The United States is one of the world's most influential hubs for motion control technology, with a strong ecosystem of stepper motor manufacturers serving industrial automation, medical equipment, robotics, semiconductor manufacturing, aerospace, CNC machinery, and laboratory instrumentation. U.S.-based stepper motor companies are recognized globally for engineering excellence, strict quality control, customization capability, and long-term product reliability.

Below, we present a detailed and structured overview of the Top 15 Stepper Motor Manufacturers in the United States, including company profile, main products, and competitive advantages, to support OEMs, engineers, and sourcing professionals in making informed decisions.

Stepper motor step loss under load is caused by torque mismatch, acceleration settings, and system design. Proper motor selection, optimized control, and factory-customized solutions—including closed-loop or integrated stepper servo motors—can prevent missed steps and ensure reliable performance.

1. BESFOC

Company Profile

BESFOC is a leading Stepper Motor Manufacturer specializing in motion control and stepper motor systems. With decades of industry experience, the company focuses on high-performance, application-ready solutions.

Main Products

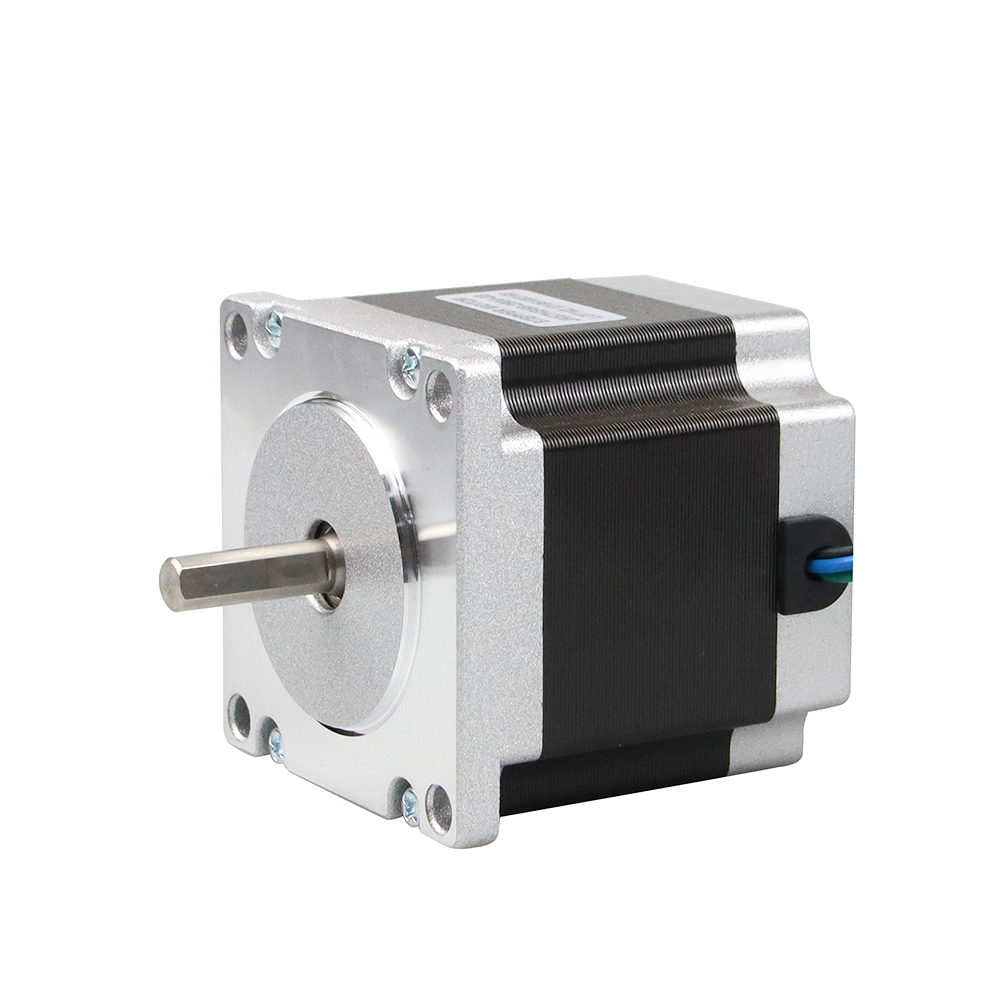

Hybrid stepper motors

Integrated stepper motor + drive systems

Closed-loop stepper motors (stepSERVO™)

Stepper motor drives and controllers

Advantages

Strong engineering and technical support

Excellent integration between motors and controls

High reliability for industrial automation

2. JKONG MOTOR

Company Profile

JKONGMOTOR is the Well-known Stepper Motor Manufacturer, delivering precision-engineered stepper motors with localized support and inventory across the U.S.

Main Products

2-phase and 5-phase stepper motors

αSTEP closed-loop stepper systems

Linear actuators and rotary actuators

Stepper motor drivers

Advantages

Exceptional positioning accuracy

Broad product catalog for OEMs

Proven performance in medical and semiconductor equipment

3. LeanMotor

Company Profile

LeanMotor is a Emerging Stepper Motor Manufacturer and operates significant engineering, sales, and application support centers, serving automation markets with advanced motion solutions.

Main Products

Hybrid stepper motors

Integrated smart stepper motors

Closed-loop stepper motors

Motion controllers and drives

Advantages

Advanced intelligent motor technology

Competitive cost-to-performance ratio

Strong customization and OEM support

4.Superior Electric (ElectroCraft Division)

Company Profile

Superior Electric, now part of ElectroCraft, has specialized in precision motion products for industrial and medical applications.

Main Products

Hybrid stepper motors

DC stepper motors

Custom motion assemblies

Advantages

Expertise in niche industrial applications

Compact and robust designs

Good customization capabilities

5. Lintech Motion

Company Profile

Lintech Motion focuses on linear motion and stepper motor systems for automation, packaging, and material handling industries.

Main Products

Advantages

Excellent linear integration expertise

Cost-effective small-batch solutions

High reliability for medium-duty applications

6. Motion Dynamics, Inc.

Company Profile

Motion Dynamics is a U.S. manufacturer providing customized stepper motors and servo solutionsprimarily for robotics and industrial automation.

Main Products

Advantages

Flexible low-volume production

Custom torque and size configurations

Strong engineering support

7. Sensata Technologies (Electromechanical Division)

Company Profile

Sensata provides precision motion components, including stepper motors, for automation and sensor-integrated systems.

Main Products

Advantages

Advanced integration with sensor feedback

Compact and high-efficiency designs

Expertise in automotive and industrial markets

8. DYNEX Stepper Motors

Company Profile

DYNEX is a Stepper Motor Manufacturer specializes in small and medium-size stepper motors, focusing on OEM and custom applications.

Main Products

Advantages

Strong ability to tailor products for specific applications

Cost-effective manufacturing

Quick prototyping support

9. Falcon Electric

Company Profile

Falcon Electric produces stepper and servo motors for precision automation, particularly for packaging and robotics.

Main Products

Advantages

High-torque, compact designs

Flexible order quantities

Strong focus on small and medium-sized enterprises (SMEs)

10. Motion Tech, Inc.

Company Profile

Motion Tech is a Stepper Motor Manufacturer provides custom stepper motors and motion solutions with U.S.-based design and support.

Main Products

Advantages

Highly customizable solutions

Small-batch production expertise

Strong technical consultation

11. Advanced Motion Systems

Company Profile

Advanced Motion Systems specializes in high-precision stepper motors for robotics, laboratory automation, and medical equipment.

Main Products

Advantages

Compact and lightweight designs

Excellent low-speed accuracy

Strong support for specialized applications

12. Electromate, Inc.

Company Profile

Electromate focuses on motion and automation solutions, including niche stepper motors for educational, industrial, and laboratory equipment.

Main Products

Advantages

Excellent support for small-scale automation projects

Educational and prototyping-focused solutions

High-quality small motors

13.MicroMo Electronics

Company Profile

MicroMo Electronics specializes in precision micro stepper motors for laboratory automation, instrumentation, and medical devices.

Main Products

Advantages

Ultra-compact, high-precision designs

Ideal for medical and scientific instruments

Strong custom engineering support

14. Motion King

Company Profile

Motion King is a U.S.-based Stepper Motor Manufacturer of small and mid-sized stepper motors for automation and robotics.

Main Products

NEMA hybrid stepper motors

Custom stepper motor assemblies

Stepper motor controllers

Advantages

15. Star Motor Systems

Company Profile

Star Motor Systems offers specialized stepper motor solutions for niche industrial applications in the United States.

Main Products

Custom hybrid stepper motors

Micro and standard stepper motors

Integrated motion assemblies

Advantages

Strong focus on niche and specialized markets

Ability to produce highly customized motors

Quality-driven manufacturing process

Main Types of Stepper Motors

Stepper motors are essential components in modern precision motion control systems, offering accurate positioning, repeatable motion, and reliable torque for a wide range of applications, from CNC machines and 3D printers to medical devices and robotics. Understanding the main types of stepper motors is crucial for selecting the right motor for specific applications. Below is a comprehensive guide to the primary categories, designs, and advantages of stepper motors.

1. Permanent Magnet (PM) Stepper Motors

Overview

Permanent Magnet stepper motors utilize permanent magnets in the rotor to generate a constant magnetic field. These motors are relatively simple in design and cost-effective, making them ideal for low-to-medium performance applications.

Characteristics

Applications

Advantages

Economical and widely available

Robust and reliable for basic positioning tasks

Easy to control with standard drivers

Overview

Hybrid stepper motors combine the features of permanent magnet and variable reluctance motors, delivering high torque, precision, and smooth operation. They are the most commonly used stepper motors in industrial and high-performance applications.

Characteristics

Step angles typically range from 0.9° to 1.8°

High torque across a wide speed range

Smooth motion and minimal vibration

Can be used in open-loop or closed-loop systems

Applications

CNC machines and milling equipment

Robotics and automated machinery

Medical imaging and laboratory equipment

Aerospace and defense systems

Advantages

High precision and repeatability

Suitable for medium-to-high-speed operation

Compatible with microstepping drivers for smoother motion

3. Variable Reluctance (VR) Stepper Motors

Overview

Variable reluctance stepper motors have a soft iron rotor without permanent magnets, relying on the magnetic reluctance principle for operation. These motors are typically lightweight, simple, and capable of high-speed operation, though they generate lower torque compared to hybrid motors.

Characteristics

Step angles typically range from 1.8° to 15°

High-speed capability with low inertia

Low torque output at startup

Applications

Advantages

Overview

Linear stepper motors are essentially rotary stepper motors “unrolled” into a straight line to provide direct linear motion without mechanical conversion. They are ideal for applications requiring precise linear positioning and high repeatability.

Characteristics

Direct linear motion with no lead screw or belt needed

High precision and repeatability

Can achieve very fine microsteps

Applications

Advantages

Eliminates backlash from mechanical transmissions

Smooth, precise, and highly repeatable motion

Compact and efficient design for linear tasks

5. Unipolar Stepper Motors

Overview

Unipolar stepper motors feature a single winding per phase with a center tap, allowing current to flow in one direction only. This simplifies the drive electronics, though torque is typically lower than bipolar motors.

Characteristics

Applications

Advantages

Simple to control and cost-effective

Reduced driver complexity

Ideal for entry-level stepper motor applications

6. Bipolar Stepper Motors

Overview

Bipolar stepper motors use two windings per phase without center taps, requiring current reversal through the windings. They generate higher torque and better efficiency than unipolar motors.

Characteristics

Step angles typically 1.8° or 0.9°

Higher torque output than unipolar designs

Requires more complex driver circuits

Applications

Advantages

Higher torque and efficiency

Precise positioning capabilities

Compatible with microstepping for ultra-smooth motion

Overview

Closed-loop or step-servo motors combine traditional stepper motors with feedback systems, such as encoders, to monitor rotor position and correct errors. They eliminate common stepper issues like missed steps and resonance.

Characteristics

Real-time position feedback

High torque at all speeds

Smooth operation and low vibration

Applications

Precision robotics

Semiconductor equipment

Aerospace motion systems

Advantages

Increased reliability in critical applications

Eliminates step loss and improves accuracy

Compatible with standard stepper drivers

Conclusion

Choosing the right type of stepper motor depends on your application’s torque requirements, speed, accuracy, and control complexity. From economical permanent magnet motors to high-precision hybrid or linear stepper motors, each type offers unique advantages tailored to industrial, medical, or automation applications. Understanding these differences ensures optimized performance, efficiency, and long-term reliability in your motion control systems.

Product Performance FAQs

1.Why does a stepper motor lose steps under load?

Step loss occurs when the motor's torque cannot overcome load torque at certain speeds or accelerations.

2.How does load torque affect stepper motor performance?

High load torque increases the risk of missed steps and reduces positioning accuracy.

3.Can increasing motor current prevent missed steps?

Raising current can increase torque, but excessive current can overheat the motor.

4.Does acceleration setting impact step loss?

Too high acceleration can cause the motor to stall or skip steps under load.

5.What is the role of the torque-speed curve in step loss?

It shows the motor's torque capability at various speeds, helping select safe operating points.

6.Is microstepping effective in reducing step loss?

Microstepping improves smoothness and reduces vibration but does not increase maximum torque.

7.When should I use a closed-loop stepper motor?

Closed-loop motors are ideal when load changes are unpredictable and step accuracy is critical.

8.How does encoder feedback help prevent step loss?

Encoders provide real-time position correction to eliminate missed steps.

9.Can a larger motor frame size reduce step loss?

Larger frames provide higher torque, lowering the risk of losing steps under heavy load.

10.Are integrated stepper servo motors better for high-load applications?

Yes, they combine high torque, feedback, and compact design for reliable performance.

Factory Customization & OEM FAQs

11.Can stepper motors be customized for higher torque?

Yes, torque can be increased via custom windings, magnet optimization, or larger frames.

12.Is it possible to customize motor current ratings?

Factories can adjust winding and electrical parameters for specific current and voltage requirements.

13.Can stepper motors be optimized for continuous heavy-load operation?

Yes, insulation, thermal design, and cooling methods can be customized for long-duty cycles.

14.Do you offer integrated motor and driver solutions?

Integrated solutions reduce wiring complexity and improve load handling reliability.

15.Can encoder type and resolution be customized?

Yes, encoders can be selected based on accuracy, speed, and application needs.

16.Are gearbox integrations available for high-load applications?

Yes, planetary or worm gearboxes can be integrated to increase output torque.

17.Can motors be optimized for low-speed, high-torque applications?

Yes, pole design and winding customization enable precise low-speed torque.

18.Do you provide OEM/ODM stepper motor services?

Full OEM/ODM services are available, including mechanical, electrical, and performance customization.

19.Can vibration and noise be reduced through customization?

Rotor balancing, damping, and driver tuning help minimize vibration and acoustic noise.

20.How does factory testing prevent step loss issues?

Dynamic load tests, thermal tests, and motion simulation ensure reliable operation before shipment.

Conclusion

The U.S. stepper motor manufacturing landscape offers unmatched depth in engineering quality, product diversity, customization capability, and long-term reliability. Whether sourcing hybrid stepper motors, closed-loop systems, linear stepper actuators, or integrated motion solutions, these 15 manufacturers represent the most trusted and capable suppliers in the United States.

Choosing the right stepper motor manufacturer ensures precision, efficiency, durability, and scalable production—critical factors in today's highly competitive industrial environment.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català