A linear stepper motor is an advanced form of stepper motor that converts rotary motion into precise linear movement without the need for mechanical conversion components such as lead screws or belts. This direct-drive mechanism provides high accuracy, repeatability, and smooth motion control, making linear stepper motors a preferred choice for automation, robotics, and precision positioning applications.

Understanding the Fundamentals of Linear Stepper Motors

Unlike traditional rotary stepper motors that generate angular displacement, linear stepper motors produce motion along a straight line. This is achieved by designing the motor stator and rotor (or moving element) in a linear configuration rather than circular. The system typically consists of two primary components:

Forcer (or Mover) – Contains the motor windings and moves linearly when energized.

Platen (or Track) – A stationary magnetic or toothed surface that interacts with the forcer to produce motion.

When the coils in the forcer are energized sequentially, a magnetic field is generated that causes the mover to align with the corresponding magnetic poles on the platen, resulting in precise linear steps.

Working Principle of a Linear Stepper Motor

A linear stepper motor operates on the same electromagnetic principles as a rotary stepper motor but produces straight-line (linear) motion instead of rotational motion. It is designed to translate digital pulse signals into precise linear movement, making it ideal for applications that demand accurate positioning, smooth motion, and high repeatability.

This article explores the working principle, core mechanisms, and control methods that define how a linear stepper motor functions.

Basic Concept of Operation

The fundamental idea behind a linear stepper motor is the interaction of magnetic fields between stationary and moving components. When electrical current flows through the motor windings, it generates magnetic fields that attract or repel magnetic poles on the stationary track (platen). By sequentially energizing these windings, the motor's moving part (forcer) steps forward or backward in small, controlled increments.

Each pulse sent to the motor corresponds to a specif

ic amount of linear movement, typically measured in micrometers. This allows for precise and repeatable motion control without the need for mechanical conversion mechanisms like screws or gears.

Main Components Involved

To understand how the motor works, it's essential to recognize the roles of its key components:

1. Platen (Stationary Track)

The platen is the fixed base of the motor, made from ferromagnetic or permanent magnetic material. It typically has evenly spaced teeth that form a magnetic pattern. These teeth act as reference points for the moving element.

2. Forcer (Moving Element)

The forcer contains multiple electromagnetic coils wound around laminated iron cores. When the coils are energized in a specific sequence, the resulting magnetic fields interact with the platen, causing the forcer to move linearly.

3. Driver and Controller

The driver sends electrical pulses to the coils, controlling their sequence, timing, and direction. The controller interprets input commands and translates them into pulse trains that determine speed, direction, and distance of motion.

Step-by-Step Working Principle

The linear stepper motor operates through a sequence of electromagnetic interactions that move the forcer incrementally along the platen. The process can be broken down into the following steps:

1. Coil Energization

When current flows through a coil, it generates a magnetic field. Depending on the polarity of the current, one side of the coil becomes a north pole and the other a south pole.

2. Magnetic Alignment

The magnetic field produced by the coil interacts with the magnetic poles on the platen. The forcer aligns itself with the nearest corresponding poles on the platen to minimize magnetic reluctance (the resistance to magnetic field flow).

3. Sequential Switching

By energizing the coils in a specific sequence, the forcer moves incrementally from one position to the next. Each step corresponds to one input pulse, allowing highly controlled, digital-based motion.

4. Direction and Speed Control

This entire process allows the forcer to move linearly and precisely over the length of the platen, with accuracy determined by the step size and control resolution.

Electromagnetic Interaction Explained

The motor's functionality relies on electromagnetic attraction and repulsion. When the motor coils are energized:

The generated magnetic fields create poles that interact with the platen's magnetic structure.

The forcer's teeth align or misalign with the platen teeth, depending on current flow.

By continuously shifting the energized coils, the magnetic equilibrium point moves, causing the forcer to follow in small, discrete steps.

This interaction is the same principle behind rotary stepper motion, but here it's unwrapped into a linear geometry, creating smooth, straight-line travel instead of rotation.

Step Resolution and Accuracy

The step size of a linear stepper motor determines its motion resolution. It depends on:

The tooth pitch of the platen.

The number of motor phases (usually two, three, or five).

The control mode (full-step, half-step, or microstep).

For example, a high-resolution linear stepper motor might achieve steps as small as 1–10 micrometers, allowing precise control for delicate operations such as laser alignment or micro-machining.

Control Modes in Linear Stepper Operation

Linear stepper motors can operate under different drive modes, each offering unique performance characteristics:

1. Full-Step Mode

All coils are energized in a sequence that moves the forcer one full step per pulse. This mode offers maximum thrust but has noticeable vibration at low speeds.

2. Half-Step Mode

Alternating between one and two energized phases per step, this mode doubles the resolution and reduces vibration, resulting in smoother motion.

3. Microstepping Mode

By precisely controlling the current in each coil using pulse-width modulation (PWM), microstepping divides each full step into smaller fractions. This produces extremely smooth, quiet, and precise linear movement—crucial for advanced automation and measurement applications.

Direction, Speed, and Thrust Control

The direction of motion is controlled by changing the excitation order of the motor's coils. Reversing the current sequence moves the forcer in the opposite direction.

Speed control is achieved by varying the pulse frequency—the faster the pulses, the faster the movement.

Thrust force, the linear equivalent of torque, depends on:

Proper balance between speed and thrust ensures optimal performance and prevents step loss.

Open-Loop and Closed-Loop Operation

Open-Loop Mode

In most applications, linear stepper motors are used in open-loop control, where motion is determined solely by the number of input pulses. This mode is cost-effective and highly reliable when load conditions are predictable.

Closed-Loop Mode

In high-precision environments, feedback devices such as encoders or linear scales are added. The controller monitors actual position and compensates for errors in real-time, ensuring maximum accuracy, stability, and repeatability.

Advantages of the Linear Stepper Motor Principle

Direct linear actuation without mechanical conversions.

Precise digital control with simple pulse signals.

No backlash or slippage, thanks to electromagnetic stepping.

High repeatability and resolution, suitable for fine positioning.

Compact design with fewer moving parts for improved reliability.

These advantages make the linear stepper motor a preferred choice for precision motion systems, such as 3D printers, semiconductor tools, and laboratory automation.

Practical Example of Operation

Consider a linear stepper motor-driven positioning stage. When the controller sends 1,000 pulses to the motor, and each pulse represents 10 micrometers of movement, the forcer will move exactly 10 millimeters along the platen. Reversing the pulse sequence drives the forcer back to its starting point—with perfect repeatability.

This digital-to-motion translation is what makes linear stepper motors highly reliable for precision automation.

Conclusion

The working principle of a linear stepper motor is built on the simple yet powerful interaction of electromagnetic fields that transform electrical pulses into controlled linear motion. By precisely managing current flow through multiple coils, the forcer moves along the platen in small, accurate steps—offering exceptional precision, reliability, and efficiency.

Whether in robotics, CNC machines, medical equipment, or optical systems, linear stepper motors provide the foundation for modern motion control, ensuring smooth, accurate, and repeatable performance.

Types of Linear Stepper Motors

Linear stepper motors come in various designs, each tailored for specific performance needs. The three most common types include:

1. Permanent Magnet Linear Stepper Motors

These use permanent magnets in the forcer to interact with electromagnetic coils. They provide high thrust, precision, and low detent force, making them ideal for micro-positioning systems.

2. Variable Reluctance Linear Stepper Motors

This type relies on the variable magnetic reluctance between toothed structures on both the mover and stator. They are cost-effective and durable, suitable for applications where extreme precision is not required.

3. Hybrid Linear Stepper Motors

Hybrid designs combine the advantages of both permanent magnet and variable reluctance motors. They offer superior resolution, torque, and linear speed, making them the most widely used in industrial automation and precision motion systems.

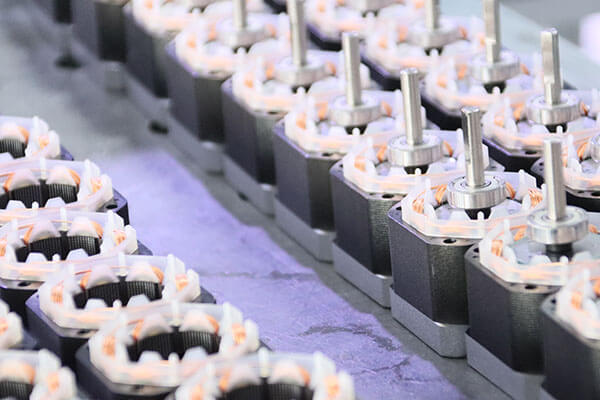

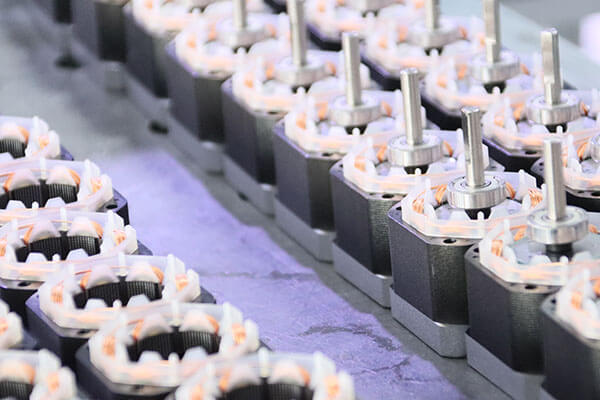

Construction and Design Features

The construction of a linear stepper motor is a key factor in its performance. A typical design includes:

Platen – A ferromagnetic track or a permanent magnet surface with evenly spaced teeth.

Forcer – Houses multiple coils wound around iron cores; each coil phase corresponds to one step sequence.

Bearings or Air Bearings – Facilitate frictionless movement, ensuring stability and minimal wear.

Encoder (optional) – Provides feedback for closed-loop control, ensuring enhanced positional accuracy.

Advanced designs may include integrated controllers, sealed housings for harsh environments, and multi-phase windings for smoother motion.

Operating Modes of Linear Stepper Motors

A linear stepper motor converts electrical pulses into precise, incremental linear motion. The flexibility and performance of these motors largely depend on their operating modes, which control how the electromagnetic coils are energized. These modes determine motion smoothness, resolution, thrust, and efficiency, making them a key factor in system design and performance optimization.

In this article, we explore the various operating modes of linear stepper motors, their characteristics, advantages, and applications.

Understanding Operating Modes

The operating mode of a linear stepper motor defines how current is applied to its multiple windings (phases). By altering the energization sequence and current magnitude, engineers can achieve different resolutions and motion characteristics.

There are three primary operating modes used in most linear stepper motor systems:

Full-Step Mode

Half-Step Mode

Microstepping Mode

Each mode offers a balance between thrust force, precision, vibration, and smoothness of motion.

1. Full-Step Mode

Overview

In full-step mode, the linear stepper motor moves by one full step each time a pulse is applied. This occurs when either one phase or two phases of the motor windings are energized at a time.

How It Works

Single-Phase Excitation: Only one winding is energized at a time. This produces a single magnetic field that pulls the forcer to the nearest aligned position.

Dual-Phase Excitation: Two windings are energized simultaneously, creating a stronger combined magnetic field that results in higher thrust.

Each pulse moves the forcer by one complete step, which corresponds to a fixed linear distance, such as 10 µm or 20 µm per step, depending on motor design.

Characteristics

Maximum step size per pulse (lowest resolution).

High thrust output when both phases are energized.

Simple control with fewer current transitions.

Noticeable vibration at lower speeds.

Applications

Full-step mode is ideal for applications requiring maximum force and moderate precision, such as:

2. Half-Step Mode

Overview

Half-step mode combines single-phase and dual-phase excitation, effectively doubling the step resolution. It offers a balance between the torque of full-step operation and the smoothness of microstepping.

How It Works

The excitation sequence alternates between energizing:

A single phase

Two adjacent phases simultaneously

This alternation moves the forcer by half the distance of a full step with each pulse. For instance, if the full step size is 20 µm, half-step mode achieves 10 µm per pulse.

Characteristics

Double the resolution compared to full-step mode.

Smoother motion and reduced vibration.

Slightly uneven thrust, since single-phase steps produce less force than dual-phase ones.

Simple to implement using standard drivers.

Applications

Half-step mode is commonly used in systems requiring a balance between performance and accuracy, such as:

3. Microstepping Mode

Overview

Microstepping is the most advanced operating mode, providing ultra-smooth and precise linear motion. Instead of switching current fully on and off, the driver modulates current levels in each winding to create small incremental steps within a full step.

How It Works

In microstepping mode, the controller generates sinusoidal or PWM (pulse-width modulated) current waveforms. This causes the magnetic field to rotate gradually rather than jumping from one step to the next.

For example, if a full step equals 20 µm, and the driver divides each full step into 10 microsteps, the resulting step size is just 2 µm per pulse.

Characteristics

Extremely smooth motion with minimal vibration and resonance.

High positional resolution and accuracy.

Lower noise compared to other modes.

Reduced available thrust, since current is shared between multiple phases.

Requires advanced driver electronics.

Applications

Microstepping mode is ideal for high-precision and quiet applications, including:

Semiconductor wafer alignment systems

Optical instruments

Medical imaging equipment

Laboratory automation devices

Comparative Analysis of Operating Modes

| Feature | Full-Step Mode | Half-Step Mode | Microstepping Mode |

| Resolution | Low | Medium | Very High |

| Motion Smoothness | Moderate | Good | Excellent |

| Vibration | Noticeable | Reduced | Minimal |

| Thrust Force | High | Medium | Lower |

| Noise Level | Moderate | Low | Very Low |

| Control Complexity | Simple | Moderate | High |

| Typical Use Case | General motion | Moderate precision | High precision |

This table highlights how microstepping mode delivers the best smoothness and resolution, while full-step mode prioritizes thrust and simplicity.

Advanced Control Enhancements

Modern linear stepper motor systems often combine these operating modes with enhanced control techniques to optimize performance:

1. Adaptive Microstepping

Automatically adjusts the microstep resolution based on speed and load conditions—using high resolution at low speeds and larger steps at high speeds for efficiency.

2. Closed-Loop Stepper Control

Integrates position feedback sensors (encoders or linear scales) to monitor motion in real time. This prevents missed steps, corrects errors, and provides servo-like performance with stepper simplicity.

3. Resonance Suppression Algorithms

Advanced controllers actively compensate for vibration and resonance that may occur at certain step frequencies, ensuring stable, quiet operation.

Selecting the Right Operating Mode

The optimal operating mode depends on the application's performance priorities:

Choose full-step mode when high thrust and simple control are required.

Choose half-step mode for balanced performance between precision and power.

Choose microstepping mode when precision, quietness, and smooth motion are essential.

Designers often select microstepping mode for high-end applications such as CNC systems, robotic arms, and precision stages, where fine movement and low noise are critical.

Practical Example

Imagine a linear stepper motor with a 20 µm full step.

In full-step mode, each pulse moves the forcer 20 µm.

In half-step mode, each pulse moves it 10 µm.

In microstepping mode (1/10 step), each pulse moves it only 2 µm.

This precision control allows smooth, predictable, and repeatable linear movement suited for any high-accuracy industrial process.

Conclusion

The operating modes of a linear stepper motor define its performance, smoothness, and precision. Whether using full-step, half-step, or microstepping, these modes allow engineers to tailor motor behavior to meet the specific needs of their applications.

From basic automation to advanced precision instruments, understanding and selecting the right operating mode ensures optimal accuracy, efficiency, and reliability in any motion control system.

Advantages of Linear Stepper Motors

Linear stepper motors offer numerous advantages that make them stand out in modern automation:

Direct Linear Motion: No need for mechanical converters like screws or belts, eliminating backlash and wear.

High Precision and Repeatability: Each step represents a fixed linear distance, ensuring consistent movement.

Simplified Design: Fewer mechanical parts mean lower maintenance and improved reliability.

Excellent Acceleration and Deceleration: Ideal for dynamic positioning and fast response systems.

Cost Efficiency: Compared to linear servo systems, stepper designs are generally more affordable while maintaining sufficient accuracy.

Ease of Control: Simple digital pulse signals can control speed, direction, and distance.

Applications of Linear Stepper Motors

Linear stepper motors are found in a wide range of industries due to their reliability and precision. Common applications include:

1. Semiconductor Manufacturing

Used in wafer positioning and lithography systems where micron-level accuracy is required.

2. 3D Printing and CNC Machines

Provide precise layer-by-layer motion, crucial for creating detailed and dimensionally accurate parts.

3. Robotics and Automation

Enable smooth and coordinated linear movements, ideal for pick-and-place, inspection, and assembly robots.

4. Medical Equipment

Used in laboratory automation, imaging devices, and drug dispensing systems requiring clean, precise, and repeatable motion.

5. Optical and Measurement Systems

Employed in instruments such as laser alignment tools, microscopes, and scanning systems, where vibration-free linear travel is essential.

Performance Characteristics

The performance of a linear stepper motor is defined by several key parameters:

Step Size: Determines the resolution of movement, typically between 1 µm and 50 µm per step.

Thrust Force: The linear equivalent of torque, dependent on current and magnetic strength.

Speed: Typically up to several hundred millimeters per second, depending on design and load.

Duty Cycle: Continuous operation capability, defined by motor heating and cooling properties.

Repeatability: The ability to return to a specific position consistently—often within a few micrometers.

Comparison: Linear Stepper Motor vs. Linear Servo Motor

While both linear stepper and servo motors offer precise motion control, they differ in several aspects:

| Feature | Linear Stepper Motor | Linear Servo Motor |

| Control Type | Open-loop or closed-loop | Closed-loop only |

| Cost | Lower | Higher |

| Accuracy | High | Very high |

| Speed Range | Moderate | High |

| Complexity | Simple | Complex |

| Maintenance | Low | Medium |

Linear stepper motors are preferred for cost-sensitive, moderate-speed applications, while linear servos excel in high-performance and high-speed environments.

Future Trends in Linear Stepper Motor Technology

The world of motion control and automation is evolving rapidly, and at the heart of this transformation lies the linear stepper motor—a critical component enabling precise, repeatable, and efficient linear motion. As industries move toward smart manufacturing, miniaturization, and energy efficiency, the demand for advanced linear stepper motor technologies continues to rise.

In this article, we explore the emerging trends, innovations, and future directions shaping the evolution of linear stepper motor technology.

1. Integration of Smart Electronics and Controllers

One of the most significant advancements in linear stepper motors is the integration of smart electronics, including onboard drivers, sensors, and microcontrollers. These integrated systems allow motors to operate as self-contained smart actuators, simplifying installation and reducing wiring complexity.

Key Developments Include:

Built-in Motion Controllers: Combine the motor, driver, and control electronics in a single compact unit.

Plug-and-Play Functionality: Simplifies connection with automation systems via USB, CANopen, or EtherCAT.

Diagnostic and Monitoring Capabilities: Integrated electronics enable real-time status reporting, including temperature, current, and vibration levels.

This shift towards intelligent linear stepper systems enhances efficiency, reliability, and system interoperability—ideal for Industry 4.0 environments.

2. Adoption of Closed-Loop Control Systems

Traditional linear stepper motors operate in open-loop mode, but future designs increasingly integrate closed-loop feedback systems for improved accuracy and stability.

How Closed-Loop Systems Are Changing Performance:

Real-Time Position Feedback: Encoders and sensors continuously track the forcer's position.

Automatic Error Correction: Eliminates missed steps or positional drift.

Enhanced Speed and Thrust Control: Maintains optimal performance even under varying load conditions.

Energy Efficiency: Reduces unnecessary power consumption by adjusting current dynamically.

By merging the simplicity of stepper control with the precision of servo systems, closed-loop linear stepper motors offer the best of both worlds—accurate, responsive, and efficient motion control.

3. Miniaturization and Compact Designs

As technology pushes toward smaller, faster, and more integrated systems, miniaturized linear stepper motors are becoming increasingly important.

Emerging Miniaturization Trends:

Micro-linear stepper motors are now being used in medical devices, optics, and micro-robotics.

Lightweight composite materials are replacing traditional metal housings for improved energy efficiency.

Precision manufacturing technologies like laser micromachining and additive manufacturing (3D printing) allow for tighter tolerances and higher performance density.

These compact designs enable high-performance motion in confined spaces, such as portable medical instruments, semiconductor equipment, and micro-automation systems.

4. Integration with IoT and AI-Based Predictive Maintenance

The next generation of linear stepper motors will be intelligent, connected devices capable of communicating with larger automation ecosystems.

Key Innovations:

IoT (Internet of Things) Integration: Motors equipped with sensors transmit real-time data such as temperature, vibration, and current draw to cloud-based monitoring systems.

AI-Powered Predictive Maintenance: Machine learning algorithms analyze operational data to predict failures before they occur, minimizing downtime.

Remote Diagnostics: Engineers can monitor and adjust system parameters from anywhere, improving responsiveness and reducing maintenance costs.

This combination of IoT and AI technologies turns linear stepper motors into smart, self-monitoring actuators, ensuring consistent performance and operational longevity.

5. Advanced Materials and Manufacturing Techniques

The use of next-generation materials and advanced manufacturing processes is redefining the durability, efficiency, and performance of linear stepper motors.

Innovations Include:

High-Temperature Rare-Earth Magnets: Provide stronger magnetic fields with improved resistance to demagnetization.

Low-Friction Bearing Systems: Air bearings and magnetic levitation reduce wear and mechanical losses.

Additive Manufacturing (3D Printing): Enables complex geometries and lightweight motor components.

Nanotechnology Coatings: Reduce corrosion, improve heat dissipation, and extend service life.

These advancements result in motors that are lighter, more powerful, and more energy-efficient, ideal for demanding industrial and aerospace applications.

6. Hybrid Linear Stepper Motor Designs

The future of linear stepper motors lies in hybrid architectures that combine the strengths of permanent magnet and variable reluctance technologies.

Benefits of Hybrid Designs:

Higher Resolution and Accuracy: Achieve finer linear step sizes (often less than 1 µm).

Improved Thrust Output: Enhanced electromagnetic efficiency provides stronger linear forces.

Reduced Vibration and Noise: Balanced phase excitation results in smoother motion.

Extended Operational Life: Less mechanical wear due to reduced vibration and heat generation.

Hybrid linear stepper motors are becoming the standard choice for high-performance applications such as semiconductor lithography, laser positioning, and precision robotics.

7. Energy-Efficient and Eco-Friendly Designs

Sustainability and energy efficiency are driving the next wave of innovation in motor technology. Manufacturers are focusing on reducing energy consumption while maintaining or enhancing performance.

Trends in Energy Efficiency:

Low-Power Drive Electronics: Minimize energy loss through smart current control algorithms.

Regenerative Systems: Recover kinetic energy during deceleration phases.

Optimized Coil Design: Reduces resistive losses and heat buildup.

Environmentally Friendly Materials: Adoption of lead-free components and recyclable materials.

These improvements align with global sustainability goals and lower total cost of ownership (TCO) for industrial users.

8. Integration with Precision Mechatronics

Future systems will see deeper integration between linear stepper motors and mechatronic assemblies, including sensors, encoders, and actuators.

Examples of Mechatronic Integration:

Linear stages with embedded feedback systems for plug-and-play precision.

Multi-axis synchronized motion control for robotic automation.

Compact mechatronic modules combining motion, sensing, and control in one assembly.

Such integration minimizes system complexity while enhancing accuracy, responsiveness, and flexibility in advanced automation setups.

9. Digital Twins and Simulation-Based Design

Another emerging trend is the use of digital twin technology in linear motor development. A digital twin is a virtual replica of a physical system, allowing engineers to simulate, analyze, and optimize motor performance in real time.

Advantages:

Predictive Modeling: Simulate heat distribution, magnetic flux, and motion dynamics.

Design Optimization: Reduce prototype costs and accelerate development cycles.

Maintenance Insights: Digital twins combined with sensor data provide real-time performance tracking and failure prediction.

This data-driven design approach enhances efficiency and reliability throughout a motor's lifecycle.

10. Expansion into Emerging Industries

As new technologies emerge, linear stepper motors are expanding beyond traditional automation and manufacturing sectors.

Growing Application Areas:

Biotechnology: Precision liquid dispensing and sample manipulation.

Aerospace: Lightweight linear actuators for flight control and payload systems.

Renewable Energy: Tracking systems for solar panels and wind-turbine blade control.

Consumer Electronics: High-speed, low-noise actuation for next-gen devices.

The adaptability of linear stepper motors ensures their continued relevance in the smart, sustainable, and interconnected industries of the future.

The future of linear stepper motor technology is defined by innovation, intelligence, and integration. As industries embrace automation, AI, and IoT, linear stepper motors are evolving into smarter, faster, and more efficient systems capable of meeting the demands of tomorrow's precision-driven world.

From closed-loop hybrid designs to miniaturized intelligent actuators, these advancements promise to revolutionize how we design and deploy motion control systems—ensuring higher accuracy, greater reliability, and unmatched performance across every field.

Conclusion

The linear stepper motor is a powerful, precise, and efficient motion solution that bridges the gap between simplicity and sophistication in modern automation. Its direct linear actuation, high repeatability, and low maintenance requirements make it indispensable in robotics, manufacturing, and scientific instrumentation.

Whether for micro-positioning in laboratories or high-speed motion in production lines, linear stepper motors continue to set the standard for precision motion control technology.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català