In the realm of automated entry and closure systems, the silent, relentless workhorse driving innovation and reliability is the integrated brushless DC (BLDC) motor. We are at the forefront of this motion technology, engineering solutions that redefine performance standards for automatic sliding doors, swing doors, revolving doors, and high-performance automated windows. This comprehensive exploration delves into the intrinsic superiority of integrated BLDC motor systems, elucidating why they have become the undisputed choice for modern architects, facility managers, and system integrators demanding longevity, efficiency, and precision.

Understanding the fundamental architecture of an integrated brushless DC (BLDC) motor system is essential to appreciating its revolutionary impact on automatic door and window applications. We design these systems not as simple components, but as holistic, intelligent motion platforms where every element is optimized for synergy, reliability, and peak performance. This deep dive into the core architecture elucidates the sophisticated engineering that transforms electrical energy into flawless, silent, and reliable mechanical motion.

The Paradigm of Integration: From Discrete Components to a Unified Motion Subsystem

Traditional motor-drive systems rely on a collection of disparate parts: a separate motor, a physically detached controller housed elsewhere, external sensor wiring, and often a distinct power supply module. This approach introduces multiple points of potential failure, electromagnetic compatibility challenges, complex installation procedures, and significant spatial demands.

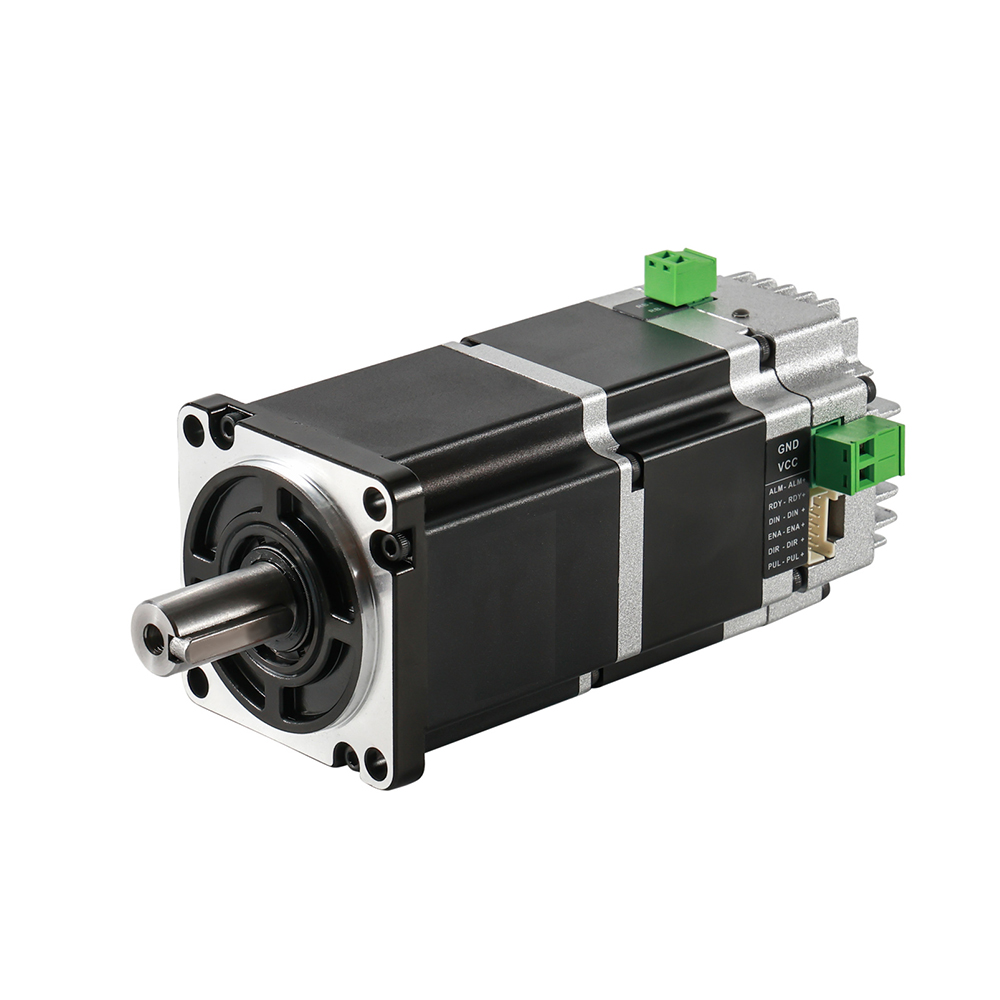

The integrated BLDC motor system shatters this paradigm. We engineer it as a self-contained electromechanical unit where the boundaries between power, control, and motion are seamlessly erased. This integration manifests in several critical layers:

The Electromagnetic Core (Stator and Rotor):

At the physical heart lies a high-grade, laminated steel stator wound with precision copper coils. The rotor is populated with powerful permanent magnets, typically constructed from rare-earth materials like Neodymium (NdFeB) for maximum magnetic flux density. The absence of any electrical connection to the rotor is the defining "brushless" characteristic, eliminating all brush-related wear.

The Integrated Controller & Power Electronics:

Mounted directly onto or within the motor housing is the printed circuit board assembly (PCBA) that functions as the system's brain and nervous system. This is not a simple switch; it is a sophisticated microcontroller-based unit managing:

Pulse-Width Modulation (PWM) for precise voltage and current control to the windings.

The Electronic Commutation Algorithm that sequentially energizes the stator phases to create a rotating magnetic field, pulling the permanent magnet rotor.

Protection Circuits for over-current, over-temperature, over-voltage, and under-voltage scenarios.

Communication Stacks to manage input signals and fieldbus protocols.

The Sensor Feedback System:

Critical for precise control is real-time knowledge of the rotor's position. This is achieved via integrated sensors. The most common configurations are:

Hall-Effect Sensors: Typically three sensors embedded in the stator, providing digital position feedback for six-step commutation. This is robust and cost-effective for many door and window applications.

High-Resolution Optical or Magnetic Encoders: These provide hundreds or thousands of pulses per revolution, enabling sinusoidal or field-oriented control (FOC). FOC is superior, providing exceptionally smooth, quiet, and efficient operation with minimal torque ripple, which is crucial for ultra-high-end automatic doors and precision window positioning.

The Mechanical Power Transmission Interface:

The motor's high-speed, low-torque output is unsuitable for direct door or window movement. Therefore, a high-efficiency, low-backlash gearbox is integral to the unit. We typically employ:

Planetary Gearheads: Favored for their compact size, high torque density, excellent efficiency, and low audible noise. Their coaxial design is ideal for integrated packages.

Worm Gear Drives: Used where very high gear ratios and inherent back-drive prevention (self-locking) are required, such as in certain window holding applications, though with a trade-off in efficiency.

Thermal Management Architecture:

Continuous operation generates heat. An integrated design allows for a holistic thermal strategy. We engineer optimized thermal pathways, using the motor housing as a heat sink, designing airflow channels, and in some cases, incorporating thermal interface materials to conduct heat away from the power electronics to the outer casing, ensuring stable operation within the specified ambient temperature range.

Unrivaled Advantages for Automatic Door Applications

For automatic doors, performance parameters are non-negotiable. Safety, smoothness, reliability, and energy consumption directly impact user experience and total cost of ownership. Integrated BLDC Motors excel across all these domains.

Exceptional Reliability and Longevity:

The absence of brushes eradicates the primary cause of wear in conventional motors. There are no brushes to arc, wear down, or generate conductive dust that can foul other components. This results in a dramatically extended operational lifespan, often exceeding 50,000 to 100,000 hours of maintenance-free operation. For a door cycling hundreds of times daily, this translates to decades of service, minimizing downtime and maintenance costs.

Superior Control and Smooth Operation:

The integrated controller provides exquisite command over torque and speed. Doors can accelerate with gentle precision, maintain a consistent travel speed, and decelerate to a soft, quiet stop. This smooth motion profile reduces mechanical stress on gears, belts, and the door structure itself, further enhancing system longevity. It also enables compliance with stringent safety standards, allowing for sensitive obstruction detection; the motor can instantly reverse or stop upon sensing an anomaly in torque or speed, a response facilitated by the motor's inherent controllability.

High Efficiency and Energy Savings:

BLDC motors convert electrical energy to mechanical motion with exceptional efficiency, often exceeding 80-90%. This is crucial for automatic doors, which may operate continuously in high-traffic environments. The efficiency gain is twofold: reduced operational cost for electricity and lower heat generation. Cooler operation preserves the integrity of internal electronics and lubricants, contributing to the system's reliability. In solar-powered or energy-neutral building applications, this efficiency is absolutely critical.

Compact Power Density and Design Flexibility:

Integrated BLDC packs tremendous power into a small form factor. This high power density allows designers to create slimmer, more aesthetically pleasing door headers and window frames without sacrificing performance. The modular nature of these units provides flexibility for different door sizes and weights, from lightweight interior sliding doors to heavy, wind-resistant exterior models.

Critical Performance in Automated Window Systems

The integration of automated window systems into modern facades, skylights, and smart buildings demands motion solutions that exceed basic open-and-close functionality. We engineer integrated brushless DC (BLDC) motor systems to deliver a suite of critical performance characteristics essential for safe, reliable, and intelligent operation in these demanding applications.

Precision Positioning and Repeatability

Automated windows serve precise functions: natural ventilation control, smoke evacuation, daylight harvesting, and climate management. This requires absolute positional accuracy. Our integrated systems, equipped with high-resolution encoders, provide closed-loop feedback control. This allows for programming multiple preset stops with millimeter-level repeatability, ensuring consistent performance over tens of thousands of cycles, regardless of changing environmental factors like wind pressure.

High Holding Torque and Wind Load Resistance

A window must hold its position securely against significant external forces. Our motor systems are specified to provide ample static holding torque, often enhanced by a worm gear drive's inherent self-locking characteristic. This design ensures windows remain in a commanded position during high winds and maintain a tight, energy-efficient seal when fully closed, without relying on constant motor power.

Silent Operation for Occupant Comfort

Noise pollution is unacceptable in offices, healthcare facilities, and residences. The brushless design, combined with precision-machined planetary gearheads and optimized motion profiles, results in exceptionally low acoustic emissions. Operation is virtually silent, ensuring automation enhances comfort without distraction.

Duty Cycle and Environmental Resilience

Automated windows face diverse conditions. Motor systems must be rated for the required duty cycle—whether frequent adjustment or sustained static holding—with robust thermal management. Furthermore, a high Ingress Protection (IP) rating is non-negotiable for exterior or wash-down applications to prevent failure from dust and moisture.

Key Performance Specification Table

| Performance Parameter | Why It's Critical | How Our Integrated BLDC Motor Delivers It |

| Positional Accuracy | Ensures consistent ventilation, sealing, and aesthetic alignment. | High-resolution encoder feedback & advanced motion controller. |

| Holding Torque | Maintains position against wind; ensures sealed closure. | Optimized motor-gearbox combination; self-locking worm gear options. |

| Noise Level | Preserves occupant comfort and peaceful environments. | Brushless design, precision gearing, and smooth S-curve motion profiling. |

| Duty Cycle & IP Rating | Guarantees long-term reliability in real-world conditions. | Robust thermal design, sealed bearings, and gasketed housings (e.g., IP65). |

| System Integration | Enables responsive, energy-efficient building automation. | Native support for BMS protocols (BACnet, Modbus) and IoT connectivity. |

Intelligent System Integration and Safety

Performance extends beyond mechanics. Native support for building management protocols allows windows to become responsive elements of a building's ecosystem, reacting to sensors for rain, wind, temperature, and air quality. Integrated safety features, including torque-limiting obstacle detection, ensure safe operation by stopping or reversing upon encountering an obstruction, protecting both people and property.

Key Selection Criteria for System Integrators

Selecting the appropriate Integrated BLDC Motor requires a detailed analysis of the application's specific demands. We advise a rigorous evaluation of the following parameters:

Rated Torque and Speed:

Calculate the required torque at the driven element (door panel or window sash), accounting for weight, friction, and any counterbalance systems. The motor must provide adequate torque across the entire speed range, with a safety factor for adverse conditions like increased friction or wind pressure.

Duty Cycle and Thermal Management:

Automatic doors have intermittent duty cycles, while windows may hold position for extended periods. The motor's thermal design must dissipate heat effectively during its expected duty cycle to prevent overheating and performance derating. Look for motors with efficient thermal pathways and rated for continuous duty at your required torque level.

Protection Rating (IP Code):

The ingress protection rating is vital. Motors for exterior doors or windows require a high IP rating (e.g., IP54, IP65) to resist dust and water ingress. Interior applications may suffice with a lower rating, but protection against dust remains important for longevity.

Gearbox Type and Ratio:

The gearbox is the torque amplifier and motion adapter. Planetary gearboxes offer high efficiency, compactness, and lower backlash, ideal for precise positioning. Worm gearboxes provide very high reduction ratios and inherent self-locking, beneficial for holding loads without power but are less efficient. The choice directly impacts performance, efficiency, and noise.

Control Interface and Programmability:

Determine the required level of integration. Does the application need simple digital I/O (open/close/stop) or analog speed control? Or is a full-fieldbus connection needed for BMS integration? The programmability of acceleration/deceleration ramps, current limits, and soft start/stop functions is essential for fine-tuning system behavior.

Safety and Redundancy Features:

For life-safety applications like fire/smoke evacuation windows or accessible entrances, additional features like redundant position sensing, manual override capabilities, and fail-safe operation in power loss scenarios must be considered and engineered into the system.

The Future of Automation: Smart, Connected, and Sustainable

The evolution of integrated BLDC motors is inextricably linked to the trends shaping construction and automation: connectivity, intelligence, and sustainability. The next generation of these systems goes beyond simple motion control.

We are developing motors with embedded predictive maintenance algorithms. By continuously monitoring parameters like current draw, temperature, and vibration, the motor itself can alert operators to impending wear on belts, gears, or guides before a failure occurs, transforming maintenance from a schedule-based chore to a condition-based necessity.

Furthermore, the role in sustainable building design is expanding. Automated windows and doors equipped with intelligent BLDC drives are critical components in passive climate control and natural ventilation strategies. They dynamically respond to environmental sensors, optimizing indoor air quality and temperature while minimizing HVAC energy consumption, contributing directly to LEED and BREEAM certification goals.

Conclusion: The Invisible Standard of Modern Automation

Integrated Brushless DC motor technology is not merely an option for high-performance automatic doors and windows; it has become the industry standard for any application where reliability, control, efficiency, and quiet operation are valued. The initial investment is swiftly offset by reduced energy bills, near-elimination of maintenance, and flawless operation over a product lifecycle measured in decades.

We dedicate our engineering expertise to perfecting this technology, providing robust, intelligent, and adaptable motion solutions that form the reliable, silent backbone of the automated built environment. From the grand entrance of a commercial tower to the smart windows of a sustainable home, integrated BLDC motors ensure seamless, safe, and efficient operation, meeting the highest expectations of today's automated world.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català