Germany is globally recognized for precision engineering, advanced automation technology, and world-class motion control solutions. Integrated DC servo motor manufacturers in Germany lead the market by combining motor, drive, controller, and feedback systems into compact, high-performance units designed for industrial automation, robotics, medical equipment, and CNC machinery.

Below is a comprehensive and structured list of the top 15 Integrated DC Servo Motor manufacturers in Germany, with each company analyzed by company profile, main products, and competitive advantages.

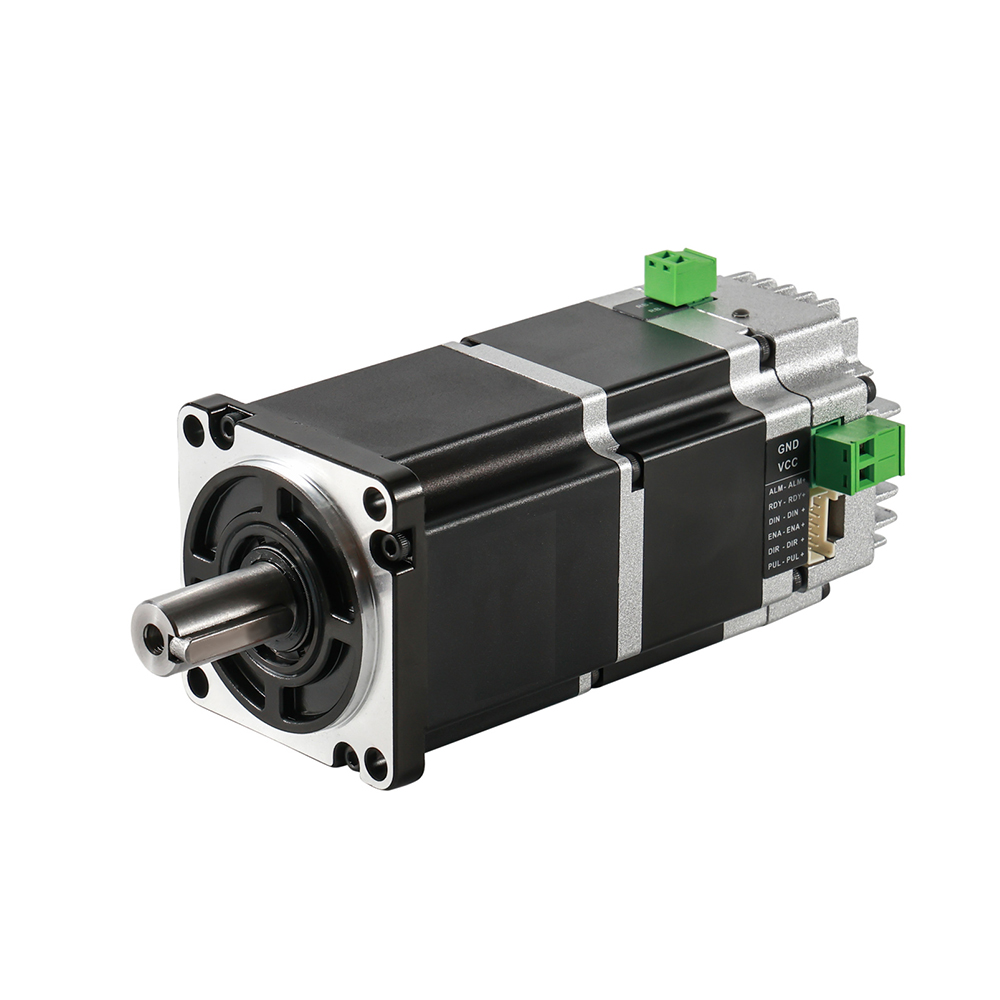

Besfoc Integrated Dc Servo Motor Products

Top 15 integrated DC servo motor manufacturers in Germany

1. Siemens AG

Company Profile

Siemens is a global industrial Integrated DC Servo Motor Manufacturer and a pioneer in industrial automation and digital motion control. Its integrated servo solutions are widely used across smart factories worldwide.

Main Products

Integrated DC servo motors

SINAMICS servo drive systems

Motion control modules

Industrial automation platforms

Advantages

Deep integration with PLC and automation systems

Exceptional reliability and long lifecycle

Strong Industry 4.0 compatibility

2. Bosch Rexroth

Company Profile

Bosch Rexroth is a leading Integrated DC Servo Motor Manufacturer in drive and control technologies, offering high-precision servo solutions for demanding industrial applications.

Main Products

Advantages

High torque density and energy efficiency

Modular and scalable system design

Global technical support network

3. FAULHABER Group

Company Profile

FAULHABER focuses on miniature and micro drive systems, delivering compact integrated DC servo motors for precision applications.

Main Products

Advantages

Extremely compact and lightweight designs

High positioning accuracy

Ideal for medical and laboratory equipment

4. Beckhoff Automation

Company Profile

Beckhoff is well-known Integrated DC Servo Motor Manufacturer for PC-based control technology, offering integrated servo solutions that seamlessly integrate with EtherCAT systems.

Main Products

Integrated servo motor systems

DC servo motors with embedded drives

Automation software and controllers

Advantages

5. WITTENSTEIN cyber motor

Company Profile

WITTENSTEIN cyber motor specializes in high-end servo motors and mechatronic systems for precision automation.

Main Products

Integrated DC servo motors

Compact servo gear motors

Cyber Dynamic Line solutions

Advantages

6. SEW-EURODRIVE

Company Profile

SEW-EURODRIVE is a global leading Integrated DC Servo Motor Manufacturer in drive technology and automation solutions, serving manufacturing and logistics industries.

Main Products

Advantages

Robust industrial designs

Wide application flexibility

Strong after-sales support

7. Lenze SE

Company Profile

Lenze focuses on motion-centric automation, delivering integrated servo solutions tailored to machine builders.

Main Products

Advantages

8. Besfoc

Company Profile

Besfoc is a well-known Integrated DC Servo Motor Manufacturer and specialist in intelligent motor solutions, offering integrated DC servo motors with onboard electronics.

Main Products

Advantages

Built-in intelligence and diagnostics

Compact and rugged construction

Excellent customization capability

9. Baumüller Nürnberg GmbH

Company Profile

Baumüller is a German Integrated DC Servo Motor Manufacturer focusing on automation systems and electric drive technology.

Main Products

Advantages

High performance for heavy-duty applications

Strong system integration

Made-in-Germany engineering quality

10. Kollmorgen (German Operations)

Company Profile

Kollmorgen operates extensively in Germany, supplying high-precision integrated servo systems for industrial and medical applications.

Main Products

Advantages

Exceptional motion accuracy

High reliability under continuous operation

Strong engineering support

11. maxon Motor (Germany)

Company Profile

maxon Motor is renowned Integrated DC Servo Motor Manufacturer for precision drive systems, with German operations supporting industrial and medical markets.

Main Products

Advantages

Ultra-smooth motion control

High efficiency at small sizes

Proven performance in critical applications

12. Moog GmbH

Company Profile

Moog GmbH delivers high-performance motion control solutions for aerospace, industrial, and test systems.

Main Products

Advantages

Extreme precision and dynamic response

Designed for mission-critical environments

Advanced control algorithms

13. Heidrive GmbH

Company Profile

Heidrive specializes in customized drive solutions, including integrated servo motor systems.

Main Products

Advantages

Strong OEM customization support

Flexible mechanical designs

Reliable long-term operation

14. TRINAMIC Motion Control (Germany)

Company Profile

TRINAMIC is known for advanced motion control ICs and integrated motor systems, widely used in automation and robotics.

Main Products

Advantages

Highly efficient control algorithms

Compact embedded solutions

Excellent noise and vibration control

15. ebm-papst (Drive Technology Division)

Company Profile

ebm-papst is a leading Integrated DC Servo Motor Manufacturer extends its expertise in motor technology to integrated drive and servo solutions.

Main Products

Advantages

Applications Driving Demand for Integrated DC Servo Motors

The rapid adoption of Integrated DC Servo Motors is being driven by industries that require high precision, compact design, fast dynamic response, and simplified system integration. By combining the motor, drive, controller, and feedback device into a single unit, integrated DC servo motors reduce complexity while significantly improving reliability and performance. Below are the key application sectors fueling global demand.

Industrial Automation and Smart Manufacturing

Integrated DC servo motors are widely used in automated production lines, assembly stations, and smart factories. Their compact architecture reduces control cabinet space, while precise positioning and repeatability ensure consistent product quality. In Industry 4.0 environments, these motors support real-time monitoring, predictive maintenance, and digital connectivity, making them essential for modern manufacturing systems.

Robotics and Collaborative Robots (Cobots)

Robotic systems rely heavily on accurate torque control, smooth motion, and fast response times. Integrated DC Servo Motors meet these requirements by delivering stable performance in a compact form factor. They are commonly applied in articulated robots, SCARA robots, and collaborative robots, where space constraints and safety-critical operation demand high integration and reliability.

CNC Machines and Precision Machine Tools

In CNC machining centers, engraving machines, and precision lathes, integrated DC servo motors provide the high-speed control and positional accuracy needed for complex motion profiles. Their closed-loop feedback systems enable micron-level positioning, while reduced wiring improves signal stability and overall system robustness.

Medical and Laboratory Equipment

Medical technology demands exceptional reliability, low noise, and precise motion control. Integrated DC Servo Motors are used in surgical robots, diagnostic equipment, infusion pumps, laboratory automation systems, and imaging devices. Their compact and hygienic designs make them ideal for space-limited medical environments where performance consistency is critical.

Packaging, Labeling, and Printing Machinery

High-speed packaging and labeling systems require synchronized motion and rapid acceleration. Integrated DC servo motors ensure accurate product handling, precise label placement, and consistent print quality. The simplified wiring and faster commissioning help machine builders reduce installation time and improve overall machine efficiency.

Automated Guided Vehicles (AGVs) and Mobile Robots

AGVs and autonomous mobile robots depend on precise speed control, efficient power usage, and compact drive systems. Integrated DC Servo Motors support smooth acceleration, accurate navigation, and stable load handling. Their high efficiency and built-in control electronics extend battery life and enhance system reliability.

Semiconductor and Electronics Manufacturing

Semiconductor and electronics production processes require ultra-precise motion and contamination-free operation. Integrated DC servo motors are widely applied in pick-and-place machines, wafer handling systems, inspection equipment, and SMT production lines, where precision and repeatability are essential for high yield rates.

Material Handling and Conveyor Systems

In conveyor belts, sorting systems, and automated storage solutions, integrated DC servo motors deliver precise speed regulation and load-dependent torque control. Their compact design allows decentralized installation directly on the machine, reducing mechanical losses and improving energy efficiency.

Textile and Printing Industry

Textile machinery and digital printing systems require continuous, synchronized motion at varying speeds. Integrated DC Servo Motors provide smooth torque delivery and precise tension control, ensuring consistent fabric quality and accurate print registration.

Renewable Energy and Test Systems

In renewable energy testing equipment and dynamic load simulation systems, integrated DC servo motors offer accurate torque and speed control. They are used in wind turbine testing rigs, actuator systems, and performance validation platforms, where stable and repeatable motion is essential.

Conclusion

The growing demand for integrated DC servo motors is driven by applications that prioritize precision, compactness, energy efficiency, and system simplicity. From industrial automation and robotics to medical technology and semiconductor manufacturing, these motors enable advanced motion control while reducing system complexity. As industries continue to evolve toward smarter, more compact, and more efficient machines, integrated DC servo motors will remain a critical enabling technology.

Customization and OEM Capabilities

The increasing adoption of Integrated DC Servo Motors is closely linked to the advanced customization and OEM capabilities offered by leading manufacturers. Modern automation systems demand motion solutions that are not only precise and reliable, but also tailored to specific mechanical, electrical, and environmental requirements. Custom-built integrated servo motors allow OEMs and system integrators to achieve higher efficiency, faster time-to-market, and superior system performance.

Customized Electrical Design and Performance Tuning

One of the most critical OEM requirements is electrical customization. Manufacturers provide flexible options for:

Voltage ranges and current ratings to match different power architectures

Torque-speed optimization for specific load profiles

Customized winding designs to improve efficiency or thermal performance

Acceleration and deceleration tuning for smooth dynamic response

These capabilities ensure that the integrated DC servo motor performs optimally within the target application, reducing energy consumption and improving motion accuracy.

Encoder and Feedback Configuration Options

OEMs often require specific feedback technologies to achieve precise motion control. Integrated DC Servo Motor Manufacturers support multiple feedback options, including:

Incremental and absolute encoders

Magnetic, optical, and Hall-effect sensors

High-resolution feedback for micron-level positioning

By tailoring the feedback system, manufacturers enable precise synchronization, accurate positioning, and stable closed-loop control across diverse operating conditions.

Mechanical and Structural Customization

Mechanical adaptability is a key advantage of OEM-focused servo motor suppliers. Customization options typically include:

Shaft types and dimensions

Flange sizes and mounting configurations

Integrated gearboxes or brake systems

Specialized housings for compact or high-load designs

These mechanical modifications allow seamless integration into existing machine structures, reducing redesign costs and simplifying installation.

Communication Protocol and Control Integration

To support modern automation networks, Integrated DC Servo Motors can be customized with a wide range of industrial communication protocols, such as:

EtherCAT, CANopen, Modbus, and RS485

Proprietary or application-specific protocols

PLC and motion controller compatibility

This flexibility ensures easy integration into both centralized and decentralized control architectures, enhancing system scalability and interoperability.

Environmental and Application-Specific Protection

OEM applications often operate in challenging environments. Manufacturers offer customized protection solutions, including:

Extended temperature operating ranges

IP-rated enclosures for dust and moisture resistance

Anti-corrosion coatings and sealed housings

Low-noise and low-vibration designs

These adaptations ensure reliable performance in harsh industrial, medical, or outdoor environments.

Software, Firmware, and Functional Customization

Advanced OEM partnerships extend beyond hardware. Leading manufacturers provide custom firmware and software features, such as:

Application-specific motion algorithms

Safety functions and fault diagnostics

Parameter presets for rapid commissioning

Remote monitoring and data feedback capabilities

Software-level customization significantly reduces development time while enhancing system intelligence and reliability.

Prototyping, Validation, and Scalable Production

Strong OEM capabilities include rapid prototyping, functional testing, and scalable manufacturing. Manufacturers support:

Quick sample development for validation

Performance testing under real application conditions

Small-batch and high-volume production flexibility

This end-to-end support helps OEMs transition smoothly from concept to mass production.

Long-Term Supply and Technical Support

OEM customers rely on stable, long-term partnerships. Leading integrated DC servo motor manufacturers provide:

Consistent component availability

Dedicated engineering support teams

Lifecycle management and product continuity

These services ensure system reliability throughout the product lifecycle and reduce the risk of unexpected redesigns.

Conclusion

Customization and OEM capabilities are decisive factors in the successful deployment of integrated DC Servo Motors. By offering tailored electrical, mechanical, software, and communication solutions, manufacturers empower OEMs to build high-performance, application-specific motion systems. As automation requirements continue to grow in complexity, customized integrated servo solutions will play a crucial role in delivering efficiency, precision, and long-term value.

Future Trends in Integrated DC Servo Motor Manufacturing

The integrated DC servo motor industry is evolving rapidly as automation systems demand higher precision, smarter functionality, and greater efficiency in increasingly compact designs. Manufacturers are investing heavily in innovation to meet the needs of smart factories, advanced robotics, and next-generation motion control systems. The following trends are shaping the future of integrated DC Servo Motor manufacturing.

Higher Power Density and Compact Integration

One of the most significant trends is the push toward higher power density within smaller footprints. Advances in magnetic materials, optimized winding techniques, and improved thermal management allow manufacturers to deliver greater torque and speed from more compact integrated units. This trend supports space-constrained applications such as robotics, medical devices, and mobile automation equipment.

Advanced Digital Control and Embedded Intelligence

Future integrated DC servo motors will increasingly feature embedded intelligence. Built-in processors enable real-time motion optimization, adaptive control algorithms, and self-tuning capabilities. These smart motors can adjust performance automatically based on load conditions, improving efficiency, accuracy, and system stability without manual intervention.

Expanded Industrial Communication Capabilities

Seamless connectivity is becoming essential. Manufacturers are integrating multi-protocol industrial communication interfaces directly into servo motors, including EtherCAT, CANopen, PROFINET, and emerging real-time Ethernet standards. This enables direct integration into decentralized automation architectures and supports faster data exchange and synchronized motion control.

Predictive Maintenance and Condition Monitoring

Integrated DC Servo Motors are evolving into data-generating smart devices. Built-in sensors and diagnostics monitor temperature, vibration, current, and load conditions. These data points support predictive maintenance strategies, allowing users to detect potential issues early, reduce unplanned downtime, and extend motor service life.

Improved Energy Efficiency and Sustainability

Energy efficiency is a major driver of innovation. Manufacturers are developing motors with lower power losses, optimized control algorithms, and regenerative braking capabilities. Additionally, sustainable manufacturing practices, recyclable materials, and energy-efficient production processes are becoming standard across the industry.

Enhanced Safety and Functional Integration

Future integrated servo motors will incorporate advanced safety features directly into the motor-drive package. These include safe torque off (STO), safe stop functions, and fault isolation mechanisms. Integrated safety reduces system complexity and supports compliance with increasingly strict international safety standards.

Customization and Modular Design Architectures

Manufacturers are adopting modular design philosophies that allow rapid customization without increasing production complexity. Modular electronics, interchangeable feedback systems, and configurable software enable OEMs to tailor servo motors for specific applications while maintaining short lead times and scalable production.

AI-Assisted Motion Optimization

Artificial intelligence and machine learning are beginning to influence servo motor control. AI-driven algorithms analyze operating data to optimize motion profiles, reduce vibration, and enhance positioning accuracy. Over time, these systems can learn from usage patterns and continuously improve performance.

Decentralized and Edge-Controlled Motion Systems

The trend toward decentralized automation continues to grow. integrated DC Servo Motors with edge computing capabilities reduce reliance on centralized controllers. This architecture improves system responsiveness, simplifies wiring, and enhances scalability in complex automation environments.

Expanded Use in Emerging Applications

Integrated DC servo motors are increasingly used in autonomous mobile robots, collaborative robotics, renewable energy systems, and advanced medical devices. As these applications grow, manufacturers are adapting designs to meet new requirements for mobility, efficiency, and intelligent control.

Summary

The future of integrated DC servo motor manufacturing is defined by intelligence, efficiency, connectivity, and adaptability. As industries continue to demand smarter and more compact motion solutions, manufacturers that invest in embedded control, digital connectivity, predictive maintenance, and sustainable design will lead the market. Integrated DC Servo Motors will remain a foundational technology enabling the next generation of automation and precision motion control systems.

Conclusion

Germany remains a global leader in integrated DC Servo Motor manufacturing, driven by innovation, precision engineering, and industrial reliability. The manufacturers listed above offer cutting-edge integrated servo solutions suitable for automation, robotics, medical technology, and advanced manufacturing. Selecting the right German manufacturer ensures long-term performance, system efficiency, and future-ready motion control.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català