Introduction to BLDC Motors in Industrial Automation

In modern industrial automation, precision, efficiency, and long-term reliability define competitive advantage. Brushless DC motors (BLDC motors) have become the preferred motion solution across automated production lines, robotics, material handling systems, and intelligent manufacturing equipment. Their ability to deliver high torque density, accurate speed control, and low maintenance operation makes them indispensable for industries aiming to optimize uptime and energy efficiency.

We recognize that selecting the right BLDC motor for industrial automation applications is not a generic decision. It requires a structured evaluation of electrical, mechanical, and environmental parameters to ensure seamless integration and long-term performance stability.

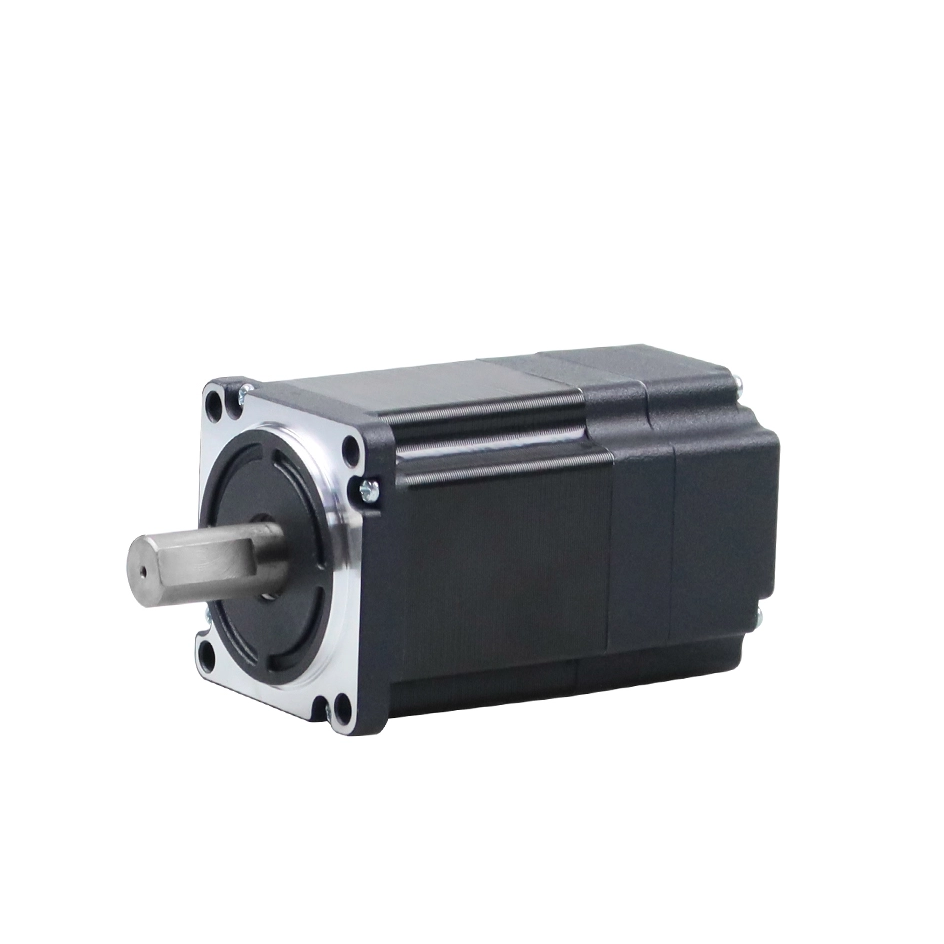

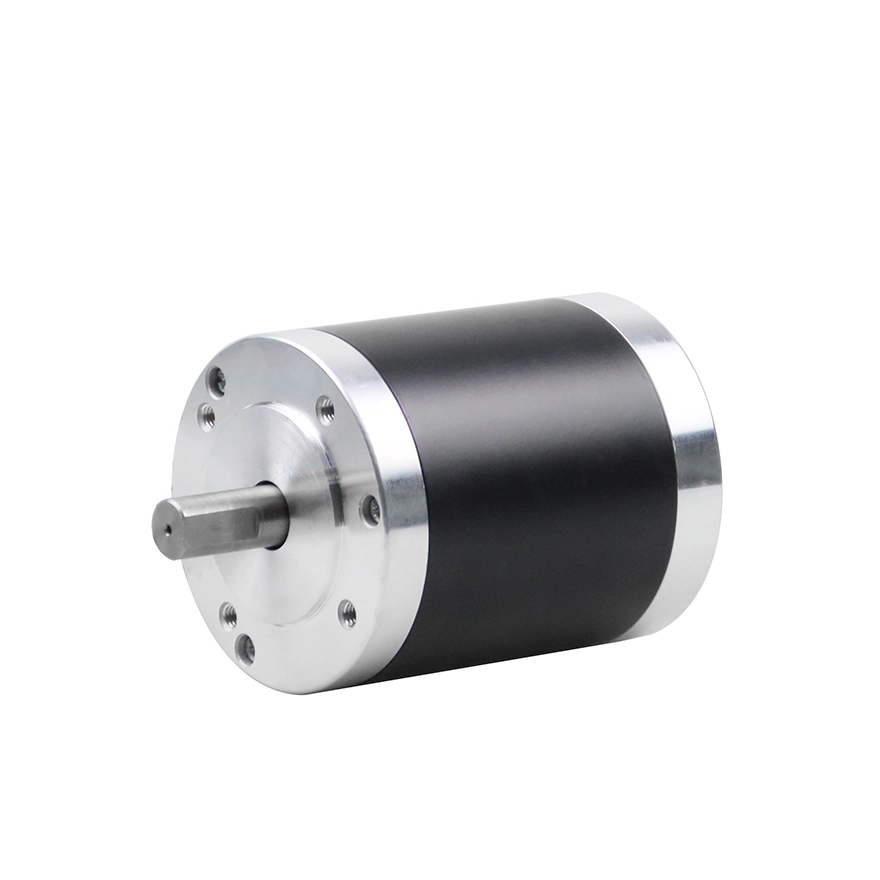

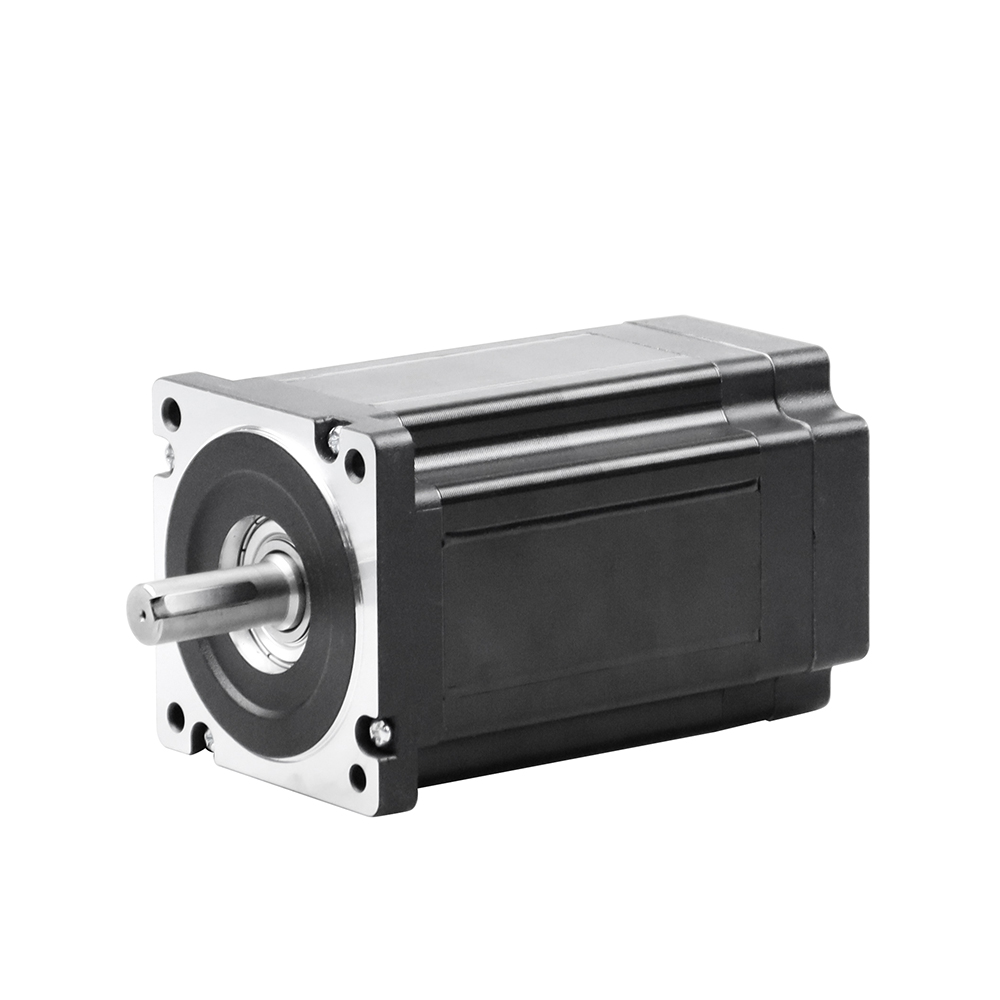

Besfoc BLDC Motor Product

Understanding BLDC Motor Fundamentals

Brushless DC motors (BLDC motors) are a core drive technology in modern industrial, commercial, and automation systems. Their operating principle, structural design, and performance advantages distinguish them clearly from traditional brushed DC motors and make them highly suitable for precision-driven applications.

What Is a BLDC Motor

A BLDC motor is an electrically commutated motor that replaces mechanical brushes and commutators with electronic switching circuitry. Instead of physical contact for current transfer, the motor relies on a controller to sequentially energize the stator windings based on rotor position. This design eliminates friction-related wear and enables higher operational efficiency.

At its core, a BLDC motor consists of:

A stator with distributed or concentrated windings

A rotor embedded with permanent magnets

An electronic controller (driver) that manages commutation and speed regulation

This architecture allows the motor to deliver consistent performance across a wide operating range.

How BLDC Motors Work

BLDC motors operate on the principle of electromagnetic attraction and repulsion. The controller switches current through stator windings in a precise sequence, generating a rotating magnetic field. The rotor magnets follow this field, producing continuous rotation.

Rotor position is determined through:

Hall effect sensors for real-time feedback

Encoders for high-precision speed and position control

Sensorless algorithms using back-EMF detection

This electronically controlled commutation ensures smooth torque output, even at high speeds or under varying loads.

Key Characteristics of BLDC Motors

BLDC motors are defined by several performance-critical characteristics:

High efficiency, often exceeding 85–90%

High torque-to-size ratio, enabling compact system design

Wide speed range with stable torque delivery

Low electrical and acoustic noise

Minimal maintenance requirements

These traits make BLDC motors especially attractive for continuous-duty and high-precision applications.

BLDC vs Brushed DC Motors

Compared to brushed DC motors, BLDC motors offer significant structural and operational advantages:

No brushes means no sparking and no brush replacement

Improved thermal performance due to stator-mounted windings

Greater speed accuracy and control flexibility

Longer service life under high duty cycles

This transition from mechanical to electronic commutation is a fundamental reason BLDC motors dominate modern motion control systems.

Role of the Motor Controller

The controller is an integral part of any BLDC motor system. It regulates:

Voltage and current levels

Commutation timing

Speed, torque, and acceleration profiles

Advanced controllers support field-oriented control (FOC), enabling precise torque control, higher efficiency, and smoother low-speed operation—critical in automation and robotics environments.

Typical BLDC Motor Configurations

BLDC motors are available in multiple configurations to suit different applications:

Inner rotor BLDC motors for high-speed performance

Outer rotor BLDC motors for high torque at lower speeds

Integrated BLDC motor systems with built-in drivers and feedback

Each configuration offers unique advantages in terms of inertia, thermal dissipation, and mechanical integration.

Why BLDC Motor Fundamentals Matter

Understanding BLDC motor fundamentals is essential for:

Accurate motor selection

Proper controller matching

Optimized system efficiency

Long-term operational reliability

A solid grasp of how BLDC motors function enables engineers and system designers to build more efficient, scalable, and reliable motion control solutions.

Torque and Speed Requirements Analysis

Accurate torque and speed requirements analysis is the foundation of selecting and applying a BLDC motor successfully. In industrial, automation, and motion control systems, improper torque or speed matching leads to inefficiency, instability, overheating, and premature system failure. A structured analysis ensures the motor operates within its optimal performance envelope while delivering reliable, repeatable motion.

Defining Load Torque Requirements

Torque represents the rotational force required to drive a load. For BLDC motor selection, we evaluate multiple torque components rather than relying on a single nominal value.

Key torque factors include:

Load torque generated by the driven mechanism

Friction torque from bearings, seals, and transmission components

Inertia torque required for acceleration and deceleration

Disturbance torque caused by process variations or external forces

The total required torque must be calculated under worst-case operating conditions to ensure stable motor performance.

Continuous Torque vs Peak Torque

BLDC motors are rated for both continuous torque and peak torque, and understanding the difference is critical.

Continuous torque is the maximum torque the motor can deliver indefinitely without exceeding thermal limits

Peak torque is the short-duration torque available during acceleration, start-up, or transient load spikes

Industrial automation systems must be designed so that normal operation remains within the continuous torque rating, while peak torque is reserved for brief dynamic events.

Speed Requirements and Operating Range

Speed requirements are defined by application functionality and process timing. BLDC motors support wide speed ranges, but correct analysis ensures efficiency and control stability.

Important speed considerations include:

Base operating speed under steady-state conditions

Maximum speed during rapid motion or indexing

Minimum controllable speed for precision or low-speed torque applications

Operating too close to maximum speed continuously can increase thermal stress and reduce motor lifespan.

Torque–Speed Curve Interpretation

The torque–speed curve illustrates how available torque varies with speed. Proper motor selection involves aligning the application's operating points within the motor's optimal curve region.

Key insights from torque–speed analysis:

Torque decreases as speed increases beyond the base speed

Power remains relatively constant within the rated operating zone

Efficient operation occurs where torque demand intersects the motor's nominal speed range

Understanding this relationship prevents underpowered or oversized motor selection.

Inertia Matching and Acceleration Performance

Acceleration performance depends on the relationship between motor inertia and load inertia. Excessive mismatch leads to slow response or unstable control.

Best practice guidelines:

Load inertia should be kept within a manageable ratio relative to motor inertia

High-inertia loads may require gear reduction or higher torque motors

Smooth acceleration profiles reduce mechanical stress and energy consumption

Proper inertia matching ensures fast response while maintaining control accuracy.

Duty Cycle and Motion Profile Considerations

Industrial automation systems rarely operate at constant speed. Most applications involve repeated start-stop cycles, indexing, or variable speed operation.

Duty cycle analysis includes:

Acceleration time

Constant-speed run time

Deceleration time

Idle or dwell periods

Thermal calculations must account for the complete motion profile to avoid overheating under intermittent high-load conditions.

Effect of Gearboxes and Transmission Systems

Gearboxes significantly influence torque and speed requirements. Gear reduction increases output torque while reducing speed, allowing smaller motors to drive larger loads.

Key considerations:

Accurate torque and speed analysis must include transmission effects to reflect real-world operating conditions.

Safety Margins and Performance Stability

A properly selected BLDC motor includes adequate safety margins without excessive oversizing.

Typical design margins:

Torque margin to handle load variations

Speed margin to avoid saturation

Thermal margin for ambient temperature fluctuations

Balanced safety margins enhance reliability while maintaining system efficiency.

Importance of Precise Torque and Speed Analysis

Thorough torque and speed requirements analysis delivers:

In BLDC motor applications, precise analysis transforms motor selection from guesswork into a controlled engineering decision, ensuring consistent and high-performance operation across demanding industrial environments.

Voltage, Power, and Electrical Compatibility

Operating Voltage Selection

BLDC motors are commonly available in 24V, 48V, 72V, and higher industrial voltage ratings. Voltage choice affects:

Power density

Current draw

Thermal behavior

Higher voltage systems reduce current losses, improving efficiency in continuous-duty industrial environments.

Power Rating and Efficiency

We align motor power ratings with real-world load conditions rather than theoretical maxima. This approach ensures:

Stable thermal margins

Consistent output torque

Extended motor lifespan

High-efficiency BLDC motors significantly reduce energy consumption across automated production systems.

Control Methods and Feedback Integration

Sensorless vs Sensored BLDC Motors

Industrial automation often demands precise motion feedback. Selection depends on application complexity:

Sensorless BLDC motors offer simplicity and cost advantages in steady-speed applications

Hall sensor or encoder-equipped BLDC motors provide accurate position and speed feedback for dynamic control systems

For robotics, pick-and-place machines, and automated assembly lines, sensored BLDC motors ensure repeatable positioning and high system accuracy.

Controller Compatibility

The motor controller must support:

Required voltage and current levels

Communication protocols (CAN, RS485, EtherCAT)

Advanced control algorithms such as FOC (Field-Oriented Control)

Seamless motor-controller integration is critical for achieving high-performance automation outcomes.

Mechanical Design and Mounting Considerations

Frame Size and Form Factor

BLDC motors used in industrial automation are available in standardized frame sizes to simplify mechanical integration. Key factors include:

Shaft diameter and length

Mounting flange standards

Axial and radial load capacities

Compact motor designs are increasingly favored in space-constrained automation equipment.

Gearbox Integration

Many applications require high torque at low speed, making BLDC motor gearbox combinations a practical solution. Planetary gearboxes offer:

Integrated motor-gearbox assemblies reduce alignment errors and installation time.

Thermal Management and Duty Cycle

Continuous Operation Capability

Industrial automation systems often operate 24/7. We prioritize BLDC motors with:

High-quality winding insulation

Optimized stator lamination design

Efficient heat dissipation paths

Thermal stability ensures consistent torque output even under prolonged operation.

Environmental Protection Ratings

Industrial environments expose motors to dust, oil mist, humidity, and temperature variations. Selecting motors with appropriate IP protection ratings safeguards against premature failure and unplanned downtime.

Reliability, Lifespan, and Maintenance Factors

Reduced Maintenance Advantages

Without brushes or commutators, BLDC motors inherently require less maintenance. This advantage is critical for:

Automated production lines

Hard-to-access installations

Mission-critical industrial systems

Lower maintenance demands translate into higher equipment availability.

Component Quality and Manufacturing Standards

Motor lifespan is directly influenced by bearing quality, magnet stability, and manufacturing precision. Industrial-grade BLDC motors are designed to withstand:

Vibration

Load fluctuations

Electrical stress

Selecting motors from experienced manufacturers ensures consistent quality and performance reliability.

Application-Specific BLDC Motor Selection

Selecting a BLDC motor based on application-specific requirements is essential for achieving optimal performance, efficiency, and long-term reliability. Each industrial and commercial application imposes unique mechanical, electrical, and environmental demands. A generic motor choice often results in compromised performance, while a targeted selection strategy ensures the motor operates precisely as intended within its application context.

BLDC Motors for Industrial Automation Systems

In industrial automation, BLDC motors are expected to deliver continuous operation, precise speed control, and high reliability.

Key selection criteria include:

High continuous torque capability for sustained loads

Stable performance under varying speed profiles

Compatibility with industrial control systems such as PLCs and motion controllers

Applications such as automated assembly lines, CNC auxiliary drives, and packaging machinery benefit from BLDC motors with advanced control interfaces and robust thermal management.

BLDC Motors in Robotics and Motion Control

Robotics applications demand exceptional dynamic response, positioning accuracy, and repeatability.

Selection priorities include:

High torque density to minimize robot arm weight

Integrated feedback devices such as encoders for closed-loop control

Low rotor inertia for rapid acceleration and deceleration

BLDC motors with encoder feedback and field-oriented control enable smooth, precise motion in articulated robots, collaborative robots, and automated pick-and-place systems.

Material Handling and Conveyor Applications

Conveyor systems prioritize reliability, energy efficiency, and smooth operation.

BLDC motor selection focuses on:

Consistent torque delivery at low to medium speeds

High efficiency for continuous-duty cycles

Compatibility with gearboxes for torque multiplication

These motors reduce operational costs by minimizing energy consumption and maintenance requirements in logistics and warehouse automation environments.

BLDC Motors for Pumps, Fans, and Compressors

In fluid and air movement systems, BLDC motors offer precise speed modulation and improved efficiency.

Critical selection factors include:

Wide speed control range for variable flow demand

High efficiency at partial loads

Resistance to environmental factors such as moisture and dust

BLDC motors are widely used in industrial pumps, ventilation systems, and cooling equipment where energy savings and quiet operation are essential.

Medical and Laboratory Equipment Applications

Medical and laboratory devices require quiet operation, accuracy, and reliability.

BLDC motor requirements typically include:

Low vibration and low acoustic noise

Compact design for space-constrained equipment

High precision speed and position control

Applications such as diagnostic devices, infusion pumps, and laboratory automation systems rely on BLDC motors for consistent and contamination-free operation.

Electric Mobility and Automated Guided Vehicles (AGVs)

AGVs and mobile robots require motors capable of handling variable loads and frequent speed changes.

Selection considerations include:

High torque at low speeds for start-up and incline operation

Efficient power usage to extend battery life

Robust construction for continuous movement and shock resistance

BLDC motors provide smooth traction control and high efficiency in battery-powered industrial transport systems.

Environmental and Mechanical Constraints

Application-specific selection must also account for environmental conditions.

Important factors include:

Operating temperature range

Exposure to dust, moisture, or chemicals

Required ingress protection (IP rating)

Selecting a BLDC motor designed for the operating environment prevents premature failure and ensures consistent performance.

Customization and Integration Requirements

Many applications benefit from customized BLDC motor solutions.

Customization options may include:

Specialized winding configurations

Integrated gearboxes or brakes

Custom shafts, flanges, or housings

Tailored motor designs simplify system integration and improve overall application efficiency.

Strategic Value of Application-Specific Selection

Application-specific BLDC motor selection ensures:

Maximum operational efficiency

Improved control accuracy

Reduced maintenance and downtime

Long-term system reliability

By aligning motor characteristics with precise application demands, BLDC motors deliver superior performance across a wide range of industrial, commercial, and specialized use cases.

Cost Optimization and Long-Term Value

Total Cost of Ownership Perspective

Initial motor cost is only one factor. We evaluate:

High-quality BLDC motors deliver superior long-term value in industrial automation environments.

Scalability and Future-Proofing

Automation systems evolve. Selecting BLDC motors with flexible control interfaces and scalable power ranges ensures compatibility with future upgrades and system expansions.

Conclusion: Strategic BLDC Motor Selection for Industrial Automation

Choosing the right BLDC motor for industrial automation applications requires a comprehensive assessment of torque, speed, electrical compatibility, control precision, and environmental conditions. By aligning motor specifications with application demands, industrial systems achieve higher efficiency, improved reliability, and sustainable operational performance.

Strategic BLDC motor selection is not merely a component choice—it is a foundational decision that defines the success and longevity of modern automated systems.

FAQs: How to Choose the Right BLDC Motor

I. Product Perspective: Performance, Efficiency & Application Fit

1. What is a BLDC motor and how does it differ from a brushed motor?

A BLDC motor uses electronic commutation instead of brushes, offering higher efficiency, longer lifespan, and lower maintenance compared with brushed motors. A standard BLDC motor is widely used in industrial and consumer applications.

2. What are the key factors when choosing the right BLDC motor?

Important factors include torque, speed range, voltage, efficiency, duty cycle, and environmental conditions. A professional BLDC motor manufacturer can help match these parameters to your application.

3. How do I determine the required torque for a BLDC motor?

Torque depends on load inertia, acceleration needs, and operating speed. Selecting the correct torque ensures stable performance of a standard BLDC motor.

4. How does speed rating affect BLDC motor selection?

The rated speed determines whether the BLDC motor can meet application demands without overheating or efficiency loss.

5. What voltage options are available for BLDC motors?

BLDC motors are commonly available in 12V, 24V, 36V, and 48V. A BLDC motor manufacturer can also provide custom voltage designs.

6. What is the difference between inner rotor and outer rotor BLDC motors?

Inner rotor motors offer higher speed and power density, while outer rotor BLDC motors provide higher torque at lower speeds.

7. Are standard BLDC motors suitable for continuous operation?

Yes, most standard BLDC motors are designed for continuous duty, provided they operate within rated load and temperature limits.

8. How important is efficiency when selecting a BLDC motor?

High efficiency reduces power consumption and heat, making BLDC motors ideal for energy-sensitive applications.

9. Can BLDC motors operate with gearboxes?

Yes, BLDC motors can be combined with planetary, spur, or worm gearboxes to increase torque and control speed.

10. What industries commonly use BLDC motors?

BLDC motors are widely used in automation, robotics, medical devices, HVAC systems, and electric vehicles.

II. Factory Customization Capability: OEM & Manufacturing Support

11. Can a BLDC motor manufacturer customize motor specifications?

Yes, a BLDC motor manufacturer can customize torque, speed, voltage, winding design, and mechanical dimensions.

12. What customization options are available beyond a standard BLDC motor?

Custom BLDC motors may include special shafts, housings, mounting flanges, or integrated gearboxes.

13. Can controllers or drivers be integrated with BLDC motors?

Yes, many manufacturers offer integrated solutions combining the BLDC motor with a matched driver or controller.

14. Are custom BLDC motors available for low-noise applications?

Yes, optimized magnetic design and precision balancing help reduce vibration and noise.

15. Can BLDC motors be customized for harsh environments?

A BLDC motor manufacturer can add IP-rated sealing, corrosion-resistant coatings, or high-temperature insulation.

16. Is small-batch or prototype production supported?

Many manufacturers support prototyping and low-MOQ orders before mass production.

17. How does a manufacturer ensure quality in customized BLDC motors?

Quality control includes torque testing, efficiency testing, thermal analysis, and endurance testing.

18. Can lead time be shortened for custom BLDC motor projects?

Yes, experienced manufacturers reduce lead time by using modular designs and standard components.

19. Can a standard BLDC motor be upgraded later to a custom design?

Yes, many projects start with a standard BLDC motor and evolve into a custom version as requirements grow.

20. Why choose an experienced BLDC motor manufacturer for your project?

An experienced BLDC motor manufacturer provides technical guidance, reliable quality, and scalable production for both standard and custom BLDC motors.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català