When comparing servo motors and DC motors, one of the most frequently asked questions among engineers and hobbyists is whether servos produce more torque than DC motors. The answer depends on several technical factors, including motor design, gearing, feedback systems, and intended application. Let's explore in depth how torque differs between these two motor types and why servo motors are often the preferred choice for high-torque precision applications.

Understanding Torque in Motors

In the world of electric motors, the term torque is fundamental. It determines how effectively a motor can perform mechanical work — whether driving an industrial machine, rotating a robotic arm, or spinning the wheels of an electric vehicle. Understanding torque in motors is essential for designing, selecting, and optimizing motion systems for any application.

What Is Torque?

Torque is the rotational equivalent of linear force. It measures how much twisting force a motor can exert to rotate an object around an axis. In simple terms, torque is what makes things spin.

It is measured in units such as Newton-meters (Nm) in the metric system or ounce-inches (oz-in) and pound-feet (lb-ft) in the imperial system. The formula for torque is:

Torque (T)=Force (F)×Distance (r)\text{Torque (T)} = \text{Force (F)} \times \text{Distance (r)}

Torque (T)=Force (F)×Distance (r)

Where:

In motor applications, this means that the longer the arm and the greater the force, the higher the torque.

How Torque Is Produced in a Motor

Torque in an electric motor is generated through electromagnetic interaction between the stator (stationary part) and the rotor (rotating part).

When current flows through the motor windings, it creates a magnetic field.

This magnetic field interacts with the field of the magnets (or other windings) in the stator.

The result is a rotational force — the torque — that causes the rotor to spin.

In mathematical form, motor torque can be expressed as:

T=kt×IT = k_t \times I

T=kt×I

Where:

This relationship shows that torque is directly proportional to current. The higher the current supplied to the motor, the more torque it produces, up to the motor's rated limit.

Types of Torque in Motors

Not all torque is the same. Motor performance is often defined by several types of torque, each representing a specific condition of operation.

1. Starting (Stall) Torque

This is the maximum torque a motor can produce when its shaft is stationary. It determines the motor's ability to start a load from rest. High stall torque is important for heavy-load applications, such as cranes, lifts, and electric vehicles.

2. Running (Rated) Torque

This is the continuous torque a motor can deliver while operating at its rated speed without overheating. It represents the motor's normal working capacity.

3. Peak Torque

This refers to the maximum short-term torque the motor can deliver before overheating or stalling. Servo motors, for example, can achieve peak torque levels several times higher than their rated torque for brief periods.

4. Holding Torque

Common in stepper and servo motors, holding torque is the amount of torque the motor can maintain when energized but not rotating. It keeps a position steady under load.

Torque-Speed Relationship

The relationship between torque and speed is a crucial characteristic of motor performance. Typically, as speed increases, torque decreases, and vice versa. This inverse relationship can be represented on a torque-speed curve.

At zero speed (stall): Maximum torque (stall torque).

At rated speed: Constant torque within operational limits.

At no load (maximum speed): Torque approaches zero.

This relationship allows engineers to select motors based on the load requirements and desired operating speed.

For instance, DC motors have a linear torque-speed curve, while AC induction motors and servo motors have more controlled and variable profiles due to advanced electronics and feedback systems.

Torque in Different Motor Types

DC Motors

DC motors generate torque proportional to the armature current. They provide high starting torque, making them ideal for applications requiring immediate acceleration.

AC Motors

AC induction and synchronous motors produce torque through alternating magnetic fields. While they can deliver steady torque, their starting torque may be lower without special control mechanisms.

Stepper Motors

Stepper motors provide incremental torque, moving in discrete steps. Their torque output depends on current, voltage, and step rate. They excel in positioning applications like 3D printers and CNC systems.

Servo Motors

Servo motors are designed for high-torque and high-precision applications. With their closed-loop feedback, they can maintain consistent torque across a wide speed range, even under fluctuating loads.

Factors Affecting Torque

Several factors influence how much torque a motor can generate:

Current Input: Torque increases with current, but excessive current can cause overheating.

Magnetic Field Strength: Stronger magnetic fields produce higher torque.

Winding Resistance: Lower resistance improves efficiency and torque output.

Motor Size and Design: Larger motors generally deliver more torque.

Gear Ratios: Gearboxes can multiply torque by reducing output speed.

Load Conditions: Friction, inertia, and external loads affect available torque.

Engineers often use torque sensors and feedback encoders to monitor torque in real time for precision control.

Calculating Motor Torque

To select a motor for a specific application, you need to calculate the required torque. The formula depends on the power and speed of the motor:

T=9550×PNT = \frac{9550 \times P}{N}

T=N9550×P

Where:

T = Torque (Nm)

P = Power (kW)

N = Speed (RPM)

This formula helps in determining the torque needed to achieve a given mechanical power output at a specific rotational speed.

Why Torque Matters in Motor Selection

Choosing the right motor involves balancing torque, speed, and power. Insufficient torque can cause:

Motor stalling

Excessive current draw

Overheating

Reduced lifespan

Conversely, over-specifying torque leads to unnecessary cost and energy waste. Therefore, understanding torque characteristics is vital for efficiency, durability, and performance optimization.

Torque is the core performance metric of any motor. It determines how effectively the motor can move, lift, or rotate a load. Whether it's a simple DC motor or an advanced servo system, understanding how torque works helps engineers design smarter, more efficient machines.

In summary, torque defines the strength of rotation, and mastering its principles is essential for anyone working with electromechanical systems.

Torque Characteristics of DC Motors

DC motors provide torque directly proportional to the current supplied to the armature. This makes it easy to control torque by adjusting the input voltage or current. DC motors can deliver good torque, but only within certain limits. Their maximum torque (stall torque) occurs when the motor shaft is not rotating, while running torque drops as speed increases.

However, standard DC motors face two limitations:

Torque consistency — Without feedback control, DC motors cannot maintain consistent torque under varying loads.

Efficiency at low speeds — DC motors often lose torque efficiency when running at very low speeds due to heat buildup and brush friction.

As a result, while DC motors are simple and effective for continuous rotation and moderate load applications, they are not ideal for precise, high-torque control scenarios.

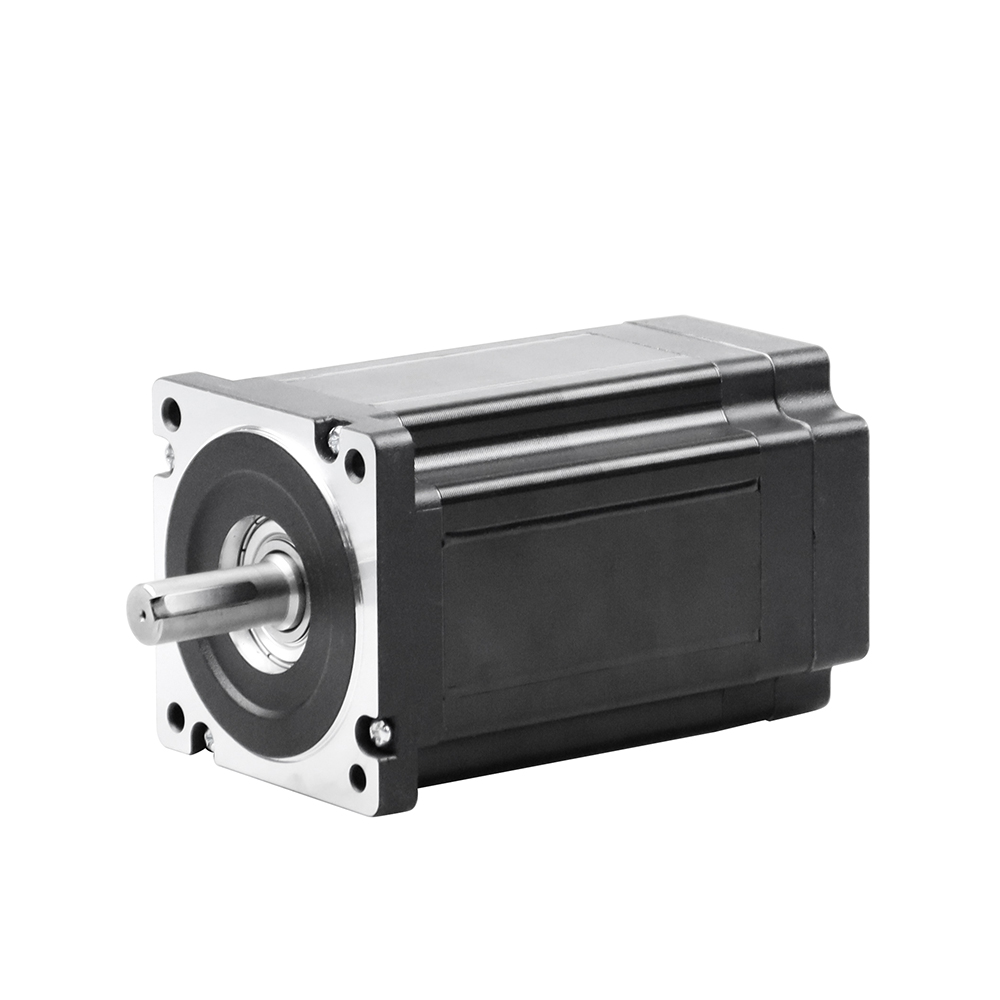

Torque Characteristics of Servo Motors

Servo motors, particularly industrial-grade AC or DC servos, are designed for high-torque output and precision control. A servo motor system includes three main parts:

Motor (actuator) – Generates mechanical power.

Feedback sensor (encoder or resolver) – Measures speed and position.

Controller (driver) – Regulates current, voltage, and feedback signals to achieve exact performance.

The closed-loop feedback allows a servo motor to automatically correct errors, ensuring constant torque even under load fluctuations. This capability makes servo motors ideal for demanding applications such as robotic arms, CNC machines, 3D printers, and automation lines.

Furthermore, many servo motors are geared to multiply torque. For example, a small servo with a built-in planetary gearbox can achieve torque outputs several times greater than an equivalent-size DC motor.

Torque Comparison: Servo vs. DC Motor

| Aspect | DC Motor | Servo Motor |

| Torque Control | Limited to input current | Closed-loop feedback ensures precise control |

| Torque at Low Speed | Drops significantly | Maintains high torque even at low RPM |

| Peak Torque Output | Moderate | Can be very high (especially with gearbox) |

| Response to Load Changes | Slow or unstable | Fast and self-correcting |

| Efficiency | Lower due to heat and friction | Higher with optimized control electronics |

In most cases, servo motors deliver more usable torque than DC motors of similar size and power rating. This is due to their optimized magnetic design, advanced control electronics, and torque-multiplying gear systems.

How Servo Motors Achieve Higher Torque

Servo motors are known for their exceptional torque performance, precise control, and reliability in demanding automation systems. Unlike conventional DC motors, which simply convert electrical energy into rotational motion, servo motors are engineered for precision, feedback, and strength. The ability of servo motors to achieve higher torque output arises from a combination of advanced design, control systems, and integrated gearing mechanisms.

Let's explore in detail how servo motors are able to generate and maintain higher torque compared to other motor types.

1. Advanced Electromagnetic Design

At the heart of every servo motor lies its optimized electromagnetic structure, which is specifically designed to produce maximum torque density—that is, more torque per unit of size and weight.

High-Performance Windings

Servo motors use low-resistance copper windings arranged to minimize energy loss and maximize magnetic efficiency. The winding configuration ensures that more current contributes directly to torque production rather than heat generation.

Strong Permanent Magnets

Modern servo motors often employ rare-earth magnets, such as neodymium (NdFeB). These magnets produce a strong and stable magnetic field, which dramatically enhances the torque generated per ampere of input current.

This combination of optimized magnetic circuits and high-quality materials allows servo motors to deliver significantly higher torque than equivalent-sized DC motors.

2. Use of Gear Reduction Systems

One of the most effective methods for increasing torque in servo systems is through gear reduction. Many servo motors come with built-in gearboxes, such as planetary or harmonic drive systems, that multiply the torque output.

How Gear Reduction Works

Torque and speed are inversely related in gear systems. A gear ratio reduces speed while proportionally increasing torque.

For example:

This means even a small servo motor can move heavy loads with remarkable precision. The trade-off in reduced speed is often desirable in robotic joints, CNC spindles, and automated positioning systems, where torque and control accuracy are more important than speed.

3. Closed-Loop Feedback Control

Servo motors operate in a closed-loop system, using encoders or resolvers to continuously monitor shaft position, velocity, and torque. This feedback is essential for maintaining stable torque under varying load conditions.

Real-Time Adjustments

When a load increases, the feedback controller instantly detects any deviation in position or speed and adjusts the current supply to maintain the desired torque.

This real-time adjustment allows servo motors to sustain high torque even during sudden load changes, something open-loop systems like regular DC motors cannot achieve.

4. High Current Handling and Efficient Cooling

Servo motors are built to handle higher currents efficiently, allowing them to generate more torque without overheating. The motor housing and internal components are designed with superior heat dissipation features, such as:

Aluminum or finned housings for heat dispersion.

Integrated cooling fans or liquid cooling in high-power servos.

High-temperature-resistant insulation materials to protect windings.

By effectively managing thermal conditions, servo motors can deliver continuous high torque for extended periods without degradation in performance or risk of burnout.

5. Precision Torque Control Through Electronics

Servo drive systems include sophisticated torque control algorithms that manage the flow of current to the motor's coils. These control techniques—such as Field-Oriented Control (FOC) or Vector Control—allow for accurate, real-time modulation of the magnetic field within the motor.

Field-Oriented Control (FOC)

In FOC, the motor current is separated into two components:

By independently managing these components, the controller ensures maximum torque per ampere and reduces energy waste. This results in smooth torque output, even at low speeds.

6. High-Resolution Encoders for Accurate Torque Feedback

High-quality optical or magnetic encoders enable servo systems to measure shaft position with extreme accuracy—sometimes down to a fraction of a degree.

This fine-resolution feedback ensures that the servo motor delivers torque only when and where it's needed, preventing overshoot, vibration, and wasted energy.

As a result, servo motors maintain consistent torque and stability, especially important in precision robotics, medical equipment, and aerospace applications.

7. Torque Ripple Minimization

Torque ripple is the unwanted fluctuation in torque output as the motor rotates. Servo motors are designed with special rotor and stator geometries to minimize torque ripple, providing smooth and stable rotation.

Key design improvements include:

Skewed stator slots to smooth magnetic transitions.

Precision rotor balancing to reduce vibration.

Advanced digital control algorithms to compensate for irregularities in real time.

Reduced torque ripple enhances both torque consistency and operational smoothness, critical in high-precision environments.

8. Superior Materials and Construction

Servo motors use high-grade materials that contribute to better torque performance:

High-permeability steel laminations reduce magnetic losses.

Reinforced shafts and bearings handle higher mechanical loads.

Precision manufacturing tolerances ensure minimal mechanical backlash.

This mechanical and magnetic efficiency ensures that almost all electrical energy is converted into useful rotational torque.

9. Dynamic Response and Instantaneous Torque Delivery

Servo motors can accelerate and decelerate rapidly, achieving instant torque response due to their lightweight rotors and low inertia designs.

This fast dynamic response allows them to:

Instantly adjust to load variations.

Deliver peak torque for short bursts when required.

Stop or change direction almost immediately without losing position accuracy.

Such responsiveness is a major reason servo motors dominate in industrial automation, robotics, and motion control systems.

10. Integration with Smart Controllers

Modern servo systems integrate with digital servo drives that communicate via protocols like EtherCAT, CANopen, or Modbus. These controllers provide:

Real-time torque monitoring.

Adaptive control for different load conditions.

Automatic tuning for optimized torque efficiency.

This intelligent integration ensures that servo motors operate at peak torque performance throughout their duty cycle, while maintaining energy efficiency and system stability.

Servo motors achieve higher torque through a combination of intelligent design and advanced control systems. From gear reduction mechanisms and rare-earth magnets to closed-loop feedback and field-oriented control, every aspect of a servo motor is optimized for maximum torque output and precision.

This makes them the preferred choice in industries where accuracy, power, and performance are critical — from robotic arms and CNC machinery to aerospace actuators and electric vehicles.

In short, servo motors don't just produce torque—they master it.

Application-Based Torque Differences

The application often determines which motor type is better suited:

In high-precision environments, servo torque control ensures stable operation without overshoot, lag, or position drift — something a simple DC motor cannot guarantee.

Efficiency and Performance at Low Speed

One major advantage of servo motors is their high torque density at low speed. In contrast, DC motors typically require additional gearing or current boost to achieve the same effect. Servo motors are designed to maintain their rated torque across a wide range of speeds, making them far more energy-efficient and stable under heavy load conditions.

For example, an AC servo motor rated at 400 W might produce over 1.3 Nm of continuous torque and handle peak loads up to 4 Nm, while a comparable DC motor may struggle to deliver even 1 Nm without excessive heating.

Conclusion: Do Servos Have More Torque?

Yes — servo motors generally have more torque than DC motors, particularly when considering torque consistency, control accuracy, and low-speed performance. Their integrated feedback and control systems allow them to deliver stable, precise torque under varying conditions, which standard DC motors cannot match without complex external systems.

While DC motors are simpler and more affordable, servo motors dominate in applications where precision, reliability, and torque performance are critical. If your project demands accurate positioning, rapid load response, or continuous torque control, a servo motor is unquestionably the better choice.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català