The demand for high-precision assembly technologies has never been greater. From consumer electronics to automotive systems and medical devices, industries are under constant pressure to manufacture products that are smaller, lighter, more reliable, and highly integrated. To meet these evolving requirements, Servo motors have become the backbone of next-generation press-fit and bonding equipment.

Unlike traditional actuation systems, servo motors deliver unparalleled accuracy, repeatability, and control, making them the ideal choice for advanced manufacturing environments.

What are integrated Servo Motor ?

An integrated servo motor is a type of servo system where the motor, feedback device (encoder or resolver), servo drive (amplifier), and often a controller are all combined into a single compact unit. Unlike traditional servo systems—where these components are installed separately—integrated Servo motors provide a self-contained solution that simplifies installation, reduces wiring, and improves overall system reliability.

Key Features of Integrated Servo Motors

All-in-One Design

Motor, encoder, and drive electronics housed together.

Eliminates the need for external drives and extensive cabling.

High Precision Control

Closed-loop feedback ensures accurate positioning, speed, and torque.

Ideal for tasks requiring repeatability and fine motion control.

Compact Footprint

Simplified Wiring & Installation

Scalability & Networking

Often supports industrial communication protocols (EtherCAT, CANopen, Modbus, etc.).

Easily integrates into smart manufacturing and Industry 4.0 environments.

Advantages of Integrated Servo Motors

Cost Savings: Reduced wiring, fewer external components, and simplified maintenance.

Improved Reliability: Fewer connections mean fewer failure points.

Energy Efficiency: Optimized motor-drive coordination lowers power consumption.

Flexibility: Can be used in both centralized and decentralized motion control systems.

Compactness: Perfect for applications with limited space.

Applications of Integrated Servo motors

Integrated servo motors are widely used in automation and robotics, where precision and space-saving designs are critical:

Packaging machines (sealing, cutting, labeling).

Robotics (robot joints, pick-and-place systems).

Medical equipment (imaging devices, diagnostic systems).

Textile and printing machines (high-speed positioning tasks).

Material handling systems (conveyors, automated storage, and retrieval systems).

In summary, an integrated servo motor combines motor, drive, and control into one unit, offering precision, efficiency, and simplicity for modern automation systems.

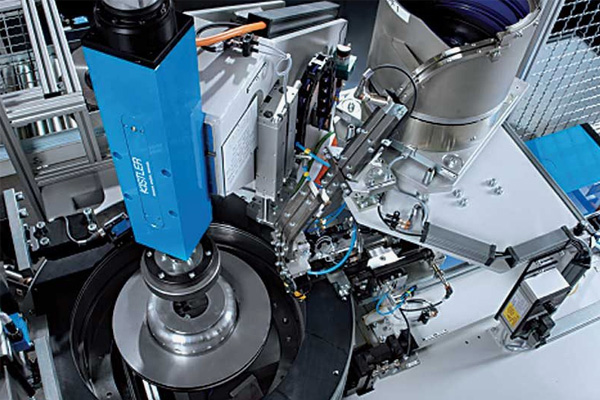

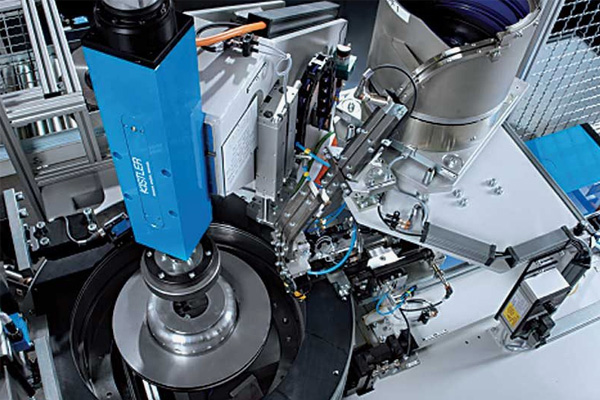

Unmatched Accuracy for Complex Assemblies

One of the greatest advantages of servo motors in press-fit and bonding is their ability to provide micron-level positioning accuracy. Modern assemblies often involve delicate components—such as microchips, sensors, and flexible circuits—that require exact placement without damaging the material. Servo motors achieve this by:

Offering precise torque and speed control.

Ensuring repeatable alignment of parts.

Allowing real-time corrections through closed-loop feedback systems.

This degree of accuracy is critical in industries such as electronics, automotive electronics, and medical device manufacturing, where even minor errors can result in defective products or safety issues.

Programmable Force and Motion Profiles

Servo-driven systems allow manufacturers to program unique motion profiles tailored to specific bonding or press-fit tasks. Unlike pneumatic or hydraulic systems, Servo motors provide variable speed and force curves, ensuring optimal bonding strength and material compatibility.

For example:

Soft materials can be joined with gradual force application.

Rigid parts can be press-fitted with controlled peak force.

Multi-stage assembly can be automated with seamless transitions between force levels.

This programmability not only enhances product quality but also reduces waste and improves throughput.

Enhanced Process Monitoring and Data Collection

Modern servo-driven bonding equipment integrates with digital control systems and Industry 4.0 platforms, enabling manufacturers to:

Track every press-fit or bonding cycle.

Monitor real-time force-displacement curves.

Detect anomalies before they result in defects.

Store production data for quality assurance and regulatory compliance.

This level of visibility is impossible with traditional systems, making servo-driven solutions essential for companies striving for zero-defect manufacturing.

Energy Efficiency and Sustainability

Compared to hydraulic or pneumatic actuation, Servo motors are more energy-efficient. They consume power only when in operation, reducing overall energy demand. Additionally, the absence of fluid-based systems eliminates leaks, contamination risks, and environmental hazards, making servo-driven solutions cleaner and more sustainable.

This efficiency translates into lower operating costs, aligning with global efforts to reduce the carbon footprint of industrial operations.

Flexibility for Rapid Changeovers

Modern manufacturing requires agility. Servo motors allow quick reprogramming of bonding and press-fit processes without the need for complex mechanical adjustments. This flexibility makes it possible to:

Switch between different product assemblies with minimal downtime.

Scale production for new product designs.

Shorten time-to-market for innovative products.

This adaptability is particularly valuable in industries such as consumer electronics, where product lifecycles are short and production requirements change rapidly.

Reliability and Reduced Maintenance

Servo-driven equipment is inherently more reliable than systems dependent on hydraulic or pneumatic components. With fewer moving parts, minimal fluid handling, and advanced self-diagnostic capabilities, Servo motors reduce:

Unexpected breakdowns.

Maintenance intervals.

Total cost of ownership.

For manufacturers, this translates into maximum uptime and higher productivity.

Top 20 Integrated Servo Motor Manufacturers in France

France is home to some of the leading innovators in motion control and automation, with a strong focus on integrated servo motors that combine motor, encoder, drive, and control electronics in a single unit. These solutions are widely used across robotics, packaging, medical devices, aerospace, and automotive manufacturing, providing precision, compact design, and reduced wiring complexity. Below, we highlight the top 20 integrated servo motor manufacturers in France, their profiles, products, and key advantages.

1. Schneider Electric

Company Profile:

A global leading integrated servo motor manufacturers in energy management and automation headquartered in Rueil-Malmaison, France.

Main Products:

Integrated servo motors, Lexium motion series, automation controllers, and industrial drives.

Advantages:

Wide product range, strong global support, advanced digital integration with EcoStruxure platform.

2. Leroy-Somer (Nidec Group)

Company Profile:

Based in Angoulême, Leroy-Somer is part of Nidec, specializing in motors and drives.

Main Products:

Integrated servo motors, synchronous and asynchronous motors, automation solutions.

Advantages:

High energy efficiency, durability, and solutions for demanding industrial environments.

3. Cedrat Technologies

Company Profile:

Located in Meylan, Cedrat specializes in mechatronics, smart actuators, and integrated motion solutions.

Main Products:

Integrated servo actuators, compact servo drives, precision motion systems.

Advantages:

Strong expertise in aerospace, defense, and scientific applications requiring high reliability.

4. Soprolec

Company Profile:

A French automation distributor and integrated servo motor manufacturer providing servo motors and integrated motion control solutions.

Main Products:

Integrated servo motors, stepper-servo systems, motion control modules.

Advantages:

Wide industry partnerships, strong customer support, tailored automation solutions.

5. Actomotion

Company Profile:

French motion control integrated servo motor manufacturer specializing in automation and servo-driven systems.

Main Products:

Integrated servo motors, motion controllers, precision actuators.

Advantages:

High flexibility, custom integration for industrial automation and robotics.

6. Technic-Achat

Company Profile:

Integrated servo motor manufacturers of automation and industrial equipment across France.

Main Products:

Integrated servo motors, servo drives, PLCs, and industrial control systems.

Advantages:

Competitive pricing, fast delivery, and broad product availability.

7. Precise Automation (France Division)

Company Profile:

Specializes in robotics and motion control, offering integrated servo systems for automation.

Main Products:

Integrated servo motors for robotics and handling systems.

Advantages:

Advanced robotics integration, compact and reliable designs.

8. Sepro Group

Company Profile:

Headquartered in La Roche-sur-Yon, Sepro is a leading integrated servo motor manufacturer in robotic solutions for injection molding.

Main Products:

Integrated servo-driven robotic arms, servo systems.

Advantages:

Strong expertise in plastics automation, energy-efficient servo systems.

9. Groupe AEM

Company Profile:

French integrated servo motor manufacturer of electric motors and automation solutions.

Main Products:

Integrated servo motors, custom servo systems, industrial drives.

Advantages:

Tailored engineering, robust industrial-grade solutions.

10. Axem Technology Motion Systems

Company Profile:

Specializes in RFID and motion technology, with integrated servo solutions for automation.

Main Products:

Integrated servo motors, motion control hardware.

Advantages:

Compact integrated designs, focus on IoT and automation connectivity.

11. Delta Equipement (France)

Company Profile:

A leading French integrated servo motor manufacturer and integrator of automation equipment.

Main Products:

Integrated servo motors, AC drives, automation components.

Advantages:

Strong technical support and partnerships with global brands.

12. ECA Group (now Exail Technologies)

Company Profile:

Known for robotics, automation, and defense systems, with advanced servo integration.

Main Products:

Integrated servo motors, robotic motion systems, marine automation.

Advantages:

Expertise in harsh environments, military and aerospace reliability.

13. LEROY Automation

Company Profile:

French integrated servo motor manufacturer focusing on automation and motion systems for rail and industrial applications.

Main Products:

Integrated servo drives, servo motors, controllers.

Advantages:

High reliability, specialized in transport and energy sectors.

14. Systèmes d’Automation Industrielle (SAI)

Company Profile:

French integrated servo motor manufacturer specializing in industrial automation and servo technologies.

Main Products:

Integrated servo motors, motion control software, PLCs.

Advantages:

Custom automation, flexible integration across industries.

15. JDC Mécatronique

Company Profile:

A French mechatronics integrated servo motor manufacturer providing motion and automation solutions.

Main Products:

Integrated servo motors, step-servo systems, linear motion drives.

Advantages:

Innovative mechatronic designs, precision control systems.

16. B&R Automation (France Division)

Company Profile:

Austrian automation giant with a strong French presence, part of ABB Group.

Main Products:

Integrated servo motors (ACOPOS series), automation software, controls.

Advantages:

Seamless integration with automation platforms, Industry 4.0 readiness.

17. OMRON France

Company Profile:

Global automation leading integrated servo motor manufacturer with a strong presence in France.

Main Products:

Integrated servo motors, Sysmac motion controllers, robotics.

Advantages:

Advanced motion control, strong digital integration, global support.

18. Stäubli Robotics (France HQ)

Company Profile:

Headquartered in Faverges, Stäubli specializes in robotics and mechatronics.

Main Products:

Integrated servo-driven robotic arms and actuators.

Advantages:

High-speed, high-precision servo solutions for robotics and automation.

19. Besfoc

Company Profile:

A global leading integrated servo motor manufacturer in motion and control technologies with French operations.

Main Products:

Integrated servo motors, servo drives, actuators.

Advantages:

Strong engineering support, rugged and scalable motion solutions.

20. Siemens France (Motion Division)

Company Profile:

Global industrial automation leading integrated servo motor manufacturer with integrated servo offerings.

Main Products:

SIMOTICS integrated servo motors, SINAMICS drives.

Advantages:

Industry 4.0 compatibility, global support, advanced digital twins integration.

Conclusion

France stands as a hub for servo motor innovation, with companies ranging from global leaders like Schneider Electric, Leroy-Somer, and Siemens France to specialized firms like Cedrat Technologies and Sepro Group. These manufacturers are pushing the boundaries of integrated servo motor design, delivering compact, reliable, and intelligent motion solutions to power the next generation of automation and robotics.

Driving the Future of Precision Assembly

Servo motors are not just an incremental improvement—they are a transformational technology enabling the next era of smart, precise, and efficient press-fit and bonding equipment. Their unmatched control, programmability, and integration with digital platforms position them as the foundation for future-ready manufacturing systems.

Industries that adopt servo-driven bonding technologies will enjoy higher quality, greater flexibility, lower costs, and enhanced sustainability, gaining a competitive edge in an increasingly demanding global market.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català