Linear stepper motors have become essential components in precision automation, laboratory equipment, medical devices, semiconductor systems, 3D printers, and countless other applications requiring precise linear movement. Among the most widely used types are non-captive and captive linear stepper motors, each delivering unique mechanical advantages and performance benefits. Although both convert rotary motion into linear displacement using an internal lead screw and nut mechanism, the way motion is produced — and how the load interacts with the motor — differs dramatically.

This detailed guide examines the core differences, mechanical structure, performance characteristics, installation considerations, and best-fit applications of captive and non-captive linear stepper motors. By understanding these distinctions, engineers and system designers can confidently select the ideal motor type for accuracy, stability, space constraints, and load requirements.

Understanding the Fundamentals of Linear Stepper Motor Design

Linear stepper motors are specialized motion devices engineered to convert the rotary movement of a traditional stepper motor directly into precise linear motion. Instead of using external mechanisms like belts, gears, or lead screw assemblies, these motors integrate the linear conversion mechanism inside the motor structure, providing compactness, accuracy, and efficiency.

At the heart of every linear stepper motor is a stepper motor rotor that contains a precisely machined lead screw nut. As the rotor turns in discrete steps, it drives a matching lead screw or shaft, producing incremental linear displacement.

Core Components of a Linear Stepper Motor

A linear stepper motor typically includes:

1. Stepper Motor Stator and Rotor

These are identical to the electromagnetic components of a rotary stepper motor. The stator generates magnetic fields, and the rotor aligns with these fields in precise increments.

2. Internal Lead Screw or Nut

A precision-threaded nut is integrated into the rotor. The lead screw or shaft engages with this nut, translating rotational motion into linear movement based on thread pitch and lead.

3. Lead Screw or Output Shaft

Depending on motor type (captive, non-captive, or external), the screw or shaft either:

Extends through the motor,

Moves in a limited stroke inside the body, or

Remains external while the rotor rotates only the nut.

4. Anti-Rotation Mechanism

To ensure the linear element does not rotate, the system may use:

This ensures pure linear motion with no twisting.

How Linear Motion Is Produced

Linear stepper motors use the same stepping principles as rotary stepper motors:

The motor receives electrical pulses.

Each pulse energizes specific stator windings.

The rotor aligns with the magnetic field, turning a precise angle.

The integrated nut drives the lead screw or shaft forward or backward.

Because each motor step corresponds to a fixed degree of rotation, and the screw’s lead defines how far the load travels per revolution, the system provides exceptional:

Positioning accuracy

Repeatability

Fine motion resolution

Linear travel per step is calculated as:

Linear Step Distance = Screw Lead ÷ Steps per Revolution

Advantages of Linear Stepper Motor Design

1. Direct Linear Motion

No belts, couplers, or external transmissions are needed. This reduces complexity and backlash.

2. Highly Precise Position Control

With microstepping, extremely fine linear increments are achievable, making them suitable for scientific, medical, and robotic applications.

3. Compact, Integrated Mechanism

Linear stepper motors combine rotary and linear functions in a single package, saving space and simplifying machine design.

4. Excellent Repeatability

Because of their discrete step structure and internal screw mechanism, they maintain consistent performance even in demanding applications.

Types of Linear Stepper Motors

The three main categories differ primarily in mechanical structure and motion output:

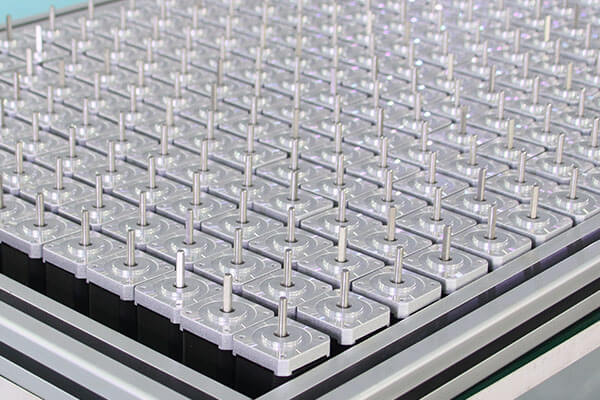

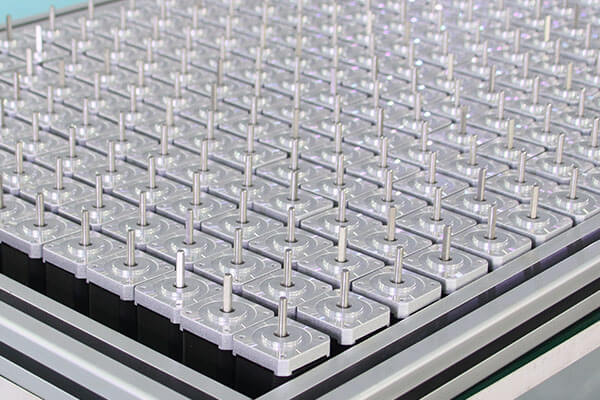

1. Non-captive linear stepper motors

Lead screw passes through the motor

Requires external guidance

Suitable for long travel distances

2. Captive Linear Stepper Motors

3. External Linear Stepper Motors

Applications That Rely on Linear Stepper Motor Design

Due to precision, compactness, and reliability, these motors are used in:

Laboratory automation

Medical syringes, pumps, and dosing systems

Optical alignment and imaging equipment

Semiconductor handling

Robotics and automation stages

3D printing and micro-positioning systems

Wherever precise and controlled linear displacement is essential, linear stepper motors offer a robust and elegant solution.

Key Differences Between Non-Captive and Captive Linear Stepper Motors

1. Mechanical Structure and Motion Behavior

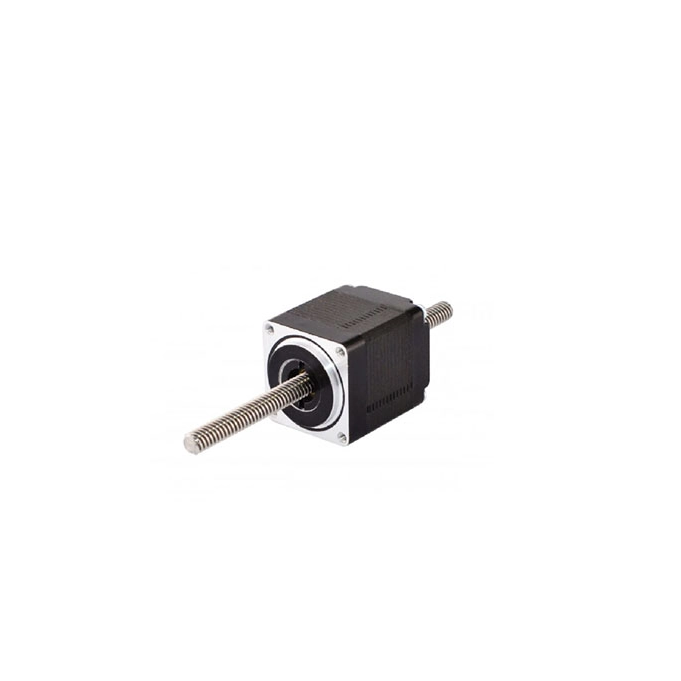

A non-captive motor contains a threaded nut in the rotor, while the lead screw passes completely through the motor body. As the rotor turns, the nut engages the screw, causing the screw to translate linearly — but the screw must be externally supported and guided.

Key characteristics:

Lead screw moves in and out through the motor body

Motor requires external guidance or a linear bearing

Allows for very long stroke lengths, limited only by screw length

Ideal when the screw itself must serve as the extension element

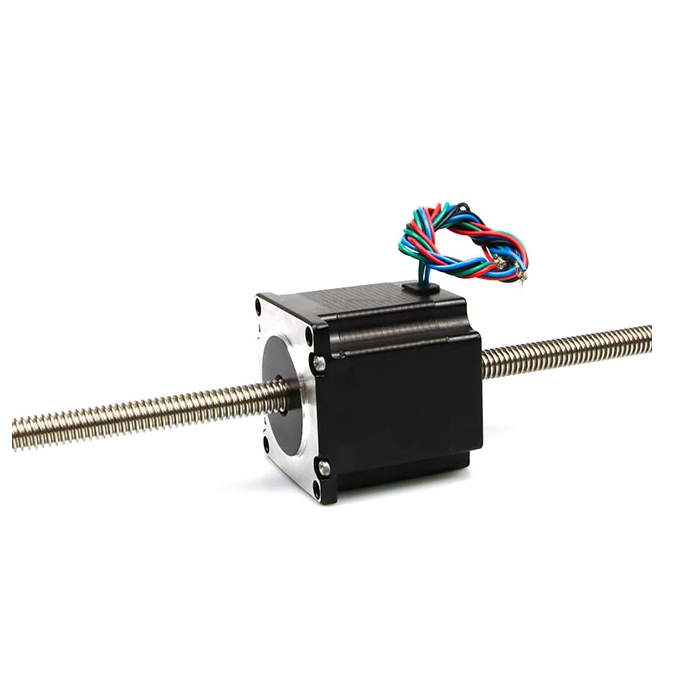

Captive Linear Stepper Motors

A captive linear stepper motor encloses the screw inside the motor housing and uses an integrated anti-rotation mechanism with a captive shaft. Instead of a long screw extending through the body, the motor outputs linear motion through a short, non-rotating shaft.

Key characteristics:

Shaft moves linearly without rotating

No external anti-rotation mechanism needed

Stroke lengths typically limited by internal guide structure

Compact, self-contained, and easy to integrate

2. Anti-Rotation Mechanism

Non-Captive Motor: External

Because the screw rotates relative to the nut inside the motor, the screw itself must be constrained. Without an anti-rotation solution, the screw would spin freely without translating.

Typical external anti-rotation components include:

Guide rails

Linear bearings

Carriages or sliders

Coupled platforms

The responsibility for alignment and motion stability lies with the system designer.

Captive Motor: Internal

The captive design incorporates an internal anti-rotation guide that keeps the output shaft from turning. This means the motor generates pure linear motion with no additional components.

This makes captive motors more plug-and-play and ideal for space-limited applications or systems without existing guidance elements.

3. Stroke Length Capabilities

Non-Captive: Extremely Long Stroke

Because the screw extends through the motor and can be manufactured at virtually any length, non-captive motors support strokes as long as needed:

This flexibility makes them perfect for robotics, material transport, and long-range positioning.

Captive: Limited Stroke

Captive motors use an internal drive mechanism that restricts maximum shaft travel. Stroke lengths are generally:

For compact devices requiring short, repetitive, precise movement, captive motors are ideal.

4. Installation and System Integration

Non-Captive Motors

Because external support is required, installation can be more complex. Engineers must integrate:

However, this also allows more customization and flexibility for advanced motion systems.

Captive Motors

Captive motors simplify installation significantly. They only require:

A mounting surface

A connection to the load

All other motion control features (anti-rotation, shaft stabilization) are built in. For compact assemblies or rapid prototyping, captive motors save time and reduce mechanical design complexity.

5. Accuracy, Repeatability, and Resolution

Both motor types use the same internal stepper mechanism, so resolution and positioning accuracy are comparable. However, mechanical structure can influence real-world performance.

Non-Captive Motors

Accuracy depends heavily on the quality of the external guidance system. If misalignment occurs, friction or binding may reduce performance.

Captive Motors

The internal guide enhances inherently stable movement, making them ideal for:

6. Load Handling and Mechanical Stability

Non-Captive Motors

Load handling depends on external guidance. With proper linear rails, they can carry larger or more complex loads. They are commonly used in:

Captive Motors

Best for light to moderate loads, because the internal guide limits force capacity. They excel when:

7. Ideal Application Scenarios

Long-stroke automation systems

Material handling and pick-and-place mechanisms

Robotics requiring large linear travel

Large-scale positioning equipment

3D printing and CNC applications

Best Uses for Captive Linear Stepper Motors

Laboratory automation

Microfluidics and dispensing systems

Medical devices

Optical alignment systems

Compact embedded electronics

Automated test equipment

When simplicity, compactness, and short travel are priorities, captive motors provide a reliable and cost-effective solution.

Summary of Key Differences

Below is a concise comparison highlighting the most important distinctions between Non-Captive and Captive linear stepper motors.

| Feature | Non-Captive Linear Stepper Motors | Captive Linear Stepper Motors |

| Mechanical Design | Lead screw passes entirely through the motor body | Internal lead screw with a guided, non-rotating output shaft |

| Anti-Rotation | Requires external anti-rotation (rails, guides, or carriages) | Built-in anti-rotation mechanism |

| Motion Output | Linear movement produced by the screw moving in/out | Linear movement produced by the motor’s output shaft |

| Stroke Length | Supports very long strokes; limited only by screw length | Short and fixed stroke lengths due to internal travel limits |

| Installation Complexity | More complex; depends on external alignment and guides | Simple, compact, plug-and-play integration |

| Load Capacity | Load handling depends heavily on external guidance | Suitable for light to moderate loads |

| Application Fit | Ideal for long-travel automation, robotics, and custom systems | Best for compact devices, precision instruments, and short-stroke tasks |

| Customization | Highly customizable screw lengths and configurations | Typically limited to standard stroke options |

| Guidance Stability | Stability determined by external components | Internal guidance ensures stable and smooth motion |

Choosing the Right Motor for Your System

Selecting between a non-captive and a captive linear stepper motor depends on the specific mechanical, spatial, and performance demands of your application. Each design offers distinct advantages, and understanding these considerations ensures optimal efficiency, reliability, and integration.

1. Define the Required Stroke Length

The length of travel is one of the most important differentiators:

Use a Non-Captive Motor when you need long or unlimited stroke lengths, such as in robotics, material handling, or extended automation rails.

Use a Captive Motor when the system requires a short, precise, and contained stroke, typical in laboratory instruments, small medical devices, and compact machinery.

2. Evaluate Available Installation Space

System size and layout greatly influence motor selection:

Non-Captive Motors extend the screw outward and require external guides, making them suitable for systems where space is available for longer travel paths.

Captive Motors offer a self-contained design, making them ideal for tight or enclosed environments where simplicity and compactness are priorities.

3. Assess Load Requirements

Your choice should match the mechanical forces and stability needed:

Non-Captive Motors work best when paired with external linear guides that support heavier or more complex loads.

Captive Motors are optimized for light to moderate loads, supported by their internal anti-rotation mechanism.

4. Consider Integration and Assembly Complexity

Installation and mechanical design time can influence overall system performance:

5. Determine the Level of Precision and Stability Needed

Precision depends on both the motor and the supporting mechanics:

Non-Captive Motors can deliver excellent precision but rely on external guides for stability.

Captive Motors offer more consistent motion in compact systems due to their internal stabilization and controlled travel path.

6. Match the Motor to Your Application Requirements

Use this quick guide to align motor type with common application categories:

Final Recommendation

To choose the right motor, balance stroke length, space constraints, load capacity, precision needs, and integration complexity. Systems requiring extended travel and customization benefit from non-captive motors, while compact, self-contained applications with shorter travel needs are better served by captive motors.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català