Introduction to Motor Selection in Modern Textile Machinery

In today’s highly competitive textile industry, motor selection directly impacts production efficiency, fabric quality, energy consumption, and long-term operating costs. As textile equipment evolves toward higher speeds, tighter tolerances, and smarter automation, two motor technologies dominate critical motion systems: BLDC motors and servo motors.

We present a comprehensive, side-by-side comparison of BLDC motors vs servo motors in textile equipment, focusing on cost structure, performance characteristics, control precision, reliability, and application suitability. This analysis is written for decision-makers seeking measurable advantages in weaving, spinning, knitting, dyeing, and finishing machinery.

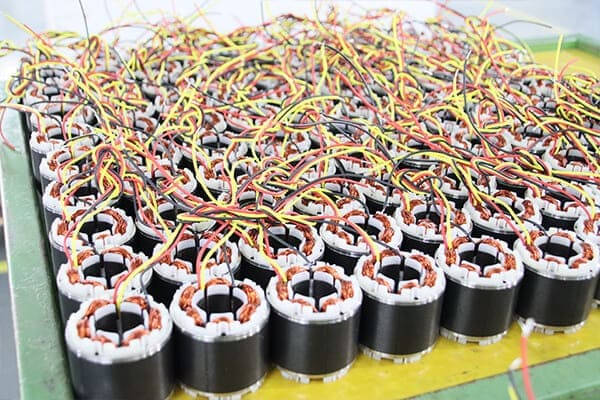

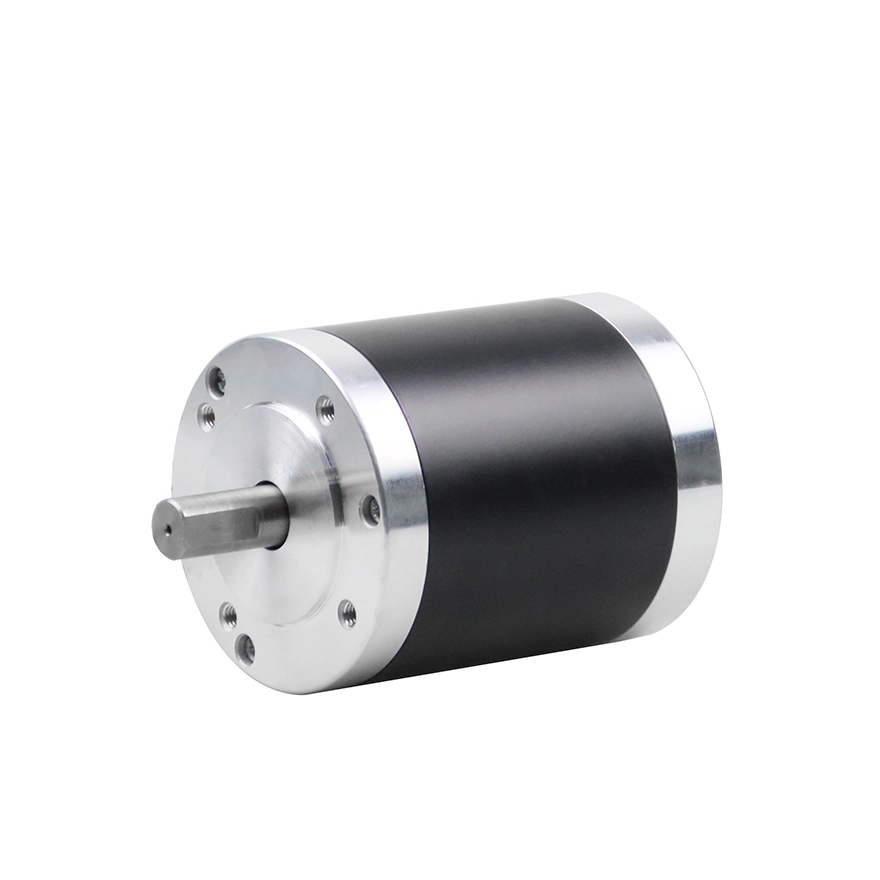

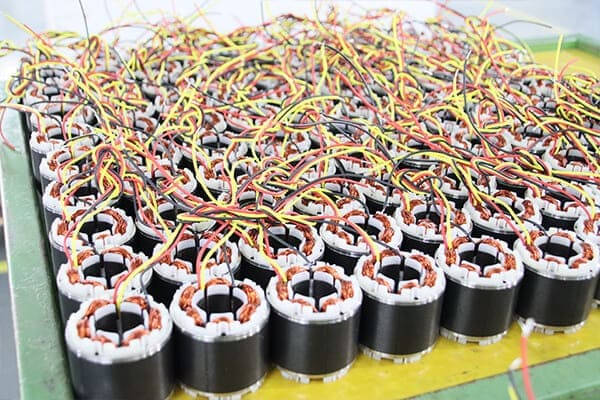

Understanding BLDC Motors in Textile Applications

What Defines a BLDC Motor

A Brushless DC motor (BLDC motor) operates using electronic commutation instead of mechanical brushes. This design significantly reduces wear, increases efficiency, and improves lifespan—key requirements for continuous-duty textile equipment.

Key Performance Characteristics of BLDC Motors

High energy efficiency due to reduced electrical and mechanical losses

Low maintenance requirements because of brushless construction

Stable speed control under variable loads

Compact design ideal for space-constrained textile machines

Lower initial system cost compared to servo systems

BLDC motors are widely used in rollers, conveyors, winding systems, fans, pumps, and auxiliary motion units within textile production lines.

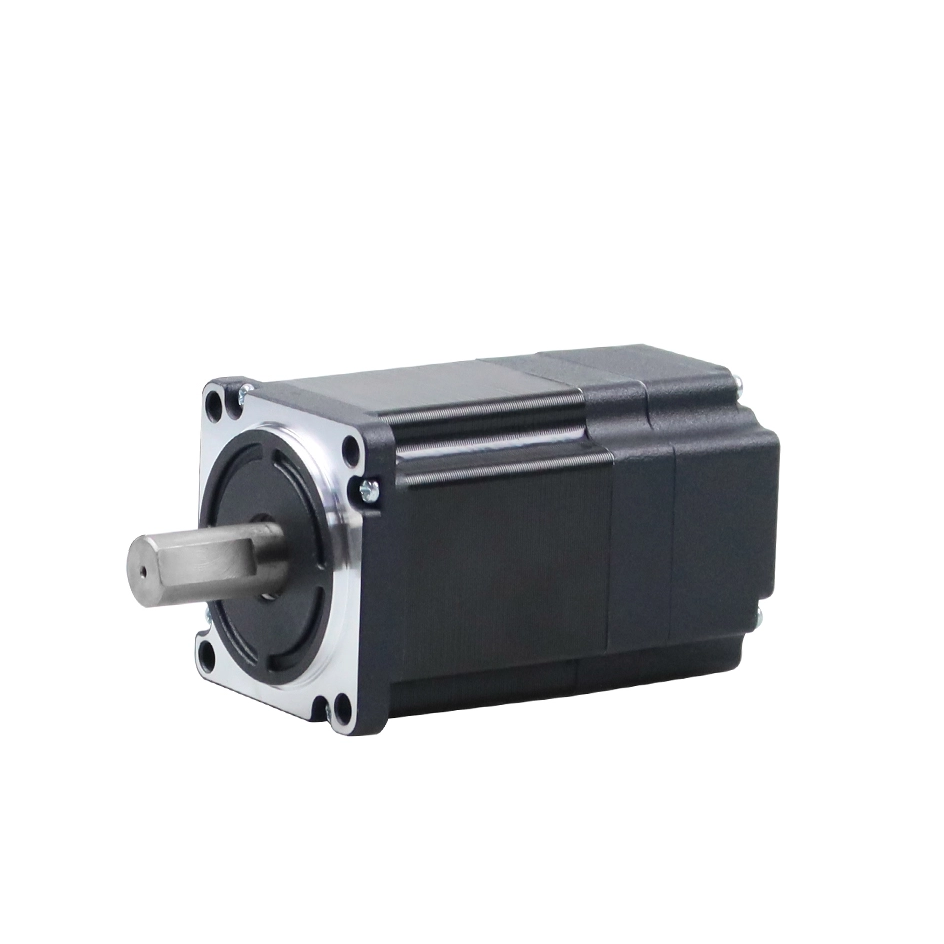

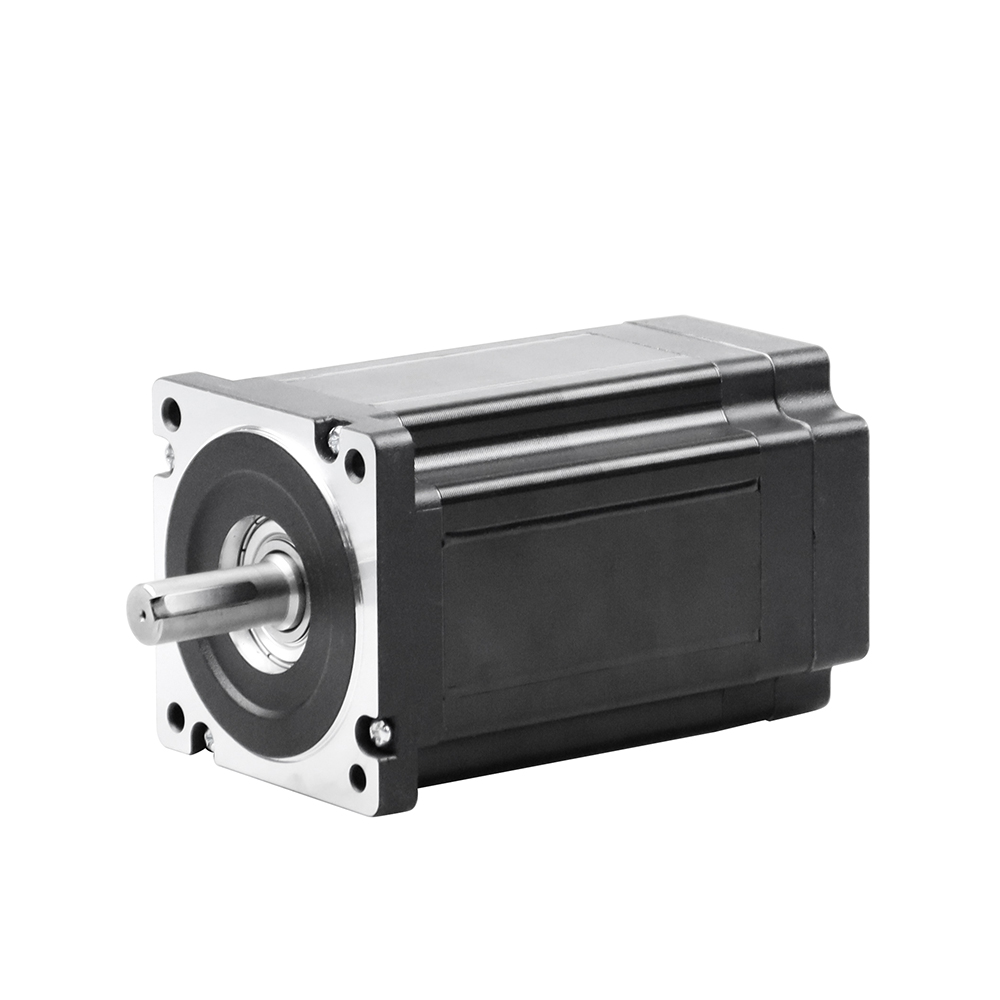

Understanding Servo Motors in Textile Equipment

What Makes a Servo Motor Different

A servo motor is a closed-loop motion system consisting of a motor, encoder, and servo drive. It continuously monitors position, speed, and torque, allowing ultra-precise motion control even under dynamic load changes.

Key Performance Characteristics of Servo Motors

Exceptional positioning accuracy (often within microns)

High torque at low speed, ideal for start-stop cycles

Fast acceleration and deceleration

Advanced feedback control via encoders or resolvers

Superior dynamic response for complex motion profiles

Servo motors are commonly deployed in needle control, pattern positioning, yarn tension control, cutting systems, and robotic textile automation.

Cost Comparison: BLDC Motor vs Servo Motor

Initial Investment Cost

From a cost perspective, BLDC motors offer a clear advantage:

BLDC motor systems require a simpler controller and no high-resolution encoder

Servo motor systems include motor, encoder, servo drive, and tuning software

On average:

For textile manufacturers operating multiple machines, this difference can translate into significant CAPEX savings.

Installation and Commissioning Cost

BLDC motors:

Simple wiring

Minimal parameter tuning

Faster commissioning

Servo motors:

For high-volume textile equipment installations, BLDC motors reduce deployment time and engineering overhead.

Maintenance and Lifecycle Cost

BLDC motors excel in long-term cost control:

No brushes to replace

Lower heat generation

Reduced downtime

Servo motors, while durable, incur:

Over a 5–10 year lifecycle, BLDC motors often deliver lower total cost of ownership (TCO) in standard textile motion tasks.

Performance Comparison in Textile Operations

Speed Control Performance

BLDC Motors in Constant-Speed Textile Operations

BLDC motors provide stable and efficient speed regulation under continuous operating conditions. They are well suited for rollers, conveyors, winding systems, and auxiliary drives, where consistent RPM ensures uniform fabric handling and process reliability.

Servo Motors in Variable-Speed Textile Processes

Servo motors excel in applications requiring frequent speed changes. With closed-loop feedback, they maintain precise speed synchronization during start-stop cycles, pattern transitions, and automated textile handling.

Torque Characteristics

BLDC Motor Torque Stability

BLDC motors deliver dependable torque across a wide speed range, supporting general textile loads such as take-up units and feeding mechanisms where moderate torque accuracy is sufficient.

Servo Motor Precision Torque Control

Servo motors provide accurate torque output at low and zero speeds. This capability is critical for yarn tension control, synchronized motion, and quality-sensitive textile processes.

Positioning Accuracy and Repeatability

BLDC Motors for Non-Critical Positioning

BLDC motors offer basic positioning using Hall sensors, suitable for coarse positioning and non-precision textile movements.

Servo Motors for High-Precision Motion

Servo motors achieve high-resolution positioning and repeatability, making them essential for embroidery, jacquard systems, fabric cutting, and pattern alignment.

Dynamic Response Capability

BLDC Motors in Steady-State Operations

BLDC motors perform best in applications with gradual speed changes and continuous motion, supporting long-duration textile production runs.

Servo Motors in High-Response Systems

Servo motors deliver rapid acceleration and deceleration while maintaining accuracy, enabling high-speed automation and robotic textile equipment.

Smoothness, Noise, and Vibration

BLDC Motor Operational Smoothness

BLDC motors operate with low vibration and noise, contributing to stable operation and reduced mechanical stress in continuous textile machinery.

Servo Motor Precision-Focused Operation

Servo motors prioritize motion accuracy and responsiveness, with slightly higher acoustic output during aggressive motion profiles.

Performance Summary

Application-Based Motor Selection

In textile operations, BLDC motors provide efficient and cost-effective performance for continuous and speed-controlled tasks, while servo motors are the preferred solution where precision, dynamic response, and positional accuracy are critical to product quality.

Energy Efficiency and Power Consumption

Energy efficiency is a decisive factor in textile factories operating 24/7.

In large-scale textile plants, BLDC motors contribute to lower electricity bills and reduced carbon footprint, especially in auxiliary and continuous-duty systems.

Reliability in Harsh Textile Environments

Textile manufacturing environments place continuous stress on drive systems due to fiber dust, high humidity, temperature variation, and long operating hours. Motor reliability under these conditions directly affects equipment uptime, maintenance frequency, and overall production efficiency.

BLDC Motors in Dust-Intensive Conditions

BLDC motors feature a simplified internal structure with no brushes and minimal mechanical contact points. This design reduces sensitivity to cotton lint, synthetic fibers, and airborne dust, allowing stable operation in spinning, weaving, and finishing areas. With fewer wear components, BLDC motors maintain consistent performance over extended duty cycles.

Servo Motors and Environmental Sensitivity

Servo motors rely on high-resolution encoders and complex feedback systems. While mechanically robust, these components can be more sensitive to contamination, vibration, and thermal fluctuation. In textile environments, additional sealing, filtration, or enclosure measures are often required to ensure long-term reliability.

Thermal Stability and Continuous Operation

BLDC Motor Heat Management

BLDC motors generate lower heat during constant-speed operation, supporting 24/7 textile production without significant thermal stress. Improved heat dissipation extends insulation life and reduces the risk of premature failure.

Servo Motor Thermal Load Considerations

Servo motors experience higher thermal variation due to frequent acceleration and deceleration. Without proper cooling or derating, sustained high-duty cycles may impact system longevity in demanding textile applications.

Maintenance Requirements and Downtime Risk

BLDC Motors and Low Maintenance Demand

With fewer electronic and mechanical dependencies, BLDC motors require minimal maintenance. This translates to lower downtime risk and reduced service intervention, particularly in large-scale textile facilities.

Servo Motors and Preventive Maintenance

Servo systems demand periodic inspection of encoders, cables, and drives. While highly reliable when properly maintained, they introduce higher maintenance complexity in harsh textile environments.

Reliability Summary

Operational Reliability in Textile Equipment

For harsh textile environments, BLDC motors offer superior reliability, environmental tolerance, and long-term stability. Servo motors remain dependable for precision-driven tasks but require enhanced protection and maintenance strategies to ensure consistent operation under challenging conditions.

Application-Based Recommendations

Best Applications for BLDC Motors in Textile Equipment

In these applications, BLDC motors provide the optimal balance of cost, efficiency, and durability.

Best Applications for Servo Motors in Textile Equipment

Servo motors justify their higher cost when precision and synchronization directly impact product quality.

Scalability and Customization

From an OEM & ODM perspective:

BLDC motors are easier to customize for voltage, speed, and mounting

Servo motors offer advanced programmability but require deeper integration

For textile machinery manufacturers targeting cost-sensitive markets, BLDC motors enable scalable product lines. For high-end automated equipment, servo motors support premium positioning capabilities.

Future Trends in Textile Motor Technology

The textile industry is moving toward:

BLDC motors are increasingly paired with IoT-enabled controllers, closing the intelligence gap with servo systems at a lower cost. Meanwhile, Servo motors continue evolving with higher-resolution feedback and AI-assisted tuning.

Conclusion: Choosing the Right Motor for Textile Equipment

The decision between BLDC motor vs servo motor in textile equipment is not about superiority—it is about application alignment.

Choose BLDC motors for cost efficiency, durability, and continuous operation

Choose servo motors for precision, dynamic control, and advanced automation

By aligning motor technology with operational requirements, textile manufacturers achieve higher productivity, lower costs, and consistent fabric quality.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català