A brushless electric motor represents the modern standard of high-efficiency, high-precision motion control used across automation, electric vehicles, aerospace systems, medical equipment, robotics, and consumer electronics. This motor technology eliminates mechanical commutation and replaces it with advanced electronic control, delivering superior reliability, exceptional power density, minimal maintenance, and unmatched performance stability. We present a complete, technically rich explanation of what a brushless electric motor truly means, how it works, where it is used, and why it dominates modern electromechanical systems.

Definition of a Brushless Electric Motor

A brushless electric motor (BLDC motor) is a type of electric motor that converts electrical energy into mechanical motion using electronic commutation instead of mechanical brushes. It operates with a stator containing windings and a rotor made of permanent magnets, while a motor controller precisely switches the current through the stator coils to produce continuous rotation. By eliminating physical brushes and commutators, a brushless electric motor achieves higher efficiency, greater reliability, lower maintenance, reduced heat generation, and superior speed and torque control compared to traditional brushed motors.

How a Brushless Electric Motor Works

A brushless electric motor (BLDC motor) operates on a fundamentally different principle than traditional brushed motors. Instead of relying on mechanical contact to switch current, it uses electronic commutation, which allows for higher efficiency, precise control, and exceptional durability. Below is a complete and technically accurate explanation of how a brushless electric motor works, from power input to continuous rotation.

Basic Working Principle of a Brushless Electric Motor

At its core, Brushless electric motors work by creating a rotating magnetic field in the stator that continuously pulls the rotor magnets along, producing smooth and controlled motion. The key difference from brushed motors is that all switching of current is performed electronically by a controller, not mechanically by brushes.

The motor contains two main sections:

When electrical power is applied to the stator windings in a controlled sequence, a magnetic field is generated and rotated electronically, forcing the rotor to follow that moving magnetic field.

Role of the Electronic Speed Controller (ESC)

The electronic speed controller (ESC) is the brain of a brushless motor system. It determines:

The ESC converts DC input power into a precisely timed three-phase AC output. This output energizes the stator windings in a rotating pattern that pulls the rotor forward continuously.

By changing:

Pulse width (PWM)

Switching frequency

Phase timing

the controller regulates speed, torque, acceleration, and direction of rotation with extreme precision.

Stator Energization and Magnetic Field Rotation

Inside the stator are three or more sets of copper windings arranged in a circular pattern. The ESC energizes these windings in a specific sequence:

Phase A is energized

Then Phase B is energized

Then Phase C is energized

The cycle repeats continuously

Each energized phase generates a strong electromagnetic field. As the sequence progresses, the magnetic field appears to rotate around the inside of the stator. This rotating magnetic field is what drives the rotor.

This process is called electronic commutation, and it replaces the mechanical commutator found in brushed motors.

Rotor Motion and Permanent Magnet Interaction

The rotor contains permanent magnets, typically made from neodymium or samarium-cobalt, which have extremely high magnetic strength.

As the stator's rotating magnetic field moves:

The north and south poles of the rotor magnets align with the stator field

The rotor is pulled forward

As soon as it moves, the field shifts again

This creates continuous rotation

Because there is no physical electrical contact between rotor and stator, friction is dramatically reduced, allowing:

Higher rotational speeds

Lower energy loss

Minimal wear over time

Rotor Position Detection: Sensors vs Sensorless Control

To switch current at the correct time, the controller must always know the exact position of the rotor. This is done in two ways:

1. Sensor-Based Brushless Motors

These use Hall-effect sensors mounted inside the motor to detect the rotor's magnetic position in real time. The sensors send electrical signals to the controller, allowing:

This approach is common in:

2. Sensorless Brushless Motors

These detect rotor position by monitoring back electromotive force (back-EMF) generated in the stator windings. As the rotor spins, it induces voltage in the unpowered phase, which the controller analyzes to determine position.

Sensorless systems are widely used in:

Cooling fans

Drones

Power tools

They offer:

Lower cost

Simpler construction

High-speed efficiency

Three-Phase Power and Continuous Rotation

A brushless motor is typically driven using three-phase electrical power. The ESC switches these three phases thousands of times per second in a precise pattern. This creates:

A continuously rotating electromagnetic field

Constant rotor attraction

Smooth and uninterrupted torque production

This three-phase system prevents:

Torque ripple

Dead spots

Sudden speed changes

The result is extremely smooth and stable rotation, even at very low or very high speeds.

Speed Control Through Pulse Width Modulation (PWM)

Speed regulation in a brushless motor is achieved using pulse width modulation (PWM). Instead of varying voltage directly, the controller rapidly switches the supply on and off:

PWM allows:

This is why brushless motors are ideal for applications that require:

Torque Production in a Brushless Motor

Torque in a brushless motor is generated by the interaction between the stator's electromagnetic field and the rotor's permanent magnetic field. The amount of torque depends on:

Because electronic commutation can be optimized at every millisecond, brushless motors produce:

Direction Control and Reversing Operation

Changing the direction of a brushless motor is purely an electronic function. By reversing the phase sequence in the controller:

Clockwise rotation becomes counterclockwise

No mechanical switching is required

No electrical arcs or contact erosion occur

This enables:

Instant direction changes

High-speed bidirectional motion

Zero mechanical wear during reversing

Thermal Behavior and Efficiency During Operation

Because there are:

No brushes

No commutator friction

No arcing losses

brushless motors generate significantly less internal heat. Most heat comes only from:

As a result, brushless motors routinely achieve:

85–97% electrical efficiency

Higher continuous torque without overheating

Longer operational life at full load

Closed-Loop Control in Brushless Motor Systems

In advanced systems, brushless motors operate in a closed-loop control environment. This means feedback is continuously sent to the controller from:

Encoders

Hall sensors

Current sensors

Temperature sensors

This allows for:

Micron-level position accuracy

Exact speed regulation

Instant load compensation

Predictive fault detection

Closed-loop brushless systems form the backbone of:

Summary of the Brushless Motor Working Process

Brushless electric motors work through the following continuous cycle:

DC power enters the controller

The controller converts it into three-phase AC

Stator windings are energized in a rotating sequence

A moving magnetic field is generated

The rotor's permanent magnets follow this field

Electronic feedback maintains perfect timing

Torque and speed are controlled digitally in real time

This process allows brushless motors to deliver maximum performance with minimal energy loss and virtually zero maintenance.

Core Components of a Brushless Electric Motor

Brushless electric motors (BLDC motor) are built around a precise combination of mechanical, magnetic, and electronic components that work together to produce efficient, reliable, and accurately controlled motion. Unlike brushed motors, brushless designs eliminate physical commutation and rely on electronic switching, which significantly improves performance and service life. The main components are described below.

1. Stator (Electromagnetic Core)

The stator is the stationary outer part of the motor and serves as the source of the rotating magnetic field. It is made from laminated silicon steel to reduce eddy current losses and contains multiple copper windings arranged in specific phase patterns (typically three-phase). When these windings are energized in sequence by the motor controller, they generate a rotating electromagnetic field that drives the rotor. The quality of the stator directly affects the motor's efficiency, torque output, and thermal performance.

2. Rotor (Permanent Magnet Assembly)

The rotor is the rotating inner component of the motor and contains high-strength permanent magnets, usually made from neodymium (NdFeB) or samarium-cobalt. These magnets interact with the stator’s rotating magnetic field to produce motion. Because the rotor does not require electrical connections, it operates with minimal energy loss, low inertia, and very high mechanical efficiency. The configuration of the rotor strongly influences the motor's speed range, torque density, and response time.

3. Electronic Speed Controller (ESC) or Motor Drive

The electronic speed controller (ESC) is the most critical external component of a brushless motor system. It performs electronic commutation, replacing the function of brushes and a mechanical commutator. The ESC converts DC power into precisely timed three-phase AC signals that energize the stator windings. By adjusting pulse width, current level, and switching sequence, the controller regulates speed, torque, direction, and acceleration with high precision. Advanced controllers also include feedback processing, temperature monitoring, and protection functions.

4. Position Sensors or Sensorless Feedback System

To maintain correct timing of phase switching, the controller must know the exact position of the rotor. This is achieved in two ways. Hall-effect sensors detect the magnetic poles of the rotor and provide real-time position data for accurate low-speed control and smooth startup. In sensorless systems, the controller estimates rotor position using back electromotive force (back-EMF) generated in the stator windings. Both methods allow precise electronic commutation, ensuring smooth and efficient operation.

5. Bearings and Mechanical Support Structure

Precision ball bearings or sleeve bearings support the rotor and allow it to spin freely with minimal friction. These bearings play a major role in the motor’s noise level, efficiency, speed capability, and service life. The motor shaft, housing, and internal support structures maintain accurate mechanical alignment between rotor and stator, which is essential for stable magnetic interaction and vibration-free operation.

6. Motor Housing and Thermal Management System

The motor housing protects internal components from dust, moisture, and mechanical damage. It also acts as a heat dissipation surface, drawing heat away from the stator windings and electronics. Many brushless motors include cooling fins, airflow channels, or integrated liquid cooling jackets to support continuous high-power operation. Effective thermal management is essential for maintaining efficiency, torque stability, and long operational life.

7. Power and Signal Connections

Brushless motors include power terminals for phase connections and additional terminals for sensor feedback, temperature monitoring, and grounding. These electrical interfaces ensure reliable communication between the motor and controller, allowing for real-time feedback, fault detection, and precision control in demanding applications.

Summary

The core components of a brushless electric motor—stator, rotor, electronic controller, position feedback system, bearings, housing, and electrical connections—work together as a fully integrated electromechanical system. This advanced architecture allows brushless motors to deliver high efficiency, precise speed control, low noise, minimal maintenance, and exceptional reliability, making them the preferred choice for modern industrial, automotive, medical, and consumer applications.

Brushless vs Brushed Motor Technology

| Feature | Brushless Motor | Brushed Motor |

| Electrical Contact | None | Carbon brushes |

| Efficiency | Very High | Moderate |

| Maintenance | Near Zero | Frequent |

| Noise Level | Ultra-Low | High |

| Lifespan | Extremely Long | Limited |

| Speed Control | Digitally Precise | Mechanically Limited |

Brushless motors eliminate the primary failure point of brushed motors—the brushes themselves—resulting in vastly improved operational durability.

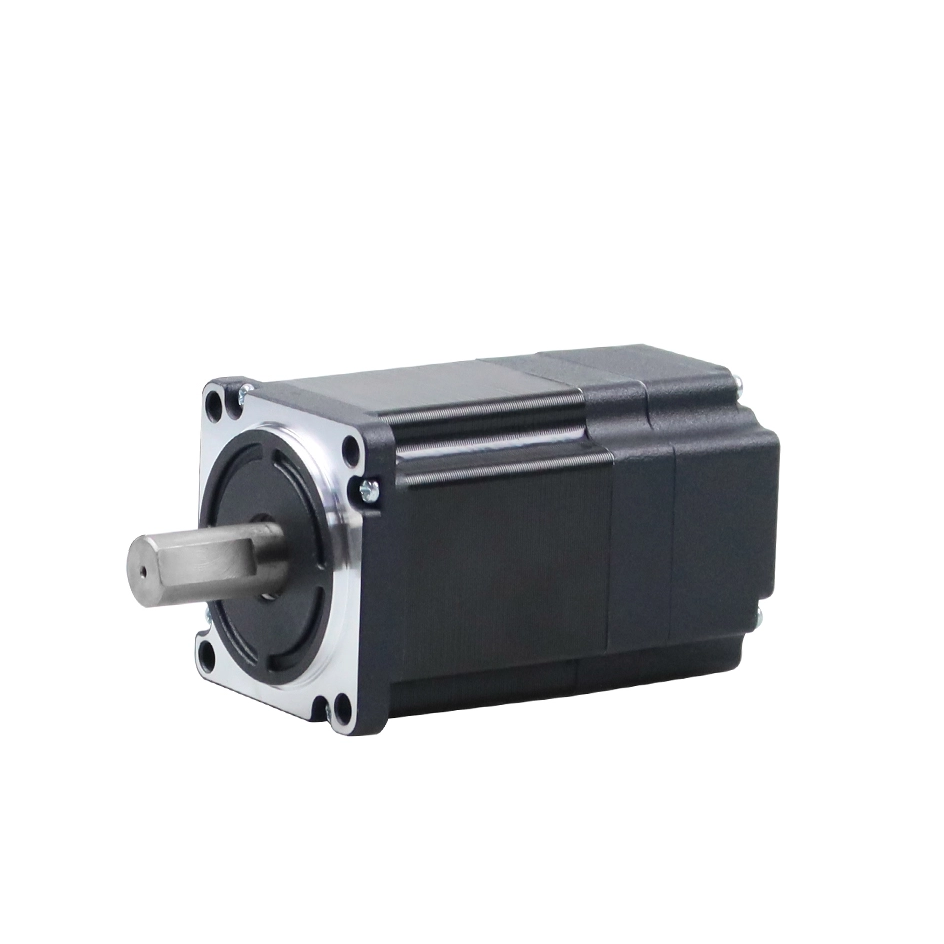

1. Brushless DC Motor (BLDC)

Optimized for efficient speed control, compact size, and battery-powered operation. Common in drones, cooling fans, power tools, and EV traction systems.

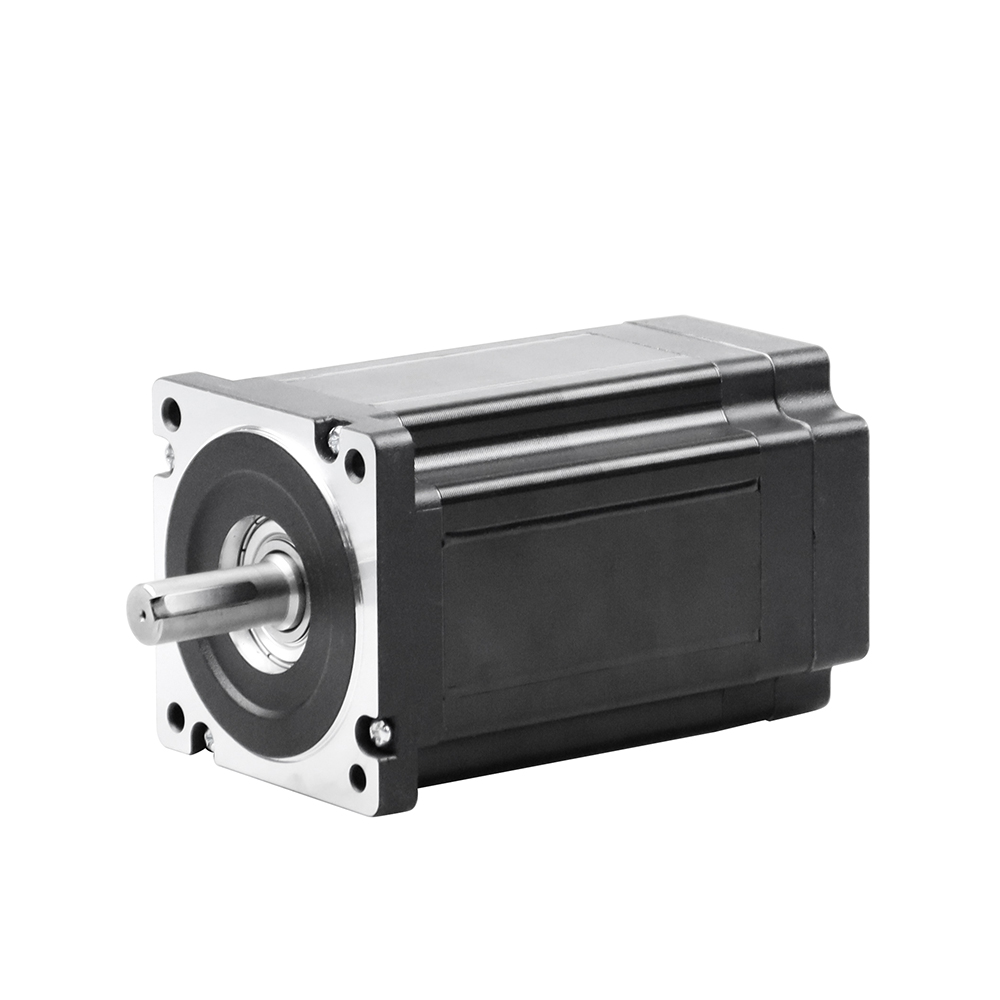

2. Brushless AC Motor (Permanent Magnet Synchronous Motor – PMSM)

Delivers superior torque control and ultra-smooth sinusoidal drive, widely used in industrial servo systems and electric vehicles.

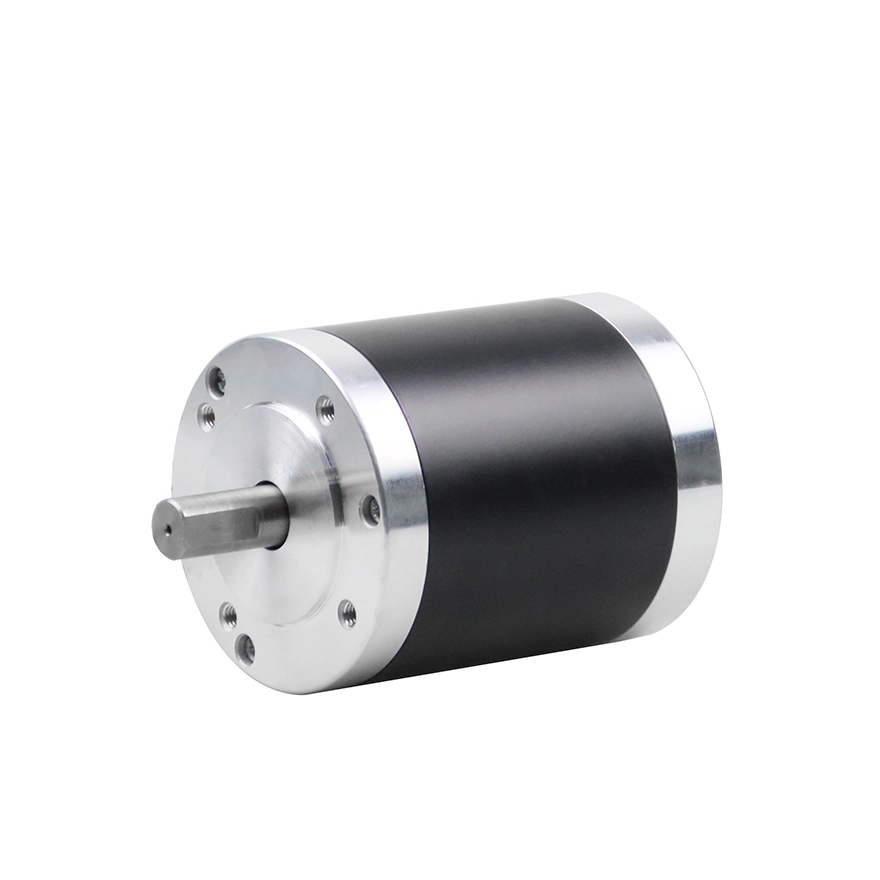

3. Outrunner and Inrunner Brushless Motors

Each configuration is optimized for specific motion and power-delivery requirements.

Key Performance Advantages of Brushless Electric Motors

Brushless motors align with modern engineering demands due to several decisive performance advantages:

Higher Energy Efficiency – Reduced electrical losses increase usable output.

Superior Torque-to-Weight Ratio – More power from smaller motor packages.

Zero Brush Wear – Eliminates performance degradation over time.

Extended Lifespan – Ideal for continuous-duty industrial environments.

Precise Speed Regulation – Maintains RPM stability under changing load.

Greater Power Density – Enables ultra-compact product design.

Improved Thermal Control – Less heat means higher sustained torque output.

These advantages define brushless motors as the professional-grade solution for precision motion systems.

Brushless motors dominate industries where accuracy, reliability, energy efficiency, and compact mechanical design are mission-critical.

Industrial Automation

Electric Vehicles and Transportation

EV traction motors

Electric scooters and bicycles

Hybrid propulsion systems

Autonomous vehicle actuators

Medical Technology

Consumer Electronics

Aerospace and Defense

Brushless motor technology functions as the core motion engine driving the modern digital economy.

Torque, Speed, and Power Control Characteristics

Brushless motors provide exceptional controllability across the entire operating range:

High Starting Torque – Instant response without mechanical lag.

Wide Speed Range – From ultra-slow micro-motion to extreme high-RPM operation.

Linear Torque Output – Stable control under dynamic loads.

Excellent Speed Regulation – Less than 1% deviation in closed-loop systems.

These characteristics enable micro-positioning accuracy measured in microns and angular precision down to arc-seconds.

Efficiency and Power Consumption Analysis

Brushless motors typically operate at 85%–97% electrical efficiency, compared to 65%–80% for brushed designs. This difference produces:

In battery-driven systems, this translates directly into extended operating runtime and reduced charging cycles.

Maintenance and Operational Longevity

The absence of brushes removes:

As a result, Brushless electric motors routinely exceed 20,000 to 50,000 operational hours in industrial duty cycles, with some advanced designs surpassing 100,000 hours in controlled environments.

Noise, Vibration, and Acoustic Performance

Brushless motors operate with:

Significantly lower vibration

Minimal electromagnetic acoustic noise

Near-silent low-speed rotation

These attributes make them ideal for medical equipment, laboratory instruments, and premium consumer devices where acoustic comfort is non-negotiable.

Electronic Control Systems and Smart Integration

Modern brushless motors integrate seamlessly with:

Advanced algorithms such as field-oriented control (FOC) and space vector modulation (SVM) allow:

This transforms brushless motors into digitally intelligent motion platforms.

Environmental and Sustainability Benefits

Brushless motors directly support global energy efficiency and sustainability initiatives:

Lower energy waste

Reduced greenhouse emissions

Longer product lifecycle

Smaller material footprint

Lower overall carbon cost per operating hour

Their efficiency directly supports green manufacturing and clean mobility strategies worldwide.

Future of Brushless Motor Technology

Brushless motor technology continues to evolve through:

AI-assisted control algorithms

Wide-bandgap semiconductor drives (SiC & GaN)

Advanced magnetic composites

Integrated cooling architectures

Ultra-high-speed rotor geometries

These developments further enhance power density, thermal performance, and real-time adaptability, shaping the future of autonomous systems, electrified transportation, and intelligent machines.

Why Brushless Electric Motors Define Modern Motion Control

A brushless electric motor is not simply an incremental upgrade—it represents a fundamental evolution in electromechanical design. The removal of physical commutation enables precision, longevity, efficiency, digital intelligence, and unmatched control fidelity across every performance metric that matters in modern applications.

Brushless motors now define:

They operate as the silent, efficient, and relentless force converting digital commands into real-world motion.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català