In the world of specialty coffee, precision is not a luxury; it is the absolute foundation of quality. From the exacting temperature of water to the consistent fineness of a grind, every variable must be mastered to achieve the perfect extraction. While the spotlight often shines on burr grinders, sophisticated boilers, and elegant interfaces, there exists a critical, behind-the-scenes component that orchestrates much of this mechanical ballet: the NEMA 23 stepper motor. We dedicate this comprehensive analysis to exploring why NEMA 23 stepper motors have become the unequivocal drive system of choice for high-end, automated, and super-automatic coffee machines, ensuring unparalleled reliability and repeatability in every cup.

Understanding the Stepper Motor: A Primer on Precision Motion Control

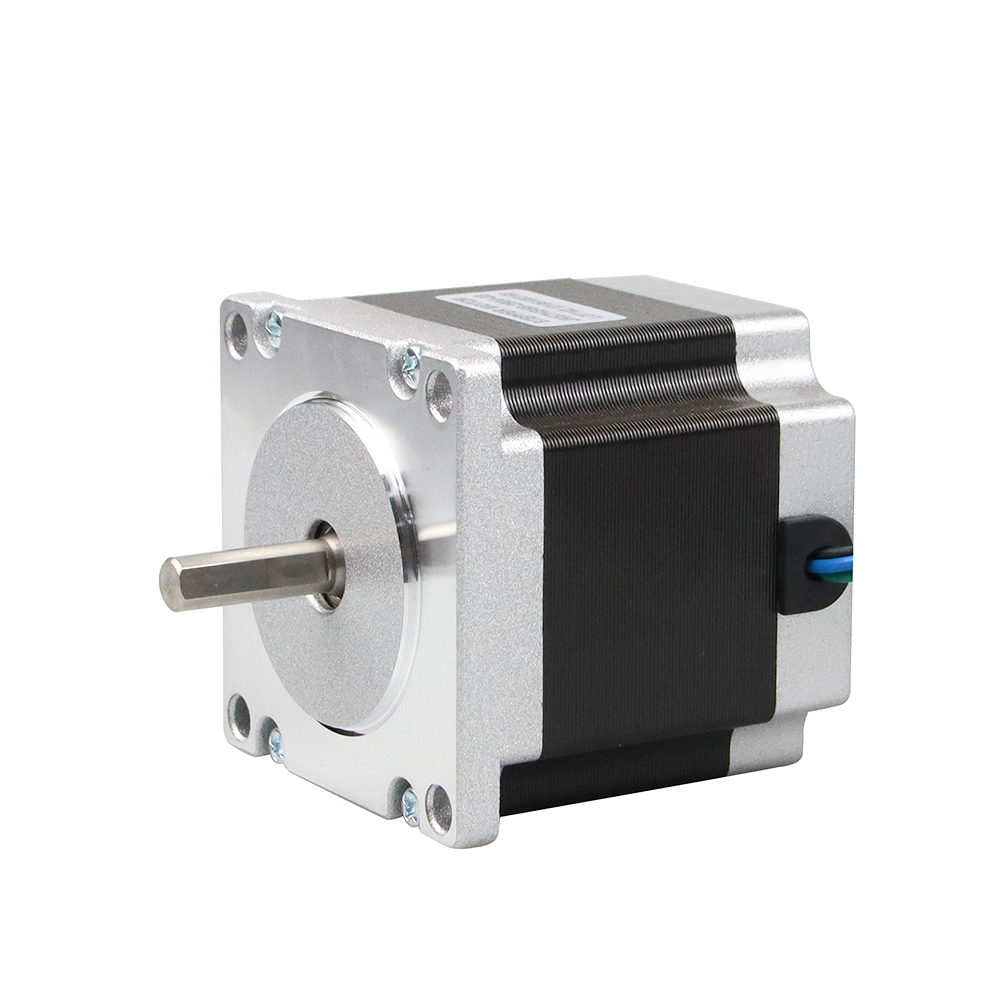

Before delving into the specifics of the NEMA 23 frame standard, we must establish what sets a stepper motor apart. Unlike conventional AC or DC motors that spin freely when powered, a stepper motor moves in discrete, precise angular increments, or "steps." This is achieved through an ingenious internal arrangement of magnetic coils and a toothed rotor. By electronically sequencing the activation of these coils, the motor's shaft rotates one precise step at a time. This digital nature of motion allows for direct and open-loop control of position, speed, and torque without the need for feedback encoders in many applications. For a coffee machine, this translates to the ability to move a grinder a specific number of steps for a dose, rotate a brewer unit with exact alignment, or position a frothing wand with millimeter accuracy—all under direct digital command from the machine's main controller.

Types of Nema 23 Stepper Motor

The NEMA 23 stepper motor is not a single product but a versatile family of motion control components, each engineered with distinct characteristics to solve specific challenges. Understanding the nuances between these types is critical for selecting the optimal motor for any precision application, from advanced automation to intricate CNC systems. We provide a detailed breakdown of the primary NEMA 23 stepper motor variants, their key features, and ideal use cases.

The most common and versatile type, hybrid stepper motors combine principles from both permanent magnet and variable reluctance stepper designs.

Key Features:

High Torque Density:

Offers an excellent balance of torque (typically 120-300 N-cm) relative to its frame size.

Standard Step Angles:

Commonly available in 1.8° (200 steps/revolution) and 0.9° (400 steps/revolution) resolutions.

Wide Speed Range:

Capable of operating effectively at low, mid, and high speeds with proper driver configuration.

Cost-Effectiveness:

Provides the most economical solution for most open-loop positioning tasks.

Primary Applications:

3D Printers and CNC Routers

Laboratory Automation and Sample Handling

Packaging Machinery

Semiconductor Fabrication Equipment

Precision Coffee Machine Grinders and Actuators

This type incorporates the stepper driver and often a controller directly onto or within the motor housing, creating a compact, all-in-one motion system.

Key Features:

Simplified Wiring:

Requires only a DC power supply and command signals (e.g., Step/Direction or via network), drastically reducing system complexity.

Compact Form Factor:

Eliminates the need for a separate driver enclosure.

Optimized Performance:

The driver is often matched to the motor's electrical characteristics, ensuring reliable operation.

Primary Applications:

Space-constrained robotic joints

Mobile platforms and AGVs

Conveyor system modules

Educational and prototyping kits

A hybrid stepper motor enhanced with a rotary encoder to provide real-time positional feedback to a specialized control system, guaranteeing accuracy.

Key Features:

Position Verification & Correction:

The controller monitors for and compensates for missed steps, ensuring the motor reaches its target position.

Increased Efficiency:

Can often run at higher speeds and with reduced current when unloaded due to smart control algorithms.

Error Reporting:

Provides diagnostic data for predictive maintenance.

Primary Applications:

High-reliability pick-and-place systems

Critical medical and diagnostic equipment

Automated optical inspection (AOI) stages

Applications where failure due to a missed step is unacceptable.

Specialized NEMA 23 Motor Configurations

For unique mechanical and environmental requirements, specialized configurations are essential.

Features an integrated planetary or spur gearbox to multiply output torque and reduce output speed.

Applications:

Direct-drive rotary stages, winches, heavy-duty actuators, and applications requiring high torque at low RPM.

Designed with a hollow bore through the center of the rotor, allowing for the passage of cables, lasers, shafts, or other components.

Built with sealed bearings, special shaft seals, and often potted or encapsulated windings to resist moisture, dust, and corrosion.

Applications:

Food and beverage processing, outdoor equipment, marine automation, and clean-in-place (CIP) systems.

Selection Summary Table

| Motor Type | Core Advantage | Ideal Use Case Scenario |

| Hybrid | Best overall performance & value | General automation, 3D printing, CNC |

| Integrated | System simplicity & compact design | Robotics, modular systems, prototyping |

| Closed Loop | Guaranteed accuracy & reliability | Mission-critical medical, aerospace, or inspection systems |

| Gear | High output torque at low speed | Direct-drive rotary tables, heavy lifting |

| Hollow Shaft | Central pass-through for components | Optical rotary stages, winding, cable management |

| Waterproof | Resistance to harsh environments | Washdown areas, outdoor tech, food processing |

Selecting the correct NEMA 23 stepper motor type requires a rigorous analysis of torque-speed demands, environmental conditions, precision requirements, and system architecture. This granular approach ensures optimal performance, longevity, and value in any engineered system.

Decoding the NEMA 23 Standard: The Ideal Balance of Power and Size

The National Electrical Manufacturers Association (NEMA) defines standard frame sizes for motors, ensuring dimensional interchangeability. The number "23" refers to a faceplate dimension of approximately 2.3 inches square. This compact yet robust form factor is pivotal for coffee machine design. NEMA 23 stepper motors typically offer a compelling synergy of characteristics:

High Torque in a Compact Package:

They generate substantial holding and dynamic torque, often ranging from 120 to 300 oz-in (Newton-centimeters vary by model), sufficient to drive hardened steel burrs through dense coffee beans or actuate stout mechanical assemblies.

Physical Manageability:

Their size allows engineers to integrate them into the densely packed interior of a modern coffee machine without overwhelming the chassis. Multiple NEMA 23 motors can be deployed for different functions—grinding, dosing, tamping, brewing unit actuation—within a single machine.

Standardized Mounting:

The standardized flange and shaft dimensions simplify mechanical design, procurement, and serviceability, a critical factor for appliance manufacturers.

Critical Applications of NEMA 23 Stepper Motors in Modern Coffee Machines

The operational excellence of a modern super-automatic coffee machine hinges on a symphony of precise mechanical movements, nearly all orchestrated by NEMA 23 stepper motors. Their digital control, high torque, and reliability make them indispensable for key subsystems.

1. Grind-by-Weight Dosing Systems:

Modern high-end machines have moved beyond simple timed grinding. A NEMA 23 stepper motor drives the grinder burrs while an integrated load cell provides real-time weight feedback. The motor operates under a sophisticated closed-loop algorithm, dynamically adjusting its step pulse sequence to decelerate and stop with pinpoint accuracy the moment the target coffee dose weight (e.g., 18.5g) is reached, ensuring chemical consistency.

2. Brew Unit Positioning and Locking:

The entire brew group—a complex assembly that holds the puck, receives water, and seals against the brew head—must translate and rotate between multiple stations. A NEMA 23 motor provides the high-torque, indexed motion to move it from the grinding chute to the brew position. Critically, it applies the final force to lock the unit against the seal under high pressure (9+ bar), a task requiring substantial holding torque to prevent leaks during extraction.

3. Programmable Tamping Force Application:

Passive tamping is insufficient for premium results. A dedicated NEMA 23 stepper motor drives a tamper piston through a programmable force profile. By controlling the motor's current (which correlates to torque) and its final positional depth, the system applies a consistent, optimal pressure (e.g., 30 lbs) to the coffee puck, eliminating a major variable in manual espresso preparation.

4. Automated Milk Texturing and Dispensing:

For milk-based drinks, precision extends to dairy. A NEMA 23 stepper motor precisely actuates a proportional steam valve or a pump in a milk circuit, controlling the exact ratio of air, steam, and liquid milk injected. This creates repeatable microfoam texture. In machines with automatic milk cleaning, another NEMA 23 drives the rinsing mechanism.

| Subsystem | Motor's Critical Function | Required Motor Characteristic |

| Grind-by-Weight | Precise burr control for dose accuracy | High low-speed torque, rapid start/stop response |

| Brew Unit | High-force linear/rotary actuation & sealing | Very high holding torque, positional accuracy |

| Programmable Tamper | Controlled force application | Smooth microstepping, precise current control |

| Milk System | Metered steam/liquid delivery | Consistent speed control, durability against moisture |

Advanced Considerations: Drivers, Heat, and Electrical Noise

Integrating a NEMA 23 stepper motor successfully requires careful attention to the supporting electronics and thermal management, as poor implementation directly impacts performance, reliability, and machine noise.

Stepper Driver Selection: The driver is the brain of the motion system. For coffee machines, key driver features are non-negotiable:

Microstepping Capability: A 1/16 or 1/32 microstepping driver is essential. It divides each full step into smaller increments, resulting in dramatically smoother motion, reduced audible noise (critical for consumer appliances), and higher effective resolution for precise dosing and positioning.

Current Regulation: Chopper-type constant current drivers (e.g., based on DRV8825 or TMC2209 chips) are standard. They maintain torque and improve efficiency by delivering the optimal current to the motor coils regardless of speed.

Voltage Selection: Operating the motor from a power supply with a voltage significantly higher than its rated voltage (e.g., 24-48V for a 3V motor) improves the torque available at higher speeds, allowing for faster cycle times without stalling.

Thermal Management: NEMA 23 stepper motors can generate significant heat during continuous or high-torque operation. In the confined, often warm interior of a coffee machine, this must be managed.

Duty Cycle Analysis:

Grinding and brewing are intermittent tasks. Motors should be sized to operate within their temperature limits for the maximum anticipated duty cycle.

Heat Sinking and Ventilation:

Passive aluminum heat sinks mounted to the motor frame are highly effective. Strategic placement away from steam paths and ensuring airflow via system fans are critical design practices.

Current Tuning:

Drivers should be configured to supply the minimum current necessary for reliable operation, reducing idle heat generation.

Mitigating Electrical Noise: Stepper motors are inductive loads and can generate back-EMF and electrical noise, which can interfere with sensitive analog sensors (like load cells) and digital controllers.

Shielding and Twisting:

Motor power cables should be twisted pairs and kept separate from low-voltage signal cables.

Ferrite Cores:

Snap-on ferrite beads on motor leads suppress high-frequency noise.

Proper Grounding:

A single-point star grounding scheme for the driver, power supply, and controller chassis prevents ground loops and noise propagation.

Technical Advantages of NEMA 23 Steppers in the Demanding Coffee Environment

Why has this specific motor type dominated? The operational environment of a coffee machine is uniquely challenging: it is subject to moisture, heat, vibration, and continuous cyclic loading. The NEMA 23 stepper motor is uniquely qualified.

High Torque at Low Speeds:

Grinding and tamping require high force at relatively low rotational speeds. NEMA 23 steppers excel here, providing maximum torque from zero RPM, unlike many other motor types that require gearing to achieve similar low-speed performance.

Open-Loop Reliability:

In many configurations, they operate without positional feedback. This simplifies the control electronics and increases system reliability—fewer components can fail. The motor simply executes the commanded steps, and the controller assumes compliance, which is a safe assumption given the motor's design.

Durability and Long Service Life:

With few wear items (primarily bearings) and a robust construction, a properly specified NEMA 23 stepper motor can withstand millions of cycles. This is mandatory for a commercial or high-use domestic coffee machine that may perform dozens of operations daily for years.

Digital Compatibility and Control:

They interface seamlessly with modern microcontrollers and dedicated stepper driver chips. This allows for advanced motion profiles, including acceleration and deceleration ramps (S-curves), which reduce mechanical stress and noise during operation—a key consideration for a consumer appliance.

Selecting the Optimal NEMA 23 Stepper Motor for Coffee Machine Design

Not all NEMA 23 stepper motors are identical. Engineering the perfect drive solution requires careful specification across several parameters:

Torque Requirement Analysis:

We calculate the peak dynamic torque required for the most demanding action (e.g., initiating grinding of a hard bean) and the holding torque needed for static positions (e.g., keeping the brew group locked). A significant safety margin is always included.

Step Angle Resolution:

Standard hybrid NEMA 23 motors offer 1.8° per step (200 steps/revolution). With microstepping drivers, this can be divided into 256 or more microsteps per full step, achieving extraordinarily smooth and precise motion, which is vital for quiet, vibration-free operation.

Current and Voltage Ratings:

The motor's current rating (e.g., 3A) and inductance dictate the choice of driver and power supply. Higher current generally correlates with higher torque. Voltage selection affects high-speed performance.

Environmental Sealing:

For components near water or steam, such as the brew unit, motors with sealed bearings or optional IP ratings are specified to prevent corrosion and failure.

Thermal Management:

Continuous operation can generate heat. We evaluate duty cycles and, if necessary, incorporate heat sinks or forced air cooling to ensure the motor remains within its operational temperature range, preserving its torque output and longevity.

The Future of Motion Control in Coffee Technology: Beyond the Basics

The evolution continues. The next generation of coffee machines is beginning to leverage even more sophisticated implementations of stepper technology. Closed-loop stepper systems, which incorporate an encoder for positional feedback, are emerging. This hybrid approach guarantees step integrity—if the motor misses a step due to an unexpected load, the controller detects and corrects it. This is the ultimate fail-safe for precision. Furthermore, the integration of can bus communication and smarter drivers allows for distributed control networks within the machine, where each NEMA 23 motor is an intelligent node, reporting status and health data for predictive maintenance and diagnostics.

Conclusion: The Unseen Engine of Excellence

From the moment you select your beverage on the display, a silent, digital orchestra of NEMA 23 stepper motors springs into action. They are the unsung mechanical protagonists, translating digital recipes into flawless physical processes. Their robust power, pinpoint accuracy, and digital controllability make them the only viable choice for manufacturers committed to delivering barista-grade consistency in an automated coffee machine. They ensure that the twentieth coffee of the day is as meticulously crafted as the first, turning complex variables of coffee science into a repeatable, reliable, and perfect consumer experience. When you next enjoy an impeccably balanced, automated espresso, consider the precise angular increments of the NEMA 23 stepper motor—the engineering cornerstone that made it possible.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català