Introduction to Modern Motion Control Technologies

In today's precision-driven automation landscape, motion control systems are no longer judged solely by torque output or step angle. Accuracy, reliability, integration level, and system intelligence have become decisive factors. As manufacturers and system integrators pursue higher efficiency and tighter control, the comparison between Integrated Stepper Servo Motors and Traditional Stepper Motors has emerged as a critical decision point.

We provide a comprehensive, technically grounded comparison to clarify where each solution excels, how they fundamentally differ, and which applications benefit most from each motor architecture.

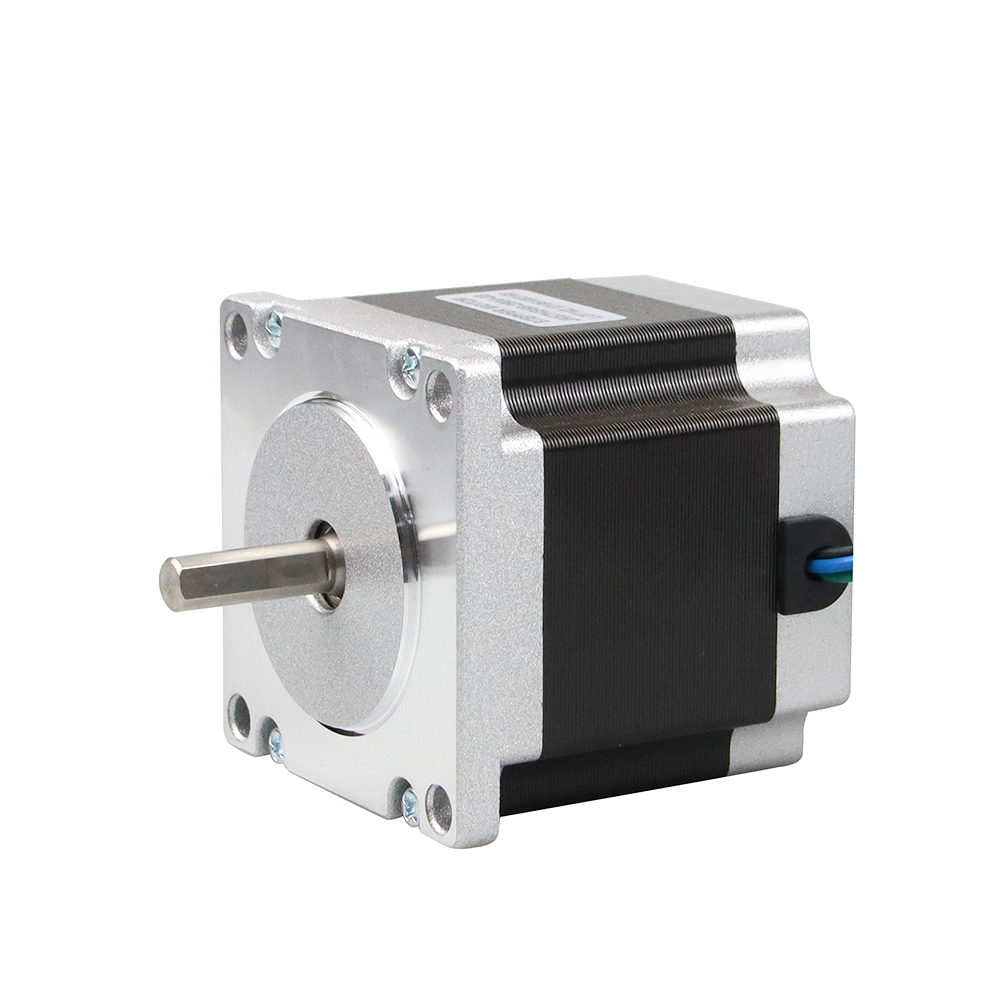

What Defines a Traditional Stepper Motor

Structural Simplicity and Open-Loop Control

A traditional stepper motor operates using a straightforward electromagnetic principle. The rotor moves in discrete steps as stator windings are energized in sequence. Most systems rely on open-loop control, meaning position is inferred from command pulses rather than verified by feedback.

Key characteristics include:

Fixed step angles (commonly 1.8° or 0.9°)

External driver and controller required

No native position feedback

Torque decreases rapidly at higher speeds

This architecture has long been favored for its low cost, predictable behavior, and ease of implementation, particularly in low-to-medium performance environments.

What Is an Integrated Stepper Servo Motor

Closed-Loop Intelligence in a Compact Form

An Integrated Stepper Servo Motor combines the stepper motor, encoder, drive electronics, and control logic into a single compact unit. Unlike traditional steppers, this system operates in closed-loop mode, continuously monitoring rotor position and dynamically correcting errors.

Core attributes include:

Built-in high-resolution encoder

Integrated servo drive and controller

Real-time position and speed feedback

Automatic error correction and fault detection

The result is a hybrid solution that merges the high torque density of stepper motors with the accuracy and reliability of servo control.

Control Architecture: Open Loop vs Closed Loop

Traditional Stepper Motor Control Limitations

Open-loop control assumes that commanded steps are always executed. Under variable loads or acceleration spikes, this assumption fails, leading to:

Once steps are lost, the system has no inherent mechanism to recover without homing.

Integrated Stepper Servo Motor Control Advantage

Closed-loop control fundamentally changes system behavior. The encoder provides constant position feedback, allowing the motor to:

Compensate for load variations instantly

Maintain commanded position without step loss

Trigger alarms or corrections when deviations occur

This control intelligence dramatically improves process reliability and repeatability.

Position Accuracy and Resolution

Step Angle vs Encoder Resolution

Traditional steppers rely on mechanical step angles and microstepping to improve smoothness. However, microstepping does not guarantee absolute positioning accuracy under load.

Integrated stepper servo motors leverage encoder feedback, achieving:

Sub-step positioning accuracy

Repeatable motion regardless of load fluctuation

True position verification rather than estimation

For applications requiring precise indexing, synchronized axes, or consistent accuracy over long cycles, integrated solutions offer a measurable advantage.

Torque Characteristics and Speed Performance

Torque behavior across varying speeds is a defining factor when comparing Integrated Stepper Servo Motors with Traditional Stepper Motors. The way torque is generated, maintained, and controlled directly influences acceleration capability, positioning accuracy, and overall machine throughput.

Torque Delivery in Traditional Stepper Motors

Traditional stepper motors are known for delivering high holding torque at low speeds, which makes them suitable for static positioning and low-speed indexing tasks. Torque is generated through discrete step excitation, and maximum torque is available only when the motor operates at or near standstill.

As rotational speed increases, traditional steppers experience a rapid torque drop-off due to inductive effects and limited current rise time. This decline restricts usable speed ranges and forces conservative acceleration profiles to avoid stalling or step loss. At higher speeds, torque margins narrow significantly, reducing system stability under variable or dynamic loads.

Speed Limitations and Resonance Effects

In traditional stepper systems, mid-range resonance can further degrade torque performance. Mechanical vibration and oscillation reduce effective torque output and may require additional damping or complex motion tuning. These constraints limit the suitability of traditional steppers for high-speed or high-inertia applications.

Optimized Torque Control in Integrated Stepper Servo Motors

Integrated stepper servo motors utilize closed-loop control with real-time encoder feedback, enabling dynamic current regulation and torque optimization. Instead of delivering fixed torque regardless of conditions, the motor supplies exactly the torque required to maintain commanded motion.

This intelligent control allows integrated motors to:

Maintain higher usable torque across a broader speed range

Achieve faster acceleration and deceleration without stalling

Compensate instantly for load changes and external disturbances

High-Speed Performance and Stability

At elevated speeds, integrated stepper servo motors outperform traditional steppers by preserving torque consistency and motion stability. Feedback-driven control eliminates resonance issues and prevents torque collapse, allowing smooth, reliable operation even in demanding motion profiles.

The result is superior performance in applications requiring rapid positioning, continuous motion, or high-speed indexing, where traditional stepper motors reach their operational limits.

Impact on Machine Productivity

Enhanced torque utilization and extended speed capability directly increase machine productivity. Integrated stepper servo motors enable shorter cycle times, higher throughput, and improved process consistency—all without sacrificing positioning accuracy or mechanical reliability.

In torque-critical and speed-intensive environments, integrated stepper servo motors deliver a decisive advantage by combining high torque density, wide speed range, and intelligent control into a single, optimized motion solution.

System Integration and Wiring Complexity

Multi-Component Architecture of Traditional Systems

A traditional stepper setup typically requires:

Separate motor

External driver

Motion controller

Power supply

Extensive wiring

This increases cabinet space requirements and introduces more potential failure points.

All-in-One Design of Integrated Stepper Servo Motors

Integrated motors consolidate all essential components into a single housing, resulting in:

For OEMs and machine builders, this translates into lower assembly time and higher system reliability.

Energy Efficiency and Thermal Management

Constant Current Draw in Traditional Steppers

Traditional stepper motors often draw full current even at standstill, generating excess heat and reducing energy efficiency.

Adaptive Power Control in Integrated Motors

Integrated stepper servo motors adjust current dynamically based on real-time demand, leading to:

This efficiency is especially valuable in 24/7 industrial environments or compact enclosures with limited cooling.

Noise, Vibration, and Smoothness

Mechanical Resonance in Traditional Stepper Motors

Open-loop stepping and fixed excitation patterns can produce resonance, audible noise, and vibration—particularly at mid-range speeds.

Servo Algorithms for Ultra-Smooth Motion

Integrated stepper servo motors use advanced control algorithms to:

This performance is essential in medical devices, laboratory automation, and precision manufacturing.

Reliability, Diagnostics, and Maintenance

Limited Fault Detection in Traditional Systems

Without feedback, traditional steppers cannot detect:

Missed steps

Overload conditions

Mechanical binding

Problems often surface only after product defects occur.

Built-In Diagnostics in Integrated Motors

Integrated stepper servo motors provide:

Position error monitoring

Overcurrent and overtemperature protection

Fault outputs and communication feedback

These features significantly reduce downtime and simplify preventive maintenance strategies.

Application Suitability Comparison

Best Use Cases for Traditional Stepper Motors

Cost-sensitive projects

Low-speed positioning

Light, predictable loads

Simple indexing tasks

Best Use Cases for Integrated Stepper Servo Motors

High-precision automation

Variable or dynamic loads

Multi-axis coordinated motion

Space-constrained machine designs

High reliability and uptime requirements

Application Field Comparison

Different application fields impose distinct requirements on motion control systems. The choice between Integrated Stepper Servo Motors and Traditional Stepper Motors should be based on precision, speed, reliability, and system complexity.

CNC equipment demands high accuracy, consistent torque, and reliable high-speed operation. Integrated stepper servo motors excel by providing closed-loop control, preventing step loss, and maintaining stable torque during rapid acceleration and deceleration. Traditional stepper motors are generally limited to auxiliary axes or low-load CNC applications where speed and precision demands are lower.

Packaging machines require fast cycle times, smooth motion, and high repeatability. Integrated stepper servo motors support dynamic load changes and high-speed indexing without vibration, improving throughput and reducing product defects. Traditional stepper motors are suitable for simple, low-speed packaging tasks but struggle in high-speed or multi-axis systems.

Medical and laboratory equipment prioritize precision, low noise, smooth motion, and reliability. Integrated stepper servo motors deliver quiet operation, accurate positioning, and built-in fault detection, making them ideal for imaging systems, pumps, and diagnostic devices. Traditional stepper motors may be used in cost-sensitive, non-critical medical applications with predictable loads.

Industrial Automation and Robotics

In automation lines and robotic subsystems, integrated stepper servo motors offer better scalability, higher efficiency, and reduced downtime. Traditional stepper motors remain effective for simple pick-and-place tasks or fixed-position mechanisms with minimal load variation.

Summary of Application Suitability

Traditional Stepper Motors: Best for simple, low-speed, cost-driven applications

Integrated Stepper Servo Motors: Best for high-precision, high-speed, and reliability-critical systems

Selecting the appropriate motor technology ensures optimal performance, efficiency, and long-term operational value across diverse application fields.

Cost Considerations and Total Cost of Ownership

When evaluating Integrated Stepper Servo Motors versus Traditional Stepper Motors, cost must be assessed beyond initial purchase price. A comprehensive Total Cost of Ownership (TCO) analysis reveals substantial long-term differences that directly impact operational efficiency, maintenance budgets, and system scalability.

Initial Investment vs System-Level Cost

Traditional stepper motors typically offer a lower upfront motor cost, making them attractive for budget-sensitive projects. However, they require multiple external components, including drivers, controllers, power supplies, feedback add-ons (if any), and extensive wiring. These additional elements increase system-level cost, assembly time, and integration complexity.

Integrated stepper servo motors consolidate the motor, encoder, drive electronics, and control logic into a single unit. While the unit price is higher, the elimination of external drivers, reduced cabling, and simplified control architecture significantly lower overall system expenditure.

Installation, Commissioning, and Engineering Time

Traditional stepper systems demand careful tuning, wiring verification, and conservative motion profiling to avoid missed steps. Engineering time increases as systems scale or become multi-axis.

Integrated stepper servo motors are typically pre-tuned at the factory and support plug-and-play installation. Faster commissioning, fewer configuration errors, and simplified diagnostics translate into lower engineering and labor costs during deployment.

Operational Efficiency and Energy Consumption

Traditional stepper motors often draw constant current regardless of load, resulting in higher energy consumption and excess heat generation. Over time, this leads to increased power costs and thermal management requirements.

Integrated stepper servo motors dynamically regulate current based on real-time load conditions. This adaptive control reduces power usage, minimizes heat, and improves overall system efficiency—delivering measurable energy savings in continuous-duty applications.

Maintenance, Downtime, and Reliability Costs

Open-loop traditional stepper systems lack position verification, making missed steps difficult to detect until product defects or system failures occur. Troubleshooting is reactive, often resulting in unplanned downtime and production losses.

Integrated stepper servo motors feature built-in diagnostics, fault monitoring, and real-time feedback. Early error detection and automatic correction reduce unplanned stoppages, lower maintenance intervention frequency, and enhance equipment uptime—dramatically improving lifecycle reliability.

Scalability and Long-Term Value

As automation systems expand, traditional stepper architectures become increasingly complex and costly to maintain. Integrated solutions scale more efficiently, offering consistent performance, simplified upgrades, and compatibility with modern digital control environments.

solutions scale more efficiently, offering consistent performance, simplified upgrades, and compatibility with modern digital control environments.

From a long-term perspective, integrated stepper servo motors consistently deliver a lower total cost of ownership, despite higher initial investment. Reduced component count, lower energy usage, minimal downtime, and extended service life make them the economically superior choice for performance-driven and industrial-grade applications.

Future Trends in Motion Control

As Industry 4.0 accelerates, demand is shifting toward smart, compact, and network-ready motion solutions. Integrated stepper servo motors align perfectly with this trend, offering:

Traditional stepper motors will remain relevant for basic tasks, but intelligent integrated solutions are clearly shaping the future of precision motion control.

Conclusion: Making the Right Choice

The decision between an Integrated Stepper Servo Motor and a Traditional Stepper Motor depends on performance expectations, system complexity, and long-term operational goals. Traditional steppers remain effective for simple, cost-driven applications. However, when accuracy, reliability, efficiency, and system integration are critical, integrated stepper servo motors deliver a decisive technical and economic advantage. BESFOC also offers custom motor solutions tailored to specific mechanical, electrical, and application requirements.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català