Introduction: Motion Control at the Core of Medical Innovation

In modern medical equipment, motion accuracy, operational stability, and patient safety are non-negotiable. From infusion pumps and diagnostic imaging systems to ventilators and automated laboratory analyzers, stepper motors play a mission-critical role in converting digital commands into precise mechanical motion. We engineer stepper motors for medical equipment with a singular focus: ultra-low noise, minimal heat generation, and uncompromising precision, ensuring compliance with stringent medical standards while supporting long-term reliability.

Drawing on extensive manufacturing expertise and customization capabilities, we design medical-grade stepper motor solutions that meet the evolving demands of healthcare technology.

Why Stepper Motors Are Essential in Medical Equipment

Stepper motors are a foundational technology in modern medical equipment because they deliver precise, predictable, and repeatable motion under strict safety and reliability requirements. In healthcare environments, even minor positioning errors, excessive noise, or thermal instability can compromise diagnostic accuracy, treatment outcomes, or patient comfort. Stepper motors address these challenges more effectively than many alternative motion solutions.

Precise Positioning Without Complex Feedback Systems

Medical devices often require accurate positioning down to microns, such as in infusion pumps, imaging tables, and laboratory automation systems. Stepper motors move in fixed angular increments, allowing exact control of position and speed directly from digital signals. This open-loop precision reduces system complexity by eliminating the need for encoders in many applications, improving overall reliability and reducing points of failure.

Exceptional Repeatability for Critical Medical Tasks

Consistency is vital in medical equipment where the same movement must be repeated thousands or even millions of times. Stepper motors provide high repeatability, ensuring that each motion cycle is identical to the last. This is essential for applications like drug delivery systems, sample dispensing, and robotic-assisted diagnostics, where dosing accuracy and positional consistency directly affect patient safety.

Low-Speed Stability and Holding Torque

Unlike many motor types, stepper motors deliver high holding torque at zero or low speed. This allows medical devices to maintain precise positions without continuous motion or mechanical braking. In imaging equipment or surgical positioning systems, this stability ensures that components remain exactly where they are placed, even during extended procedures.

Quiet and Smooth Operation in Clinical Environments

Noise control is a critical requirement in hospitals and laboratories. Through microstepping control and optimized motor design, stepper motors can operate with minimal vibration and acoustic output. This enables their use in noise-sensitive environments such as intensive care units, diagnostic imaging rooms, and patient wards, where comfort and concentration are essential.

Thermal Stability for Patient and Device Safety

Medical devices are often compact and enclosed, making heat management a major concern. Stepper motors can be engineered for low temperature rise and efficient current control, ensuring stable performance without excessive heat generation. This protects sensitive electronic components and supports compliance with medical safety standards.

Scalable Customization for Diverse Medical Applications

From portable diagnostic devices to large-scale imaging systems, medical equipment varies widely in size and function. Stepper motors offer extensive customization options, including different frame sizes, step angles, torque ratings, and integrated lead screws. This flexibility allows manufacturers to tailor motion systems precisely to each medical application.

Many medical devices operate continuously or for extended periods. Stepper motors are designed for long service life and stable performance under continuous operation, making them suitable for ventilators, laboratory analyzers, and automated monitoring systems that must run without interruption.

Cost-Effective Precision for Medical OEMs

By delivering high accuracy without the added cost and complexity of closed-loop systems, stepper motors provide excellent cost-to-performance value. This allows medical equipment manufacturers to maintain high quality standards while optimizing overall system cost and reliability.

In summary, stepper motors are essential in medical equipment because they combine precision, repeatability, stability, low noise, and thermal control in a robust and adaptable motion solution. These characteristics make them a trusted choice for manufacturers developing reliable, safe, and high-performance medical devices.

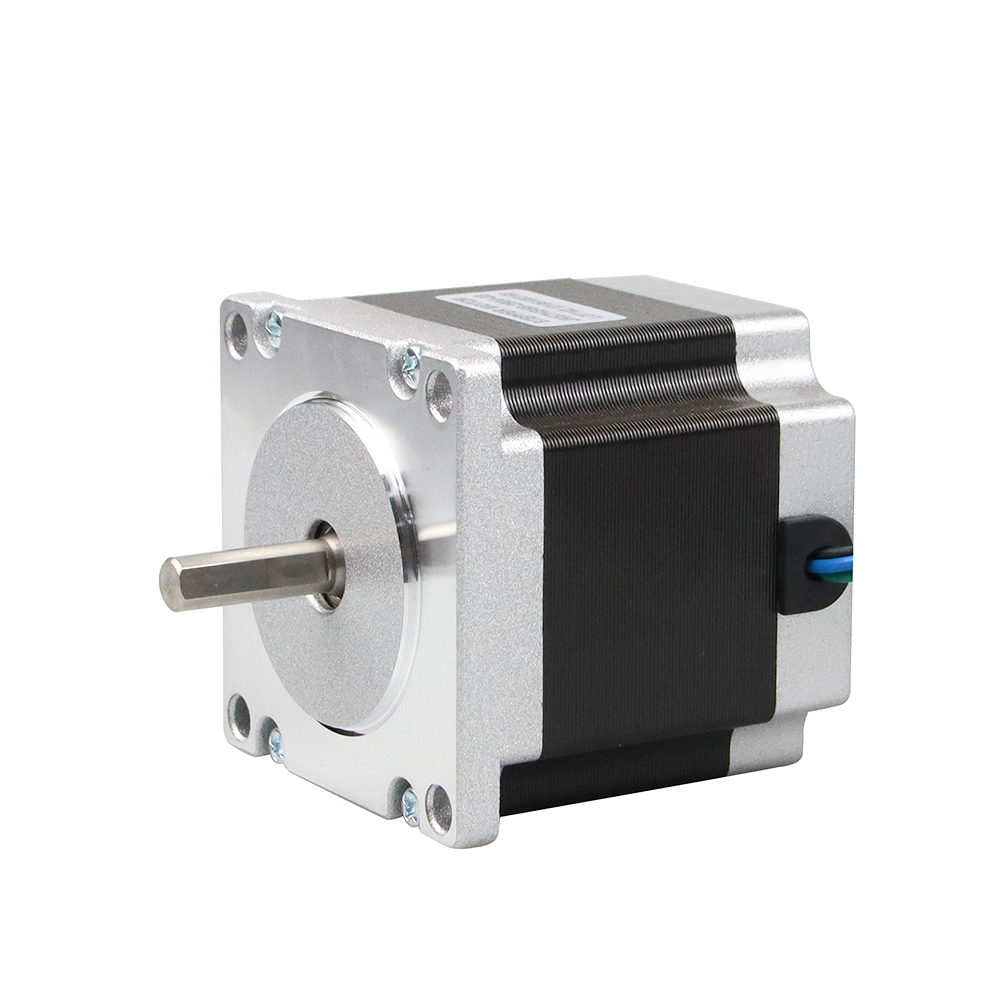

BESFOC Medical Stepper Motor Product Range

BESFOC offers a comprehensive stepper motor portfolio designed to meet the strict requirements of medical environments.

NEMA 8 / 11 / 14 / 17 / 23 / 24 / 34

High torque and smooth operation

Optimized for continuous and intermittent duty cycles

Excellent thermal stability

Recommended for: imaging systems, pumps, automated diagnostic equipment

Recommended for: syringe pumps, sample handling, micro‑fluidic systems

Recommended for: medical beds, rehabilitation equipment, positioning mechanisms

Recommended for: compact medical devices and OEM system integration

Noise Control: A Critical Factor in Clinical Environments

Why Low Noise Matters in Medical Applications

Excessive noise can disrupt patient comfort, interfere with diagnostics, and reduce clinician confidence. In environments such as ICU wards, imaging rooms, and operating theaters, silent or near-silent operation is a fundamental requirement.

Engineering Strategies for Ultra-Low Noise Stepper Motors

We achieve exceptionally low acoustic profiles through multiple design optimizations:

High-precision rotor balancing to reduce vibration

Advanced microstepping drive compatibility for smoother motion transitions

Optimized stator lamination geometry to minimize magnetic resonance

High-quality bearings and dampening materials

These measures ensure stepper motors operate smoothly, even at low speeds where noise is traditionally most noticeable.

Heat Management: Protecting Performance and Patient Safety

The Impact of Heat in Medical Devices

Heat generation in compact medical devices can compromise electronic stability, material integrity, and patient safety. Excessive temperature rise may also affect calibration accuracy in sensitive instruments.

Low-Temperature Rise Motor Design

We design medical stepper motors with thermal efficiency as a core principle, incorporating:

Low-resistance copper windings to reduce I⊃2;R losses

Optimized current ratings matched to real application loads

Improved heat dissipation paths via motor housing and mounting interfaces

These strategies ensure stable temperature control, even in enclosed or portable medical devices.

Precision & Accuracy: Meeting Micron-Level Demands

High Resolution for Medical Motion Control

Medical equipment often requires micron-level positioning accuracy. Our stepper motors support:

Fine step angles (1.8°, 0.9°, and customized options)

High microstepping compatibility for ultra-smooth linear motion

Low detent torque designs to eliminate mechanical ripple

This level of precision is essential in applications such as CT scanner positioning systems, robotic surgical tools, and diagnostic sample handling.

Repeatability Over Long Service Life

Precision is not only about accuracy—it is about repeatability over millions of cycles. Through rigorous quality control and endurance testing, our motors deliver consistent positioning accuracy throughout their lifespan.

Medical-Grade Reliability and Compliance

Materials and Manufacturing Standards

Medical environments demand components that withstand sterilization processes, humidity, and continuous use. We manufacture stepper motors using:

High-grade electrical steel laminations

Medical-compatible insulation materials

Strict process control aligned with ISO-based quality systems

These practices ensure long-term reliability and regulatory readiness for medical device integration.

Customization Capabilities for Medical Equipment Manufacturers

Tailored Motor Design for Specific Medical Applications

No two medical devices are identical. We provide full customization capabilities, including:

Custom shaft lengths and geometries

Integrated lead screws for linear motion systems

Specialized connectors and medical-grade cabling

Customized voltage, current, and torque profiles

This allows seamless integration into OEM medical equipment designs without compromise.

Compact and Lightweight Solutions

Portable and wearable medical devices demand compact motor designs. We offer high torque density stepper motors that deliver exceptional performance within limited installation space.

Typical Medical Applications for Stepper Motors

Infusion and Syringe Pumps

Precise flow rate control

Silent operation for patient comfort

Long-term reliability for continuous dosing

Diagnostic and Imaging Equipment

Stable positioning for sensors and optics

Minimal vibration to preserve image accuracy

Low electromagnetic interference

Laboratory Automation Systems

High repeatability for sample handling

Smooth motion for robotic arms

Reduced maintenance requirements

Respiratory and Ventilation Devices

Stepper Motors vs. Other Motion Technologies in Medical Devices

Selecting the right motion technology is a critical decision in medical device design, directly affecting precision, safety, reliability, noise levels, and system cost. Stepper motors are widely used in medical equipment, but they are not the only option. Understanding how stepper motors compare with other motion technologies helps medical equipment manufacturers choose the most suitable solution for each application.

Stepper Motors vs. DC Motors

Control and Accuracy

DC motors are primarily speed-controlled devices. To achieve precise positioning, they require encoders, sensors, and closed-loop controllers, increasing system complexity. Stepper motors, by contrast, provide inherent positional control through discrete step movements, making them ideal for medical applications that demand accurate, repeatable positioning without complex feedback systems.

Reliability and Maintenance

Traditional brushed DC motors rely on mechanical brushes that wear over time, generating particles and electrical noise—undesirable in clean medical environments. Stepper motors are brushless by design, offering longer service life and reduced maintenance requirements.

Use Case Comparison

DC motors: Suitable for simple continuous rotation tasks

Stepper motors: Preferred for infusion pumps, dosing systems, and precision positioning applications

Stepper Motors vs. Brushless DC (BLDC) Motors

Precision at Low Speeds

BLDC motors excel at high-speed, efficient operation, but precise low-speed positioning requires advanced closed-loop control. Stepper motors naturally perform well at low speeds with high holding torque, making them ideal for controlled medical motion such as syringe drives and imaging alignment systems.

System Complexity

BLDC systems depend on electronic commutation and feedback mechanisms. Stepper motor systems are simpler to integrate, reducing design time and minimizing potential failure points in medical equipment.

Noise and Vibration

With proper microstepping, stepper motors can achieve very low vibration and acoustic noise, meeting clinical environment requirements comparable to BLDC solutions in many applications.

Stepper Motors vs. Servo Motors

Accuracy and Repeatability

Servo motors provide high dynamic accuracy through continuous feedback, but stepper motors offer excellent repeatability and sufficient precision for most medical applications, particularly where movement patterns are predictable and loads are well defined.

Cost and System Design

Servo systems involve higher upfront costs due to encoders, tuning requirements, and sophisticated controllers. Stepper motors provide cost-effective precision with simpler control architecture, making them attractive for scalable medical device production.

Stability at Standstill

Stepper motors deliver full holding torque at zero speed, allowing medical devices to maintain position without constant motion. Servo motors typically require continuous feedback and control loops to hold position, increasing energy consumption and system complexity.

Stepper Motors vs. Piezoelectric Actuators

Travel Range and Load Capacity

Piezo actuators offer nanometer-level resolution but limited travel and load capacity. Stepper motors provide longer travel distances and higher torque, making them suitable for broader medical applications.

System Integration

Stepper motors integrate easily with mechanical components such as lead screws and gearboxes, supporting linear motion systems commonly used in medical automation.

Application Scope

Stepper Motors vs. Linear Motors

Precision vs. Cost

Linear motors deliver direct-drive motion with high speed and accuracy but come with higher cost, increased heat generation, and complex control requirements. Stepper motors paired with lead screws offer a balanced solution for medical devices requiring accuracy, reliability, and affordability.

Compact Design

Stepper motor-based linear actuators are more compact and easier to enclose, an important advantage in portable and space-constrained medical equipment.

Why Stepper Motors Remain the Preferred Choice in Medical Devices

Stepper motors strike an optimal balance between precision, reliability, noise control, thermal stability, and cost efficiency. Their ability to deliver accurate, repeatable motion without complex feedback systems makes them especially well suited for medical environments where system stability and safety are paramount.

For applications such as infusion systems, diagnostic equipment, laboratory automation, and patient care devices, stepper motors continue to be a trusted and proven motion technology. By offering dependable performance and flexible customization, they support the development of medical devices that meet the highest standards of quality and reliability.

One of BESFOC's core strengths is factory‑level customization. We work closely with medical equipment manufacturers to deliver tailor‑made motion solutions:

Customization Options Include:

Special shaft designs

Custom winding and voltage ratings

Encoders for closed‑loop control

Special lubrication for clean environments

Low‑noise and low‑vibration optimization

Cable, connector, and harness customization

Whether you are developing a new medical device or upgrading an existing system, BESFOC provides engineering‑driven customization support.

Future Trends in Medical Stepper Motor Technology

As medical devices evolve toward smaller, smarter, and more connected systems, stepper motors are advancing in parallel:

Lower noise through advanced drive algorithms

Higher efficiency materials to further reduce heat

Integration with smart controllers and monitoring systems

We continue to invest in innovation to ensure our stepper motors meet future-ready medical equipment requirements.

Conclusion: Engineering Motion You Can Trust in Medical Equipment

Stepper motors are the backbone of reliable motion control in medical equipment. By prioritizing low noise, efficient heat management, and extreme precision, we deliver solutions that meet the highest expectations of medical device manufacturers worldwide. Through advanced engineering, strict quality control, and deep customization capabilities, we support the development of safer, quieter, and more accurate medical technologies.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català