A stepper motor is an electric motor that rotates its shaft in precise, fixed-degree steps. Due to its internal structure, you can track the shaft's exact angular position by counting the steps—no sensor needed. This precision makes stepper motors ideal for many applications.

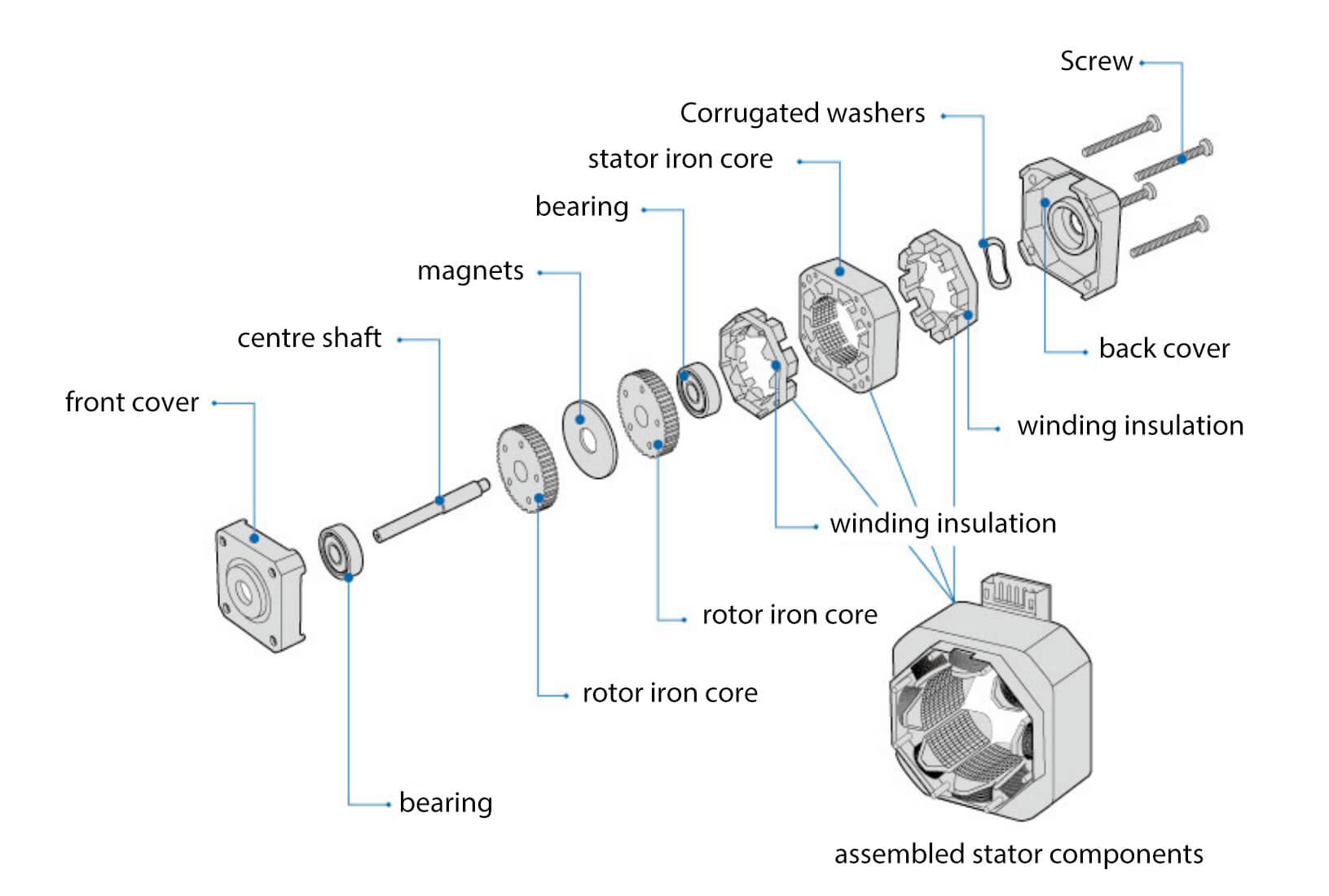

The operation of a stepper motor system revolves around the interaction between the rotor and stator. Here’s a detailed look at how a typical stepper motor works:

Signal Generation: A controller generates a sequence of electrical pulses that represent the desired movement.

Driver Activation: The driver receives the signals from the controller and energizes the motor windings in a specific sequence, creating a rotating magnetic field.

Rotor Movement: The magnetic field generated by the stator interacts with the rotor, causing it to rotate in discrete steps. The number of steps corresponds to the pulse frequency sent by the controller.

Feedback (Optional): In some systems, a feedback mechanism, such as an encoder, may be used to ensure that the motor has moved the correct distance. However, many stepper motor systems operate without feedback, relying on the precise control of the driver and controller.

BesFoc Hybrid Stepper Motor Kinds:

Hybrid stepper motors combine features of both PM and VR motors to deliver superior performance. They offer better torque and accuracy, making them suitable for more demanding applications such as CNC machines, 3D printers, and robotic systems.

Hybrid stepper motors are BesFoc main products. Our stepper motors include 2-phase and 3-phase, with step angles of 0.9°, 1.2° and 1.8°, and motor sizes of nema8, 11, 14, 16, 17, 23, 24, 34, 42 and 52. In addition to standard hybrid stepper motors, we also specialize in the production of linear stepper motors, closed-loop stepper motors, hollow-shaft stepper motors, IP65 IP67 waterproof stepper motors, geared stepper motors and Integrated stepper servo motors, etc., in which the stepping motor parameters, encoder, gearbox, brake, built-in drivers, etc. can be customized according to different needs.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català