Introduction to High-Speed Motion Stability

In modern automation, high-speed motion control is no longer optional—it is a baseline requirement across CNC machinery, semiconductor equipment, medical devices, packaging lines, and robotics. As speeds increase, so do challenges related to vibration, resonance, torque ripple, position error, and system instability. We address these challenges directly by adopting integrated stepper servo motors, a motion solution engineered to deliver exceptional stability, precision, and reliability at elevated speeds.

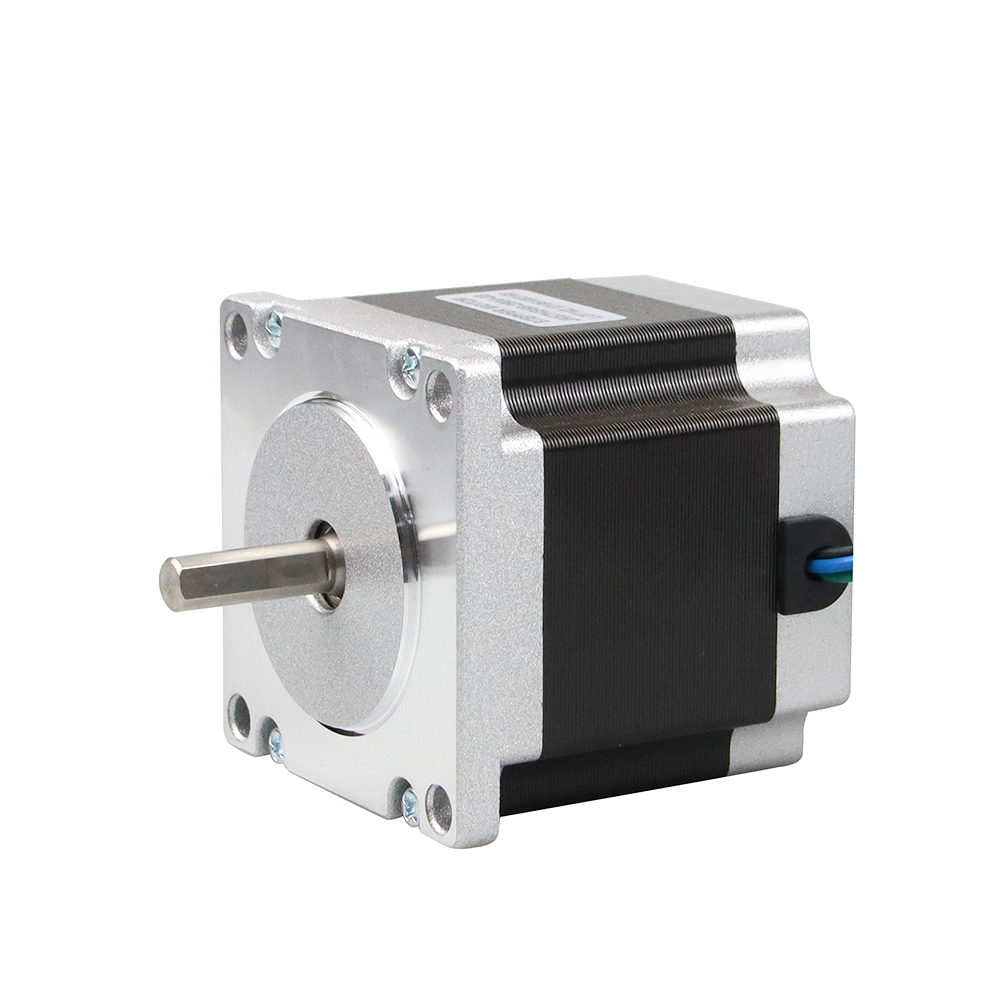

Unlike conventional stepper motors or separated servo systems, integrated stepper servo motors combine motor, driver, encoder, and control algorithms into a single compact unit. This architecture fundamentally changes how motion systems behave under dynamic conditions, especially in high-speed applications where stability determines throughput and product quality.

Understanding Integrated Stepper Servo Motor Architecture

Integrated stepper servo motors unify multiple motion components into a tightly optimized system:

By eliminating external cabling, signal delays, and mismatched components, we achieve real-time feedback correction and seamless torque regulation. This integration forms the technical foundation for superior stability during rapid acceleration, deceleration, and continuous high-speed operation.

Closed-Loop Control Eliminates Step Loss at High Speed

One of the most critical challenges in high-speed motion systems is step loss, which occurs when a motor fails to follow its commanded motion due to sudden load changes, inertia, or resonance. In traditional open-loop stepper motors, the system assumes that every commanded step is executed perfectly. At high speeds, this assumption often fails, resulting in missed steps, position errors, and instability.

Integrated stepper servo motors overcome this limitation through true closed-loop control. A high-resolution encoder continuously monitors the rotor's actual position and feeds real-time data to the motor controller. When the controller detects any deviation between the commanded position and the actual rotor position, it instantly adjusts current and torque to correct the error.

This approach delivers several key advantages for high-speed applications:

Zero step loss: Every commanded movement is accurately executed, even under varying loads or rapid acceleration.

Precise positioning: High-speed motion maintains micrometer-level accuracy, crucial for CNC, robotics, and semiconductor equipment.

Consistent torque delivery: The system automatically compensates for load fluctuations, ensuring stable operation.

By maintaining real-time synchronization between command and motion, closed-loop control allows stepper motors to achieve servo-level performance while preserving their inherent advantages of high torque and compact size. This capability is essential for applications where high-speed stability and precision cannot be compromised.

Advanced Anti-Resonance Control for Smooth High-Speed Motion

Mechanical resonance is a primary cause of instability in high-speed motion systems. Traditional stepper motors are especially prone to mid-band resonance, which leads to vibration, noise, and positional errors.

Integrated stepper servo motors utilize adaptive anti-resonance algorithms that dynamically suppress oscillations. These algorithms analyze motion feedback in real time and adjust current vectors to neutralize resonance effects.

The result is:

Smooth rotation across the entire speed range

Significantly reduced vibration and noise

Enhanced stability during rapid speed transitions

This makes integrated stepper servo motors ideal for high-speed indexing and continuous motion applications.

Higher Acceleration Without Compromising Stability

In high-speed motion systems, achieving fast acceleration and deceleration is often essential for maximizing throughput. However, traditional stepper motors operating in open-loop configurations face significant limitations. Rapid acceleration can cause step loss, torque drop, and mechanical vibration, all of which reduce stability and compromise positioning accuracy.

Integrated stepper servo motors address this challenge through a combination of closed-loop feedback, real-time torque control, and optimized motor-driver integration. The high-resolution encoder continuously monitors rotor position and velocity, allowing the controller to instantly adjust current output to maintain precise torque during acceleration and deceleration phases.

Key benefits of this approach include:

Higher usable acceleration: Integrated systems can safely accelerate and decelerate at rates far exceeding traditional stepper limits, enabling faster cycle times in CNC machines, robotics, and automated assembly lines.

Immediate torque response: Unlike open-loop systems, the motor delivers torque precisely where and when it is needed, preventing missed steps and maintaining motion accuracy.

Stable start-stop operation: Even with frequent directional changes, the motor remains stable, eliminating vibration and oscillation that could degrade mechanical components or product quality.

Because the motor, encoder, and driver are designed as a single optimized unit, integrated stepper servo motors maintain consistent torque and positional accuracy under extreme dynamic conditions. This ensures that high acceleration does not compromise stability, making these motors ideal for applications requiring both speed and precision, such as high-speed pick-and-place systems, precision robotics, and industrial automation processes.

The combination of dynamic torque compensation, real-time feedback, and adaptive control algorithms allows engineers to push acceleration limits without the trade-offs typically associated with stepper motors, providing a reliable, high-performance solution for demanding high-speed applications.

Torque Consistency at Elevated Speeds

Torque drop-off at high speed is a common limitation of traditional stepper motors. As speed increases, available torque decreases, leading to instability and missed steps.

Integrated stepper servo motors mitigate this issue through:

Optimized current control

Field-oriented control techniques

Real-time torque compensation

We maintain usable torque across a wider speed range, ensuring stable operation even at high RPMs. This torque consistency is critical for applications requiring precise force control and constant velocity.

Reduced Mechanical Stress and Extended System Life

Instability at high speed does more than affect performance—it accelerates wear on mechanical components. Vibration, shock loading, and torque ripple shorten the lifespan of bearings, couplings, and linear guides.

By delivering smooth, controlled motion, integrated stepper servo motors:

Reduce mechanical fatigue

Minimize backlash excitation

Lower thermal stress on components

We enable longer service intervals and reduced maintenance costs, making these motors a cost-effective solution over the full system lifecycle.

Compact Design Enhances System Rigidity

High-speed stability is strongly influenced by mechanical rigidity. External drivers, long motor cables, and loosely integrated components introduce compliance and signal delay.

Integrated stepper servo motors eliminate these weaknesses through:

Compact, single-unit construction

Short internal signal paths

Reduced electromagnetic interference

This compactness increases overall system stiffness, directly contributing to improved positional stability and repeatability at high speeds.

Energy Efficiency and Thermal Stability

Thermal fluctuation is an often-overlooked factor in motion stability. Overheating alters motor characteristics, leading to drift and inconsistent performance.

Integrated stepper servo motors improve thermal behavior by:

Delivering current only when required

Reducing idle power consumption

Optimizing heat dissipation within a single enclosure

We maintain thermal equilibrium during continuous high-speed operation, ensuring stable performance over long duty cycles.

Simplified Tuning for High-Speed Applications

Traditional servo systems require complex tuning of PID parameters to achieve stability at high speed. Incorrect tuning leads to oscillation, overshoot, or sluggish response.

Integrated stepper servo motors are pre-optimized at the factory, offering:

We achieve high-speed stability without extensive manual tuning, reducing engineering effort and deployment risk.

Superior Performance in Real-World High-Speed Applications

Integrated stepper servo motors excel across demanding industries, including:

In each case, stability at speed translates directly into accuracy, reliability, and productivity.

Why Integrated Stepper Servo Motors Outperform Traditional Solutions

Compared to open-loop steppers and separated servo systems, integrated stepper servo motors deliver a unique combination of advantages:

Servo-level stability with stepper simplicity

High torque at low and high speeds

Elimination of step loss and resonance

Compact, robust system design

Lower total cost of ownership

We consistently see higher system uptime and improved motion quality in high-speed environments.

FAQs: Integrated Stepper Servo Motors and Stability

1. What is an integrated stepper servo motor?

An integrated stepper servo motor combines a stepper motor, encoder, and driver in one compact unit to improve motion stability and accuracy.

2. How does an integrated stepper servo motor improve stepper motor stability?

By providing real-time feedback and closed-loop control, it minimizes missed steps, vibration, and oscillations.

3. Can integrated stepper servo motors handle higher loads than traditional stepper motors?

Yes, they maintain torque consistency under varying loads, reducing step loss and improving reliability.

4. How does encoder feedback enhance stepper motor performance?

Encoder feedback allows the stepper motor to correct its position continuously, eliminating errors caused by load changes.

5. Are integrated stepper servo motors more precise than standard stepper motors?

Yes, closed-loop control ensures higher positional accuracy and smoother motion.

6. Do integrated stepper servo motors reduce vibration in stepper motor systems?

Yes, they reduce mechanical resonance and torque ripple, improving stability in dynamic applications.

7. How does the driver integration improve stepper motor reliability?

The built-in driver optimizes current control, preventing overheating and mechanical stress on the stepper motor.

8. Can integrated stepper servo motors improve performance at low speeds?

Yes, closed-loop control prevents low-speed resonance and ensures smooth motion.

9. Are integrated stepper servo motors suitable for CNC machines?

Absolutely; they provide precise, stable motion for high-accuracy CNC operations.

10. Can these motors reduce maintenance for stepper motor systems?

Yes, integrated design reduces wiring complexity, calibration needs, and mechanical stress, lowering maintenance.

11. Can a stepper motor manufacturer customize integrated stepper servo motors for specific torque requirements?

Yes, torque and speed profiles can be tailored to meet application-specific needs.

12.Are integrated stepper servo motors customizable for different voltage and current ratings?

Yes, manufacturers can optimize electrical specifications for performance and thermal management.

13. Can integrated stepper servo motors be optimized for continuous-duty operation?

Yes, thermal design, insulation class, and cooling options can be customized for long-term use.

Yes, full OEM/ODM customization is available, including mechanical, electrical, and performance tuning.

15. Can encoder resolution be customized for specific applications?

Yes, high- or low-resolution encoders can be selected to match precision and cost requirements.

16. Are integrated stepper servo motors compatible with industrial automation systems?

Yes, manufacturers can adapt interfaces and communication protocols for automation integration.

17. Can gearbox integration be combined with integrated stepper servo motors?

Yes, planetary or worm gearboxes can be integrated to increase torque without compromising stability.

18. Can stepper motor manufacturers provide noise-optimized integrated motors?

Yes, rotor balancing, damping, and driver tuning can reduce vibration and acoustic noise.

19. Do manufacturers perform testing on integrated stepper servo motors?

Yes, load, thermal, and motion simulations verify stability and reliability before shipping.

20. How should customers select a stepper motor manufacturer for integrated stepper servo motors?

Choose a manufacturer with engineering expertise, customization capabilities, and experience in closed-loop stepper solutions.

Conclusion: Stability as a Competitive Advantage

In high-speed motion control, stability defines success. Integrated stepper servo motors provide a technologically superior solution by combining closed-loop intelligence, mechanical integration, and advanced control algorithms into a single, optimized platform.

We leverage these motors to achieve smoother motion, higher speeds, tighter tolerances, and long-term reliability. For any application where speed and stability must coexist, integrated stepper servo motors represent a decisive engineering advantage.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català