Introduction to BLDC Motors in Modern Home Appliances

We are witnessing a rapid transformation in home appliance technology, driven by energy efficiency regulations, smart control systems, and consumer demand for quieter, longer-lasting products. At the center of this evolution is the BLDC motor (Brushless Direct Current Motor). Compared with traditional brushed DC motors and AC induction motors, BLDC motors deliver superior efficiency, precise speed control, low noise, and extended service life, making them the preferred choice for premium and next-generation home appliances.

Selecting the right BLDC motor for home appliance applications is not a one-size-fits-all decision. It requires a systematic evaluation of electrical, mechanical, thermal, and application-specific parameters. We outline a professional, application-oriented approach that appliance manufacturers and product engineers can rely on.

Understanding Home Appliance Load Characteristics

Every home appliance imposes a unique load profile on the motor. We begin by analyzing the operating load type, as it directly affects torque, speed stability, and motor lifespan.

Constant Load Applications: Refrigerators, ventilation fans, and air purifiers typically operate under steady-state loads.

Variable Load Applications: Washing machines, dryers, and vacuum cleaners experience frequent load changes.

High Inertia Loads: Drum-based appliances require motors capable of handling large startup torque and frequent acceleration/deceleration cycles.

Matching the BLDC motor torque curve with real load conditions ensures stable operation, prevents overheating, and improves long-term reliability.

Torque and Speed Requirements for Appliance Motors

We define torque and speed requirements as the foundation of correct motor selection for home appliances. An accurate match between the motor’s output characteristics and the appliance’s operating profile ensures stable performance, high efficiency, low noise, and long service life. Any mismatch—either undersizing or oversizing—leads to premature failure, energy loss, or unnecessary cost.

Understanding Operating Torque Profiles

Every appliance exhibits a distinct torque demand pattern. We categorize these profiles to determine the correct rated torque and peak torque values:

Starting Torque: Required to overcome static friction, load inertia, and mechanical resistance at startup. Appliances such as washing machines, dryers, and compressors demand high starting torque.

Rated (Continuous) Torque: The torque needed during normal, steady-state operation. This value determines thermal stability and continuous duty capability.

Peak Torque: Short-duration torque required during acceleration, load fluctuation, or sudden resistance changes. Motors must support peak torque without magnetic saturation or overheating.

We always recommend selecting a motor with sufficient torque margin, typically 20–40% above calculated continuous requirements, to ensure durability under real-world conditions.

Speed Range and Control Accuracy

Speed requirements vary significantly across appliance categories. We evaluate not only the rated speed, but also the adjustable speed range and speed stability.

Low-Speed Precision: Essential for appliances such as washing machines, mixers, and robotic cleaners, where smooth operation at low RPM prevents vibration and noise.

High-Speed Capability: Required for vacuum cleaners, centrifugal fans, and hair dryers, where airflow or suction performance depends directly on rotational speed.

Wide Speed Regulation: Modern appliances increasingly demand seamless speed transitions, enabled by BLDC motors with advanced electronic control.

BLDC motors excel in maintaining constant speed under load changes, which is critical for consistent appliance performance.

Load Inertia and Acceleration Demands

Rotational inertia plays a decisive role in torque and speed matching. Appliances with rotating drums, impellers, or large fan blades impose higher inertia loads.

We calculate:

Acceleration torque required to reach target speed

Deceleration torque during braking or speed reduction

Dynamic torque reserve for repeated start-stop cycles

Motors selected without considering inertia often suffer from overheating, controller stress, and shortened bearing life.

Duty Cycle and Thermal Impact

Torque and speed must always be evaluated in relation to the duty cycle:

Continuous Duty (S1): Air purifiers, refrigerators, and circulation fans

Intermittent Duty (S3/S6): Washing machines and dishwashers

Short-Time Duty (S2): High-power appliances with limited runtime

Higher torque at lower speeds increases current draw and heat generation. We ensure that torque-speed operating points remain within the motor's thermal limits across the full duty cycle.

Application-Specific Optimization

Different home appliances prioritize torque and speed differently:

Washing Machines: High torque at low speed, stable operation at high spin speeds

Fans and Blowers: Moderate torque, wide speed range, low noise

Vacuum Cleaners: High-speed operation with stable torque under variable airflow resistance

Compressors: High startup torque with efficient steady-state performance

By tailoring the BLDC motor torque-speed curve to the appliance’s real operating conditions, we achieve optimal performance without unnecessary cost or complexity.

Conclusion

We treat torque and speed requirements not as isolated parameters, but as a dynamic system-level design decision. Proper evaluation of load type, inertia, duty cycle, and control requirements allows us to select BLDC motors that deliver reliable, efficient, and quiet operation across the full lifespan of modern home appliances.

Energy Efficiency and Regulatory Compliance

We position energy efficiency and regulatory compliance as core design priorities in modern home appliance motor selection. With increasingly strict global energy regulations and rising consumer awareness, appliances powered by high-efficiency motors are no longer a premium option—they are a market requirement. BLDC motors play a decisive role in meeting these demands by delivering superior electrical efficiency, precise power control, and reduced environmental impact.

Why Energy Efficiency Is Critical in Home Appliances

Energy consumption directly affects appliance operating cost, environmental footprint, and product marketability. We focus on maximizing system-level efficiency, not just motor efficiency alone.

Key efficiency drivers include:

Reduced electrical losses in windings and magnets

Optimized electromagnetic design for minimal torque ripple

High-efficiency electronic commutation via advanced controllers

Compared to traditional AC induction motors, BLDC motors typically reduce energy consumption by 20–40%, significantly improving appliance energy ratings.

Motor Efficiency vs System Efficiency

We evaluate efficiency across the entire drive system, including:

Motor core efficiency

Controller (inverter) efficiency

Power supply and standby losses

Mechanical transmission efficiency

A high-efficiency BLDC motor paired with a poorly matched controller can underperform. Proper motor–controller integration ensures stable operation across variable speeds and loads while maintaining peak efficiency.

Global Energy Regulations and Standards

Home appliances must comply with regional and international efficiency regulations. We design BLDC motor solutions that support compliance with major standards, including:

IEC and EN standards for global and European markets

ErP (Energy-related Products Directive) for energy labeling and minimum efficiency thresholds

DOE regulations for North American energy performance

ENERGY STAR® requirements for premium efficiency appliances

Motors that support these standards help manufacturers achieve faster certifications and wider market access.

Energy Labeling and Consumer Impact

Energy labels influence purchasing decisions. Appliances equipped with high-efficiency BLDC motors consistently achieve higher energy classes due to:

Lower power draw during continuous operation

Reduced losses during partial-load conditions

Improved efficiency at variable speeds

This translates into measurable annual energy savings for end users and a stronger value proposition for appliance brands.

Standby Power and Low-Load Performance

Regulations increasingly address standby and no-load power consumption. We optimize BLDC motor systems to minimize idle power usage through:

Intelligent controller sleep modes

High-efficiency power electronics

Optimized firmware for low-speed operation

Low standby consumption is essential for compliance with modern eco-design requirements.

Thermal Efficiency and Reliability

Higher efficiency directly reduces heat generation. We ensure that BLDC motors operate with:

Lower winding temperatures

Reduced thermal stress on insulation materials

Extended bearing and component life

Improved thermal efficiency enhances long-term reliability while supporting continuous or high-duty appliance operation.

Sustainability and Environmental Compliance

Beyond energy consumption, compliance also includes environmental considerations. We support sustainable appliance design through:

Reduced carbon emissions from lower power usage

Long motor service life, minimizing replacement waste

Compliance with RoHS and REACH material standards

BLDC motors align with global sustainability initiatives and long-term environmental regulations.

Future-Proofing Appliance Designs

Energy regulations evolve continuously. We select BLDC motor platforms that allow:

Firmware updates for efficiency optimization

Scalability across multiple appliance models

Integration with smart energy management systems

Future-ready motor solutions protect appliance investments and extend product lifecycle relevance.

Conclusion

We treat energy efficiency and regulatory compliance as strategic advantages rather than constraints. By leveraging high-efficiency BLDC motor technology, appliance manufacturers achieve lower energy consumption, regulatory alignment, improved reliability, and enhanced market competitiveness in a rapidly evolving global landscape.

Noise, Vibration, and Acoustic Performance

Noise is a critical purchasing factor for home appliances. We prioritize low acoustic emission through motor and system design.

Key considerations include:

Electromagnetic noise caused by torque ripple

Mechanical vibration from bearings and rotor imbalance

Switching noise from motor controllers

Advanced BLDC motors with optimized winding design, skewed stators, and precision bearings significantly reduce audible noise, making them ideal for bedroom and kitchen appliances.

Voltage, Power Supply, and Control Compatibility

Home appliances operate under diverse voltage standards worldwide. Selecting the correct BLDC motor voltage rating ensures compatibility and safety.

Common voltage options include:

12V / 24V DC for compact appliances

48V DC for high-efficiency systems

110V / 220V AC input with integrated controller

Equally important is controller compatibility. We assess:

Seamless motor-controller integration improves efficiency, reliability, and speed regulation accuracy.

Thermal Management and Continuous Operation

Home appliances often run for extended periods. Thermal performance directly impacts motor lifespan and safety.

We analyze:

Winding temperature rise

Insulation class (Class B, F, or H)

Cooling method (natural or forced air)

A properly selected BLDC motor with optimized thermal design maintains stable performance even under continuous or high-load operation, reducing warranty risks.

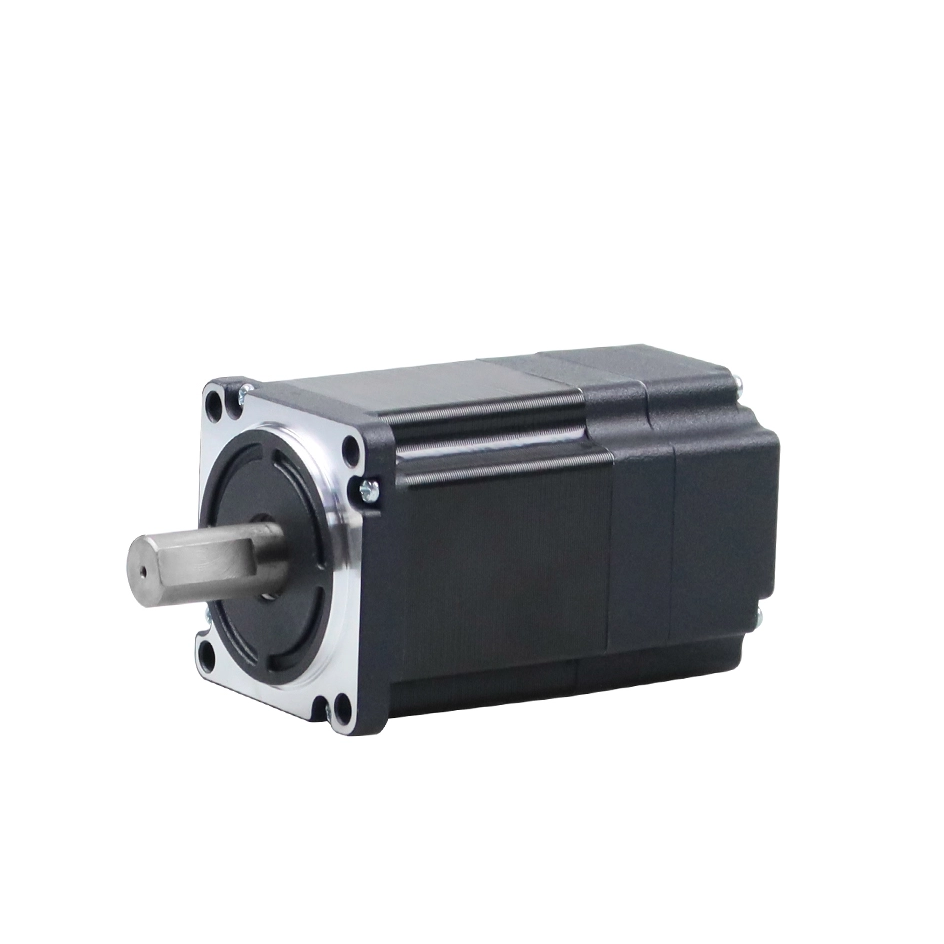

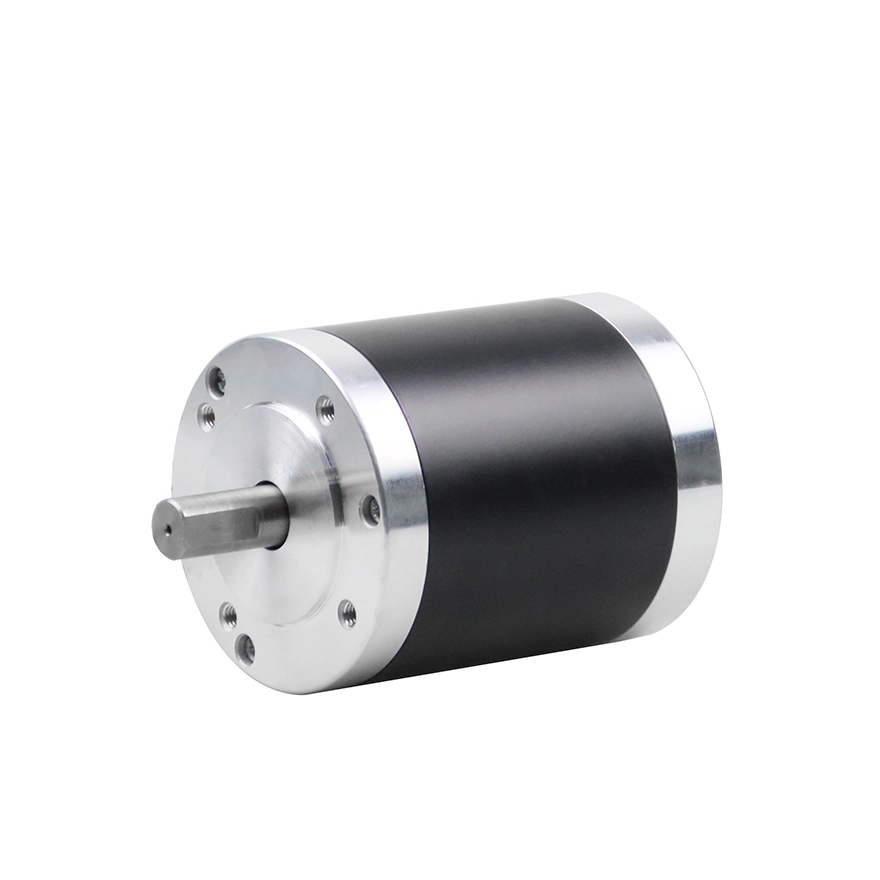

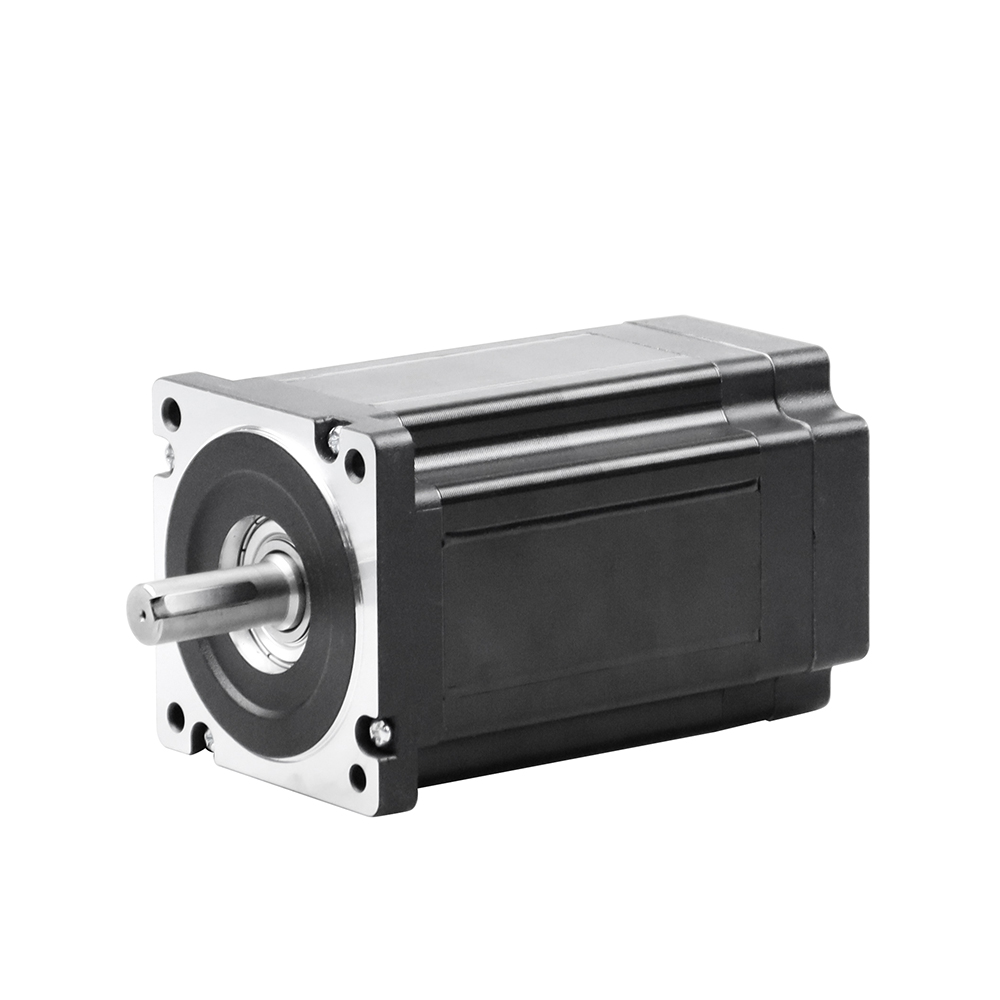

Mechanical Design and Installation Constraints

Appliance design imposes strict space and mounting limitations. We ensure that the BLDC motor mechanical structure aligns with product requirements.

Critical mechanical parameters include:

Motor outer diameter and length

Shaft type and tolerance

Mounting flange or bracket design

Bearing life and load capacity

Compact, high power-density BLDC motors enable slimmer appliance designs without compromising performance.

Reliability, Service Life, and Maintenance-Free Operation

One of the strongest advantages of BLDC motors for home appliances is their maintenance-free nature. Without brushes, mechanical wear is significantly reduced.

We focus on:

Bearing quality and lubrication

Rotor balancing

Environmental protection (dust, humidity, grease)

A well-designed BLDC motor can exceed 20,000–50,000 hours of service life, supporting premium appliance positioning.

Customization for Specific Appliance Applications

We regard customization as a critical factor in achieving optimal motor performance in modern home appliances. While standard motors can meet basic functional requirements, they rarely deliver the highest levels of efficiency, reliability, noise control, and cost optimization across diverse appliance platforms. Customized BLDC motor solutions allow us to precisely align motor characteristics with real operating conditions, ensuring superior appliance performance and long-term market competitiveness.

Why Standard Motors Are Often Insufficient

Home appliances differ widely in load behavior, duty cycle, installation space, and user expectations. Standardized motors are typically designed for general-purpose use, resulting in compromises such as:

Excessive power consumption due to oversizing

Unnecessary noise and vibration

Limited speed regulation accuracy

Reduced efficiency under partial-load conditions

Customization eliminates these inefficiencies by tailoring the motor to the exact appliance requirements.

Electrical Customization for Performance Optimization

We customize key electrical parameters to match application-specific demands:

Winding configuration optimized for torque, speed, or efficiency

Voltage and current ratings aligned with regional power standards

Magnet grade selection balancing performance and cost

Back-EMF characteristics tuned for stable speed control

These adjustments allow BLDC motors to operate at peak efficiency across the appliance’s real operating range.

Mechanical Customization for Seamless Integration

Mechanical integration is often constrained by appliance design. We provide mechanical customization to ensure precise fit and reliable operation:

Custom shaft length, diameter, and tolerance

Application-specific mounting flanges or brackets

Optimized bearing selection for load and lifespan

Compact housing designs for space-limited installations

for space-limited installations

Proper mechanical customization reduces assembly complexity and improves overall appliance durability.

Thermal and Cooling Optimization

Different appliances impose varying thermal loads. We adapt motor designs to maintain thermal stability through:

Optimized stator lamination and slot fill

Improved heat dissipation paths

Natural or forced-air cooling configurations

Customized thermal design ensures consistent performance even under high-duty or high-ambient-temperature conditions.

Noise and Vibration Control Through Custom Design

Acoustic performance is a decisive factor in appliance quality perception. We reduce noise and vibration by customizing:

Winding patterns to minimize torque ripple

Rotor balancing for smooth rotation

Bearing types and preload settings

Controller switching strategies

Low-noise BLDC motors are essential for premium appliances such as air purifiers, refrigerators, and bedroom fans.

Controller and Firmware Customization

Motor performance is inseparable from its controller. We provide tailored control solutions that include:

Sensorless or Hall-sensor control strategies

Application-specific startup and acceleration profiles

Intelligent fault detection and protection

Communication interfaces for smart appliances

Customized firmware enables precise speed regulation, improved efficiency, and enhanced system diagnostics.

Application-Specific Custom Motor Solutions

We develop customized BLDC motors for a wide range of home appliances, including:

Washing machines requiring high torque at low speed and stable high-speed operation

Fans and blowers needing wide speed regulation and ultra-low noise

Vacuum cleaners demanding high-speed performance under variable load

Refrigeration systems prioritizing continuous duty and energy efficiency

Each application benefits from a motor design optimized for its unique operational profile.

Cost-Effective Customization and Scalability

Customization does not imply high cost. We optimize designs to achieve:

Strategic customization balances performance improvements with manufacturing efficiency, ensuring commercial viability.

Conclusion

We view customization for specific appliance applications as a strategic advantage rather than a complexity. By tailoring BLDC motor designs to real-world operating conditions, we enable home appliances to achieve higher efficiency, lower noise, longer service life, and stronger market differentiation in an increasingly competitive industry.

Cost Optimization Without Performance Compromise

While BLDC motors offer long-term savings, upfront cost remains a concern. We address this by optimizing the total system cost, not just motor price.

Cost optimization strategies include:

Selecting appropriate magnet grade

Balancing controller complexity

Reducing overspecification

Improving manufacturing scalability

A strategically selected BLDC motor delivers lower total cost of ownership over the appliance lifecycle.

Future Trends in BLDC Motors for Home Appliances

The future of home appliances is intelligent, connected, and energy-aware. BLDC motors will continue to evolve with advancements in:

Smart motor control algorithms

Integrated motor-drive modules

IoT-enabled diagnostics

Higher efficiency magnetic materials

Selecting forward-compatible BLDC motors ensures product longevity and future market readiness.

Conclusion: A Structured Approach to BLDC Motor Selection

We believe that choosing the right BLDC motor for home appliance applications requires a holistic evaluation of performance, efficiency, reliability, and integration. By aligning motor characteristics with real application demands, manufacturers can achieve superior appliance performance, regulatory compliance, and long-term customer satisfaction.

FAQs: How to Choose a BLDC Motor for Home Appliance Applications

I. Product Perspective: Performance, Efficiency & Appliance Requirements

1. What is a BLDC motor and why is it preferred in home appliances?

A BLDC motor uses electronic commutation, offering higher efficiency, lower noise, and longer service life than brushed motors, making a standard BLDC motor ideal for modern home appliances.

2. Which home appliances commonly use BLDC motors?

BLDC motors are widely used in washing machines, refrigerators, air conditioners, vacuum cleaners, dishwashers, and smart fans.

3. How do I choose the right standard BLDC motor for a home appliance?

Key factors include rated torque, speed range, voltage, efficiency class, and noise level. A professional BLDC motor manufacturer can help match these parameters.

4. Why is energy efficiency critical for home appliance BLDC motors?

High-efficiency BLDC motors reduce power consumption and help appliances meet global energy-saving regulations.

5. What voltage options are common for home appliance BLDC motors?

Standard options include 12V, 24V, 36V, 48V, and AC-input inverter-driven BLDC motors, depending on appliance design.

6. How important is low noise in BLDC motors for home appliances?

Noise control is critical; a well-designed standard BLDC motor ensures smooth operation and improved user comfort.

7. Can BLDC motors support variable speed control in appliances?

Yes, BLDC motors provide precise speed control, enabling smart features like soft start, variable airflow, and load-adaptive operation.

8. What is the typical lifespan of a BLDC motor in home appliances?

A high-quality BLDC motor can operate for tens of thousands of hours due to brushless construction and reduced wear.

9. Are BLDC motors suitable for continuous-duty appliance operation?

Yes, most standard BLDC motors are designed for continuous or intermittent duty in appliance environments.

10. How does motor size affect appliance design?

Compact BLDC motor designs allow smaller, lighter, and more efficient home appliance layouts.

II. Factory Customization Capability: OEM & Home Appliance Manufacturing Support

11. Can a BLDC motor manufacturer customize motors for specific home appliances?

Yes, a BLDC motor manufacturer can customize torque, speed, housing, and mounting to fit appliance designs.

12. What customization options are available beyond a standard BLDC motor?

Custom BLDC motors may include special windings, shaft types, connectors, and integrated control boards.

13. Can BLDC motors be customized for ultra-low noise applications?

Yes, optimized magnetic design, precision balancing, and control algorithms reduce vibration and noise.

14. Is it possible to integrate the driver or inverter with the BLDC motor?

Many manufacturers offer integrated BLDC motor solutions with built-in drivers for compact appliance designs.

15. Can BLDC motors be customized to meet global certification requirements?

A qualified BLDC motor manufacturer supports compliance with CE, UL, RoHS, and energy-efficiency standards.

16. Are custom BLDC motors available for high-volume appliance production?

Yes, manufacturers support scalable production from prototype to mass production for home appliance OEMs.

17. What is the typical MOQ for a custom BLDC motor project?

MOQ varies based on customization level, but many manufacturers support low-MOQ sampling for evaluation.

18. How does customization affect BLDC motor lead time?

Standard BLDC motors have short lead times, while custom BLDC motors require additional design and validation time.

Quality assurance includes efficiency testing, noise testing, thermal aging, and endurance testing.

20. Why choose an experienced BLDC motor manufacturer for home appliances?

An experienced BLDC motor manufacturer provides stable quality, cost optimization, regulatory support, and long-term supply reliability.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català