Introduction to the NEMA 17 Stepper Motor

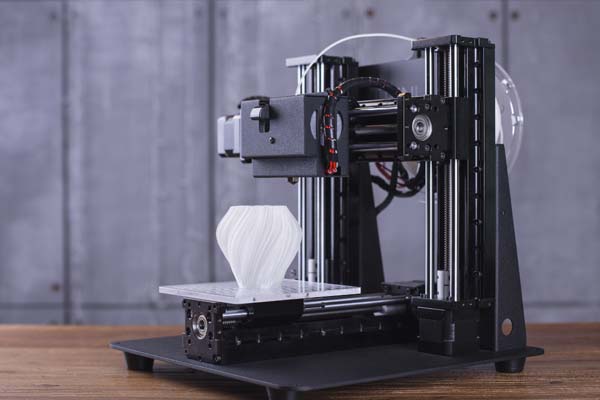

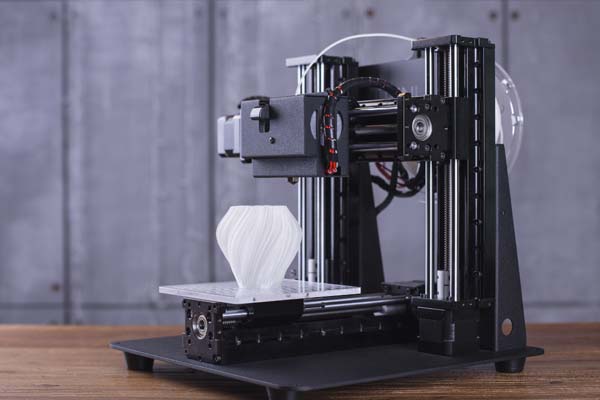

In the realm of precision motion control, where digital instructions must be translated into exact physical movement, one component stands as a ubiquitous and critical workhorse: the NEMA 17 stepper motor. This unassuming device is the beating heart of countless desktop machines, most notably the modern 3D printer, where its performance directly dictates print quality, reliability, and speed. The designation "NEMA 17" refers to a standard set by the National Electrical Manufacturers Association (NEMA), specifying a faceplate size of 1.7 inches square (approximately 42.3mm). This standardization is crucial, as it ensures interchangeability and simplifies mechanical design across a vast ecosystem of manufacturers and applications. Far more than just a simple rotary motor, the stepper motor operates on the principle of discrete steps, converting electronic pulses into precise angular movements, a function that is indispensable for additive manufacturing and computer-controlled positioning.

Within this guide, we will provide an exhaustive exploration of the NEMA 17 stepper motor, dissecting its internal architecture, examining its various types, and elucidating the distinct advantages that make it the dominant choice for printer applications. We will move beyond basic specifications to deliver a deep technical understanding that empowers engineers, hobbyists, and procurement specialists to make informed decisions and optimize their systems for peak performance.

Fundamental Operation and Internal Architecture

The NEMA 17 stepper motor is an electromechanical transducer that converts digital pulse sequences into precise mechanical rotation. Its core operational principle is open-loop control, where the controller commands movement by sending a known number of electrical pulses without direct positional feedback, relying on the motor's inherent design to follow accurately.

Core Components and Their Functions

The hybrid design, standard in most modern printer motors, merges principles from variable reluctance and permanent magnet motors for optimal performance. Key components include:

| Component | Description | Primary Function |

| Stator | The stationary outer frame with stacked electromagnetic laminations. | Houses the motor windings and creates the controlled magnetic field that drives the rotor. |

| Windings (Coils) | Copper wire arranged in phases (typically two) within the stator. | When energized, these become electromagnets. The sequence of energization creates the rotating magnetic field. |

| Rotor | The central rotating shaft with a permanent magnet core and fine teeth. | The teeth are magnetized. They align with the stator's magnetic field, causing rotation. |

| Bearings | Precision ball or sleeve bearings at each end of the shaft. | Facilitate smooth, low-friction rotation and define axial/radial play. |

The Stepping Sequence: How Motion is Created

A standard bipolar NEMA 17 motor has two independent windings (Phase A and Phase B). The driver circuit applies voltage to these windings in a specific step sequence:

One Phase ON (Full Step): One winding is energized, magnetizing its stator teeth and attracting the nearest rotor teeth into alignment. This is a 1.8° step.

Two Phase ON (Full Step): The first winding remains energized, and the second is powered. The rotor moves to a position between the two stator magnetic fields, achieving another 1.8° step.

This pattern continues, alternating which phase is dominant. By reversing the current direction in the windings, the magnetic poles are reversed, allowing for a complete 200-step (1.8° each) revolution.

This basic full-step mode provides maximum torque but can cause vibration. Modern drivers use microstepping, which proportionally controls the current in both windings simultaneously to position the rotor at numerous intermediate points between full steps, enabling remarkably smooth and quiet operation essential for high-quality printing.

Primary Types of NEMA 17 Stepper Motors

While the NEMA 17 standard defines the mounting face, motors within this class are engineered with different configurations to serve specialized functions. The choice of type is dictated by the specific demands of torque, precision, space, and environmental conditions.

This is the most prevalent type found in consumer-grade 3D printers and CNC machines. It combines a permanent magnet rotor with a toothed electromagnetic stator.

Key Features

High Torque at Low Speed: Excellent holding and dynamic torque in a compact frame.

Standard Step Angles: Typically 1.8° (200 steps/rev) or 0.9° (400 steps/rev).

Bipolar Design: Most common, offering the best torque-to-size ratio.

Cost-Effectiveness: Provides a superior balance of performance and affordability.

Applications

Primary X, Y, and Z-axis movement in desktop 3D printers.

Extruder drive mechanisms.

Laser engraver/cutter positioning stages.

General automation where precision positioning is required.

This motor incorporates a planetary or spur gearbox directly attached to the output shaft of a standard hybrid motor.

Key Features

High Output Torque: Gear reduction multiplies the motor's torque significantly.

Lower Output Speed: Gear reduction decreases output RPM while increasing resolution.

Increased Axial Load Capacity: The gearbox can handle higher thrust loads.

Potential Backlash: A minimal, inherent mechanical play exists between gears.

Applications

Heavy-duty extruders (e.g., for flexible filaments).

Z-axis drives in large-format or high-payload printers.

Rotary tables or applications requiring high torque at very low speeds.

Conveyor drives in automated systems.

This type combines the stepper motor with a compact, onboard microstepping driver and controller electronics in a single unit.

Key Features

Simplified Wiring: Requires only a DC power supply and step/direction signals.

Space-Saving Design: Eliminates the need for a separate driver board.

Optimized Performance: The motor and driver are matched by the manufacturer.

Thermal Management: Heat from the driver is a key design consideration.

Applications

Space-constrained robotic joints and arms.

Educational kits and simplified prototyping.

Upgrades for systems with limited controller outputs.

A standard hybrid motor is enhanced with an integrated rotary encoder that provides real-time positional feedback to the controller.

Key Features

Error Correction: The system detects and compensates for missed steps, preventing positional loss.

Increased Efficiency: Can often run at higher speeds or with reduced current when unloaded.

Higher System Cost: Adds the expense of the encoder and a compatible closed-loop driver.

Reliability: Critical for applications where a lost step would be catastrophic.

Applications

High-reliability production 3D printers.

Mission-critical CNC axes.

Automated optical positioning and inspection systems.

This motor features a hollow bore through the center of the rotor, allowing a shaft, cable, or laser beam to pass through.

Key Features

Through-Hole Design: Enables direct mounting or passage of components.

Compact Assembly: Eliminates the need for external couplings in some designs.

Reduced Torque: Hollow construction can slightly reduce available torque compared to a solid shaft.

Specialized Mounting: Often uses a flange or face-mounting system.

Applications

Rotary sensors and encoders (passing the measured shaft directly through).

Fiber optic cable winding and positioning.

Direct-drive systems where the load is mounted on the motor's outer body.

These motors are sealed with O-rings, gaskets, and special shaft seals to protect internal components from moisture, dust, and contaminants.

Key Features

IP Rating: Typically rated IP65 (dust-tight and protected against water jets) or higher.

Corrosion-Resistant Materials: Use of treated metals, stainless steel shafts, and protective coatings.

Specialized Connectors: Sealed cable glands or waterproof connectors.

Potential Thermal Limitations: Sealing can slightly impact heat dissipation.

Applications

Food and beverage processing equipment (wash-down environments).

Outdoor robotics and automated systems.

Medical and laboratory automation where cleaning/sterilization is required.

Marine and underwater research devices.

The Paramount Advantages of Using NEMA 17 Stepper Motors in Printers

The selection of a NEMA 17 stepper motor as the universal actuator in desktop 3D printing is a result of a deliberate engineering convergence. Its advantages provide an optimal balance of performance, reliability, and cost that is uniquely suited to the demands of additive manufacturing.

Precision and Repeatability Through Digital Control

The fundamental digital nature of stepper operation grants printers exceptional positional accuracy. The controller commands movement by sending a precise number of pulses, each corresponding to a fixed angular step. This open-loop system ensures that, when properly sized, the motor does not accumulate positional error over time. For 3D printing, this translates directly into excellent layer alignment and dimensional accuracy of the finished part, as each movement of the extruder or build platform is executed with deterministic reliability.

Superior Low-Speed Torque and Holding Force

Unlike many motor types that suffer from torque drop-off at low rotational speeds, NEMA 17 motors deliver maximum torque in the low RPM range where printers primarily operate. This is critical for the extruder, which must overcome the resistance of the hot end to push filament consistently at all print speeds. Furthermore, the motor's robust static holding torque is essential for the Z-axis, preventing any downward drift of the gantry or build plate due to gravity, thereby ensuring consistent layer height throughout a multi-hour print.

Simplified, Cost-Effective System Architecture

The ability to operate accurately without expensive feedback components like encoders is a profound advantage. This open-loop control drastically simplifies the printer's electronics, reduces overall system cost, and enhances long-term reliability by eliminating potential points of failure. This design philosophy has been instrumental in making high-precision desktop manufacturing accessible and maintainable for a global audience.

Standardization Enables Innovation and Compatibility

The NEMA 17 mounting standard creates a universal ecosystem. Printer manufacturers, upgrade kit producers, and hobbyists can design and swap components with guaranteed mechanical compatibility. This fosters a vibrant aftermarket, drives competition, and accelerates innovation in motor design and driver technology, all while ensuring easy sourcing and replacement.

Inherent Durability and Maintenance-Free Operation

With no physical brushes to wear out, the NEMA 17 hybrid stepper motor is a fundamentally robust device. Its lifespan is determined by bearing longevity, often exceeding tens of thousands of hours of operation. When paired with a properly configured driver, it requires zero routine maintenance, providing a foundation of reliable, consistent performance that is crucial for unattended print jobs. This combination of precision, torque, simplicity, and ruggedness solidifies its role as the indispensable mechanical driver in 3D printing.

Selecting the Optimal NEMA 17 Motor for Your Printer Application

Not all NEMA 17 stepper motors are created equal. Different roles within a printer have different priorities.

Extruder Motor:

This is often the most critical motor for print quality. It requires smooth, consistent torque to push filament reliably. High microstepping is vital here to ensure smooth extrusion, especially at slow speeds for fine details. Motors with lower inductance often perform better at the higher step rates used for fast extrusion. Geared extruders may use a motor with slightly lower current but benefit from the gear reduction.

X and Y Axis Motors:

These motors control the print head's planar movement. They must accelerate and decelerate quickly. Key factors are a good torque-speed curve to maintain force at higher travel speeds and smooth microstepping to prevent visible artifacts (like salmon skin) on the print surface. Low-vibration motors paired with advanced drivers (e.g., Trinamic's TMC series) are highly desirable here.

Z Axis Motor(s):

The primary requirement is strong, reliable holding torque to prevent the vertical axis from slipping under load. Precision is also key, as any error in the Z-axis is cumulative and directly affects layer height. For dual-Z setups, two matched motors are typically used. Since they operate at very low speeds, their high-speed torque characteristics are less important.

Always cross-reference the motor's current rating with your controller board's driver capabilities, and ensure the physical shaft length and diameter (commonly 5mm) are compatible with your couplers or drive gears.

Advanced Considerations: Drivers, Heat, and Electrical Noise

The ultimate performance of a NEMA 17 stepper motor is not determined in isolation. It is the product of a tightly integrated system where the choice of driver, thermal management, and electrical design are critical to achieving reliable, precise, and quiet operation in a 3D printer.

The Critical Role of Stepper Drivers

The stepper driver is the sophisticated intermediary between the printer's control board and the motor. It translates low-current step and direction signals into the high-power phase currents needed to drive the windings. Key driver characteristics include:

| Driver Feature | Impact on Motor Performance | Printer Application Consideration |

| Microstepping Resolution | Determines smoothness and audible noise. Higher microstepping (1/16, 1/32) enables buttery-smooth motion. | Essential for silent printing and eliminating "salmon skin" artifacts on prints. |

| Current Control Algorithm | Manages torque, efficiency, and heat. SpreadCycle offers maximum torque; StealthChop2 prioritizes silence. | Extruders often use SpreadCycle for torque; X/Y axes use StealthChop for quiet travel. |

| Current Matching & Limiting | Prevents overheating and skipped steps. Must be set to the motor's rated phase current. | Incorrect setting is the leading cause of motor failure or poor performance. |

| Voltage Compatibility | Higher driver supply voltage improves high-speed torque by forcing current through the motor's inductance faster. | 24V systems offer significant performance gains over legacy 12V systems. |

Managing Motor and Driver Thermals

Heat is an inevitable byproduct of current flowing through the motor's copper windings and the driver's MOSFETs. Effective thermal management is non-negotiable for long-term reliability.

Optimal Current Tuning:

The single most important factor. The driver's current limit should match the motor's rated current. An under-currented motor loses torque; an over-currented one wastes energy as excessive heat, degrading bearings and magnet wire insulation.

Active Cooling:

Driver modules on the control board often require directed airflow from a small fan. Enclosed printer electronics compartments must be ventilated to exhaust heat buildup from all components.

Motor Temperature Monitoring:

While not common on basic printers, advanced systems may monitor motor case temperature with thermistors, allowing firmware to trigger a safety shutdown in an overheat condition.

Mitigating Electrical Noise and EMI

The rapid switching of high currents in stepper drivers generates significant electrical noise (Electromagnetic Interference or EMI). This noise can interfere with sensitive electronics, cause communication errors, or produce audible whining.

Quality Shielded Cabling:

Using shielded 4-conductor cable for motor connections is highly recommended. The shield must be properly grounded at the control board end to contain radiating noise.

Ferrite Core Chokes:

Clamping snap-on ferrite beads onto motor cables near the driver provides a simple, effective method of suppressing high-frequency noise.

Power Supply Filtering:

A well-designed printer uses a filtered, switched-mode power supply (SMPS) and may include additional bulk capacitors on the driver power rails to smooth voltage spikes and provide clean, stable power, which is crucial for consistent microstepping performance.

Conclusion: The Engine of Innovation

The NEMA 17 stepper motor is a masterpiece of pragmatic engineering—a standardized, cost-effective, and remarkably capable component that has become the indispensable engine of the desktop manufacturing revolution. Its blend of precision, torque, reliability, and simplicity makes it perfectly suited to the demanding environment of 3D printing. From the subtle purr of a perfectly calibrated extruder to the rapid, precise sweeps of the X-axis, the performance of the entire machine hinges on the quality and appropriate application of these motors.

By understanding the nuances between bipolar and unipolar designs, the transformative power of microstepping, and the specific requirements of each axis, we can push our machines to their limits. We select not just a motor, but the very component that translates our digital creativity into tangible, high-fidelity physical reality. The continued evolution of both NEMA 17 motor designs and their accompanying driver technology promises even greater levels of speed, silence, and precision, further solidifying their role as the fundamental actuator in the next generation of personal fabrication tools.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català