Understanding Maximum Shear Stress in Hollow Shaft Motors

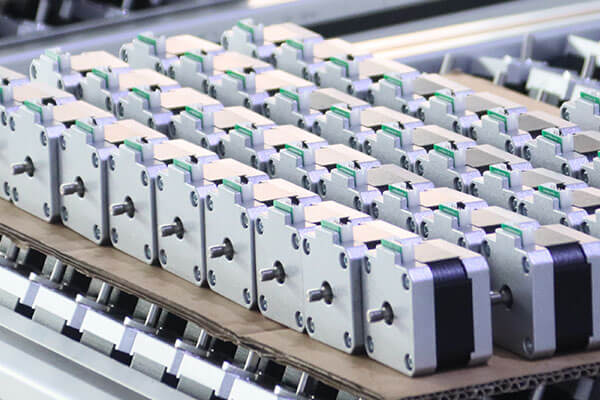

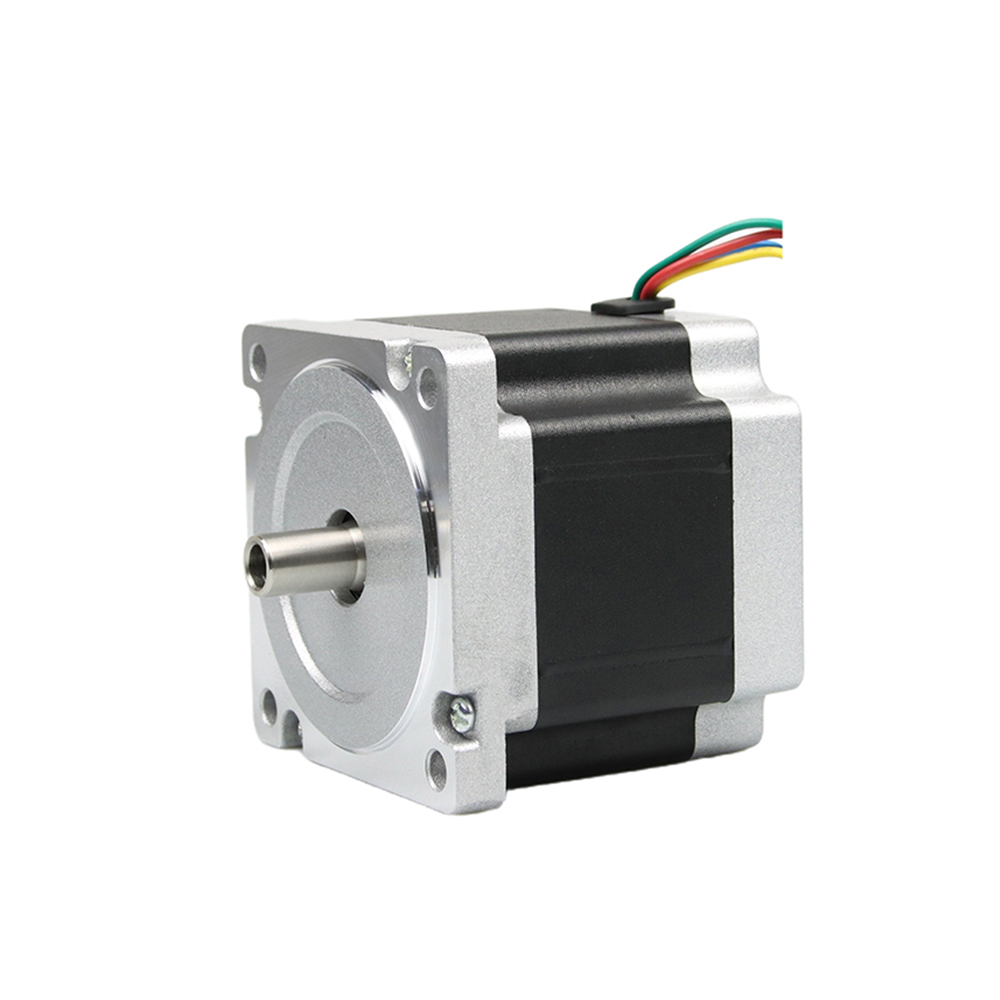

Maximum shear stress is one of the most critical parameters when analyzing the performance and safety of hollow shaft stepper motors. Hollow shaft motors, widely used in industrial machinery, robotics, servo systems, and precision motion applications, rely on an optimal combination of strength, torque capacity, and weight reduction. The concept of maximum shear stress helps engineers ensure that the motor shaft can withstand applied loads without failure.

What is Shear Stress?

Shear stress occurs when a force is applied tangentially to a surface, causing internal layers of a material to slide relative to each other. In the context of motors:

Torque (rotational force) applied to the shaft generates torsional shear stress.

The magnitude of shear stress varies along the radius of the shaft.

Hollow shafts experience their maximum shear stress at the outer surface, while the inner surface experiences less stress.

Hollow vs Solid Shafts

Hollow shafts are designed to maximize strength while minimizing weight:

Material is removed from the low-stress central region.

The outer radius, where shear stress is highest, remains solid.

Hollow shafts can achieve comparable or higher torque capacity than solid shafts with the same material weight.

They reduce rotational inertia, improving motor responsiveness.

Calculating Maximum Shear Stress

The maximum shear stress (τₘₐₓ) in a hollow shaft under torsion is calculated using the formula:

τmax=T⋅roJ\tau_{max} = \frac{T \cdot r_o}{J}

τmax=JT⋅ro

Where:

For a hollow shaft:

J=π2(ro4−ri4)J = \frac{\pi}{2} (r_o^4 - r_i^4)

J=2π(ro4−ri4)

This formula shows that outer radius and wall thickness have a significant effect on maximum shear stress, and careful optimization ensures safety and performance.

Material Considerations

The allowable shear stress depends on the shaft material:

Alloy steel: high yield strength, suitable for heavy-duty motors

Aluminum alloys: lighter, used in high-speed applications

Titanium alloys: extremely strong and corrosion-resistant

The allowable shear stress is often determined using the maximum shear stress theory:

τallowable≈0.577⋅σy\tau_{allowable} \approx 0.577 \cdot \sigma_y

τallowable≈0.577⋅σy

Where σᵧ is the yield strength in tension. Safety factors are applied to account for fatigue, shock, and surface imperfections.

Dynamic Loads and Fatigue

Hollow shaft stepper motors frequently operate under cyclic torque and varying loads, which can induce fatigue:

Repeated shear stress cycles may cause micro-cracks over time.

Surface quality at the outer diameter is critical for fatigue resistance.

Proper design ensures maximum shear stress remains below fatigue limits for the material.

Conclusion

Understanding maximum shear stress is essential for designing reliable and efficient hollow shaft stepper motors. By combining optimized shaft geometry, suitable material selection, and fatigue considerations, engineers can ensure high torque transmission, reduced weight, and long-term durability. Hollow shafts are particularly effective in applications requiring high-performance, precision motion, and rapid response.

Why Hollow Shaft Motors Experience Different Shear Stress Profiles

Hollow shaft stepper motors exhibit unique shear stress profiles compared to solid shafts due to their geometry and material distribution. Understanding these differences is crucial for engineers designing high-performance motors for robotics, industrial machinery, and precision automation systems.

Torsional Loading in Hollow Shafts

When a torque is applied to a shaft, the material experiences torsional shear stress, which varies across the shaft radius:

Outer surface: experiences maximum shear stress because it is farthest from the axis of rotation.

Inner surface: experiences lower shear stress due to proximity to the neutral axis.

Middle section (hollow wall): sees stress values between the inner and outer surfaces.

This linear variation from the center to the outer radius is what defines the shear stress profile in hollow shafts.

Geometrical Influence on Shear Stress

The hollow design removes material from the low-stress central region:

Less material near the center means the shaft is lighter.

Stress concentration moves to the outer radius, where the shaft is strongest.

This configuration results in a more efficient distribution of material, maximizing torsional resistance per unit weight.

The polar moment of inertia (J), a measure of a shaft’s resistance to torsion, is significantly affected by the inner and outer radii:

J=π2(ro4−ri4)J = \frac{\pi}{2} (r_o^4 - r_i^4)

J=2π(ro4−ri4)

Where rₒ is the outer radius and rᵢ is the inner radius. Even a small increase in outer radius greatly increases torsional strength, while increasing the inner radius reduces weight without significantly compromising torque capacity.

Advantages of Hollow Shaft Shear Stress Profiles

The unique stress profile of hollow shafts provides several benefits:

Higher Torque-to-Weight Ratio

Material is concentrated where shear stress is highest, allowing hollow shafts to carry more torque for the same weight.

Reduced Rotational Inertia

Removing central material reduces the moment of inertia, which improves motor acceleration and deceleration.

Improved Fatigue Resistance

Stress is more evenly distributed across the cross-section, reducing localized fatigue failure.

Enhanced Heat Dissipation

Hollow shafts have greater surface area relative to volume, allowing better thermal management during high-speed or high-load operation.

Practical Implications for Motor Design

Understanding the shear stress profile helps engineers:

Optimize outer and inner diameters for maximum torque capacity.

Select materials with appropriate yield and fatigue strength.

Ensure surface finish quality at the outer radius to prevent crack initiation.

Apply safety factors to account for dynamic loads, shock, and vibration.

By analyzing these profiles, designers can prevent torsional failure, extend motor life, and achieve high efficiency in precision applications.

Conclusion

Hollow shaft motors experience different shear stress profiles primarily because of their geometry. The removal of low-stress central material shifts maximum stress to the outer radius, improving torque efficiency and reducing weight. Proper understanding of these profiles allows engineers to design robust, high-performance, and long-lasting hollow shaft stepper motors suitable for demanding industrial and robotic applications.

Maximum Shear Stress Formula for a Hollow Shaft Motor

Understanding the maximum shear stress in a hollow shaft stepper motor is essential for designing shafts that are strong, lightweight, and capable of withstanding torsional loads. Hollow shafts are widely used in industrial machinery, robotics, and precision motor systems, where performance and reliability are critical. The shear stress formula provides engineers with a quantitative method to determine whether a shaft can safely transmit torque without failure.

Torsion and Shear Stress Basics

When a torque (T) is applied to a shaft, it generates torsional shear stress throughout the shaft material. The maximum shear stress is located at the outer radius of the shaft, while stress decreases toward the inner radius in hollow shafts.

This stress is a function of:

Accurate calculation ensures the shaft operates safely below the material's allowable stress limit.

Maximum Shear Stress Formula

For a hollow circular shaft subjected to torsion, the maximum shear stress (τₘₐₓ) is calculated as:

\boldsymbol{\tau_{max} = \frac{T \cdot r_o}{J}}

τmax=JT⋅ro

Where:

τₘₐₓ = Maximum shear stress (Pa or MPa)

T = Applied torque (N·m)

rₒ = Outer radius of the shaft (m)

J = Polar moment of inertia (m⁴)

Polar Moment of Inertia for Hollow Shafts

The polar moment of inertia (J) represents the shaft's resistance to torsional deformation. For a hollow shaft:

\boldsymbol{J = \frac{\pi}{2} (r_o^4 - r_i^4)}

J=2π(ro4−ri4)

Where:

This equation highlights that the torsional strength is highly sensitive to the outer radius, due to the fourth-power relationship, while increasing the inner radius reduces material weight with only a modest decrease in torsional resistance.

Rearranging the Formula for Maximum Torque

Designers often need to determine the maximum torque (Tₘₐₓ) that a hollow shaft stepper motor can safely transmit without exceeding the allowable shear stress:

\boldsymbol{T_{max} = \frac{\tau_{allowable} \cdot J}{r_o}}

Tmax=roτallowable⋅J

Where τₐₗₗₒwₐbₗₑ is determined from the shaft material's yield strength and any applied safety factors. This calculation is fundamental for:

Material Considerations

The allowable shear stress depends on the material:

Alloy steel: High strength and fatigue resistance

Aluminum alloys: Lightweight, suitable for high-speed applications

Titanium alloys: Extremely strong and corrosion-resistant

For ductile materials, the maximum shear stress theory is often used:

\boldsymbol{\tau_{allowable} \approx 0.577 \cdot \sigma_y}

τallowable≈0.577⋅σy

Where σᵧ is the material's yield strength in tension. Engineers incorporate safety factors to account for dynamic loads, fatigue, and manufacturing tolerances.

Practical Applications of the Formula

The maximum shear stress formula is used to:

Determine shaft dimensions for high-torque motors

Evaluate weight reduction benefits of hollow shafts

Optimize outer and inner diameters for efficiency and durability

Ensure compliance with fatigue and thermal considerations

By applying this formula, engineers can balance strength, weight, and performance, which is especially important in servo motors, robotics, and direct-drive systems.

Conclusion

The maximum shear stress formula provides a precise method to calculate the torsional load capacity of hollow shaft stepper motors. Understanding this relationship allows engineers to design shafts that maximize torque transmission, reduce weight, and improve reliability. Proper application ensures safe operation under dynamic loads, making hollow shaft motors ideal for high-performance and precision applications.

Location of Maximum Shear Stress in a Hollow Shaft

In hollow shaft motors, maximum shear stress always occurs at the outer surface of the shaft. This is a fundamental principle of torsion mechanics and applies regardless of shaft geometry. The stress decreases linearly from the outer radius toward the inner radius, where it reaches a lower but still non-zero value.

This behavior has practical implications:

Surface finish and material quality at the outer diameter are critical

Surface defects can initiate fatigue cracks

Protective coatings and precision machining enhance shaft lifespan

Material Properties and Allowable Shear Stress

The maximum permissible shear stress depends heavily on the shaft material. Common materials used in hollow shaft stepper motors include:

Allowable shear stress is typically derived from the yield strength of the material using established failure theories. For ductile materials, the maximum shear stress theory is widely applied:

\boldsymbol{\tau_{allowable} \approx 0.577 \cdot \sigma_y}

τallowable≈0.577⋅σy

Where σᵧ is the yield strength in tension.

Design engineers incorporate safety factors to account for fatigue, shock loading, and manufacturing tolerances, ensuring the working shear stress remains well below the theoretical maximum.

Torque Capacity vs Maximum Shear Stress

The relationship between torque capacity and maximum shear stress is direct and proportional. Rearranging the torsion equation gives the maximum allowable torque:

\boldsymbol{T_{max} = \frac{\tau_{allowable} \cdot J}{r_o}}

Tmax=roτallowable⋅J

This equation is essential for motor selection and shaft sizing. Hollow shaft stepper motors are often chosen because they can deliver higher torque capacity at the same maximum shear stress compared to solid shafts of equal mass.

This advantage is particularly important in applications requiring:

High torque density

Compact motor envelopes

Continuous duty cycles

Precision speed control

Impact of Shaft Dimensions on Maximum Shear Stress

Outer Diameter Influence

Increasing the outer diameter significantly increases the polar moment of inertia, which reduces maximum shear stress for a given torque. Even small increases in outer radius yield large gains in torsional strength due to the fourth-power relationship.

Inner Diameter Optimization

Increasing the inner diameter reduces weight but also decreases torsional resistance. Optimal hollow shaft design carefully balances weight reduction against stress limits to maintain mechanical integrity.

This optimization is why hollow shaft motors outperform solid shaft motors in high-performance electromechanical systems.

Dynamic Loads and Fatigue Considerations

Maximum shear stress calculations must account for dynamic loading, not just static torque. Hollow shaft stepper motors frequently operate under:

Under such conditions, fatigue strength becomes the governing factor. Repeated shear stress cycles below the yield limit can still cause failure over time. Engineers therefore apply fatigue correction factors and endurance limits to ensure long-term reliability.

Thermal Effects on Shear Stress Limits

Temperature directly influences material strength. Elevated operating temperatures reduce yield strength and, consequently, allowable shear stress. Hollow shaft stepper motors benefit from improved heat dissipation due to increased surface area, but thermal analysis remains essential.

Designs operating at high temperatures must derate torque capacity accordingly to prevent exceeding maximum shear stress under real-world conditions.

Comparison: Hollow Shaft vs Solid Shaft Maximum Shear Stress

For equal weight and material, hollow shafts consistently demonstrate:

Lower maximum shear stress under identical torque

Higher torque capacity at equal stress levels

Improved fatigue resistance

Reduced rotational inertia

These advantages explain why hollow shaft stepper motors dominate modern servo motors, direct-drive systems, and robotic joints.

Practical Engineering Guidelines

To control maximum shear stress in hollow shaft motors, we apply the following principles:

Select materials with high yield and fatigue strength

Optimize outer and inner diameters using torsion equations

Maintain conservative safety factors

Ensure superior surface finish at the outer radius

Account for thermal and dynamic loading effects

These guidelines ensure robust performance across demanding industrial environments.

Conclusion: Defining the Maximum Shear Stress of a Hollow Shaft Motor

The maximum shear stress of a hollow shaft stepper motor is a precisely defined mechanical limit governed by torque, geometry, and material properties. By leveraging hollow shaft design, engineers achieve superior torque transmission while minimizing stress, weight, and inertia. Accurate calculation and control of maximum shear stress are fundamental to ensuring reliability, efficiency, and long service life in advanced motor systems.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català