Linear motors have become a defining technology in modern automation, precision engineering, medical equipment, semiconductor fabrication, and high-speed manufacturing. Yet one question continues to surface across industries: Why are Linear motors so expensive?

The answer lies in the combination of advanced engineering, premium materials, stringent manufacturing requirements, and the superior performance advantages they deliver. Below, we break down each cost-driving factor with depth, clarity, and industry expertise to provide a complete, authoritative explanation.

High-Precision Engineering and Design Requirements

Linear motors eliminate mechanical transmission components—such as screws, gears, or belts—to deliver direct linear motion, which demands extreme engineering precision. Each component must be crafted with exacting tolerances to ensure smooth, frictionless movement.

1. Complex Magnetic Circuit Design

Linear motors rely on highly efficient magnetic circuits. Achieving uniform thrust, minimal cogging, and high acceleration requires:

This level of engineering work significantly increases development and production costs compared to conventional electromechanical drives.

2. High-Tolerance Manufacturing

To maintain micron-level repeatability, Linear motors incorporate components manufactured to ultra-tight tolerances. This often requires:

High-precision CNC machining

Laser cutting

Automated coil winding with minimal deviations

Stringent multi-stage quality inspections

These processes are far more expensive than the manufacturing of typical rotary motors or mechanical actuators.

Use of Premium Raw Materials

At the core of every linear motor lies a set of materials that directly impact the system’s efficiency, thermal performance, and lifetime.

1. Rare-Earth Permanent Magnets

Modern linear motors use Neodymium-Iron-Boron (NdFeB) magnets, often in high-grade compositions such as N48, N52, or even high-temperature variants. These magnets are among the most expensive materials used in electric motion systems.

Cost drivers include:

Price fluctuations in rare-earth elements

High magnetic strength requirements

Precision magnetization

Specialty coatings (nickel, epoxy, Parylene) for corrosion protection

Linear motors may contain several meters of magnetic rail, making magnets one of the largest contributors to overall cost.

2. High-Conductivity Copper Windings

To achieve high force output and rapid acceleration, coils are wound using oxygen-free high-conductivity (OFHC) copper. This premium grade increases cost but ensures:

3. Advanced Composite and Thermal Materials

Linear motors often integrate:

High-density laminated steel cores

Low-loss magnetic composites

High-temperature insulation materials

Specialized heat spreaders or liquid cooling jackets

These materials contribute to higher thermal stability and sustained peak performance, but they are not inexpensive to source or manufacture.

Precision Motion Control Electronics

Linear motors deliver exceptional performance only when paired with advanced motion control electronics engineered to manage high-speed operation, micron-level precision, and dynamic responsiveness. Unlike simple motors that can run on basic controllers, linear motors require a sophisticated ecosystem of drives, feedback systems, sensors, and real-time computing hardware. These electronic components significantly influence the overall cost and performance of a linear motor system.

Advanced Servo Drives Designed for High-Speed Operation

A linear motor’s power and precision come from its servo drive—the electronic unit responsible for converting incoming electrical energy into controlled, high-performance motion. These drives are far more complex than standard motor drivers and incorporate:

High-bandwidth current loops for rapid response

Fast sampling rates, often in the tens or hundreds of kilohertz

High-power transistors such as IGBTs or MOSFETs for efficient switching

Real-time trajectory calculation to synchronize motion with external systems

Adaptive control algorithms that compensate for disturbances and load changes

Because linear motors produce high acceleration and require smooth, ripple-free thrust, their servo drives must perform complex calculations with minimal latency. This demands premium electronic components, advanced firmware, and internal processing power far beyond typical motor controllers.

High-Resolution Feedback and Position Sensing

To achieve the ultra-precise movement that linear motors are known for, they rely on high-resolution feedback devices that track position, speed, and phase with extreme accuracy. These devices include:

Optical linear encoders capable of sub-micron or nanometer resolution

Magnetic encoders for rugged industrial environments

Laser interferometers for the highest precision applications

Sinusoidal feedback systems for smooth commutation

These sensors not only measure the motor’s position but also provide continuous feedback to the controller, enabling real-time correction and stabilization.

Their high precision, specialized materials, and delicate manufacturing add significant cost, especially in applications requiring:

Complex Commutation and Control Algorithms

Unlike rotary motors, which use predictable circular motion, linear motors require more complex commutation strategies to maintain consistent force and smooth movement across long travel distances.

Modern servo controllers employ algorithms such as:

These algorithms optimize:

Thrust force linearity

Position accuracy

Vibration suppression

Heat reduction

System responsiveness

Developing and implementing these control techniques requires extensive engineering effort, advanced software development, and continuous refinement.

High-Speed Data Processing and Communication

To maintain micron-level precision at high speeds, linear motor systems depend on controllers capable of processing enormous volumes of data in real time. They integrate high-speed communication protocols such as:

EtherCAT

CANopen

Profinet

SERCOS III

These networks support:

Real-time synchronization of multi-axis systems

Deterministic communication

High data throughput for encoder signals and diagnostic data

The electronics must also support:

Built-in diagnostics

Predictive maintenance features

Safety functions such as Safe Torque Off (STO)

Integration with PLCs and automation networks

This level of connectivity and intelligence increases system cost but is essential for industrial automation.

Thermal, Electrical, and Noise Management

Linear motors operate with high current densities and require electronics that can endure and manage:

High thermal loads

Electromagnetic interference (EMI)

High voltage and current fluctuation

Noise-sensitive precision applicationsServo drives must include:

Oversized heat sinks

Active cooling options

Shielding and grounding circuits

Isolated power electronics

These improvements ensure stable operation in industrial environments but increase component and manufacturing cost.

Integration With Safety and Redundancy Systems

In many industries—such as robotics, semiconductor handling, and medical devices—Linear motors must incorporate safety features that comply with strict regulations, including:

Redundant feedback channels

Safe motion monitoring

Overcurrent, overvoltage, and thermal protection

Fail-safe shutdown mechanisms

These requirements demand additional sensors, advanced firmware, and specialized circuitry, contributing further to the overall cost.

Specialized Manufacturing and Assembly Processes

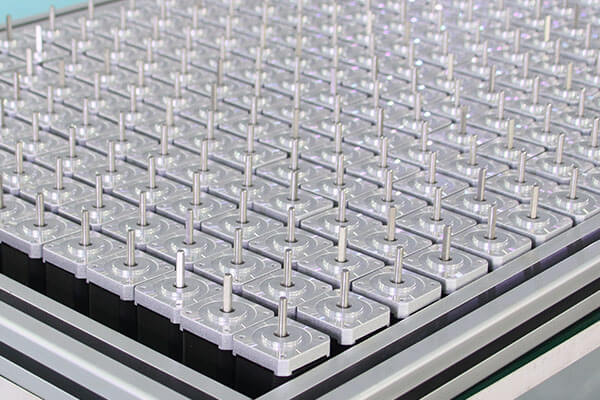

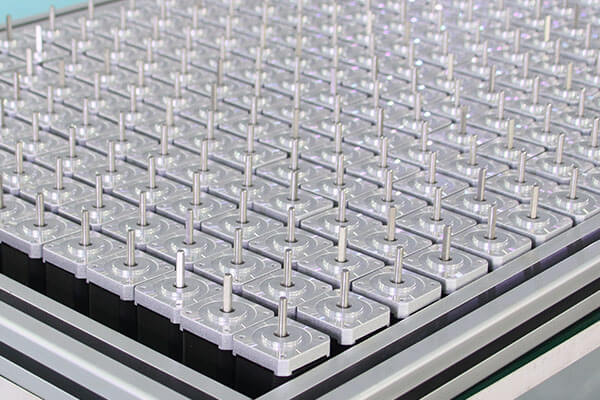

Linear motors are not mass-produced in the same quantities as rotary motors. This means fewer economies of scale.

1. Low-Volume, High-Complexity Production

Applications requiring linear motors—such as lithography machines, robotics, or automated inspection systems—often have specialized needs. Manufacturers must:

Custom-engineer magnetic arrays

Customize motor lengths, coil designs, and mounting surfaces

Optimize thermal solutions for each installation environment

This customization requires engineering hours and proprietary processes, adding to the cost.

2. Precision Alignment During Assembly

Assembly requires:

These factors directly impact production labor costs.

Stringent Quality and Performance Testing

Linear motors must pass rigorous performance, safety, and reliability tests before shipment. Testing can include:

Thermal cycling

Long-duration dynamic load testing

Thrust-force measurements

Vibration and resonance analysis

Electrical safety certification

Each stage requires advanced equipment and expert oversight, adding time and expense to the production process.

Superior Performance Justifies the Investment

Although Linear motors carry a high upfront cost, they deliver unmatched performance benefits that often reduce long-term operational expenses.

1. Zero Mechanical Contact

With no gears, belts, or screws:

There is no mechanical wear

Maintenance is dramatically reduced

Long-term reliability is significantly improved

This alone lowers lifecycle cost, especially in high-duty environments.

2. Exceptional Accuracy and Repeatability

Linear motors consistently achieve:

Micron or sub-micron positioning

Smooth, vibration-free motion

Extremely stable velocity control

This makes them indispensable in:

Precision manufacturing

High-speed pick-and-place

Semiconductor and electronics assembly

Microscopy and medical imaging

3. High Speed and Acceleration

Direct-drive technology enables:

These performance traits are impossible to match with mechanical transmission systems.

Environmental and Durability Requirements

Linear motors are deployed in environments that demand exceptional robustness, stability, and long-term reliability—far beyond what conventional mechanical actuators typically encounter. Because they serve in high-performance, mission-critical applications, their design must accommodate strict environmental and durability requirements, each of which contributes to their elevated cost.

Engineered for Harsh Industrial Conditions

Many Linear motors operate in environments exposed to dust, humidity, vibration, chemicals, or high temperatures. To ensure uninterrupted performance, manufacturers incorporate specialized materials, coatings, and structural protections that maintain efficiency and precision under stress.

Typical protective measures include:

Corrosion-resistant housings made of stainless steel or anodized aluminum

Sealings and gaskets that block dust, moisture, or oil penetration

Protective magnet coatings such as nickel, epoxy, or Parylene for long-term stability

Specialized insulation materials for coils subject to elevated temperatures

These materials and processes significantly increase production costs but are essential to prevent degradation in demanding industrial settings.

Cleanroom and Vacuum Compatibility

In semiconductor manufacturing, biotechnology, and precision metrology, equipment must operate in controlled environments where even microscopic contaminants can damage products or compromise measurements. Linear motors used in these settings must be engineered to:

Generate minimal particulates

Operate without lubricants that may outgas

Withstand ultra-low pressures in vacuum chambers

Maintain precision despite thermal fluctuations

Manufacturing motors that meet ISO cleanroom or vacuum compatibility standards requires custom materials, low-outgassing coatings, and rigorous testing—each adding to cost and complexity.

High Load and Continuous Duty Endurance

Linear motors often run at high speeds, with rapid acceleration and sustained loads. This continuous dynamic stress demands exceptional durability.

Key requirements include:

High-strength structural frames to resist deformation

Advanced thermal management systems, from heat spreaders to liquid cooling

Coils designed for high current density without overheating

Fatigue-resistant magnet tracks capable of withstanding millions of cycles

These engineering features ensure longevity, but they require premium materials and advanced manufacturing practices.

Extreme Temperature and Environmental Stability

Certain industries—such as aerospace, automotive testing, or heavy manufacturing—expose equipment to extreme temperatures or fluctuating environmental conditions. Linear motors for these applications must be designed to:

Function consistently in both high-heat and low-temperature environments

Maintain performance despite thermal expansion or contraction

Resist condensation, oxidation, or salt spray

Deliver stable accuracy even under rapid temperature cycling

Achieving this involves selecting specialized alloys, high-grade insulation, and thermal control systems, increasing both material and production costs.

Long-Term Reliability for Mission-Critical Applications

Many industries rely on linear motors for processes that cannot tolerate downtime, including:

Semiconductor wafer handling

Medical imaging systems

High-speed packaging

Aerospace component testing

Automated inspection and measurement tools

To ensure long-term operation without failure, linear motors undergo:

Accelerated life-cycle testing

Thermal and mechanical stress testing

Vibration and shock resistance evaluation

Continuous-duty performance validation

These rigorous procedures guarantee reliability but add significant time, labor, and equipment expenses to the manufacturing process.

Compliance With Industry Standards

Linear motors must often meet strict international standards and certifications such as:

ISO cleanroom classifications

CE, UL, and RoHS compliance

EMC (Electromagnetic Compatibility) regulations

Industry-specific compliance, such as FDA or automotive standards

Achieving certification requires thorough documentation, specialized testing facilities, and compliance engineering—all contributing to the overall cost.

The Cost Reflects a High-End, High-Performance Technology

Linear motors are expensive because they represent the pinnacle of motion control engineering. Their cost reflects:

For industries that depend on accuracy, longevity, and efficiency, Linear motors offer the best performance-to-cost ratio despite higher initial pricing.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català