India has emerged as a strategic hub for industrial automation, motion control systems, and smart manufacturing. With the rapid expansion of robotics, CNC machinery, packaging equipment, medical devices, and industrial automation, the demand for integrated DC servo motors has increased significantly. We present a carefully curated and in-depth list of the top 15 Integrated DC Servo Motor manufacturers in India, highlighting their company profile, core products, and competitive advantages to help system integrators, OEMs, and industrial buyers make informed decisions.

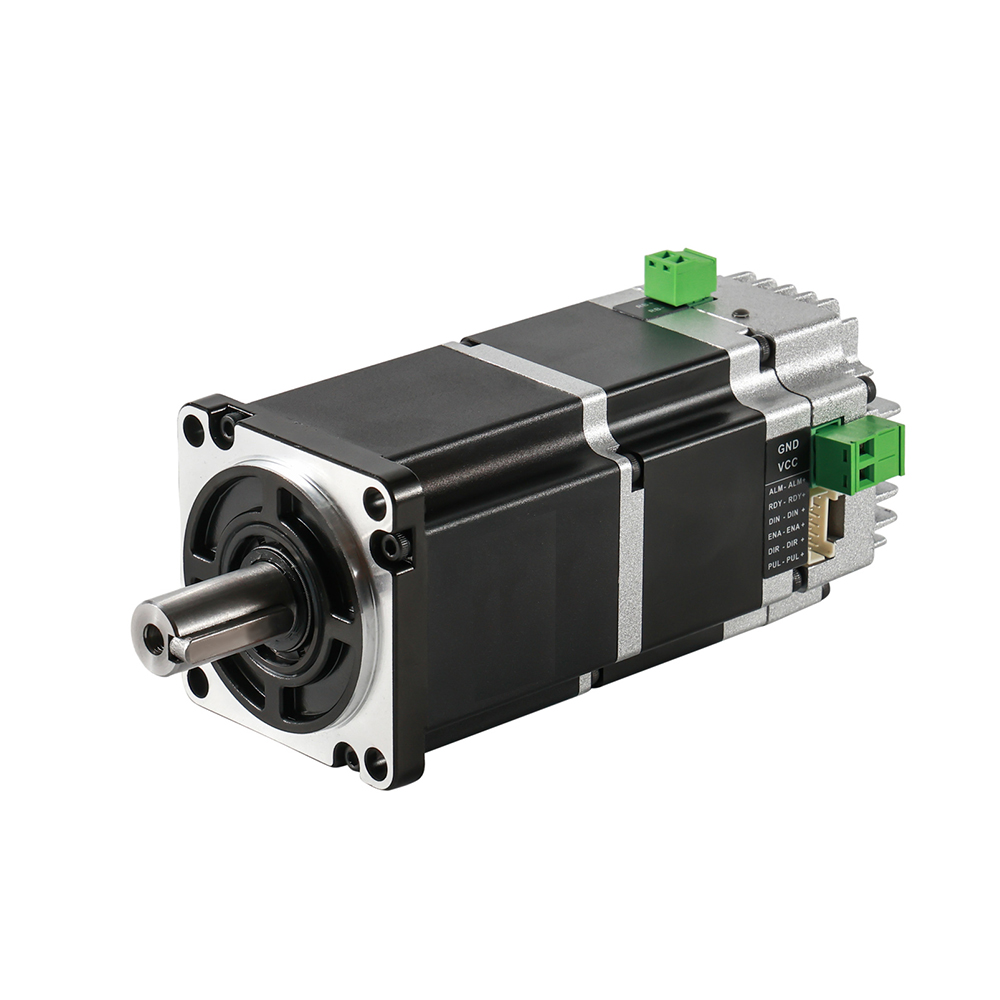

Besfoc Integrated DC Servo Motor Products

Top Integrated DC Servo Motor Manufacturers in India

1. ABB India Ltd.

Company Profile

ABB India is a global leading Integrated DC Servo Motor Manfacturer in motion control and industrial automation, with decades of engineering excellence and a strong manufacturing presence in India.

Main Products

Advantages

Exceptional precision and reliability

Strong local service network

Proven performance in heavy-duty industrial environments

2. Siemens India

Company Profile

Siemens India delivers advanced digital motion control technologies, supporting smart factories across automotive, electronics, and process industries.

Main Products

Advantages

3. Delta Electronics India

Company Profile

Delta Electronics is recognized for energy-efficient automation solutions, offering cost-effective servo motor technologies for Indian OEMs.

Main Products

Advantages

4. Panasonic Life Solutions India

Company Profile

Panasonic India combines Japanese engineering excellence with local manufacturing to support India's automation growth.

Main Products

Advantages

High-speed response and accuracy

Excellent thermal stability

Ideal for electronics and packaging industries

5. Yaskawa India Pvt. Ltd.

Company Profile

Yaskawa is a globally trusted Integrated DC Servo Motor Manfacturer in servo and motion control, with a strong footprint in Indian robotics and automation.

Main Products

Advantages

Superior motion precision

Proven reliability in high-cycle applications

Advanced control algorithms

6. Mitsubishi Electric India

Company Profile

Mitsubishi Electric India delivers premium servo and factory automation solutions designed for high-performance applications.

Main Products

Integrated DC servo motors

MELSERVO systems

CNC and PLC solutions

Advantages

7. Schneider Electric India

Company Profile

Schneider Electric is a global leader in energy management and automation, with a strong emphasis on smart manufacturing.

Main Products

Advantages

8. Rockwell Automation India

Company Profile

Rockwell Automation supports Indian industries with advanced motion and control technologies for smart factories.

Main Products

Advantages

High system compatibility

Robust industrial performance

Excellent lifecycle support

9. Bosch Rexroth India

Company Profile

Bosch Rexroth India specializes in precision motion and drive technologies for demanding industrial environments.

Main Products

Advantages

10. JKONGMOTOR

Company Profile

JKongmotor is a well-known Integrated DC Servo Motor Manfacturer for high-performance servo solutions tailored for precision-critical applications.

Main Products

Advantages

Exceptional positioning accuracy

Compact and lightweight solutions

Ideal for medical and robotics applications

11. Moog India

Company Profile

Moog India provides advanced motion control solutions for aerospace, industrial automation, and test systems.

Main Products

Advantages

Extreme accuracy and responsiveness

High reliability under dynamic loads

Advanced feedback systems

12. Beckhoff Automation India

Company Profile

Beckhoff India pioneers PC-based control technology, offering highly integrated motion solutions.

Main Products

Advantages

13. Besfoc

Company Profile

Besfoc is Emerging Integrated DC Servo Motor Manfacturer which focuses on compact and efficient motion control components for OEMs.

Main Products

Advantages

14. Inovance Technology India

Company Profile

Inovance India is rapidly growing in the Indian automation market with cost-effective servo solutions.

Main Products

Advantages

High performance at competitive pricing

Strong customization capability

Fast local technical support

15. L&T Electrical & Automation

Company Profile

Larsen & Toubro is a trusted Indian Integrated DC Servo Motor Manfacturer delivering robust automation and motion solutions.

Main Products

Advantages

Deep understanding of Indian industrial needs

Strong project execution capability

Reliable after-sales support

Why Integrated DC Servo Motors Are Critical for Indian Automation

Integrated DC servo motors have become a cornerstone of modern automation in India, driven by the rapid transformation of manufacturing toward high precision, energy efficiency, and intelligent control. As Indian industries accelerate adoption of Industry 4.0, smart factories, and digitally connected production lines, Integrated DC Servo Motors play a decisive role in ensuring performance, reliability, and scalability.

Compact Integration Reduces System Complexity

One of the most critical advantages of Integrated DC Servo Motors is the all-in-one architecture, where the motor, encoder, drive, and controller are housed within a single compact unit. For Indian manufacturers facing space constraints in machinery design, this integration eliminates bulky external drives, reduces cabinet size, and minimizes wiring errors, resulting in faster installation and cleaner system layouts.

Higher Precision for Advanced Manufacturing

Indian automation sectors such as CNC machining, electronics assembly, robotics, textile machinery, and packaging systems demand high positional accuracy and repeatability. Integrated DC servo motors deliver precise speed control, accurate positioning, and smooth torque output, enabling manufacturers to meet tighter tolerances and improved product quality standards.

Improved Energy Efficiency and Lower Operating Costs

Energy efficiency is a major concern for Indian industries due to rising electricity costs. Integrated DC Servo Motors are designed with optimized power electronics and closed-loop control, ensuring power is consumed only when required. This leads to significant energy savings, reduced heat generation, and lower maintenance costs, making them ideal for continuous-duty industrial applications.

Faster Installation and Reduced Downtime

With fewer components and simplified wiring, integrated DC servo motors significantly reduce commissioning time. Indian factories benefit from quicker machine deployment and easier troubleshooting, minimizing production downtime. This is especially valuable for small and medium enterprises (SMEs) that require rapid scalability without extensive engineering resources.

Enhanced Reliability in Harsh Industrial Environments

Many Indian manufacturing environments involve dust, heat, vibration, and voltage fluctuations. Integrated DC servo motors are engineered with robust housings, efficient thermal management, and stable feedback systems, ensuring consistent performance even under challenging operating conditions. This reliability directly translates into longer service life and reduced maintenance intervention.

Seamless Compatibility with Automation Systems

Integrated DC servo motors support modern communication protocols such as CANopen, EtherCAT, and Modbus, enabling seamless integration with PLCs, HMIs, and industrial networks. This compatibility is critical for Indian manufacturers transitioning to digitized production systems and real-time monitoring, supporting predictive maintenance and data-driven decision-making.

Scalability for Diverse Industrial Applications

India's automation landscape spans diverse sectors, from automotive and pharmaceuticals to food processing and renewable energy equipment. Integrated DC Servo Motors offer scalable torque, speed, and control options, allowing manufacturers to deploy standardized solutions across multiple machine platforms while maintaining flexibility for customization.

Supporting the Growth of Industry 4.0 in India

As India advances toward smart manufacturing and Make in India initiatives, integrated DC servo motors serve as a foundational technology. Their ability to deliver precision motion control, real-time feedback, and digital connectivity aligns perfectly with the goals of increased productivity, reduced waste, and global competitiveness.

Conclusion

Integrated DC servo motors are critical to Indian automation because they combine precision, efficiency, reliability, and intelligent control into a single compact solution. By reducing system complexity, lowering operational costs, and enabling advanced motion control, these motors empower Indian manufacturers to achieve higher productivity and remain competitive in the global automation market.

Key Factors Driving Demand for Integrated DC Servo Motors in India

The demand for integrated DC servo motors in India is accelerating rapidly as industries transition toward high-precision, energy-efficient, and digitally connected automation systems. Multiple structural, technological, and economic factors are converging to make integrated DC Servo Motors a critical component in India's industrial growth. Below, we outline the key drivers shaping this rising demand.

Rapid Growth of Industrial Automation

India's manufacturing sector is undergoing a significant shift toward automation-driven production. Industries such as automotive, electronics, packaging, textiles, pharmaceuticals, and food processing increasingly rely on precise motion control to improve productivity and consistency. Integrated DC servo motors deliver accurate positioning, fast response times, and closed-loop control, making them essential for modern automated machinery.

Adoption of Industry 4.0 and Smart Factories

The push toward Industry 4.0 is a major catalyst for integrated DC Servo Motor adoption. Smart factories require real-time feedback, precise motion synchronization, and seamless digital communication. Integrated DC servo motors support advanced communication protocols and intelligent control features, enabling predictive maintenance, data monitoring, and system optimization across connected production lines.

Demand for Compact and Space-Saving Designs

Space optimization is a critical consideration for Indian machine builders and OEMs. Integrated DC servo motors combine the motor, drive, encoder, and controller into a single compact unit, significantly reducing control cabinet size, wiring complexity, and installation footprint. This compact architecture supports flexible machine design and faster system integration.

Rising Focus on Energy Efficiency

With increasing energy costs and sustainability goals, Indian industries are prioritizing energy-efficient motion solutions. Integrated DC Servo Motors optimize power consumption through precise speed and torque control, reducing energy waste during idle or partial-load conditions. This efficiency directly lowers operational costs and aligns with India's energy conservation initiatives.

Expansion of Robotics and Precision Equipment

India's growing adoption of industrial robots, collaborative robots, CNC machines, and medical devices is driving demand for high-performance servo systems. Integrated DC Servo Motors offer smooth motion, high torque density, and excellent repeatability, making them ideal for robotics, pick-and-place systems, and precision assembly equipment.

Lower Installation and Maintenance Costs

Integrated DC servo motors simplify system architecture by eliminating external drives and extensive wiring. This results in shorter commissioning times, reduced installation errors, and easier troubleshooting. Indian manufacturers benefit from lower maintenance requirements and reduced downtime, which is especially important for cost-sensitive production environments.

Customization for Diverse Indian Applications

India's industrial landscape is highly diverse, requiring motion solutions tailored to varying voltage conditions, load profiles, and environmental factors. Integrated DC servo motor manufacturers offer customized configurations, including torque ratings, shaft designs, and communication interfaces, supporting a wide range of applications across multiple sectors.

Government Initiatives and Manufacturing Policies

Programs such as Make in India, Digital India, and Production-Linked Incentives (PLI) encourage investment in advanced manufacturing technologies. These initiatives accelerate the adoption of automation components, including integrated DC servo motors, as companies modernize production to meet global quality and efficiency standards.

Improved Reliability in Challenging Environments

Indian industrial environments often involve high temperatures, dust, vibration, and power fluctuations. Integrated DC Servo Motors are designed with robust housings, stable feedback systems, and efficient thermal management, ensuring reliable performance under demanding conditions and extending equipment lifespan.

Strong Growth of OEM and System Integrator Ecosystem

The expansion of India's OEM and automation integrator network has increased demand for standardized, easy-to-integrate motion solutions. Integrated DC servo motors simplify design, reduce engineering effort, and allow faster deployment, making them a preferred choice for machine builders seeking scalable solutions.

Summary

The growing demand for integrated DC Servo Motors in India is driven by automation expansion, Industry 4.0 adoption, energy efficiency requirements, compact system design, and government-led manufacturing initiatives. By delivering precision, reliability, and intelligent control in a single integrated unit, these motors are becoming a foundational technology in India's evolving industrial automation landscape.

Conclusion: Choosing the Right Integrated DC Servo Motor Manufacturer in India

Selecting the right Integrated DC Servo Motor Manufacturer in India depends on application requirements, precision levels, system compatibility, and long-term support. We recommend partnering with manufacturers that offer strong local service, proven engineering expertise, and scalable solutions to ensure maximum productivity and reliability in automation systems.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català