specification of electrical parameters like current ratings and step angle to match system requirements.

13. What industries benefit most from non captive linear stepper motors?

Industries such as robotics, medical, automation, optical imaging and laboratory equipment benefit from these high precision linear motion devices.

14. How does reduced backlash improve motion performance in a non captive linear stepper motor?

Reduced backlash enhances repeatability and accuracy in positioning tasks making the system more reliable under dynamic movement.

15. Can non captive linear stepper motors be designed for environmental protection or rugged use?

Yes Besfoc can provide environmental protection features and rugged components for specific operating conditions through customization.

16. How does Besfoc handle OEM ODM Customized lead times for linear Stepper Motor orders?

Besfoc uses in house production and design support to offer competitive lead times on samples and customized bulk orders.

17. What technical support does Besfoc offer for integrating non captive linear stepper motors?

Besfoc provides technical support including product selection, wiring guidance and optimal performance setup.

18. Are connectors and lead wires customizable for non captive linear stepper motors?

Yes customers can choose specific connectors, lead lengths and wire options to match their assembly requirements.

19. How does Besfoc ensure quality in customized linear Stepper Motor production?

Quality is ensured by experienced manufacturing processes, multiple quality checks and proven performance in global applications.

20. Why is OEM ODM Customized service important when selecting a non captive linear stepper motor?

OEM ODM Customized services allow the motor to meet exact dimensions, motion profiles, connection interfaces and performance needs reducing integration effort and improving system results.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català