Packaging machines demand precision, reliability, speed stability, and long-term durability under continuous operation. Selecting the best stepper motor for packaging machinery is not a generic decision—it directly affects throughput, product consistency, downtime, and maintenance cost. We present a comprehensive, technically grounded guide that identifies the optimal stepper motor solutions for modern packaging systems across food, pharmaceutical, cosmetic, and industrial sectors.

Understanding Motion Requirements in Packaging Machines

Packaging equipment performs highly repetitive, synchronized actions such as indexing, sealing, cutting, filling, labeling, cartoning, and palletizing. These processes require motors capable of delivering:

Accurate positioning without feedback

Consistent torque at low and medium speeds

Fast acceleration and deceleration

Stable performance in 24/7 duty cycles

Minimal vibration and noise

Stepper motors are widely adopted in packaging machinery because they inherently meet these requirements while maintaining cost efficiency and control simplicity.

Why Stepper Motors Dominate Packaging Automation

Stepper motors have become the core motion solution in packaging automation because they align perfectly with the mechanical, operational, and economic demands of modern packaging equipment. From form-fill-seal machines to labeling, cartoning, and indexing systems, stepper motors consistently outperform alternative motor technologies in real-world packaging scenarios.

Precise Positioning Without Feedback Complexity

Packaging machines rely heavily on repeatable, deterministic motion. Stepper motors move in discrete steps, allowing controllers to calculate exact position and speed without encoders or feedback devices. This inherent precision is ideal for tasks such as:

By eliminating feedback components in many applications, stepper motors reduce system complexity while maintaining high positional accuracy.

Exceptional Low-Speed Torque for Intermittent Motion

Most packaging processes involve start-stop, indexing, and dwell cycles rather than continuous rotation. High Torque Stepper motors excel in these conditions due to their high holding torque and strong low-speed torque output.

This makes them especially effective for:

Intermittent conveyor indexing

Rotary cutting and sealing mechanisms

Filling and dosing systems

Unlike AC motors, stepper motors maintain torque at zero speed, ensuring components remain locked in position during pauses.

Simplified Control Architecture

Stepper motors integrate seamlessly with PLCs, motion controllers, and industrial drivers. Their pulse-and-direction control method simplifies system design and reduces commissioning time.

Key control advantages include:

No tuning required compared to servo systems

Predictable motion profiles

Easy multi-axis synchronization

This simplicity is a major reason stepper motors dominate OEM packaging machine designs.

Cost-Effective Performance for High-Volume Machinery

Packaging machines are often produced at scale. Stepper motors offer a lower total system cost compared to servo solutions while delivering sufficient performance for the majority of packaging tasks.

Cost benefits include:

Lower motor and drive cost

Reduced wiring and installation labor

Minimal maintenance requirements

For manufacturers balancing performance and budget, stepper motors provide unmatched value.

Packaging lines frequently operate 24/7 in industrial environments. Stepper motors are built with robust bearings, laminated stators, and industrial insulation systems that withstand:

Their mechanical simplicity contributes to long service life and low failure rates.

Excellent Compatibility with Modular Machine Design

Modern packaging equipment is increasingly modular. Stepper motors support this trend through:

This allows machine builders to design scalable platforms that are easy to customize for different packaging formats.

Smooth Motion Through Microstepping Technology

Advanced microstepping drivers significantly enhance stepper motor performance by reducing vibration and resonance. This results in:

Smoother film transport

Reduced mechanical wear

Lower acoustic noise

These characteristics are essential in food, pharmaceutical, and cosmetic packaging environments.

Scalable Performance with Closed-Loop Options

For high-speed or high-precision packaging lines, closed-loop stepper motors bridge the gap between traditional steppers and servos. They deliver:

This scalability allows stepper motors to remain dominant even as packaging machines become faster and more intelligent.

Ideal Balance Between Performance and Practicality

Stepper motors dominate packaging automation because they deliver exactly what packaging systems require: precision, reliability, simplicity, and cost efficiency. They provide the optimal balance between mechanical performance and operational practicality, making them the preferred choice for packaging machinery across industries.

In an environment where uptime, accuracy, and scalability define success, stepper motors continue to be the foundation of packaging automation worldwide.

Best Types of Stepper Motors for Packaging Machines

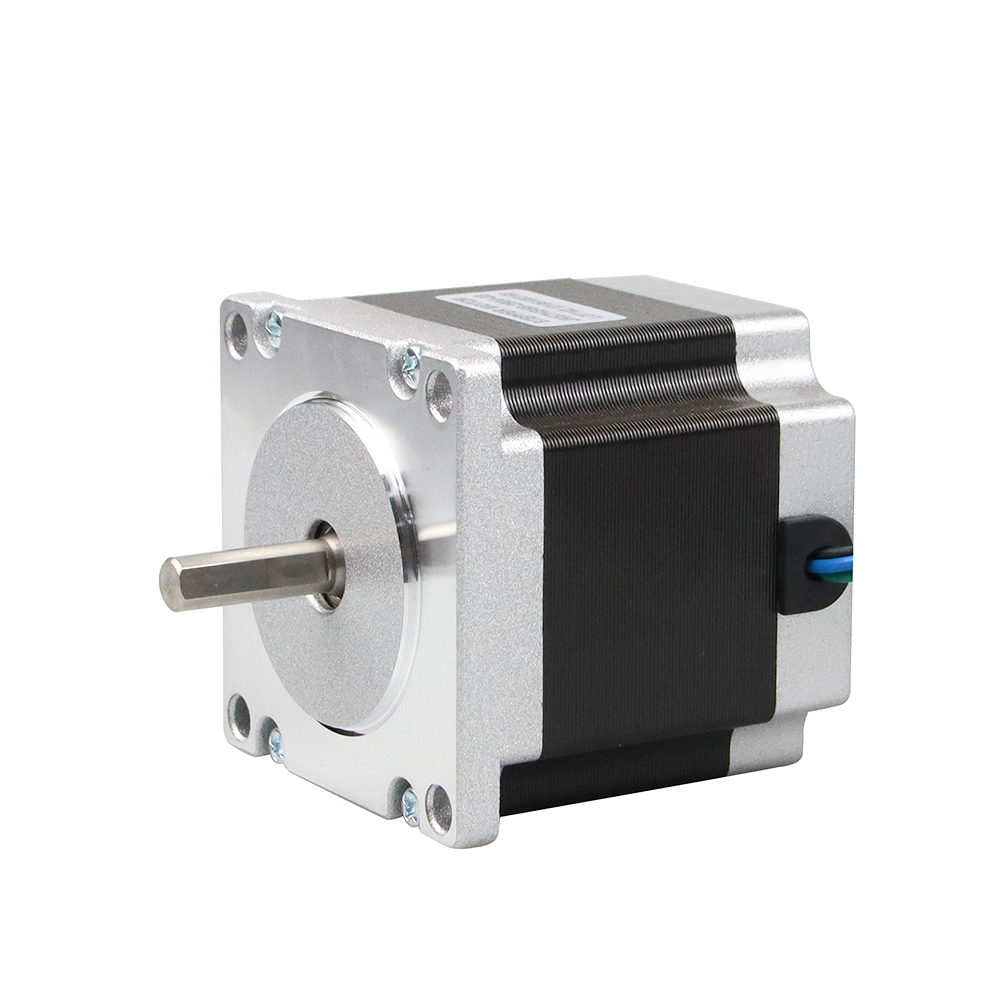

Hybrid Stepper Motors – The Industry Standard

Hybrid stepper motors combine permanent magnet and variable reluctance technologies, delivering superior torque density and positioning accuracy. For packaging machines, they represent the optimal balance between performance and cost.

Key advantages include:

High torque at low speed

Excellent step resolution

Wide compatibility with industrial drivers

Robust mechanical construction

Hybrid stepper motors are the most widely used choice in vertical form-fill-seal (VFFS), horizontal packaging machines, and flow wrappers.

For advanced packaging equipment where space efficiency and wiring simplicity are critical, integrated stepper motors are increasingly preferred. These units combine the motor, driver, and sometimes controller into a single housing.

Benefits include:

Integrated stepper motors are ideal for modular packaging machines, multi-axis pick-and-place systems, and OEM-designed compact equipment.

Selecting the Correct NEMA Size for Packaging Applications

NEMA 17 stepper motors are suitable for lightweight packaging tasks such as:

Label feeding

Date coding mechanisms

Small conveyor indexing

They offer compact size and sufficient torque for low-load operations but are not recommended for primary drive axes.

NEMA 23 stepper motors are widely regarded as the best all-around option for packaging machines. They deliver an excellent torque-to-size ratio and support higher speeds with stable performance.

Typical applications include:

Film pulling rollers

Sealing jaw actuation

Carton indexing

Medium-load conveyors

Their versatility makes them the default choice for most mid-sized packaging systems.

For high-inertia loads or large-format machines, NEMA 34 stepper motors provide the required power.

Used in:

Case packing machines

Large indexing tables

Palletizing subsystems

These motors deliver high torque but require robust drivers and mechanical support.

Key Performance Factors That Define the Best Stepper Motor

Torque Curve Stability

Packaging machines often operate at varying speeds. The best stepper motors maintain usable torque across the operating speed range, preventing missed steps and product misalignment.

Microstepping Capability

Advanced microstepping improves:

Motion smoothness

Noise reduction

Positioning accuracy

For packaging applications involving delicate materials, microstepping drivers paired with high-quality stepper motors are essential.

Thermal Management and Duty Cycle

Continuous operation demands motors with:

Motors designed for industrial packaging environments ensure long service life without derating.

Low Vibration and Acoustic Noise

Packaging machines often operate in food and pharmaceutical environments where noise levels matter. Motors with optimized rotor design and precision bearings significantly reduce vibration.

Open-Loop vs Closed-Loop Stepper Motors in Packaging

Still widely used due to:

Lower cost

Simpler control

Proven reliability

Ideal for systems with predictable loads and short acceleration cycles.

Closed-Loop Stepper Motors

For high-speed or high-value packaging lines, closed-loop stepper motors eliminate step loss by monitoring rotor position.

Advantages include:

They are increasingly adopted in high-speed flow wrappers and precision dosing machines.

Environmental and Compliance Considerations

Packaging machines operate in regulated, high-responsibility environments where hygiene, safety, durability, and regulatory compliance are non-negotiable. Selecting stepper motors that meet environmental and compliance requirements is essential to ensure legal conformity, operational stability, and long-term reliability across global markets.

Hygienic Design for Food and Pharmaceutical Packaging

In food, beverage, and pharmaceutical packaging, motors must support clean-in-place (CIP) and washdown procedures. Stepper motors designed for these sectors feature:

Smooth, non-porous housings

Sealed shafts to prevent contamination

Food-grade compatible materials

Resistance to detergents and sanitizing chemicals

Hygienic motor design directly reduces contamination risks and simplifies compliance with HACCP and GMP standards.

Ingress Protection (IP) Ratings

Packaging environments often involve dust, moisture, powders, oils, or splashing liquids. Stepper motors with appropriate IP protection levels are critical:

High IP ratings protect internal windings and bearings, preventing premature failure and maintaining consistent motor performance.

Thermal Stability and Environmental Tolerance

Packaging lines may operate in high-temperature, cold-storage, or variable-humidity environments. Industrial stepper motors are engineered to withstand:

Elevated ambient temperatures

Condensation and humidity

Rapid temperature fluctuations

Proper thermal design ensures torque stability, insulation integrity, and uninterrupted operation under demanding conditions.

Electrical Safety and EMC Compliance

Packaging machinery must meet strict electrical safety and electromagnetic compatibility (EMC) requirements to operate legally and reliably. Compliant stepper motors and drivers support:

Reduced electromagnetic interference

Stable signal transmission

Safe integration with PLCs and sensors

Compliance minimizes interference between machine subsystems and protects sensitive electronics.

Global Regulatory Certifications

To support international machine deployment, stepper motors used in packaging equipment must meet global compliance standards, including:

Using certified motors simplifies machine approval processes and accelerates time-to-market.

Energy Efficiency and Sustainability

Environmental responsibility is becoming a key consideration in packaging automation. Modern stepper motors contribute to sustainability through:

Energy-efficient motors support green manufacturing initiatives and help reduce overall operational costs.

Durability in Harsh Industrial Conditions

Packaging machines are exposed to vibration, repetitive motion, and mechanical shock. Stepper motors designed for industrial environments incorporate:

This durability ensures consistent performance and compliance throughout the machine's service life.

Traceability and Documentation Requirements

Regulated industries often require full traceability of machine components. High-quality stepper motor manufacturers provide:

This documentation is critical for audits, certifications, and long-term operational accountability.

Compliance as a Competitive Advantage

Selecting stepper motors that meet environmental and regulatory standards is not just a legal necessity—it is a strategic advantage. Compliance-ready motors reduce risk, simplify machine certification, and enhance customer trust.

In modern packaging automation, environmental resilience and regulatory conformity are as important as torque and speed. Stepper motors engineered with these considerations in mind ensure safe, reliable, and globally compliant packaging solutions.

Packaging Machine Stepper Motor FAQ

Below is a comprehensive FAQ section addressing the most common technical, operational, and purchasing questions related to stepper motors used in packaging machines. This content is designed to support engineers, OEMs, and procurement teams in making informed decisions.

1. What maintenance is required for stepper motors in packaging machines?

Stepper motors require minimal maintenance. Periodic inspection of mechanical couplings and ensuring proper ventilation are typically sufficient.

2. Are integrated stepper motors suitable for modular packaging machines?

Yes. Integrated stepper motors reduce wiring, save space, and improve reliability, making them ideal for modular and compact packaging equipment.

3. How do environmental factors affect stepper motor selection?

Factors such as dust, humidity, temperature, and chemical exposure determine required IP ratings, insulation class, and housing materials. Proper selection ensures reliable operation and compliance.

4. Can stepper motors meet global compliance standards?

Industrial stepper motors are available with CE, UL, RoHS, and REACH compliance, enabling global deployment of packaging machinery.

5. How do stepper motors improve overall packaging machine efficiency?

Stepper motors enhance efficiency by:

Reducing positioning errors

Minimizing downtime

Lowering energy consumption

Simplifying control systems

These benefits translate directly into higher throughput and lower operating costs.

6. What is the typical lifespan of a stepper motor in packaging equipment?

With proper sizing and operation, stepper motors commonly achieve tens of thousands of operating hours, making them highly reliable for industrial packaging use.

7. Are stepper motors suitable for high-speed packaging machines?

Yes, especially closed-loop stepper motors and high-voltage systems. They provide stable performance at elevated speeds without sacrificing accuracy.

8. How do stepper motors contribute to packaging accuracy?

Their precise step control ensures repeatable motion, maintaining consistent package dimensions, seal quality, and labeling alignment.

9. What role does torque margin play in stepper motor selection?

Adequate torque margin prevents missed steps during acceleration or load changes, ensuring stable and reliable packaging operations.

10. Why are stepper motors the preferred choice for OEM packaging machine builders?

Stepper motors offer the ideal combination of precision, reliability, scalability, cost efficiency, and global compliance, making them the preferred motion solution for packaging automation worldwide.

Cost Efficiency and Long-Term Value

While initial motor price matters, the best stepper motor for packaging machines delivers:

Investing in industrial-grade stepper motors significantly reduces total cost of ownership over the machine lifecycle.

Future Trends in Packaging Stepper Motor Technology

Packaging automation continues to evolve toward:

Smarter integrated motors

IO-Link and fieldbus connectivity

Energy-optimized motor designs

Compact high-torque solutions

Manufacturers that adopt advanced stepper motor technologies gain higher throughput, better product quality, and improved machine intelligence.

Final Determination: Which Stepper Motor Is Best for Packaging Machines?

The optimal choice depends on application requirements, but in most industrial packaging scenarios:

Hybrid NEMA 23 stepper motors deliver the best balance of torque, precision, and cost

Integrated stepper motors provide superior system simplicity and reliability

Closed-loop stepper motors are best for high-speed, high-value packaging lines

Selecting the right stepper motor ensures consistent packaging accuracy, operational stability, and competitive manufacturing efficiency.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català