Choosing the right motion control solution is one of the most critical decisions in CNC machine design. The motor system directly affects positioning accuracy, cutting stability, production efficiency, system complexity, and long-term maintenance costs.

Based on BESFOC's product portfolio and real-world CNC applications, this article provides a clear, engineering-oriented comparison between Stepper Motors and Integrated Stepper Servo Motors, helping OEMs, system integrators, and automation engineers make informed decisions.

Understanding CNC Motion Control Requirements

CNC motion control requirements are defined by the need for precision, consistency, speed, and long-term operational stability. In modern CNC machines, the motion control system is responsible not only for positioning the tool or workpiece, but also for ensuring repeatable machining accuracy across thousands of cycles. Any weakness in motion control directly translates into dimensional errors, surface defects, reduced throughput, and increased maintenance costs.

High Positioning Accuracy and Repeatability

CNC machines rely on motion systems capable of achieving micron-level positioning accuracy. This requires motors to respond precisely to control commands and maintain consistent movement over time. Repeatability is especially critical in batch production, where identical parts must be produced with minimal deviation. Even small positioning errors can result in scrap, rework, or tool wear.

Stable Torque Output Across Operating Speeds

During CNC operations, motors must deliver smooth and stable torque at both low and medium speeds. Low-speed torque is essential for precise contouring, tapping, and Z-axis positioning, while mid-speed stability ensures efficient material removal. Torque fluctuation can cause chatter, uneven cutting, and premature tool failure.

Smooth Acceleration and Deceleration Control

CNC machines frequently change direction and speed. Effective motion control systems provide controlled acceleration and deceleration to minimize mechanical shock. Smooth motion profiles reduce vibration, protect ball screws and linear guides, and improve overall machining quality.

Vibration Suppression and Resonance Control

Vibration is a major challenge in CNC motion systems. Poorly controlled motors can introduce resonance, leading to noise, surface ripples, and reduced dimensional accuracy. Advanced motion control solutions are designed to minimize vibration and resonance, ensuring smoother tool paths and better surface finishes.

Reliability in Continuous Industrial Operation

Industrial CNC machines often operate for long hours under heavy load. Motion control components must withstand continuous duty cycles, temperature variations, and mechanical stress without losing accuracy. Reliability directly impacts machine uptime, productivity, and total cost of ownership.

Ease of Integration and System Diagnostics

Modern CNC manufacturers demand motion systems that are easy to integrate, configure, and maintain. Simplified wiring, standardized interfaces, and built-in diagnostics help reduce installation time and troubleshooting complexity. Systems that provide real-time status feedback enable faster fault detection and preventive maintenance.

By meeting these core CNC motion control requirements, manufacturers can ensure higher machining accuracy, improved production efficiency, and long-term system stability, forming the foundation for reliable and competitive CNC machine performance.

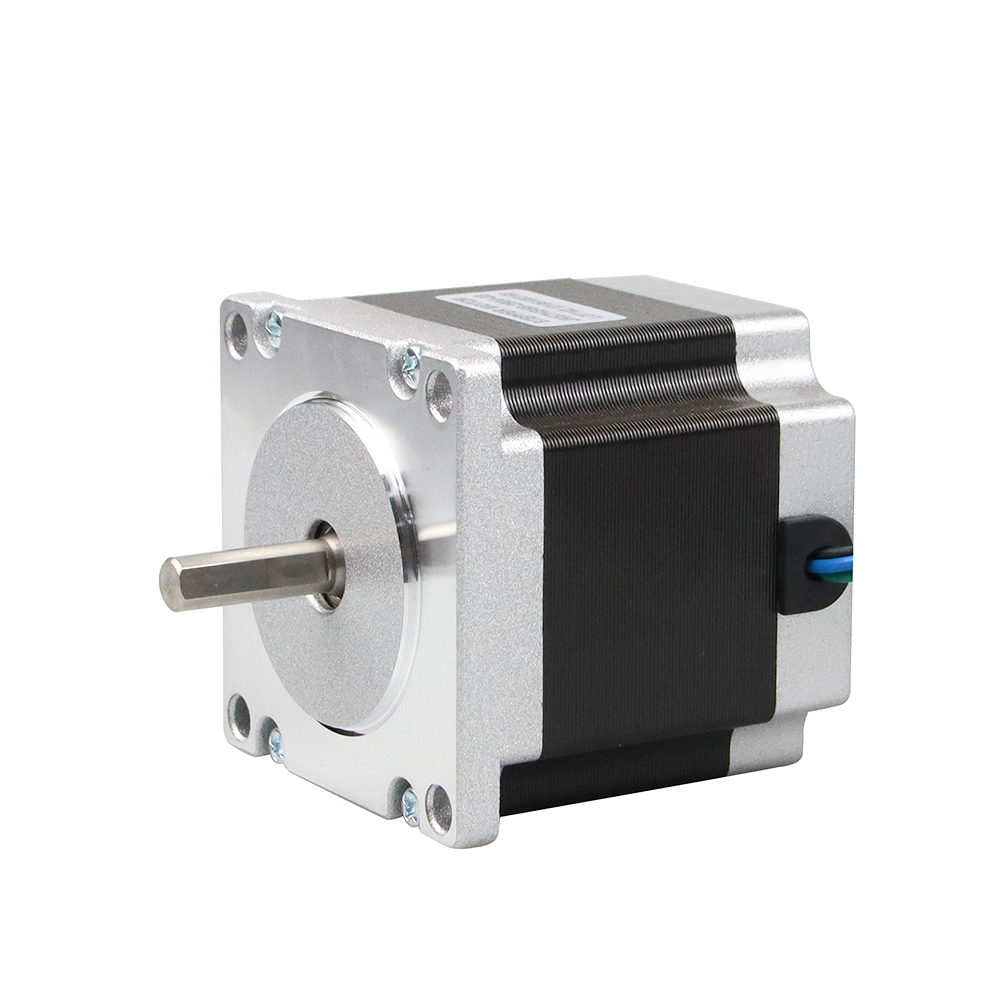

What Is a Stepper Motor in CNC Applications?

A Stepper Motor is an open-loop motion device that moves in discrete steps. In CNC machines, stepper motors are commonly paired with external stepper drivers and controlled via pulse signals.

Key Characteristics of CNC Stepper Motors

Open-loop control (no position feedback)

High holding torque

Simple wiring and control logic

Cost-effective for entry-level CNC machines

Predictable step-by-step positioning

Advantages of Stepper Motors for CNC Machines

Low system cost: Ideal for budget-sensitive CNC routers and desktop machines

Simple control architecture: No encoder tuning required

Strong low-speed torque: Suitable for Z-axis and light-load axes

Wide size availability: NEMA 17 STEPPER MOTOR, NEMA 23 STEPPER MOTOR, NEMA 34 STEPPER MOTOR options available at BESFOC

Limitations of Stepper Motors

Risk of lost steps under overload

Torque drops significantly at high speeds

Mechanical resonance and vibration

No real-time position correction

Stepper motors are best suited for light-duty CNC machines, woodworking routers, engraving machines, and educational CNC platforms.

What Is an Integrated Stepper Servo Motor?

An Integrated Stepper Servo Motor combines a stepper motor, servo driver, and encoder into a single compact unit. This design creates a closed-loop control system that bridges the gap between traditional stepper motors and AC servo motors.

Core Features of Integrated Stepper Servo Motors

Closed-loop feedback control

Automatic error correction

Higher usable torque at speed

Integrated driver and encoder

Reduced wiring and cabinet space

BESFOC's integrated Stepper Servo Motors are designed specifically for industrial CNC environments, focusing on reliability, compactness, and simplified commissioning.

Performance Comparison: Stepper Motor vs Integrated Stepper Servo Motor

Position Accuracy and Reliability

Stepper Motor: Accurate under normal load, but cannot detect missed steps

Integrated Stepper Servo Motor: Encoder feedback ensures zero step loss, even under sudden load changes

Winner: Integrated Stepper Servo Motor

Speed and Torque Characteristics

Winner: Integrated Stepper Servo Motor

Vibration and Noise

Winner: Integrated Stepper Servo Motor

System Integration and Wiring

Winner: Integrated Stepper Servo Motor

Cost Considerations

Winner: Depends on project budget and performance goals

Typical CNC Application Scenarios

When to Choose a Stepper Motor

When to Choose an Integrated Stepper Servo Motor

Industrial CNC routers

Metal milling and cutting machines

High-speed engraving systems

Multi-axis CNC machines

Applications requiring high reliability and zero step loss

Why CNC Manufacturers Choose BESFOC Motion Solutions

BESFOC provides a complete CNC motor ecosystem, including:

Hybrid Stepper Motors

Integrated Stepper Servo Motors

Closed-Loop Stepper Systems

Planetary Gear Stepper Motors

Worm Gear Stepper Motors

Key BESFOC Advantages

In-house motor and driver manufacturing

Custom torque, voltage, and encoder options

Compact integrated designs

Global OEM support

Stable supply for mass production

Selection Guide: Stepper vs Integrated Stepper Servo for CNC

| CNC Requirement | Recommended Solution |

| Low cost | Stepper Motor |

| High positioning reliability | Integrated Stepper Servo |

| High-speed operation | Integrated Stepper Servo |

| Simple control system | Stepper Motor |

| Industrial continuous duty | Integrated Stepper Servo |

| Compact machine design | Integrated Stepper Servo |

Conclution

For CNC machines, the choice between a Stepper Motor and an Integrated Stepper Servo Motor is not simply about price—it is about performance stability, production efficiency, and long-term operational reliability.

Stepper motors remain a practical solution for entry-level and light-duty CNC machines.

Integrated stepper servo motors offer a future-ready solution for industrial CNC systems requiring precision, speed, and zero step loss.

By aligning motor selection with actual CNC application demands, manufacturers can significantly enhance machine value, reliability, and customer satisfaction.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català