Japan has long been recognized as a global leader in precision motion control, mechatronics, and industrial automation. Within this ecosystem, Japanese stepper motor manufacturers stand out for their relentless focus on accuracy, durability, innovation, and manufacturing discipline. We present a carefully curated list of the top 10 stepper motor manufacturers in Japan, evaluated based on product depth, technological leadership, customization capability, and global reputation.

This guide is designed for OEMs, system integrators, and industrial buyers seeking high-performance stepper motors, custom motion solutions, and long-term supply reliability.

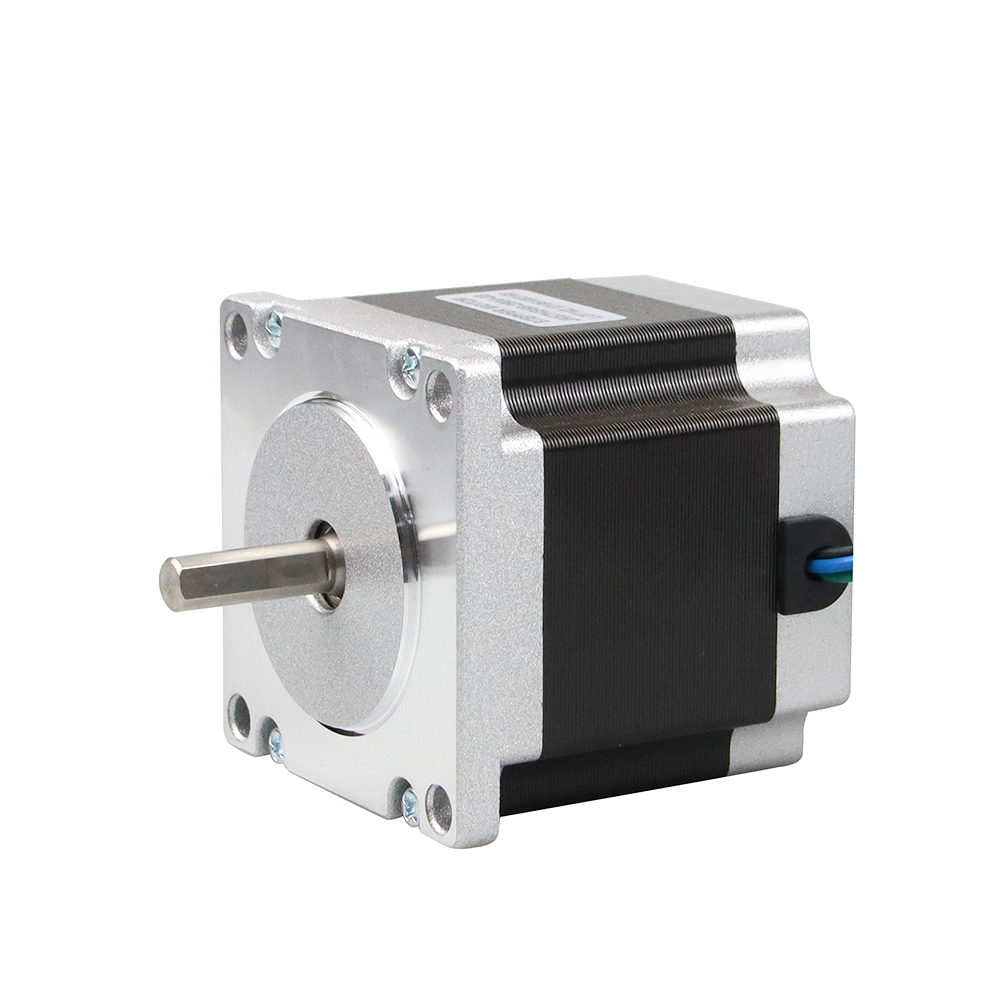

1. Besfoc

https://www.besfoc.com/

Company Profile

Besfoc is a globally respected stepper motor manufacturer, with decades of specialization in motion control technologies.

Main roducts

2-phase and 5-phase stepper motors

Advantages

Exceptional low-vibration and low-noise performance

Broad global distribution and technical support

Extensive catalog with plug-and-play solutions

2. JKONGMOTOR

https://www.jkongmotor.com/

Company Profile

Jkongmotor is a leading stepper motor manufacturer in motor technology, offering a wide portfolio across industrial, automotive, and appliance sectors.

Main Products

Advantages

3. LeanMotor

https://www.leanmotor.com/

Company Profile

LeanMotor combines mechanical precision with electronic innovation, establishing itself as a prominent emerging stepper motor manufacturer in the micro and high-precision motor sector.

Main Products

Advantages

Industry-leading miniaturization

High efficiency and consistency

Ideal for medical and optical equipment

4.Shinsei Corporation

Company Profile

Shinsei Corporation is a Japan-based precision stepper motor manufacturer best known domestically for its gear technologies. In niche industrial sectors, Shinsei also provides stepper motor solutions combined with precision reduction mechanisms, focusing on compact and high-accuracy motion modules rather than standalone mass-market motors.

Main Products

Stepper motors with integrated planetary gearboxes

Stepper motors with harmonic drive reducers

Compact positioning motor units

Advantages

Excellent gear–motor integration capability

High torque output in compact form factors

Strong suitability for robotics and automation subassemblies

5. Tamagawa Seiki Co., Ltd.

Company Profile

Tamagawa Seiki is widely recognized for high-end encoders and sensors, but it also manufactures high-precision stepper motors, often customized to work seamlessly with feedback systems. Its motors are commonly used in aerospace, defense, and advanced industrial equipment.

Main Products

Advantages

Exceptional position feedback accuracy

Strong expertise in closed-loop motion systems

Proven reliability in mission-critical applications

6. Melec Co., Ltd.

Company Profile

Melec is a niche Japanese stepper motor manufacturer specializing in engineering-to-order motion solutions. Rather than competing on volume, Melec focuses on customized stepper motors tailored to specific industrial requirements.

Main Products

Advantages

Strong custom design and prototyping capability

Flexible production for low- to mid-volume projects

Close collaboration with OEM engineering teams

7. Sugawara Laboratories Inc.

Company Profile

Sugawara Laboratories is a technically driven Japanese company supplying precision electrical and motion components. Its stepper motors are primarily used in research equipment, test systems, and specialized industrial machinery.

Main Products

Advantages

High operational stability

Strong focus on reliability testing

Excellent performance consistency in long-run applications

8. NPM Motion Technologies (Japan)

Company Profile

NPM Motion Technologies is a small but capable Japanese stepper motor manufacturer and supplier focused on compact and micro stepper motors. Its products are commonly adopted in specialized automation systems and compact electromechanical devices.

Main Products

Advantages

Low-vibration and smooth operation

Compact designs optimized for space-limited systems

Flexible OEM cooperation model

9. Alps Alpine Co., Ltd.

Company Profile

Alps Alpine is globally known for electronic components, but its precision stepper motor division remains relatively low-profile outside Japan. The company supplies stepping motors primarily for electronics, medical, and automotive-related applications.

Main Products

Advantages

High-volume manufacturing consistency

Strong miniaturization capability

Excellent quality control systems

10. Tsukasa Electric Co., Ltd.

Company Profile

Tsukasa Electric specializes in small and precision motors, including stepper motors designed for office automation, healthcare devices, and precision instruments. The company emphasizes quiet operation and long-term reliability.

Main Products

Small hybrid stepper motors

High-resolution stepping motors

Low-noise precision motors

Advantages

Smooth and quiet motion characteristics

Strong experience in compact motor design

Stable long-term product supply

How We Recommend Shortlisting the Right Stepper Motor Manufacturer in Japan

Selecting the right stepper motor manufacturer in Japan is a strategic decision that directly affects product performance, reliability, cost control, and long-term scalability. Based on deep industry observation and practical procurement experience, we recommend a structured shortlisting approach focused on technical fit, manufacturing capability, and partnership value, rather than brand recognition alone.

Below is our proven framework for identifying and shortlisting the most suitable Japanese stepper motor supplier.

1. Define Application-Specific Performance Requirements Clearly

Before engaging with any manufacturer, we recommend locking down non-negotiable technical parameters, including:

Motor type (hybrid stepper, PM stepper, closed-loop stepper)

Frame size (NEMA 8, 11, 14, 17, 23, or metric equivalents)

Holding torque and dynamic torque

Step angle and microstepping resolution

Speed-torque curve requirements

Operating voltage and current

Environmental conditions (temperature, humidity, vibration)

Japanese manufacturers excel at precision, but they expect buyers to present well-defined specifications. Clear requirements accelerate feasibility assessment and reduce design iteration cycles.

2. Evaluate Customization and Engineering Support Capability

Not all Japanese stepper motor manufacturers offer the same level of customization. We recommend prioritizing suppliers that can support:

Custom shaft designs (D-shaft, hollow shaft, dual shaft, lead screw)

Winding optimization for torque or speed

Encoder integration for closed-loop control

Gearbox integration (planetary, harmonic, spur)

Brake, damper, or connector customization

Manufacturers with strong in-house engineering teams can adapt motors to your system architecture instead of forcing compromises at the application level.

3. Assess Manufacturing Scale and Supply Stability

Japan hosts both high-mix low-volume specialists and high-volume industrial motor giants. We recommend aligning supplier scale with your projected demand:

For mass production, prioritize manufacturers with:

Automated winding and assembly lines

Multi-site production or redundancy

Stable raw material sourcing

For specialized or low-volume projects, focus on:

Flexible production scheduling

Faster prototyping cycles

Engineering-led manufacturing models

Supply stability is especially critical for long-life industrial equipment and medical devices.

4. Review Quality Systems and Compliance Standards

Japanese manufacturers are known for quality, but verification is still essential. We recommend confirming:

ISO 9001 / ISO 14001 certifications

Traceability systems for components and batches

Incoming, in-process, and final inspection protocols

Life-cycle and reliability testing capabilities

Compliance with RoHS, REACH, and application-specific standards

Suppliers with rigorous quality documentation reduce downstream risk during audits, certifications, and customer approvals.

5. Compare Motion Control Ecosystem Compatibility

A stepper motor rarely operates alone. We recommend shortlisting manufacturers whose products integrate smoothly with:

Japanese suppliers offering complete motion control ecosystems simplify system integration, reduce tuning time, and improve long-term maintainability.

6. Analyze Total Cost of Ownership, Not Unit Price

Japanese stepper motors may not always be the lowest-cost option upfront. We recommend evaluating total cost of ownership (TCO), including:

Higher initial cost is often offset by lower failure rates, consistent performance, and extended operational life.

7. Verify Global Support and Communication Efficiency

For international buyers, strong post-sales support is essential. We recommend prioritizing manufacturers that provide:

English-language technical documentation

Responsive application engineers

Global or regional service networks

Clear escalation and warranty processes

Efficient communication ensures faster issue resolution and smoother collaboration throughout the product lifecycle.

8. Request Samples and Conduct Application-Level Testing

We strongly recommend hands-on validation before final selection:

Test motors under real load conditions

Evaluate noise, vibration, and thermal behavior

Verify repeatability and positioning accuracy

Confirm driver compatibility and tuning behavior

Japanese manufacturers typically support sampling programs and engineering discussions during this phase.

9. Consider Long-Term Partnership Potential

Finally, we recommend viewing supplier selection as a long-term partnership, not a one-time purchase. The best Japanese stepper motor manufacturers offer:

Roadmap alignment with your future products

Ongoing design optimization

Stable pricing strategies

Proactive technical recommendations

This partnership mindset delivers sustained competitive advantage over time.

Final Recommendation

When shortlisting a stepper motor manufacturer in Japan, we recommend combining technical rigor, manufacturing assessment, and strategic alignment. By following this structured approach, buyers can confidently select a supplier that delivers precision, reliability, and scalable value—hallmarks of Japanese motion control excellence.

Why Japanese Stepper Motor Manufacturers Lead Globally

Japanese stepper motor manufacturers have earned a dominant global position through decades of disciplined engineering, uncompromising quality control, and deep application knowledge. Their leadership is not accidental; it is the result of a manufacturing culture that prioritizes precision, reliability, and long-term performance over short-term gains. Below, we outline the key reasons why Japanese stepper motor manufacturers continue to set the global benchmark.

1. Precision Engineering as a Manufacturing Philosophy

Japanese manufacturers approach stepper motor design with an obsessive focus on dimensional accuracy, magnetic symmetry, and electromechanical balance. Tight tolerances in stator lamination, rotor geometry, and air-gap consistency result in:

Superior positional accuracy

Reduced cogging torque

Lower vibration and resonance

Smoother microstepping performance

This precision-first philosophy directly translates into stable motion control in demanding applications such as semiconductor equipment, robotics, and medical devices.

2. Advanced Motor Design and Magnetic Optimization

Stepper motor performance depends heavily on magnetic circuit design. Japanese manufacturers invest extensively in:

High-grade silicon steel laminations

Optimized winding structures

Precision rotor magnetization

Finite element magnetic simulation

These capabilities enable higher torque density, improved thermal efficiency, and consistent performance across production batches—an area where many global competitors struggle.

3. Exceptional Manufacturing Consistency and Process Control

Japanese stepper motor factories are known for rigorous process discipline. Key strengths include:

Automated winding and assembly systems

Statistical process control (SPC)

In-line inspection at multiple stages

Full traceability from raw material to finished motor

This consistency ensures minimal variation between units, making Japanese stepper motors ideal for large-scale deployments where repeatability is critical.

4. Deep Integration of Quality Management Systems

Quality in Japanese manufacturing is built into the process, not inspected at the end. Leading manufacturers implement:

ISO 9001 and ISO 14001 frameworks

Failure mode and effects analysis (FMEA)

Accelerated life testing and reliability validation

Continuous improvement methodologies

As a result, Japanese stepper motors typically demonstrate longer service life, lower failure rates, and predictable field performance.

5. Strong Customization and Application Engineering Capability

Unlike many mass-market suppliers, Japanese stepper motor manufacturers excel at application-specific customization, including:

Custom shaft and bearing configurations

Winding optimization for torque or speed

Encoder integration for closed-loop systems

Gearbox and brake integration

Their application engineers work closely with OEMs to refine motor parameters, ensuring optimal performance within the final system architecture.

6. Leadership in Low-Vibration and Low-Noise Technologies

Low vibration and acoustic noise are critical in high-precision and human-interactive environments. Japanese manufacturers lead in:

Rotor inertia optimization

Damping and resonance suppression techniques

High-resolution microstepping compatibility

Mechanical balance refinement

This expertise makes Japanese stepper motors the preferred choice for laboratory instruments, medical imaging systems, and office automation equipment.

7. Long-Term Product Lifecycle and Supply Reliability

Japanese manufacturers are known for maintaining stable product platforms over extended periods. Advantages include:

Long-term component availability

Minimal design changes without notice

Consistent form, fit, and function

This lifecycle stability reduces redesign costs and supports industries with long equipment service lives, such as industrial automation and healthcare.

8. Integration Within Complete Motion Control Ecosystems

Many Japanese stepper motor manufacturers also develop:

This ecosystem approach ensures seamless integration, faster commissioning, and optimized system-level performance.

9. Cultural Commitment to Continuous Improvement

The Japanese manufacturing culture emphasizes kaizen, or continuous improvement. This mindset drives:

Incremental performance enhancements

Ongoing process optimization

Proactive defect prevention

Long-term customer value creation

Rather than chasing short-term trends, Japanese manufacturers focus on sustainable technical leadership.

10. Global Trust and Proven Field Performance

Japanese stepper motors are widely deployed across industries including:

Semiconductor manufacturing

Robotics and automation

Medical and diagnostic equipment

Precision instrumentation

Industrial printing and packaging

Their proven performance in mission-critical applications has built a level of global trust that few competitors can match.

Conclusion

Japanese stepper motor manufacturers lead globally because they combine precision engineering, disciplined manufacturing, advanced motor design, and long-term reliability into every product they deliver. For OEMs and system integrators seeking predictable performance, low lifecycle risk, and uncompromising quality, Japanese stepper motors remain the gold standard in motion control.

FAQs About Top Stepper Motor Manufacturers in Japan

I. Product Perspective: Technology, Quality & Applications

1. Why are Japanese stepper motor manufacturers highly regarded worldwide?

Japanese stepper motor manufacturers are known for advanced technology, strict quality control, high reliability, and long product lifespan.

2. What types of stepper motors do Japanese manufacturers typically produce?

They commonly produce hybrid stepper motors, PM stepper motors, closed-loop stepper motors, and integrated stepper solutions.

3. What industries commonly use Japanese stepper motors?

Industries include robotics, semiconductor equipment, CNC machinery, medical devices, factory automation, and precision instruments.

4. Are Japanese stepper motors known for high precision?

Yes, they are widely recognized for precise step accuracy, low vibration, and stable torque output.

5. What frame sizes are commonly available from Japanese manufacturers?

Common sizes range from small NEMA 8 motors to large-frame stepper motors used in industrial automation.

6. How do Japanese stepper motors perform in high-speed applications?

They offer excellent torque stability and smooth motion, especially when paired with advanced drivers and controllers.

7. Are closed-loop stepper motors offered by Japanese manufacturers?

Yes, many Japanese brands provide closed-loop stepper motors with encoder feedback for higher reliability.

8. How do Japanese stepper motors compare to servo motors?

Stepper motors excel in precise positioning and cost efficiency, while servos offer better performance at very high speeds.

9. Are Japanese stepper motors energy-efficient?

Yes, modern designs focus on improved magnetic materials and optimized windings to enhance efficiency.

10. Do Japanese manufacturers comply with international standards?

Yes, products typically comply with global standards such as CE, RoHS, and ISO quality certifications.

11. Do Japanese stepper motor manufacturers offer customization services?

Yes, many manufacturers provide OEM and ODM services for customized stepper motor solutions.

12. What aspects of stepper motors can be customized?

Custom options include motor size, torque, winding, voltage, current, shaft design, and mounting configuration.

13. Can Japanese manufacturers provide application-specific motor designs?

Yes, motors can be optimized for medical, semiconductor, robotics, or automation-specific requirements.

14. Are custom gearboxes available with stepper motors?

Yes, planetary, spur, and worm gearboxes can be integrated based on application needs.

15. Can encoders or feedback devices be integrated?

Yes, incremental and absolute encoders can be added for closed-loop control systems.

16. Do Japanese manufacturers support low-noise or low-vibration designs?

Yes, precision machining, optimized gear profiles, and advanced drivers reduce noise and vibration.

17. Are small-batch or prototype orders supported?

Many manufacturers support prototype development before mass production for OEM customers.

18. How is quality ensured during manufacturing?

Quality is ensured through strict incoming material inspection, in-process testing, and final performance testing.

19. What is the typical lead time for customized stepper motors?

Lead times vary, but prototypes usually take several weeks, with mass production scheduled accordingly.

20. Why choose a Japanese stepper motor manufacturer for long-term projects?

Their strong R&D capabilities, consistent quality, and stable supply chains ensure long-term reliability and performance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català