A hollow shaft motor is a specialized type of electric motor engineered with a central shaft that is intentionally hollow rather than solid. This unique structural design allows the shaft to accommodate cables, drive components, or mechanical elements directly through its core—offering remarkable flexibility, compactness, and mechanical integration benefits. As industries push toward more efficient, compact, and high-precision motion systems, hollow shaft motors have become essential in robotics, automation, CNC machinery, and advanced industrial equipment.

This comprehensive guide explores every aspect of hollow shaft motors, including their design principles, working mechanisms, advantages, variations, and real-world applications.

Understanding the Structure and Working Principle of Hollow Shaft Motors

A hollow shaft motor is an electric motor designed with a central opening running through the axis of rotation. Instead of using a solid shaft like traditional motors, it incorporates a hollow bore, allowing cables, drive shafts, air lines, or mechanical elements to pass directly through the center.

This design provides unique advantages in compact machinery, precise motion control, and applications where cable management is critical.

1. Core Structural Components

A hollow shaft motor shares the same fundamental components as other electric motors, but each part is engineered to support the open central structure.

a. Stator

The stationary outer part of the motor

Consists of laminated steel cores and copper windings

Generates a rotating magnetic field when energized

b. Hollow Rotor

The rotating component with a precision-machined hollow center

Designed to maintain mechanical strength despite having an internal bore

Can be cylindrical or integrated with a hub to mount external loads

c. Bearings

d. Housing

e. Central Hollow Shaft / Bore

The defining feature

Allows wiring, optics, shafts, or tubing to pass through

Improves cable management and system compactness

2. Working Principle of a Hollow Shaft Motor

Although the structural geometry differs from traditional designs, the operating principle remains the same: electromagnetic interaction between the stator and rotor creates rotation.

Here's how it works:

Step 1: Stator Energization

When current flows through the stator windings, they generate a rotating magnetic field.

Step 2: Rotor Motion

This magnetic field interacts with the rotor—whether it is a permanent magnet or an electromagnetic rotor—causing it to rotate around the central bore.

Step 3: Torque Transmission

The rotor's motion delivers torque to the connected load through a coupling or direct mounting.

Step 4: Pass-Through Functionality

While the rotor is spinning, the hollow center allows:

Signal cables

Pneumatic lines

Fiber optics

Drive shafts

Lead screws

to pass uninterrupted through the motor, reducing mechanical complexity and eliminating external cable loops.

3. Why the Hollow Structure Works Without Reducing Performance

The hollow rotor is engineered to maintain structural strength and magnetic efficiency despite the absence of a solid core. Manufacturers achieve this by:

Using stronger magnetic materials

Optimizing rotor thickness

Reinforcing the surrounding frame

Balancing the rotor to avoid vibration

As a result, hollow shaft motors can provide high torque, excellent precision, and smooth rotation, comparable to or even surpassing many conventional motors.

4. Advantages of This Working Principle

The hollow shaft design directly enhances performance in many ways:

✔ Space Efficiency

Eliminates the need for external cable loops or separate routing openings.

✔ Improved Cable Management

Rotating joints no longer stress wires or tubes, increasing reliability.

✔ Direct Integration

Mechanical components like screws or shafts can be placed directly through the motor.

✔ Higher System Precision

The ability to mount loads closer to the motor axis reduces backlash and vibration.

How It Works

A hollow shaft motor operates using the same electromagnetic principles as traditional electric motors, but with an internal geometry designed to accommodate a hollow passage through the center. This structure enables torque generation while allowing cables, mechanical shafts, or fluid lines to pass directly through the motor body.

Below is a step-by-step breakdown of how it works:

1. Creation of a Rotating Magnetic Field (Stator Operation)

The process begins in the stator, the stationary outer part of the motor. When electrical current flows through the stator windings, it produces a rotating magnetic field. This rotating field is the driving force that makes the rotor spin.

In AC motors, the field is created by alternating current phases.

In BLDC and servo motors, electronic controllers energize the windings in precise sequences.

In stepper motors, the field moves in small steps for accurate positioning.

Despite the hollow center, the stator's magnetic circuit is designed to provide strong and uniform magnetic flux.

2. Rotor Interaction and Rotation

Inside the stator is the hollow rotor, which contains magnets or conductive laminations depending on the motor type. The rotating magnetic field from the stator pulls and pushes on the rotor's magnetic elements, forcing it to rotate around its axis.

Even though the rotor is hollow, it remains structurally rigid and magnetically optimized to:

Maintain strong torque output

Resist deformation

Operate smoothly at high speeds

Provide precise angular movement

The magnetic interaction between stator and rotor is identical in principle to a solid-shaft motor.

3. Torque Transmission Through the Hollow Shaft

As the rotor spins, torque is transferred to the attached mechanical load through the motor's hollow shaft or mounting hub. This can occur in different ways:

Direct drive: Load attaches directly to the rotor, eliminating gears.

Coupled drive: A coupling or flange connects the rotor to external drive components.

Integrated drive: Lead screws, tubes, or shafts run through the hollow bore and rotate along with the rotor.

This direct transfer of torque improves mechanical efficiency and reduces play or backlash.

4. Simultaneous Pass-Through of Cables or Mechanisms

The key advantage of a hollow shaft motor is the central pass-through channel. While the motor rotates, the hollow center allows:

to run through the motor without interference.

Because these elements rotate with the motor, there is no twisting, snagging, or strain on cables—greatly improving reliability.

5. Continuous Closed-Loop or Open-Loop Control

Depending on the type, the motor operates under different control modes:

Open-Loop (Stepper Motors)

Closed-Loop (Servo and BLDC)

Many hollow shaft motors integrate optical or magnetic encoders directly into the rotor for improved accuracy.

6. Efficient Operation Under Load

The hollow rotor is engineered to balance structural strength with the central bore. Advanced materials and precise machining ensure:

This allows hollow shaft motors to operate continuously in demanding industrial environments.

In Summary

A hollow shaft motor works by:

Generating a rotating magnetic field in the stator

Inducing rotation in the hollow rotor

Transmitting torque through the hollow shaft

Allowing simultaneous pass-through of cables or mechanical elements

Maintaining precise control via open-loop or closed-loop electronics

Its ability to rotate while keeping the central path free makes it uniquely valuable in robotics, automation, medical devices, and compact machinery.

Why Hollow Shaft Motors Are Superior for Modern Motion Systems

Hollow shaft motors have become a preferred choice in advanced automation, robotics, medical equipment, and precision machinery because they deliver a unique combination of performance, flexibility, and compact integration that traditional solid-shaft motors cannot match. Their ability to provide rotational torque while maintaining an open central pathway significantly enhances design efficiency and system reliability.

Below are the key reasons why hollow shaft motors stand out in modern motion engineering.

1. Exceptional Space Optimization

One of the most valuable benefits of a hollow shaft motor is its ability to reduce overall system size. By using the internal hollow bore for cable routing or mechanical components, engineers eliminate the need for:

This compact integration allows designers to build smaller, cleaner, and more efficient devices, especially in robotics and compact automation modules.

2. Superior Cable and Media Management

In rotating systems, managing cables and fluid lines is often a major challenge. Hollow shaft motors solve this by allowing cables and tubes to pass directly through the motor’s center.

Benefits include:

This makes hollow shaft motors ideal for continuous-rotation joints, robotic wrists, gimbals, and inspection equipment where unrestricted cable movement is essential.

3. Enhanced Mechanical Integration

The central bore of a hollow shaft motor enables seamless integration with other mechanical components, such as:

This ability to combine multiple functions in one unit reduces mechanical complexity and enhances system performance. Mechanical alignment also becomes more precise because the load can be mounted closer to the motor’s rotational axis.

4. High Torque Density and Precision Performance

Though they contain a hollow core, these motors are engineered to maintain or even exceed the torque output of comparable solid-shaft designs. Modern hollow shaft motors use:

High-strength rotor materials

Optimized electromagnetic geometry

Advanced laminations and magnet configurations

As a result, they deliver:

Strong continuous and peak torque

High accuracy and repeatability

Smooth, low-vibration rotation

Excellent dynamic response

This makes them highly suitable for precision machinery and direct-drive systems.

5. Improved System Reliability and Reduced Wear

In traditional rotary systems, cables wrapped around the motor often experience:

Bending fatigue

Torsional twisting

Connector failures

Insulation wear

By routing cables internally, hollow shaft motors significantly reduce mechanical stress, extending both cable life and system lifespan. The simplified mechanical design also reduces points of failure and the need for routine maintenance.

6. Ideal for High-Precision and High-Duty Applications

Because hollow shaft motors enable direct-drive configurations, they eliminate backlash and improve positional accuracy—critical advantages for:

Their smooth, precise motion is invaluable in applications requiring micrometer-level accuracy and continuous operation.

7. Greater Design Flexibility for Engineers

The hollow shaft design gives engineers more freedom when planning system layouts. They can:

Install sensors directly through the motor

Use smaller enclosures

Build cleaner, modular systems

Combine rotary and linear functions in a single axis

This design flexibility supports innovation in next-generation automation, compact robots, and advanced motion platforms.

8. Reduced Overall Cost in Complex Systems

Although the motor itself may cost slightly more, the overall system cost is often reduced thanks to:

Fewer mechanical components

Less wiring hardware

Reduced installation time

Lower maintenance demands

Longer cable and component life

In many industrial systems, these savings are significant over the lifetime of the equipment.

In Summary

Hollow shaft motors are superior for modern motion systems because they offer:

Better use of space

Cleaner cable management

Strong torque performance

Superior integration with mechanical components

Higher precision and reliability

Reduced system complexity and long-term cost

For engineers building compact, efficient, and high-performance machines, hollow shaft motors provide a powerful and versatile foundation.

Types of Hollow Shaft Motors

Several motor technologies offer hollow shaft variations. Each serves different performance needs and application environments.

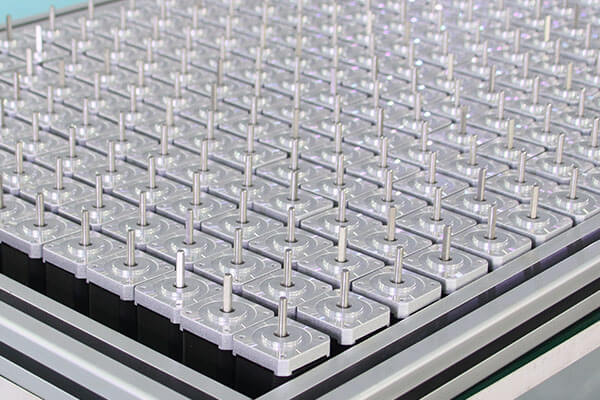

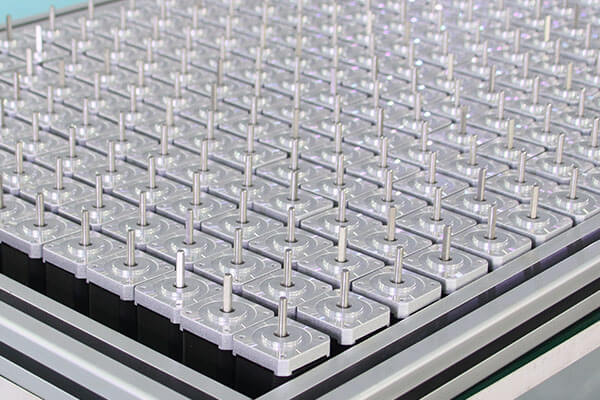

1. Hollow Shaft Stepper Motors

Known for high precision and open-loop control, hollow shaft stepper motors are ideal for:

The hollow core allows direct coupling to threaded rods or lead screws.

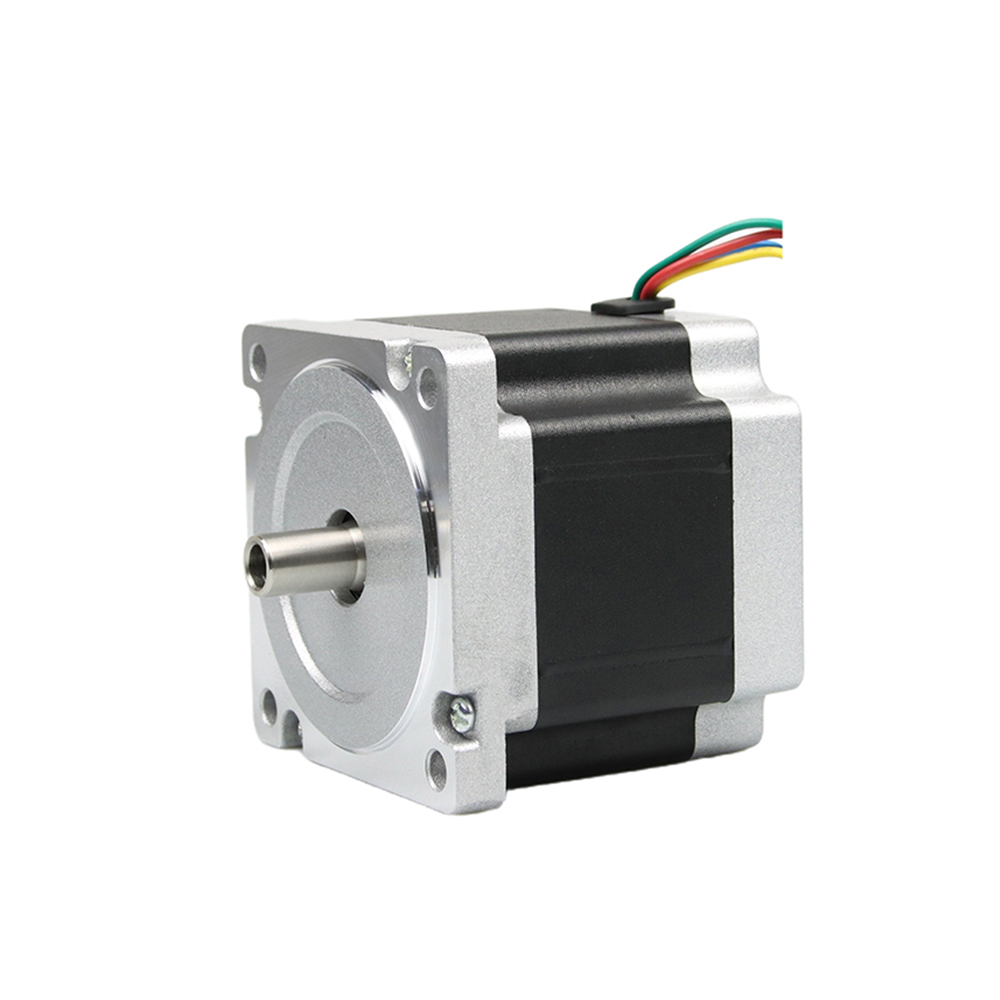

2. Hollow Shaft Servo Motors

These motors deliver high torque, precise speed control, and advanced feedback capabilities. They are widely used in:

Servo versions often integrate high-resolution encoders.

3. Hollow Shaft Brushless DC Motors (BLDC)

BLDC hollow shaft motors provide:

High efficiency

Long life

Silent operation

Low thermal load

They are common in medical devices, lab automation, and compact robotic units.

4. Direct-Drive Hollow Shaft Motors

These motors eliminate gearboxes and link directly to the load. Benefits include:

Zero backlash

Smooth motion

Very high precision

Minimal maintenance

They are used in semiconductor manufacturing, robotic arms, and precision rotary stages.

Engineering Applications of Hollow Shaft Motors

Hollow shaft motors play a critical role across numerous industries due to their flexibility and mechanical advantages.

Robotics

Robotic joints and articulated arms rely on hollow shaft motors for:

They are essential in collaborative robots (cobots).

CNC Machinery and Automation

In CNC rotary tables and positioning systems, the hollow shaft allows:

Medical and Laboratory Equipment

Hollow shafts enable clinical and scientific machines to incorporate:

This supports sterilized environments and smooth operation.

Surveillance, Aerospace, and Defense

Gimbal systems, antennas, and satellite components benefit from:

Packaging and Industrial Machinery

Hollow shaft motors provide adjustable mounting and robust performance required for high-speed manufacturing environments.

Choosing the Right Hollow Shaft Motor for Your System

When selecting a hollow shaft motor, engineers should consider:

1. Bore Diameter Requirements

The internal hollow size must accommodate your:

Cable bundle

Shaft coupling

Tubing

Mechanical components

2. Torque and Speed Specifications

Select according to:

Load requirements

Acceleration needs

Duty cycle

Expected precision

3. Motor Type

Choose between:

Stepper (simpler, cost-effective)

Servo (high performance)

BLDC (efficient, compact)

Direct drive (maximum precision)

4. Environmental Conditions

Consider:

5. Integration and Mounting

Verify compatibility with:

Gearboxes

Harmonic drives

Bearings

Feedback sensors

The right combination ensures long-term reliability and optimal mechanical synergy.

Conclusion

A hollow shaft motor is one of the most innovative solutions in modern motion engineering, providing unique advantages in compactness, cable management, integration flexibility, and precise motion control. Its ability to combine torque output with a central pass-through channel makes it indispensable in robotics, CNC systems, medical devices, and advanced industrial automation.

Engineers who understand the design principles and application benefits of hollow shaft motors can build smarter, more reliable, and more efficient motion systems that push the boundaries of performance and innovation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català