A BLDC motor, or Brushless Direct Current motor, is an electric motor that operates using direct current (DC) electricity but does not use brushes or a mechanical commutator. Instead, it relies on electronic commutation to control the rotation of the motor.

How a BLDC Motor Works

A BLDC (Brushless Direct Current) motor works by using electronic switching instead of mechanical brushes to create rotation. The motor’s movement is controlled by an electronic controller that energizes the stator windings in a precise sequence, producing a rotating magnetic field that drives the rotor.

Main Parts Involved

A BLDC motor consists of three key elements:

Stator: Fixed part of the motor with copper windings arranged in phases (usually three-phase).

Rotor: Rotating part made of permanent magnets.

Electronic Controller (Driver): Controls the timing and sequence of current flow to the stator windings.

Electronic Commutation

In a traditional brushed motor, brushes and a commutator switch the current mechanically.

In a BLDC motor, this process is replaced by electronic commutation:

The controller determines the rotor’s position.

It energizes specific stator windings at the correct time.

This creates a rotating magnetic field.

The rotor’s permanent magnets follow this magnetic field, causing rotation.

Rotor Position Detection

To know when to switch the current, the controller must track the rotor position. This is done in two ways:

Continuous Rotation Process

The operation follows a repeating cycle:

Controller energizes one set of stator windings.

Rotor aligns with the magnetic field.

Controller switches to the next winding set.

The magnetic field shifts, pulling the rotor forward.

The cycle repeats, producing smooth continuous rotation.

Speed and Torque Control

Speed is controlled by adjusting the voltage or the switching frequency.

Torque is controlled by regulating the current supplied to the motor.

Advanced controllers use techniques such as PWM (Pulse Width Modulation) and Field-Oriented Control (FOC) for precise performance.

Why This Design Is Efficient

No brushes means no friction losses from brush contact.

No sparking, resulting in less heat and electrical noise.

Better heat dissipation since windings are on the stator.

Higher power density and longer service life.

Summary

A BLDC motor works by using an electronic controller to sequentially energize stator windings, creating a rotating magnetic field that drives a permanent-magnet rotor. This brushless, electronically controlled operation results in high efficiency, precise control, low maintenance, and long lifespan, making BLDC motors ideal for modern applications.

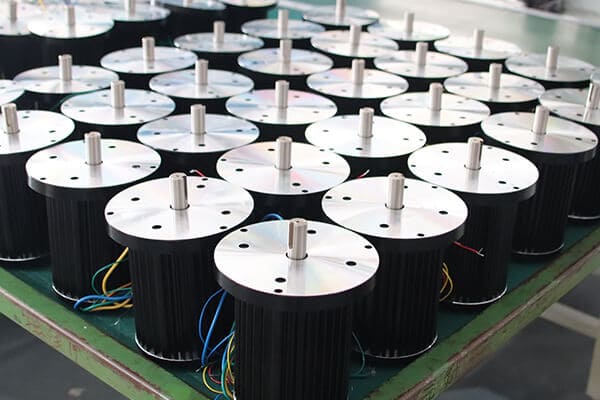

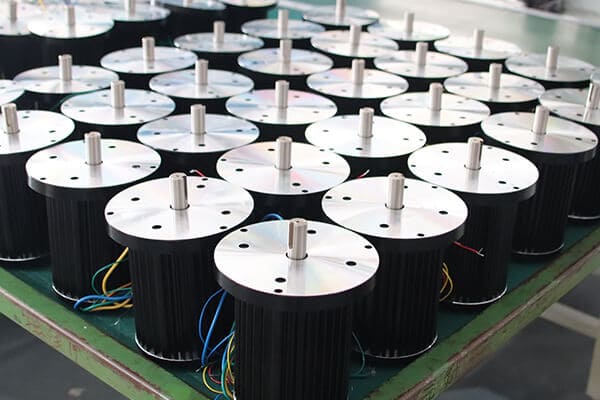

Key Components of a BLDC Motor

A BLDC (Brushless Direct Current) motor is made up of several essential components that work together to deliver efficient, precise, and reliable motion. Unlike brushed motors, BLDC Motors rely on electronic control instead of mechanical brushes.

Stator

The stator is the stationary part of the motor and contains multiple copper windings arranged in phases (typically three-phase).

Function:

Key Features:

Rotor

The rotor is the rotating part of the motor and is fitted with permanent magnets.

Function:

Key Features:

Electronic Controller (Driver)

The electronic controller replaces brushes and the mechanical commutator found in traditional DC motors.

Function:

Switches current through the stator windings in the correct sequence

Controls speed, torque, and direction of rotation

Key Features:

Position Sensors (Optional)

Some BLDC motors include rotor position sensors to improve control accuracy.

Types:

Function:

Shaft

The shaft transmits mechanical power from the rotor to the load.

Function:

Key Features:

Bearings

Bearings support the rotor and shaft, allowing smooth rotation.

Function:

Key Features:

Housing (Frame)

The housing encloses and protects internal components.

Function:

Key Features:

Summary

The key components of a BLDC motor—stator, rotor, electronic controller, sensors, shaft, bearings, and housing—work together to deliver high efficiency, precise control, and long operational life. This advanced design makes BLDC motors ideal for modern industrial, automotive, and electronic applications.

High efficiency: No energy loss from brushes

Long lifespan: No brush wear or sparking

Low maintenance: Fewer mechanical parts

Quiet operation: Reduced electrical and mechanical noise

Precise control: Excellent speed and torque control

Common Applications

BLDC Motor vs Brushed DC Motor

Unlike brushed DC motors, BLDC motors do not require physical contact between moving parts for commutation. This makes them more efficient, more reliable, and better suited for modern high-performance applications.

In simple terms, a BLDC motor is a high-efficiency, electronically controlled motor designed for long life and precise motion control.

Top 25 BLDC Motor Manufacturers in Russia

Below is a structured and professional list of the Top 25 BLDC Motor Manufacturers in Russia, written in clear H3 format and including company profile, main products, and key advantages.

This list combines established manufacturers, state-owned enterprises, and high-tech specialists active in BLDC and brushless motor solutions for industrial, aerospace, robotics, medical, and defense applications.

1.NPO Energomash

Company Profile:

A leading Russian BLDC motor manufacturer with extensive experience in high-reliability electromechanical systems.

Main Products:

BLDC motors for spacecraft systems, precision actuators, electric drive units

Advantages:

Exceptional reliability, aerospace-grade quality, long operational life

2.United Engine Corporation (UEC)

Company Profile:

Part of Rostec, UEC is a major BLDC motor manufacturer in advanced propulsion and electric drive technologies.

Main Products:

High-performance BLDC motors, electric propulsion components

Advantages:

Strong R&D base, integration with aviation systems, state-level support

3.KRET (Concern Radio-Electronic Technologies)

Company Profile:

A diversified electronics and electromechanical group serving defense and aviation sectors.

Main Products:

BLDC motors for avionics, electromechanical actuators, servo systems

Advantages:

High precision, military-grade durability, advanced control electronics

4.Electroprivod (Saint Petersburg)

Company Profile:

An industrial BLDC motor manufacturer with a strong focus on automation.

Main Products:

Industrial BLDC motors, servo drives, motion-control systems

Advantages:

Wide product range, customization capability, strong industrial integration

5.Perm Motors

Company Profile:

A historic BLDC motor manufacturer expanding into modern brushless technologies.

Main Products:

Medium- and high-power BLDC motors, industrial electric motors

Advantages:

Robust mechanical design, scalable production, long service life

6.Kaluga Electric Motor Plant (KEMZ)

Company Profile:

A BLDC motor manufacturer specializes in compact electric motors for high-precision applications.

Main Products:

Small and medium BLDC motors, integrated motor-drive units

Advantages:

Compact design, high efficiency, suitable for robotics and medical devices

7.MPEI Spin-Off Companies

Company Profile:

Technology startups originating from Moscow Power Engineering Institute.

Main Products:

Experimental and custom BLDC motors, research-grade electric drives

Advantages:

Strong innovation, cutting-edge motor design, academic expertise

8.Elin Motor

Company Profile:

A regional BLDC motor manufacturer focusing on customized electric motor solutions.

Main Products:

Custom BLDC motors, industrial drives

Advantages:

Flexible design, tailored solutions, strong engineering support

9.Ruselectro Motors

Company Profile:

A Moscow-based supplier of electric motors and drive electronics.

Main Products:

BLDC motors, servo motors, motor controllers

Advantages:

Good cost-performance ratio, strong integration capability

10.Energia Automation

Company Profile:

An automation-focused BLDC motor manufacturer producing motors and control systems.

Main Products:

BLDC motors with integrated controllers, smart drive systems

Advantages:

System-level solutions, compact integration, modern control algorithms

11.JKong Motor

Company Profile:

A long-established BLDC motor manufacturer serving heavy industry and automation.

Main Products:

Industrial BLDC motors, AC and DC motors

Advantages:

Durable construction, stable production capacity

12.Siberian Electric Motors (SibEM)

Company Profile:

A regional BLDC motor manufacturer focusing on energy-efficient motor technologies.

Main Products:

High-efficiency BLDC motors, industrial electric drives

Advantages:

Energy savings, reliable operation in harsh environments

13.ElectroDrive Systems (Kazan)

Company Profile:

Specialist in servo and motion-control technologies.

Main Products:

BLDC servo motors, precision motion systems

Advantages:

High positioning accuracy, CNC and robotics compatibility

14.Avionika Group

Company Profile:

A BLDC motor supplier of aircraft electronic and electromechanical systems.

Main Products:

Aerospace BLDC motors, actuators, electromechanical assemblies

Advantages:

Aviation certification experience, high safety standards

15.Rostec Electric Technologies

Company Profile:

A state-owned industrial cluster under Rostec.

Main Products:

BLDC motors for defense, transport, and industrial applications

Advantages:

Large-scale manufacturing, strategic national support

16.Besfoc

Company Profile:

A growing BLDC motor manufacturer of industrial drive solutions.

Main Products:

BLDC motors, variable-speed drives

Advantages:

Reliable industrial performance, competitive pricing

17.Volga Electric Motors

Company Profile:

Produces motors for fluid handling and automation systems.

Main Products:

Medium-power BLDC motors, pump and compressor motors

Advantages:

Energy-efficient designs, stable continuous-duty operation

18.Motorika

Company Profile:

A medical technology BLDC motor manufacturer specializing in powered prosthetics.

Main Products:

Compact BLDC motors for prosthetic limbs and medical robotics

Advantages:

Lightweight design, quiet operation, high torque density

19.Electrosila

Company Profile:

One of Russia’s oldest electrical engineering companies.

Main Products:

Large electric motors, high-power BLDC variants

Advantages:

Heavy-duty expertise, long operational heritage

20.Ural Electromechanical Plant

Company Profile:

Supplies motors for industrial and metallurgical applications.

Main Products:

Industrial BLDC motors, electromechanical systems

Advantages:

Rugged construction, suitable for harsh environments

21.Robotics Center Skolkovo – Partner Manufacturers

Company Profile:

An innovation ecosystem supporting robotics startups.

Main Products:

BLDC motors for robotics, autonomous systems

Advantages:

High innovation rate, startup-driven designs

22.Kronstadt Technologies

Company Profile:

A BLDC motor manufacturer Focuses on unmanned systems and electromechanical components.

Main Products:

BLDC motors for UAVs and autonomous vehicles

Advantages:

Lightweight motors, high power-to-weight ratio

23.Vector Electric Drives

Company Profile:

A BLDC motor manufacturer of modern electric drive systems.

Main Products:

BLDC motors, digital motor controllers

Advantages:

Advanced electronics integration, smooth speed control

24.Neva Electric Machines

Company Profile:

Serves industrial automation and transport sectors.

Main Products:

BLDC motors, traction motors

Advantages:

Transport-grade reliability, scalable designs

25.Baikal Electromechanics

Company Profile:

A regional engineering BLDC motor manufacturer focusing on specialized motors.

Main Products:

Custom BLDC motors, special-purpose drives

Advantages:

Custom engineering expertise, application-specific optimization

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català