Stepper motors are essential components in modern automation, robotics, and CNC machinery due to their precision, repeatability, and control. Among the various types available, the distinction between open-loop and closed-loop stepper motors is crucial for determining the best fit for an application. In this article, we will dive deep into their operation principles, performance characteristics, advantages, disadvantages, and real-world applications, providing a complete understanding of how these two systems differ and when to use each one.

Understanding the Basics of Stepper Motors

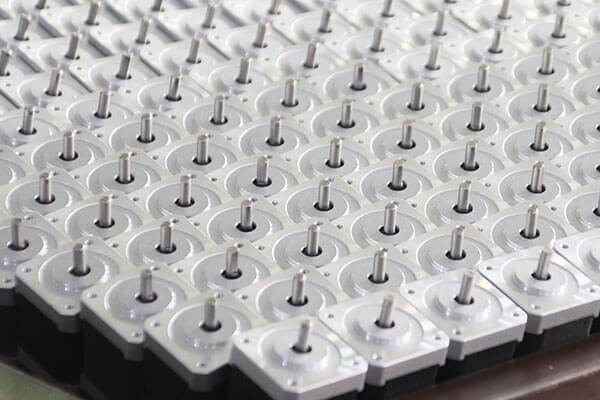

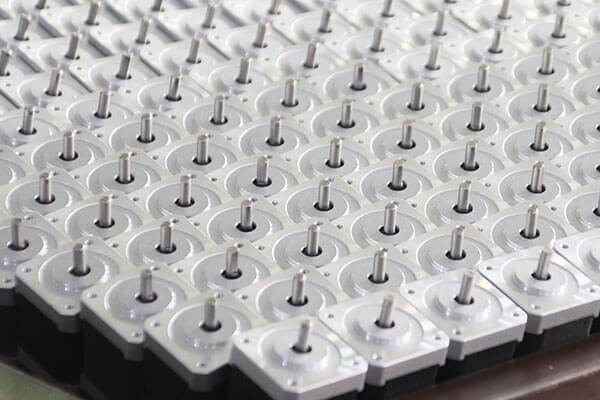

Stepper motors are among the most essential components in modern automation, robotics, and precision control systems. They are specifically designed to convert electrical pulses into mechanical movement, enabling highly accurate positioning and speed control without the need for complex feedback systems. In this comprehensive guide, we will explore the working principles, structure, types, and applications of stepper motors to help you understand why they are widely used in today's technology-driven world.

What Is a Stepper Motor?

A stepper motor is an electromechanical device that divides a full rotation into a large number of equal steps. Each pulse of electrical current moves the motor shaft by one of these steps. This unique characteristic allows stepper motors to achieve precise control of angular position, speed, and acceleration, making them ideal for automation and motion control systems.

Unlike traditional DC motors that rotate continuously when power is applied, stepper motors move in discrete increments. The rotation angle per step depends on the motor design, and the total rotation is determined by the number of pulses sent to the motor.

How a Stepper Motor Works

The basic working principle of a stepper motor is based on electromagnetic induction. When electric current passes through the coils of the stator (the stationary part), it generates a magnetic field that attracts the teeth of the rotor (the rotating part). By energizing the coils in a precise sequence, the rotor moves step-by-step in a controlled direction.

Each pulse sent from the driver energizes a new set of coils, causing the rotor to align with the magnetic field. The speed of rotation is determined by the frequency of pulses, and the direction of rotation depends on the order of coil activation.

In simple terms:

Key Components of a Stepper Motor

Stator – The stationary outer section of the motor that contains multiple electromagnetic coils.

Rotor – The rotating part that has either permanent magnets or soft iron teeth.

Windings/Coils – Wires wound around the stator poles that generate magnetic fields when energized.

Shaft – The central axis connected to the rotor, which performs the mechanical rotation.

Driver/Controller – The electronic circuit that sends the pulse signals to control the stepper motor's movement.

These components work together to ensure accurate step movement and precise control of position.

Types of Stepper Motors

Stepper motors come in various designs, each suited for different performance requirements. The three most common types are:

1. Permanent Magnet Stepper Motor (PM Stepper)

This type uses a permanent magnet rotor and operates through magnetic attraction and repulsion. It provides good holding torque and is used in low-speed applications such as instruments and simple automation devices.

2. Variable Reluctance Stepper Motor (VR Stepper)

A VR stepper motor has a soft iron rotor with teeth that align with the magnetic field of the stator. It offers high stepping accuracy but lower torque than PM types. It is commonly used in applications that require fine angular resolution.

3. Hybrid Stepper Motor

The hybrid stepper combines the features of PM and VR types. It has both a toothed rotor and a permanent magnet, allowing it to deliver high torque, better precision, and smoother motion. Hybrid steppers are widely used in CNC machines, 3D printers, and robotics.

Key Features of Stepper Motors

Precise Positioning: Each pulse corresponds to an exact step, enabling accurate positioning without feedback systems.

Repeatability: Stepper motors can return to a specific position consistently.

Excellent Low-Speed Torque: They deliver high torque at low speeds, ideal for direct-drive applications.

Simple Open-Loop Control: No need for encoders or feedback mechanisms for most basic tasks.

Reliability and Durability: Stepper motors have no brushes, resulting in longer operational life and minimal maintenance.

Step Angle and Resolution

The step angle defines how much the shaft rotates with each step. It is calculated using the formula:

Step Angle=360°Number of Steps per Revolution\text{Step Angle} = \frac{360°}{\text{Number of Steps per Revolution}}

Step Angle=Number of Steps per Revolution360°

For example:

The smaller the step angle, the higher the resolution and the smoother the motion.

Advantages of Stepper Motors

Excellent Positioning Control: Ideal for applications requiring precise angular control.

Open-Loop Operation: Eliminates the need for feedback sensors, reducing cost and complexity.

High Torque at Low Speed: Performs efficiently without additional gear reduction.

Reliable and Robust Design: No brushes or commutators, reducing wear and extending lifespan.

Compatibility with Digital Control: Easily integrated with microcontrollers and pulse generators.

Limitations of Stepper Motors

Limited Speed Range: Torque decreases as speed increases.

Possible Step Loss: Without feedback, missed steps can lead to position errors under high loads.

Resonance Issues: Stepper motors may vibrate at certain speeds.

Power Inefficiency: They draw constant current even when stationary, causing heat buildup.

Despite these limitations, stepper motors remain one of the most cost-effective solutions for precision control in various applications.

Applications of Stepper Motors

Stepper motors are widely used in industries that demand accuracy, repeatability, and controlled motion. Common applications include:

3D Printers: For accurate positioning of print heads and beds.

CNC Machines: For precise tool movement and cutting paths.

Robotics: To control arm joints and actuators.

Camera Systems: For smooth pan, tilt, and focus adjustments.

Medical Devices: For syringe pumps, imaging systems, and diagnostic tools.

Textile and Printing Machines: For fabric feeding and roller control.

In each of these applications, the ability to control motion with digital precision makes stepper motors invaluable.

Conclusion

Understanding the basics of stepper motors is essential for anyone working with motion control, automation, or robotics. These motors offer high precision, excellent reliability, and ease of control, making them one of the most versatile actuators in modern engineering. By learning how they work, their types, and their strengths, you can choose the right motor for your next project and achieve optimal performance.

What Is an Open-Loop Stepper Motor System?

An open-loop stepper motor system operates without any position feedback. It assumes that the motor moves exactly as commanded by the control pulses sent from the driver.

When a controller sends a specific number of pulses to the motor driver, each pulse corresponds to a single step. The motor moves one step for every pulse, and the system assumes perfect execution. There is no mechanism to verify if the motor actually reached the intended position.

Key Characteristics of Open-Loop Systems

No feedback sensors (no encoder or position sensor)

Simpler design and lower cost

Control is based purely on command pulses

Prone to missed steps under high load or acceleration

Works best for low- to medium-speed applications

Advantages of Open-Loop Stepper Motors

Cost-Effective Solution: Without encoders or sensors, open-loop systems are more affordable to implement and maintain.

Simplified Control Electronics: The lack of feedback reduces wiring complexity and system configuration.

High Reliability in Predictable Loads: For applications with stable and predictable mechanical loads, open-loop systems perform reliably.

Precise Positioning in Controlled Environments: When properly tuned, open-loop motors can deliver accurate results at low speeds.

Disadvantages of Open-Loop Stepper Motors

No Error Correction: If steps are missed due to overload or acceleration, the system cannot detect or correct them.

Resonance and Vibration Issues: At certain speeds, stepper motors can resonate, reducing performance and increasing noise.

Limited Speed and Torque: Stepper torque decreases with higher speed, making it unsuitable for high-performance tasks.

Overheating Risk: Continuous operation at high torque may cause overheating since current remains constant regardless of load.

What Is a Closed-Loop Stepper Motor System?

A closed-loop stepper motor system integrates a feedback mechanism, typically an encoder, to continuously monitor the motor's position, speed, and direction. The feedback is sent back to the controller, allowing it to compare actual movement with the commanded movement in real-time.

If any discrepancy is detected, the controller adjusts the current or speed to correct the motor's position instantly. This feedback loop transforms the stepper motor into a hybrid system that combines the precision of a stepper motor with the dynamic performance of a servo system.

Key Characteristics of Closed-Loop Systems

Equipped with an encoder or sensor

Real-time position correction

Higher torque utilization and smoother motion

Reduced vibration and noise

Capable of high-speed operation

No Lost Steps: The encoder feedback ensures the motor always reaches the desired position, eliminating step loss.

Higher Efficiency: Current is dynamically adjusted according to load, reducing heat generation and improving efficiency.

Increased Torque at Higher Speeds: Feedback allows better control, enabling the motor to operate effectively at higher RPMs.

Quieter and Smoother Operation: Advanced control algorithms reduce resonance and mechanical vibration.

Better Dynamic Response: Closed-loop systems adapt to changes in load instantly, maintaining accuracy and stability.

Higher Cost: The addition of encoders and advanced drivers increases overall system cost.

More Complex Setup: Requires tuning and proper integration between the encoder and driver.

Slightly Larger Footprint: Additional components make the system bulkier than open-loop alternatives.

Performance Comparison: Open-Loop vs. Closed-Loop Stepper Motors

| Feature | Open-Loop Stepper Motor | Closed-Loop Stepper Motor |

| Feedback System | None | Encoder-based feedback |

| Position Accuracy | Assumed (no verification) | Verified and corrected |

| Torque at High Speed | Drops significantly | Maintained effectively |

| Heat Generation | High (constant current) | Lower (current adjusted by load) |

| Risk of Step Loss | High under load | Virtually none |

| Noise and Vibration | Higher | Reduced |

| System Cost | Low | Higher |

| Efficiency | Moderate | High |

| Best Application | Low-speed, low-cost projects | High-performance, precision systems |

Applications of Open-Loop Stepper Motors

Open-loop systems are ideal for budget-friendly and moderate-performance applications where feedback is not essential. Common uses include:

These applications involve predictable loads and short movements, where the simplicity and cost-efficiency of open-loop control provide significant advantages.

Applications of Closed-Loop Stepper Motors

Closed-loop stepper motors excel in demanding, high-precision environments where dynamic load changes and high-speed performance are required. Common applications include:

CNC Milling and Industrial Automation

Robotics and Robotic Arms

Packaging Machinery

Medical Equipment

Printing and Scanning Systems

Precision Motion Control Systems

These use cases demand accurate feedback, smooth motion, and instant error correction, all of which closed-loop systems deliver with superior reliability.

Choosing Between Open-Loop and Closed-Loop Stepper Motors

Selecting the right stepper motor system—open-loop or closed-loop—is a critical decision that directly impacts the performance, accuracy, and efficiency of your motion control application. While both motor types share the same stepping principle, their control methods and operational characteristics differ significantly. Understanding these differences allows engineers, designers, and automation experts to make informed choices based on their project's needs.

This article provides an in-depth comparison between open-loop and closed-loop stepper motors, analyzing their working mechanisms, advantages, disadvantages, and ideal applications to help you select the most suitable system for your application.

Understanding Open-Loop Stepper Motors

An open-loop stepper motor operates without any feedback system. It assumes that the motor moves exactly according to the number of control pulses it receives from the driver. Each electrical pulse corresponds to a single rotational step, meaning that position and speed are determined entirely by the input command signals.

Since the system does not verify whether the motor has actually achieved the commanded position, open-loop control relies heavily on accurate pulse timing and consistent load conditions. This makes it simple, cost-effective, and highly reliable for applications where load variations are minimal.

Advantages of Open-Loop Stepper Motors

Low Cost and Simple Design: Open-loop systems don't require encoders or sensors, making them inexpensive and easy to set up.

Ease of Integration: Fewer components mean reduced wiring and simplified configuration.

High Reliability in Predictable Loads: Excellent for systems with stable, consistent mechanical loads.

Precise Control for Basic Applications: Provides accurate motion as long as the load does not exceed torque limits.

Limitations of Open-Loop Stepper Motors

No Feedback: Missed steps cannot be detected or corrected.

Torque Reduction at High Speed: Torque drops significantly as speed increases.

Overheating: Current remains constant even when the motor is idle or under light load.

Resonance and Vibration: May experience oscillations or noise at certain stepping frequencies.

Open-loop stepper systems are best suited for budget-friendly projects, light-load automation, and low-to-medium-speed operations.

Understanding Closed-Loop Stepper Motors

A closed-loop stepper motor includes a feedback mechanism, typically an encoder or resolver, which continuously monitors the rotor's position, speed, and direction. The feedback data is sent back to the driver, allowing the system to compare commanded motion with actual motion and correct any discrepancies in real time.

This system behaves similarly to a servo motor, combining the precision stepping of a stepper motor with the adaptive control of a servo system. Closed-loop systems offer superior performance, especially in applications requiring high torque, smooth motion, and no missed steps.

Advantages of Closed-Loop Stepper Motors

No Step Loss: The feedback loop ensures precise synchronization between the motor's position and the input command.

High Efficiency and Reduced Heat: Current is automatically adjusted based on load, minimizing power consumption and thermal stress.

Higher Torque at High Speed: Delivers strong torque across a wider speed range compared to open-loop motors.

Smooth and Quiet Operation: Advanced control eliminates resonance and vibration.

Automatic Error Correction: Instantly compensates for disturbances or overloads.

Limitations of Closed-Loop Stepper Motors

Higher Cost: Feedback devices and advanced controllers add to overall system expense.

More Complex Setup: Requires calibration between encoder and controller.

Larger System Footprint: Additional hardware increases size and wiring complexity.

Closed-loop stepper motors are ideal for high-performance, precision-critical applications where reliability and accuracy are non-negotiable.

Key Factors to Consider When Choosing Between Open-Loop and Closed-Loop Systems

1. Performance Requirements

If your application requires high precision, speed, or dynamic response, a closed-loop stepper motor is the superior choice. Open-loop systems perform well under consistent and predictable conditions but can struggle with variable loads or acceleration changes.

2. Budget Constraints

Open-loop systems are significantly more affordable due to their simplicity. For cost-sensitive applications such as hobby projects, educational setups, or small machinery, open-loop control is often sufficient. However, for industrial-grade systems where performance outweighs cost, closed-loop systems justify the investment.

3. Load Conditions

For constant or light loads, open-loop motors are efficient and reliable. When dealing with changing or unpredictable loads, closed-loop systems excel by maintaining torque and accuracy through feedback correction.

4. Speed and Torque Needs

If your application involves high-speed operation or requires constant torque, closed-loop motors outperform open-loop types. They maintain torque across a wider range and avoid stalling under high acceleration.

5. Accuracy and Repeatability

Closed-loop systems ensure perfect position tracking and instant correction, eliminating cumulative errors. For operations demanding tight tolerances, such as CNC machining or robotic actuation, closed-loop control is indispensable.

6. Heat and Efficiency

Open-loop motors draw full current continuously, generating more heat and wasting energy. Closed-loop systems dynamically regulate current, staying cooler and more efficient during operation.

7. Application Complexity

If simplicity, low maintenance, and low cost are priorities, open-loop stepper motors are ideal. If your system involves complex motion, feedback-based correction, or multi-axis synchronization, then closed-loop stepper motors provide the reliability you need.

Comparison Table: Open-Loop vs. Closed-Loop Stepper Motors

| Feature | Open-Loop Stepper Motor | Closed-Loop Stepper Motor |

| Feedback Mechanism | None | Encoder-based feedback |

| Position Accuracy | Assumed (no correction) | Verified and corrected |

| Torque at High Speed | Decreases quickly | Maintained effectively |

| Efficiency | Moderate | High (adaptive current control) |

| Heat Generation | High (constant current) | Low (variable current) |

| Step Loss | Possible | Virtually none |

| Noise and Vibration | Higher | Minimal |

| Cost | Low | Higher |

| Maintenance | Minimal | Moderate (due to sensors) |

| Ideal Use Case | Low-speed, low-cost automation | High-speed, precision control |

When to Use an Open-Loop Stepper Motor

Choose an open-loop system if:

The load is constant and predictable.

High precision feedback is not required.

You are working within a tight budget.

The motor will operate at low to moderate speeds.

Applications include 3D printers, small CNC routers, camera sliders, or textile machinery.

Open-loop motors excel in situations where cost, simplicity, and reliability outweigh the need for feedback correction.

When to Use a Closed-Loop Stepper Motor

Choose a closed-loop system if:

High accuracy and reliability are crucial.

The system faces variable or heavy loads.

Heat management and energy efficiency are priorities.

The motor must run quietly and smoothly.

Applications include industrial automation, robotics, packaging systems, medical devices, and CNC milling.

Closed-loop stepper motors combine stepper precision with servo-like performance, making them the go-to solution for advanced motion control systems.

Choosing between open-loop and closed-loop stepper motors ultimately depends on your application's performance, precision, and budgetary needs. Open-loop motors offer simplicity, affordability, and sufficient control for stable-load tasks, while closed-loop systems provide real-time feedback, superior torque, and reliable accuracy for demanding environments.

If your project prioritizes cost and simplicity, open-loop stepper motors are a smart choice. However, if precision, speed, and error correction are critical, investing in a closed-loop stepper motor will deliver long-term efficiency and dependability.

Conclusion

The difference between open-loop and closed-loop stepper motors lies in feedback and control precision. Open-loop motors offer simplicity and cost savings, ideal for low-demand systems. Closed-loop motors, on the other hand, provide higher accuracy, better efficiency, and no step loss, making them perfect for professional automation and robotics.

Understanding these differences allows engineers and designers to choose the most efficient and cost-effective solution for their specific application.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català