In today's industrial and commercial landscape, energy efficiency is no longer optional—it is a fundamental design requirement. As system architects, OEMs, and engineers pursue higher performance with lower operating costs, the debate between BLDC motors (Brushless DC motors) and AC motors has intensified. We examine both technologies in depth, focusing on efficiency, performance, lifecycle cost, control precision, and application suitability to determine which motor technology delivers superior results for energy-efficient systems.

Before evaluating performance, we clarify the structural and operational foundations of both motor types.

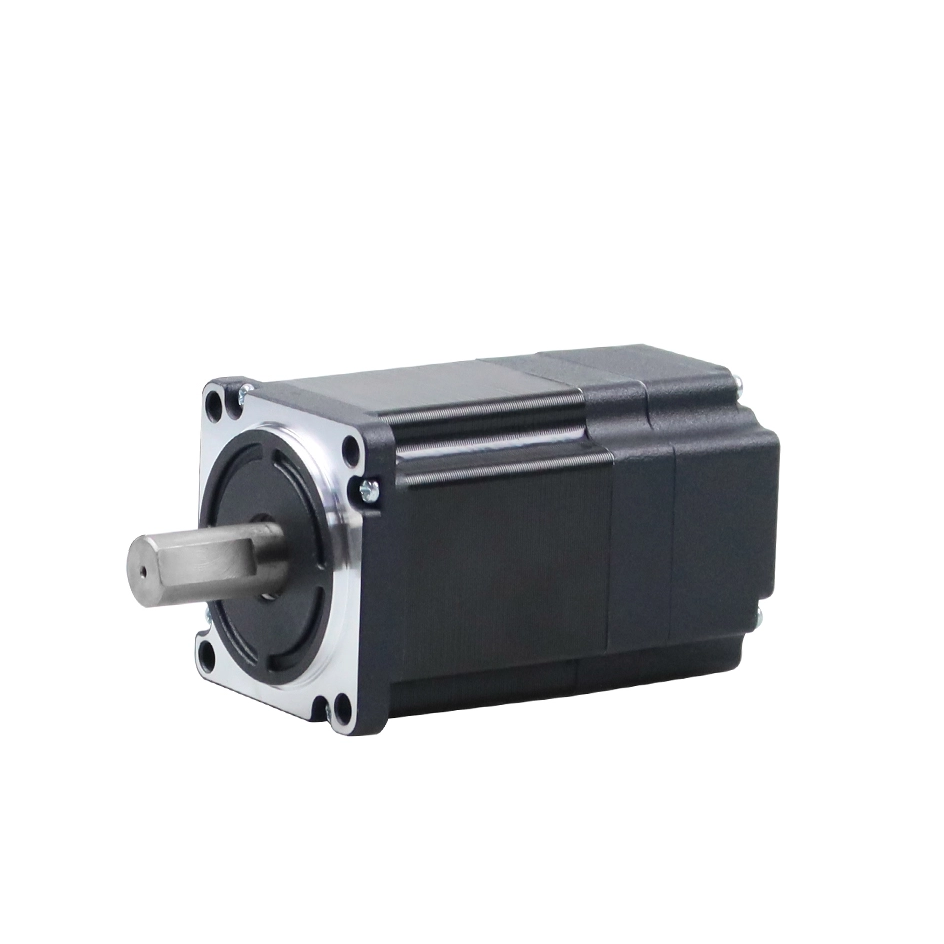

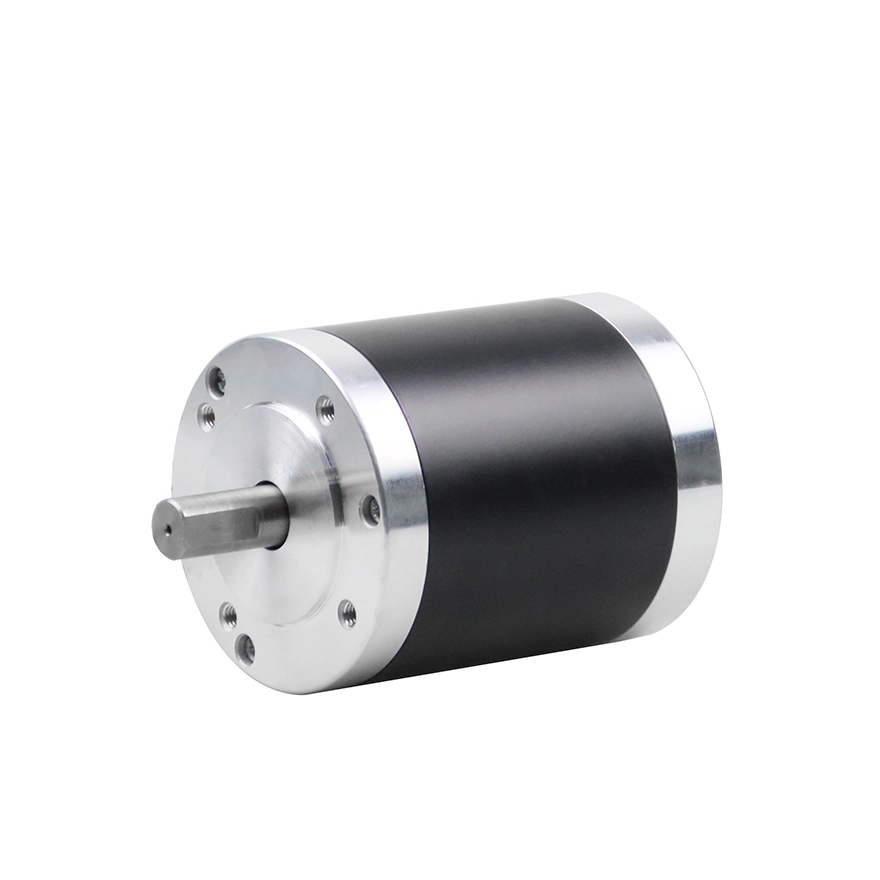

BLDC Motor Overview

A Brushless DC motor (BLDC) operates using electronic commutation instead of mechanical brushes. It consists of:

The absence of brushes eliminates mechanical friction and sparking, resulting in higher efficiency, lower maintenance, and longer service life.

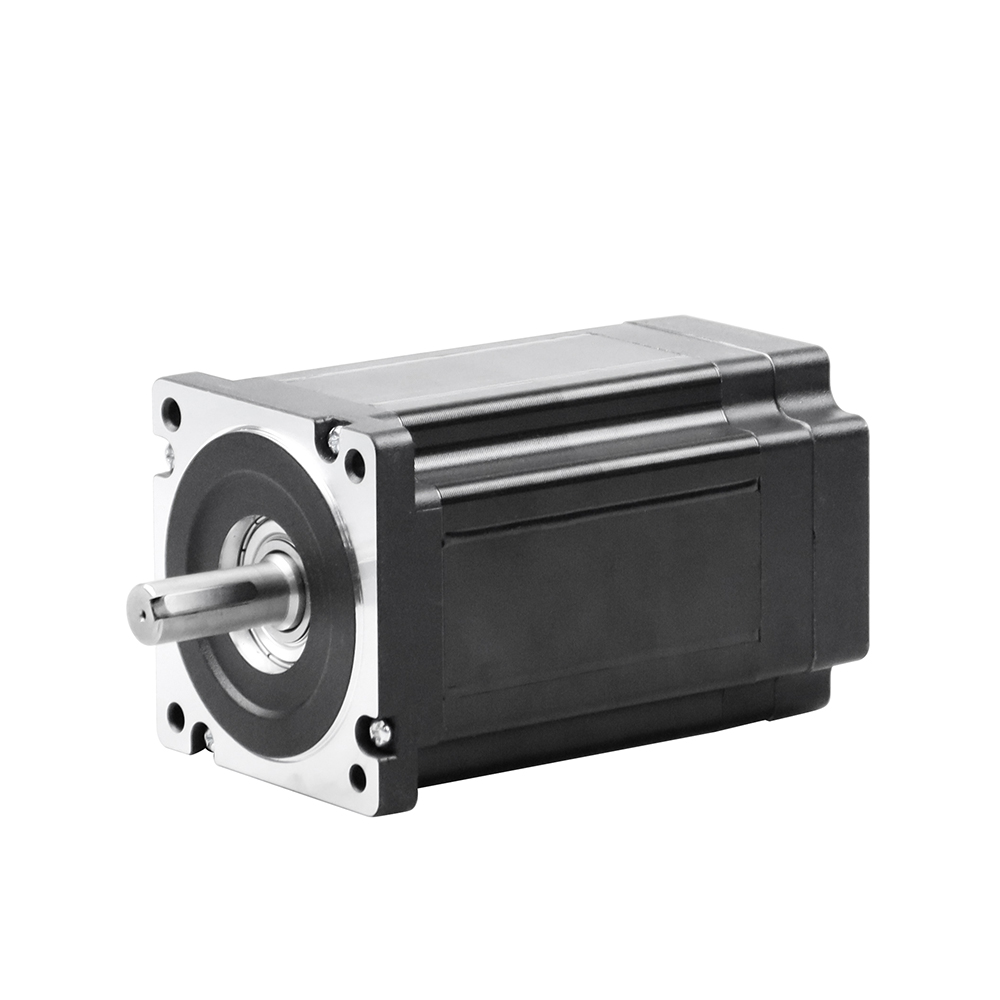

AC Motor Overview

AC motors are powered by alternating current and are broadly classified into:

Induction motors dominate industrial applications due to their durability and cost-effectiveness. However, they rely on electromagnetic induction rather than permanent magnets, which impacts efficiency under varying load conditions.

Energy Efficiency Comparison: BLDC vs AC Motors

1. Electrical Efficiency Under Load

When evaluating energy-efficient systems, real-world operating conditions matter more than nameplate ratings.

The key difference lies in rotor losses. Induction motors generate rotor currents to produce torque, resulting in heat losses. BLDC motors use permanent magnets, eliminating rotor copper losses and significantly improving efficiency—especially at partial loads.

In variable-speed applications, BLDC motors maintain high efficiency across a wide RPM range, while traditional AC motors often experience efficiency drops at lower speeds unless paired with advanced variable frequency drives (VFDs).

Conclusion: For systems operating under variable loads, BLDC motors provide superior energy utilization.

2. Power Factor and Energy Consumption

AC induction motors typically operate with a lagging power factor, particularly under light load conditions. Poor power factor leads to:

BLDC motors, controlled electronically, maintain a near-unity power factor, improving overall electrical system performance and reducing wasted energy.

In large facilities with multiple motors, this translates into measurable reductions in energy costs and improved grid stability.

Speed Control and Precision

3. Variable Speed Performance

Modern energy-efficient systems demand precise speed regulation. Applications such as HVAC compressors, robotics, electric vehicles, and smart appliances require smooth torque and controlled acceleration.

While VFD-driven AC motors can achieve advanced control, the system becomes more complex and often less efficient than an integrated BLDC drive solution.

BLDC motors inherently provide:

High starting torque

Fast acceleration

Accurate RPM control

Reduced speed ripple

For precision-driven applications, BLDC technology outperforms traditional AC motor systems in both control stability and energy optimization.

Thermal Performance and Heat Generation

4. Heat Loss and Cooling Requirements

Heat generation directly impacts energy efficiency and lifespan.

Induction AC motors generate heat due to:

BLDC motors reduce internal heat generation because:

Lower heat production means:

For compact or enclosed systems where heat dissipation is critical, BLDC motors deliver clear advantages.

Maintenance and Lifecycle Cost

5. Operational Longevity

Maintenance is a critical factor in evaluating total system efficiency.

AC induction motors are mechanically robust but require:

Bearing maintenance

Cooling fan upkeep

Insulation monitoring

Brushed DC motors suffer from brush wear, but BLDC motors eliminate this issue entirely.

BLDC motors offer:

Although BLDC systems have higher upfront electronic complexity, their lower maintenance cost over time significantly reduces total cost of ownership (TCO).

Initial Investment vs Long-Term Savings

6. Cost Considerations

AC motors generally have a lower initial purchase cost, particularly for simple, fixed-speed applications.

BLDC motors involve:

This increases initial investment. However, in energy-intensive applications operating continuously, the efficiency gains result in:

Over multi-year operation cycles, BLDC systems often deliver superior ROI, especially in high-duty environments.

Noise and Acoustic Performance

7. Quiet Operation in Energy-Efficient Designs

Noise reduction is increasingly important in residential and commercial energy-efficient systems.

BLDC motors provide:

Traditional AC motors may produce:

Electromagnetic hum

Mechanical vibration

Fan noise

For applications such as smart HVAC systems, medical devices, and consumer appliances, BLDC motors ensure quieter, more refined operation.

Application-Specific Comparison

8. HVAC and Smart Climate Systems

Modern HVAC systems rely heavily on variable-speed compressors and fans. BLDC motors:

Adjust airflow dynamically

Reduce startup current spikes

Optimize energy use under fluctuating loads

While high-efficiency AC motors with VFDs are common, BLDC systems achieve better performance in smart, demand-driven climate control systems.

9. Industrial Automation

In robotics and CNC equipment, torque precision and dynamic response are essential. BLDC motors outperform standard AC induction motors in:

Position accuracy

Torque consistency

Rapid load changes

However, in heavy industrial environments requiring extreme durability and constant speed, premium AC motors remain competitive.

10. Electric Vehicles and Mobility Systems

Electric mobility systems overwhelmingly favor BLDC and PMSM (Permanent Magnet Synchronous Motors) due to:

AC induction motors are used in some EV platforms but typically require more complex thermal management.

Environmental Impact and Sustainability

11. Carbon Footprint Reduction

Energy efficiency directly correlates with reduced carbon emissions. Because BLDC motors consume less electricity under variable loads, they:

Lower greenhouse gas emissions

Support sustainability goals

Improve compliance with global energy standards

In regions with strict efficiency regulations, such as IE3 and IE4 motor classifications, BLDC technology aligns well with evolving energy policies.

When AC Motors Are the Better Choice

While BLDC motors dominate many modern energy-efficient and precision-driven applications, there are specific scenarios where AC motors—particularly induction motors—remain the optimal solution. In environments where simplicity, durability, cost control, and operational robustness outweigh the need for advanced electronic control, AC motors continue to provide exceptional value.

Below, we outline the conditions under which AC motors are the superior choice.

1. Fixed-Speed, Continuous Operation Applications

AC induction motors excel in constant-speed systems that operate under steady loads. Applications such as:

do not require dynamic speed modulation. In these cases, the inherent simplicity of an AC motor minimizes complexity while delivering dependable performance.

Because these systems operate at a stable frequency supplied directly from the grid, they avoid the need for sophisticated electronic controllers. This reduces potential failure points and lowers system cost.

For fixed-speed industrial processes, AC motors provide a reliable and cost-effective solution.

2. Lower Initial Investment Requirements

In projects where capital expenditure (CAPEX) is a primary constraint, AC motors offer a significant advantage.

Compared to BLDC motors, AC motors:

Do not require permanent magnets

Avoid rare-earth material dependency

Can operate directly from AC power

Often require simpler control electronics

This makes them substantially more affordable in high-volume or budget-sensitive applications.

For facilities deploying dozens or hundreds of motors, the lower upfront cost of AC motors can represent considerable financial savings without compromising essential functionality.

3. Harsh Industrial Environments

AC motors are widely recognized for their rugged mechanical construction. In heavy-duty environments such as:

motors are exposed to dust, vibration, extreme temperatures, and moisture.

Induction motors are inherently robust because:

They have no permanent magnets that can demagnetize under extreme heat

Their construction tolerates mechanical shock

They feature sealed housings suitable for IP-rated protection

In these demanding conditions, the simpler electromagnetic design of AC motors enhances durability and reduces vulnerability to electronic failure.

4. High-Power Industrial Applications

For very high-power requirements, AC motors—especially three-phase induction motors—are often more practical and scalable.

In applications exceeding several hundred kilowatts, AC motors:

Provide proven large-scale performance

Integrate seamlessly into industrial three-phase infrastructure

Offer standardized mounting and maintenance procedures

Although BLDC and permanent magnet synchronous motors are advancing in high-power sectors, AC induction motors remain the dominant choice for large pumps, heavy compressors, and bulk material handling systems.

5. Simplified Maintenance in Established Facilities

Industrial facilities with long-standing AC motor infrastructure benefit from:

Existing technician expertise

Readily available spare parts

Established maintenance procedures

Compatibility with legacy systems

Switching to BLDC systems may require retraining staff and upgrading power electronics infrastructure. In facilities prioritizing operational continuity, AC motors offer logistical simplicity and proven serviceability.

6. Grid Compatibility and Direct Line Operation

One of the strongest advantages of AC motors is their ability to operate directly from the power grid without requiring advanced electronic commutation.

In applications where:

Speed variation is unnecessary

Electrical harmonics must be minimized

System simplicity is prioritized

AC motors provide a straightforward solution.

Although Variable Frequency Drives (VFDs) can enhance AC motor efficiency and control, they are optional rather than mandatory. This flexibility makes AC motors adaptable across diverse operating environments.

7. Reduced Sensitivity to Electronic Failure

BLDC systems rely heavily on control electronics. While modern controllers are highly reliable, they remain sensitive to:

AC induction motors, particularly those operating without VFDs, contain fewer sensitive electronic components. In remote installations or infrastructure with unstable power conditions, this reduced dependency can enhance reliability.

8. Long-Term Mechanical Stability

Induction motors have a long-established reputation for durability. Many industrial AC motors operate continuously for decades with minimal issues beyond routine bearing replacement.

Their advantages include:

For facilities prioritizing predictable long-term mechanical stability over advanced control features, AC motors remain a dependable investment.

Strategic Considerations for Motor Selection

Choosing between BLDC and AC motors depends on balancing:

Where advanced variable-speed control, high torque density, and optimized energy performance are critical, BLDC motors provide measurable advantages.

However, when applications demand:

Robustness over sophistication

Simplicity over precision

Lower upfront cost over long-term optimization

High-power scalability in industrial settings

AC motors continue to be the better choice.

Conclusion

Despite the rapid advancement of brushless motor technologies, AC motors remain indispensable in industrial and large-scale applications. Their combination of durability, affordability, scalability, and mechanical simplicity ensures they remain relevant in modern energy systems.

For fixed-speed, high-power, or harsh-environment operations, AC motors deliver reliable performance with minimal complexity. In these scenarios, their practical advantages outweigh the efficiency gains offered by more electronically intensive alternatives.

Ultimately, AC motors are not obsolete—they are strategically optimal in the right application context.

Final Verdict: Which Motor Is Better for Energy-Efficient Systems?

When evaluating energy-efficient systems, the answer depends on application complexity, load variability, and long-term operational strategy.

For variable-speed, precision-driven, and high-efficiency applications, BLDC motors are superior.

For simple, fixed-speed, heavy-duty industrial use, advanced AC motors remain viable.

However, as energy standards tighten and intelligent control systems become the norm, BLDC motors are increasingly the preferred choice for next-generation energy-efficient designs.

Their combination of:

Positions BLDC technology as the dominant solution for modern sustainable engineering.

Energy efficiency is not solely about motor selection—it is about system integration. Yet when performance, precision, and long-term savings define the goal, BLDC motors consistently deliver measurable advantages over traditional AC motor systems.

FAQs: BLDC Motor vs AC Motor for Energy-Efficient Systems

I. Product Perspective: Performance, Efficiency & Application Comparison

1. What is the main difference between a BLDC motor and an AC motor?

A BLDC motor uses electronic commutation, while an AC motor operates using alternating current directly. A standard BLDC motor typically offers higher efficiency and precise control in energy-efficient systems.

2. Which motor is more energy efficient: BLDC or AC motor?

In most variable-speed applications, a standard BLDC motor provides higher energy efficiency than a conventional AC motor due to reduced electrical and mechanical losses.

3. Why are BLDC motors preferred in energy-efficient systems?

BLDC motors minimize friction, reduce heat generation, and optimize power consumption, making them ideal for energy-efficient systems.

4. Are AC motors still suitable for energy-efficient applications?

Yes, inverter-driven AC motors can achieve good efficiency, but a properly designed standard BLDC motor often delivers superior performance in compact systems.

5. Which motor type offers better speed control?

A BLDC motor provides more precise speed and torque control compared to a traditional AC motor.

6. How do maintenance requirements compare between BLDC and AC motors?

Both are low-maintenance compared to brushed motors, but a standard BLDC motor eliminates brush wear entirely.

7. Are BLDC motors quieter than AC motors?

Yes, BLDC motors typically operate more quietly, especially in home appliances and HVAC systems.

8. Which motor is better for variable load conditions?

BLDC motors respond quickly to load changes, making them suitable for energy-efficient dynamic systems.

9. Is the initial cost of a BLDC motor higher than an AC motor?

Yes, the upfront cost of a BLDC motor can be higher, but lower energy consumption and longer lifespan reduce total ownership cost.

10. What industries prefer BLDC motors for energy efficiency?

Industries such as HVAC, electric vehicles, robotics, home appliances, and medical devices often choose BLDC motors.

II. Factory Customization Capability: OEM Solutions & Engineering Support

11. Can a BLDC motor manufacturer customize motors for energy-efficient systems?

Yes, a professional BLDC motor manufacturer can optimize winding design, magnetic structure, and efficiency curves for specific applications.

12. What customization options are available beyond a standard BLDC motor?

Custom BLDC motors may include integrated controllers, special shafts, customized housing, and efficiency-optimized windings.

13. Can BLDC motors be designed to replace AC motors in existing systems?

Yes, many BLDC motor manufacturers offer custom BLDC motor solutions as energy-efficient replacements for AC motors.

14. Is it possible to integrate the driver with a BLDC motor?

Yes, integrated BLDC motor solutions combine the motor and driver to improve efficiency and simplify installation.

15. Can BLDC motors be optimized for ultra-high efficiency?

Yes, advanced electromagnetic design and high-grade materials allow a BLDC motor manufacturer to maximize system efficiency.

16. What is the typical MOQ for customized BLDC motors?

MOQ depends on customization complexity, but many manufacturers support prototype and pilot production runs.

17. How does customization affect lead time?

A standard BLDC motor has shorter lead time, while custom BLDC motor projects require additional engineering and validation.

18. Can manufacturers provide energy-efficiency testing reports?

Yes, reputable BLDC motor manufacturers provide efficiency curves, thermal data, and performance test reports.

19. Are BLDC motors suitable for high-volume production?

Yes, experienced manufacturers support scalable production from small batches to mass production.

20. Why choose a professional BLDC motor manufacturer for energy-efficient systems?

A professional BLDC motor manufacturer offers engineering expertise, consistent quality control, and optimized motor solutions tailored for energy-efficient applications.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català