We explore the fundamental mechanical, electrical, and application-level differences between solid shaft stepper motors and hollow shaft stepper motors, two critical motor shaft configurations widely used across industrial automation, robotics, CNC machinery, packaging systems, medical devices, and motion control applications. Understanding their distinctions enables engineers, system designers, and procurement specialists to optimize torque transfer, mechanical integration, system rigidity, and overall machine performance.

Definition of Solid Shaft Stepper Motors

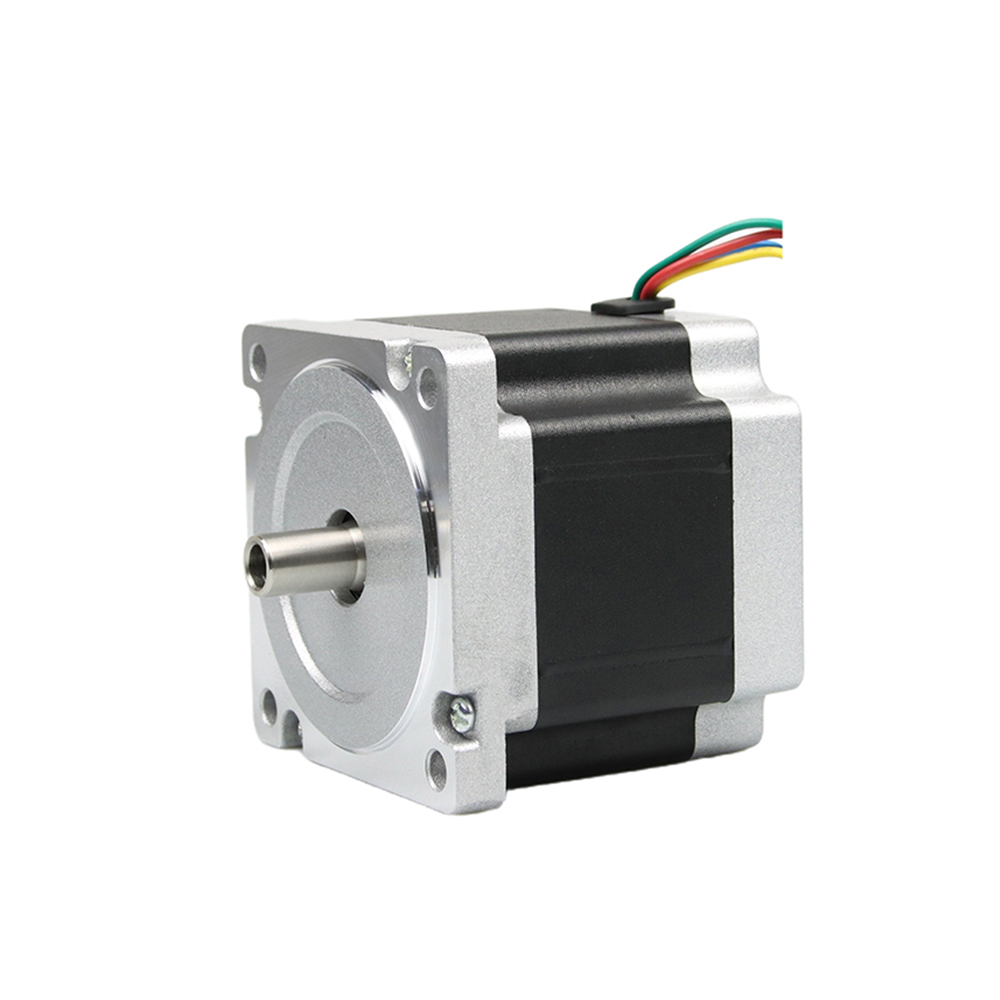

A solid shaft stepper motor is a conventional motor design where the rotating shaft is a single, continuous, cylindrical metal rod extending from the rotor core. This shaft directly transfers rotational torque to couplings, gears, pulleys, or sprockets.

Key Structural Characteristics:

Monolithic shaft construction

High torsional rigidity

Uniform stress distribution

Direct power transmission

Typically supported by dual bearings

Solid shafts remain the dominant standard across motors for decades due to their strength, dimensional stability, and mechanical simplicity.

Definition of Hollow Shaft Stepper Motors

A hollow shaft stepper motor features a central bore running completely through the shaft, allowing other components such as leadscrews, cables, fluid lines, optical fibers, or support rods to pass directly through the motor body. This design transforms the motor from a simple power unit into a high-integration motion module.

Key Structural Characteristics:

Axial through-hole shaft design

Optimized load distribution around the outer wall

Direct mounting over driven shafts

Enhanced system compactness

Elimination of intermediate couplings

Hollow shaft stepper motors are increasingly used in precision automation, semiconductor manufacturing, medical imaging equipment, and space-constrained robotic assemblies.

Structural and Mechanical Design Differences

We examine the structural and mechanical design of solid shaft stepper motors and hollow shaft stepper motors as the foundation that directly defines their performance, durability, precision, and system integration behavior. The difference between a fully solid core and a bored shaft geometry creates significant variations in stress distribution, torsional rigidity, bending resistance, vibration response, and mechanical efficiency.

Solid Shaft Stepper Motor Structural Design

A solid shaft stepper motor features a continuous cylindrical metal shaft with no internal cavity, typically manufactured from high-strength alloy steel, carbon steel, or hardened stainless steel depending on the application. This uninterrupted material structure provides:

Maximum torsional rigidity due to full material cross-section

Uniform stress distribution along the shaft axis

Exceptional resistance to bending and deflection under radial loads

High tolerance to sudden shock, impact, and torque spikes

Superior fatigue life in heavy-duty cyclic operation

Mechanically, the solid shaft behaves as a single, monolithic torque transmission element, making it highly resistant to elastic deformation. This is especially critical in press machines, heavy conveyors, crushers, mixers, and large gear-driven systems, where shafts experience extreme torsional and radial loading simultaneously.

From a design perspective, bearing placement on solid shaft stepper motors is optimized for maximum radial and axial load capacity, allowing these motors to operate reliably in high-vibration and high-impact environments without premature bearing failure.

Hollow Shaft Stepper Motor Structural Design

A hollow shaft stepper motor is engineered with a precision-machined axial bore running through the shaft, strategically redistributing material away from the shaft center toward the outer diameter. This results in a higher strength-to-weight ratio and optimized mass distribution.

Key mechanical characteristics include:

Lower polar moment of inertia for faster acceleration and deceleration

Improved torsional efficiency per unit mass

Reduced rotating mass without sacrificing structural strength

Enhanced coaxial alignment for direct shaft mounting

Optimized mechanical balance at high rotational speeds

By shifting material outward, hollow shaft designs maintain high torsional strength while significantly reducing shaft weight, which directly improves servo responsiveness, positioning accuracy, and dynamic stability. This structural efficiency makes hollow shaft stepper motors ideal for robot joints, direct-drive rotary tables, linear actuator integration, and high-speed positioning systems.

Additionally, the internal bore allows mechanical, electrical, pneumatic, and optical components to pass directly through the shaft, eliminating complex external routing and enabling ultra-compact, fully integrated motion assemblies.

Stress Distribution and Load Behavior Comparison

In solid shafts, mechanical stress is distributed evenly across the full cross-section, which delivers maximum resistance to torsional shear and bending deformation.

In hollow shafts, stress is concentrated toward the outer diameter where material is most effective in resisting torsion, providing equivalent strength with lower mass.

This structural efficiency allows hollow shafts to achieve comparable torque performance to solid shafts at reduced material volume, which is a major advantage in weight-sensitive automation systems.

Deflection, Alignment, and Stability Performance

Solid shafts exhibit minimal radial deflection under heavy side loads, making them ideal for:

Hollow shafts, while still rigid, are optimized for:

Perfect coaxial alignment

Direct-drive system architectures

Zero-backlash assembly

High-speed precision motion

Because hollow shafts eliminate many intermediate mechanical interfaces, they offer superior long-term alignment stability and reduced cumulative assembly tolerances.

Vibration and Dynamic Response Characteristics

The added mass of a solid shaft increases its ability to absorb mechanical shock, but this also raises the system’s inertia, which can limit dynamic performance in fast motion cycles.

Hollow shafts, by contrast, deliver:

Lower vibration transmission

Reduced harmonic resonance

Improved high-speed balance

Quieter operation

Higher control-loop bandwidth in servo systems

This makes hollow shaft stepper motors significantly better suited for precision automation and high-speed motion control.

Mechanical Design Conclusion

From a purely structural and mechanical viewpoint:

Solid shaft stepper motors dominate in raw mechanical strength, impact resistance, and extreme load endurance.

Hollow shaft stepper motors dominate in structural efficiency, dynamic performance, precision alignment, and compact system integration.

Both designs are mechanically optimized for different performance priorities, and neither is universally superior—their structural differences define their ideal operating domains.

Torque Transmission and Load Capacity Comparison

We analyze torque transmission and load capacity as the most decisive performance factors separating solid shaft stepper motors and hollow shaft stepper motors. These two parameters directly determine power delivery stability, mechanical endurance, shock resistance, service life, and suitability for heavy-duty versus precision-driven systems. Although both designs efficiently transmit torque, their structural geometry causes significant performance divergence under real-world mechanical loads.

Torque Transmission in Solid Shaft Stepper Motors

A solid shaft stepper motor transmits torque through a fully continuous metal cross-section, meaning every portion of the shaft contributes directly to torsional load resistance. This full material composition gives solid shaft stepper motors several decisive advantages in torque performance:

Extremely high peak torque capability

Exceptional overload tolerance during start-up and braking

Superior resistance to torque spikes caused by sudden load changes

Maximum torsional stiffness under continuous duty

Minimal elastic twist under extreme mechanical stress

Because torque is distributed uniformly across the entire shaft diameter, solid shafts exhibit minimal angular deflection, even under severe operating conditions. This makes them mechanically ideal for:

Heavy industrial conveyors

Hydraulic pump drives

Crushers and mixers

Extruders and rolling mills

Large gear-reduction systems

In these environments, torque is not only high but also unstable and highly impulsive, and the solid shaft’s ability to withstand repetitive shock torque without material fatigue is a critical engineering advantage.

Torque Transmission in Hollow Shaft Stepper Motors

A hollow shaft stepper motor transmits torque through a ring-shaped cross-section, where material is distributed near the outer diameter of the shaft rather than at the center. This design is mechanically efficient because torsional resistance increases exponentially as material moves farther from the centerline.

Key torque-related advantages of hollow shaft stepper motors include:

High torque-to-weight ratio

Excellent continuous torque density

Lower rotational inertia for fast dynamic response

Superior torque smoothness at high speeds

Reduced energy loss during acceleration and deceleration

Although a hollow shaft removes central material, it does not significantly reduce torsional strength when properly engineered. Instead, the design maximizes torque efficiency per unit of mass, making hollow shafts dominant in:

Direct-drive rotary tables

Robotic joint actuators

Precision automation systems

High-speed servo-driven machinery

Medical imaging platforms

Hollow shaft stepper motors excel in applications requiring smooth, controlled, and rapidly changing torque outputs, where dynamic response is more important than raw overload tolerance.

Peak Torque vs. Continuous Torque Performance

Solid shaft stepper motors dominate in peak torque capacity, making them ideal for heavy starting loads and stall-prone machinery.

Hollow shaft stepper motors dominate in continuous torque stability, especially in high-speed, closed-loop servo applications.

This distinction is critical:

Load Capacity: Radial, Axial, and Combined Loads

Solid Shaft Load Capacity

Solid shaft stepper motors inherently tolerate higher combined mechanical loads:

High radial loads from belts, pulleys, and gears

Substantial axial thrust from screw-driven systems

Combined torque + bending loads in misaligned assemblies

Their solid cross-section provides maximum shaft stiffness, minimizing flex under side loading. This property dramatically reduces:

Solid shaft stepper motors therefore dominate in belt-driven, chain-driven, and gear-driven systems subjected to continuous side loading.

Hollow Shaft Load Capacity

Hollow shaft stepper motors primarily excel in coaxial load transmission, where torque is transferred directly through the shaft with minimal bending forces.

Key load characteristics include:

Optimized axial load handling in direct-drive systems

Reduced bearing stress due to precise coaxial alignment

Minimal radial load tolerance when used without external support

Superior load distribution in integrated motion systems

While hollow shafts can withstand significant torque, they are less tolerant of large external side loads unless additional support bearings or reinforced couplings are used. Their design philosophy favors:

Shock Load and Fatigue Resistance Comparison

Solid shaft stepper motors exhibit maximum shock resistance, absorbing sudden torque reversals without developing microfractures.

Hollow shaft stepper motors reduce fatigue stress through efficient mass distribution, but remain more sensitive to extreme impulsive torque events.

This means:

Torque Ripple, Smoothness, and Control Stability

Solid shaft systems often involve external couplings and transmissions, which can introduce:

Hollow shaft stepper motors, when directly mounted, offer:

Ultra-smooth torque delivery

Instantaneous torque response

Higher control-loop bandwidth

Virtually zero mechanical backlash

This advantage is critical in:

Robotics

Semiconductor handling systems

Laser positioning platforms

High-speed packaging machinery

Energy Efficiency Under Load

Torque transmission efficiency is directly affected by mechanical interfaces:

Solid shaft systems often lose energy through multi-stage couplings, gear trains, and adapters.

Hollow shaft systems minimize losses through direct mechanical engagement, allowing:

Engineering Verdict on Torque and Load Capacity

From a strict performance standpoint:

Solid shaft stepper motors provide unmatched peak torque resistance, impact survivability, and heavy-load endurance.

Hollow shaft stepper motors deliver superior torque efficiency, smoother torque control, and faster dynamic response under continuous operation.

The selection between the two is not about superiority—it is about matching torque behavior and load mechanics to the operational reality of the system. Solid shafts dominate force-driven machinery, while hollow shafts dominate precision-driven motion systems.

Installation, Mounting, and Mechanical Integration

Solid Shaft Stepper Motor Integration:

Hollow Shaft Stepper Motor Integration:

Enables:

Direct shaft insertion

Clamping, shrink-fit, or locking collar mounting

Zero-backlash transmission

Results in:

Hollow shaft stepper motors dramatically simplify machine assembly while improving alignment accuracy and repeatability.

Weight, Inertia, and Dynamic Performance

Dynamic performance is heavily influenced by rotational inertia and moving mass distribution.

Solid shafts concentrate mass at the center, increasing polar moment of inertia.

Hollow shafts move mass toward the outer diameter, lowering effective inertia while preserving torsional strength.

Performance Consequences:

Faster acceleration and deceleration

Improved servo loop stability

Lower vibration and resonance

Higher system bandwidth

For high-speed automation, pick-and-place systems, and robotic joints, hollow shaft stepper motors provide exceptional motion smoothness and control precision.

Space Efficiency and System Packaging

Solid shaft stepper motors require external couplings and mechanical transmission elements, increasing:

Hollow shaft stepper motors:

Allow direct drive integration

Reduce assembly envelope dimensions

Enable ultra-compact axis design

Support through-shaft cable routing

This advantage is decisive in:

Precision, Accuracy, and Backlash Behavior

Solid Shaft Systems:

Hollow Shaft Systems:

Direct mechanical interface eliminates backlash

Higher repeatability

Improved positioning accuracy

Superior micro-step resolution

In closed-loop systems, hollow shafts provide measurably better positioning fidelity.

Thermal Management and Heat Dissipation

Solid shafts conduct heat axially along their entire core, promoting:

Hollow shafts alter heat flow dynamics:

Increased outer surface area

Enhanced air convection

Lower central thermal mass

Highly effective for ventilated designs

For high-speed servo motors, hollow shaft designs often demonstrate lower operating temperatures at equivalent load conditions.

Maintenance, Reliability, and Service Life

Solid Shaft Reliability:

Hollow Shaft Reliability:

Both systems offer exceptional longevity when properly applied, but solid shafts dominate in abusive environments, while hollow shafts dominate in precision-critical operations.

Application-Specific Use Cases

Ideal Applications for Solid Shaft Stepper Motors:

Ideal Applications for Hollow Shaft Stepper Motors:

Direct-drive rotary tables

Linear actuator motors

Optical positioning systems

Robot joint actuators

Medical imaging platforms

Semiconductor fabrication equipment

Cost Structure and Manufacturing Complexity

Solid shaft stepper motors are:

Hollow shaft stepper motors involve:

Consequently, solid shaft stepper motors retain a cost advantage, while hollow shaft stepper motors deliver higher value density per system square inch.

Compatibility with Gearboxes, Encoders, and Transmission Systems

Solid Shaft Compatibility:

Universal gearbox coupling compatibility

Standard encoder mounting

Fully interchangeable across legacy systems

Hollow Shaft Compatibility:

Ideal for:

Through-bore encoders

Torque tubes

Integrated brake systems

Enables:

The hollow shaft ecosystem supports next-generation fully integrated smart motion modules.

Vibration, Noise, and Mechanical Stability

Solid shafts offer:

Higher damping against impact

Greater tolerance for shock loading

Lower susceptibility to fracture under sudden torque reversals

Hollow shafts offer:

Lower vibration transmission

Reduced harmonic resonance

Quieter high-speed operation

Superior dynamic balance

Energy Efficiency and Power Density

Efficiency differences stem from:

Hollow shaft stepper motors demonstrate:

Solid shaft stepper motors remain highly efficient under sustained heavy loads but suffer from higher parasitic losses in multi-stage transmission systems.

Summary of Core Differences Between Solid Shaft and Hollow Shaft stepper Motors

| Feature | Solid Shaft Stepper Motor | Hollow Shaft stepper Motor |

| Shaft Structure | Fully solid | Central axial bore |

| Torque Capacity | Extremely high | High torque-to-weight |

| Installation | Couplings required | Direct shaft mounting |

| Space Efficiency | Larger | Compact |

| Weight & Inertia | Higher | Lower |

| Precision | Good | Excellent |

| Backlash | Possible | Virtually eliminated |

| Cost | Lower | Higher |

| Best Use | Heavy-duty machinery | Precision automation |

Final Engineering Perspective

We conclude that solid shaft stepper motors remain irreplaceable in high-load, impact-intensive, and torque-dominated industrial environments, where brute mechanical strength and shock resistance are paramount. In contrast, hollow shaft stepper motors define the future of compact, high-precision, and highly integrated electromechanical systems, where space efficiency, dynamic performance, and mechanical accuracy drive system excellence.

Choosing between the two is not merely a cost decision—it is a strategic architectural choice that defines system behavior, performance limits, assembly efficiency, and long-term reliability.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català