Stepper motor losing steps under load is one of the most common yet costly problems in motion control systems. It leads to positioning errors, process instability, product defects, and in severe cases, complete system failure. We address this issue from an engineering and application-driven perspective, providing actionable, proven solutions used in industrial automation, CNC machinery, robotics, medical devices, and precision equipment.

This guide delivers deep technical clarity, practical optimization strategies, and system-level fixes that eliminate missed steps under load conditions.

Stepper motor step loss under load is primarily caused by torque mismatch, control settings, and system design. Proper motor selection, optimized parameters, and customized factory solutions—such as closed-loop control or integrated stepper servo motors—can effectively eliminate missed steps and improve system reliability.

Understanding Step Loss in Stepper Motors

Stepper motors operate in an open-loop control system, meaning they execute commanded steps without position feedback. When the required torque exceeds available torque, the motor fails to rotate to the next step, resulting in lost steps.

Under load, this issue is amplified by mechanical resistance, inertia, electrical limitations, and dynamic operating conditions.

Insufficient Available Torque

When the applied load torque exceeds the motor's instantaneous torque capability, the rotor stalls or slips.

Key contributors include:

Undersized motor selection

High acceleration demands

Operating beyond the motor's torque-speed curve

Excessive Acceleration or Deceleration

Rapid acceleration requires significantly higher torque than constant-speed operation. If acceleration ramps are too aggressive, the motor cannot follow the step commands.

Low current limits reduce holding and dynamic torque, while excessive current leads to thermal saturation, reducing torque over time.

Power Supply Voltage Limitations

Stepper motors rely on high voltage to overcome inductive impedance at speed. Low voltage causes:

Mechanical Load and Inertia Mismatch

High inertia loads, poor coupling alignment, and mechanical friction dramatically increase torque demand during motion transitions.

Resonance and Vibration Effects

Mid-range resonance causes oscillations that disrupt rotor synchronization, especially under partial load.

Effective Solutions to Prevent Step Loss Under Load

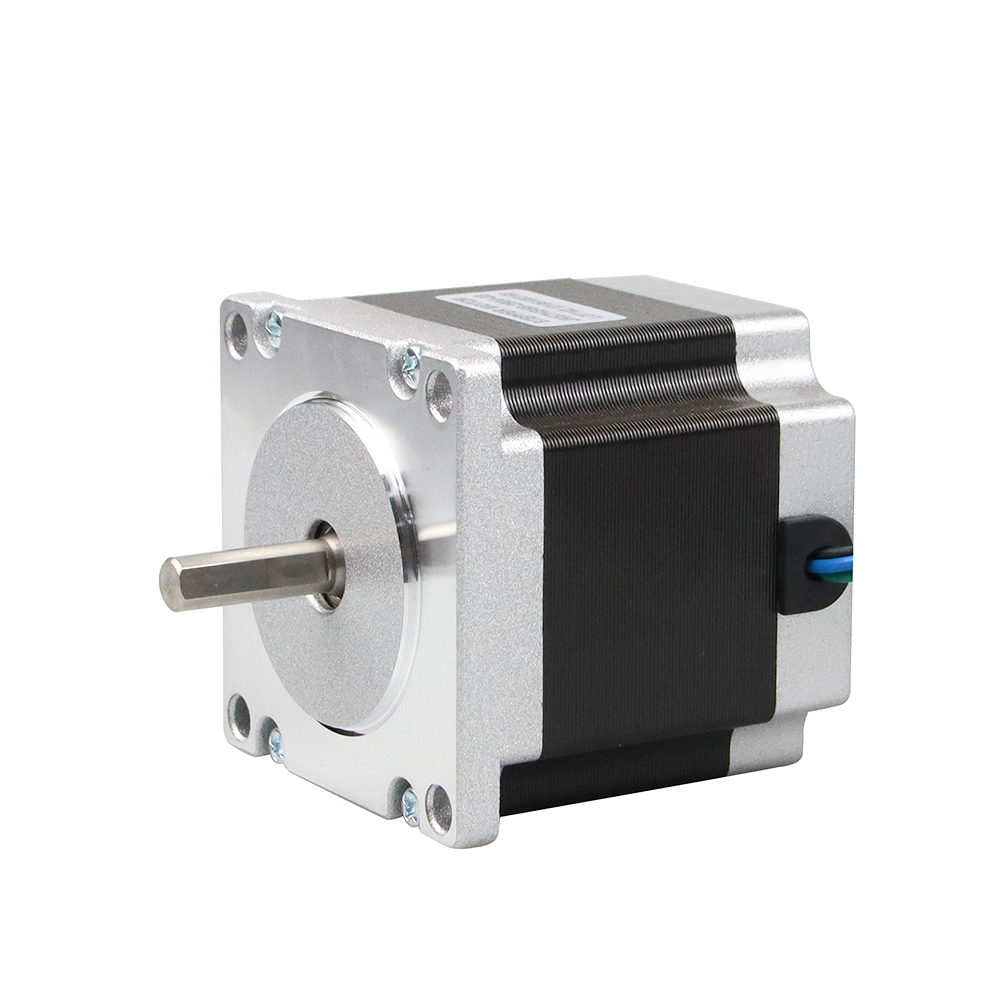

1. Select the Correct Stepper Motor Size

Proper motor sizing is the foundation of reliable motion control.

Best practices include:

Ensure 30–50% torque margin above maximum load torque

Evaluate torque at operating speed, not holding torque

Consider frame size upgrades (e.g., NEMA 17 to NEMA 23)

A larger motor with adequate torque reserve prevents step loss during load spikes and acceleration events.

2. Optimize Acceleration and Deceleration Profiles

Reducing acceleration stress is one of the fastest fixes.

Recommended actions:

Use trapezoidal or S-curve motion profiles

Lower initial acceleration and ramp gradually

Match acceleration to motor torque-speed capabilities

Controlled ramps significantly reduce inertial torque demands.

3. Increase Power Supply Voltage (Within Drive Limits)

Higher voltage improves current response at speed.

Benefits include:

Always ensure voltage remains within driver-rated limits.

4. Correct Drive Current Configuration

Proper current tuning ensures optimal torque without overheating.

Guidelines:

Set RMS current to motor rated current

Enable dynamic current reduction only when stationary

Avoid conservative undercurrent settings

Thermal monitoring is essential to prevent torque degradation over time.

5. Improve Mechanical System Efficiency

Mechanical losses often cause hidden torque overloads.

Critical checks:

Reducing friction directly increases available torque margin.

6. Reduce Load Inertia or Add Gear Reduction

High inertia is a major cause of step loss during acceleration.

Solutions:

Reduce rotating mass where possible

Add planetary gearboxes to increase output torque

Use belt reduction for inertia matching

Gear reduction improves torque while lowering reflected inertia.

7. Implement Microstepping Correctly

Microstepping improves smoothness but reduces incremental torque per microstep.

Best practices:

Use microstepping for smooth motion, not torque increase

Avoid excessive microstep resolutions under heavy load

Balance resolution with torque requirements

For heavy loads, lower microstep settings often improve reliability.

8. Eliminate Resonance with Damping Techniques

Resonance is a silent contributor to step loss.

Mitigation methods:

Modern digital stepper drives dramatically reduce resonance-related issues.

9. Upgrade to Closed-Loop Stepper Systems

When step loss cannot be tolerated, closed-loop control provides guaranteed positioning.

Advantages include:

Real-time position correction

Stall detection and recovery

Higher dynamic torque utilization

Closed-loop steppers bridge the gap between traditional steppers and servo systems.

10. Monitor Thermal Conditions Continuously

Temperature rise reduces winding resistance efficiency and magnetic strength.

Recommendations:

Maintain ambient temperature within specifications

Ensure adequate ventilation

Avoid continuous holding torque at high current

Thermal stability ensures consistent torque output over long duty cycles.

Advanced Diagnostic Techniques

Dynamic Load Testing

Measure torque performance under real operating loads to identify overload conditions during acceleration and peak demand.

Current and Voltage Analysis

Monitor phase current and supply voltage to detect insufficient current rise, voltage drops, or driver saturation at speed.

Thermal Monitoring

Track motor and driver temperatures to identify torque loss caused by overheating or thermal derating.

Motion Profile Verification

Analyze acceleration, deceleration, and speed curves to confirm they align with the motor’s torque-speed capability.

Resonance Detection

Identify vibration or audible noise in mid-speed ranges that may indicate resonance-induced step loss.

Mechanical Inspection

Check couplings, bearings, belts, and lead screws for misalignment, backlash, or excessive friction.

These targeted diagnostics quickly isolate the root cause of step loss and guide precise corrective actions.

Common Application-Specific Considerations

Stepper motor performance and the risk of step loss vary significantly depending on the application environment, motion profile, and load characteristics. Understanding application-specific requirements allows us to apply targeted design and tuning strategies that ensure stable operation under real-world conditions. Below are the most common application categories and the critical considerations associated with each.

CNC systems place heavy and highly variable loads on stepper motors, particularly during cutting operations. Axes are subjected to fluctuating cutting forces, rapid direction changes, and high inertia loads from lead screws and spindles.

Key considerations include:

High dynamic torque demand, especially on Z-axis and gantry systems

The need for conservative acceleration and deceleration profiles

Oversizing motors to maintain torque margin during peak cutting loads

Implementing gear or belt reduction to improve torque and inertia matching

Avoiding excessive microstepping that can reduce usable torque

In precision machining, even a single missed step can compromise dimensional accuracy, making torque margin and motion tuning critical.

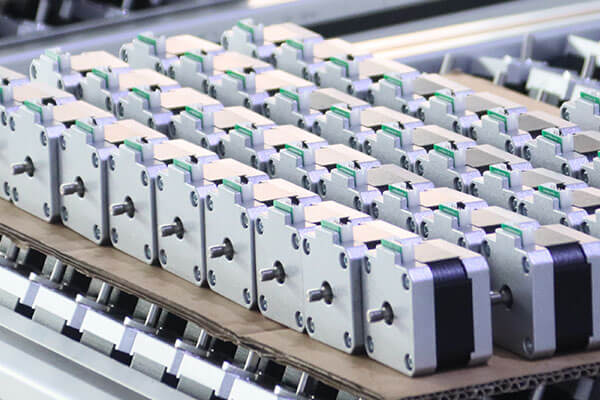

Industrial Automation and Assembly Lines

Automation systems typically operate continuously with repetitive motion cycles. Reliability and thermal stability are often more important than peak speed.

Important factors include:

Continuous duty cycles that can cause thermal buildup

Consistent positioning accuracy over long production runs

Variable payloads depending on the production stage

Mechanical wear over time increasing friction and torque demand

Proper thermal management, conservative current settings, and regular mechanical maintenance help prevent gradual step loss in these environments.

Robotics and Pick-and-Place Systems

Robotic applications involve rapid acceleration, deceleration, and frequent directional changes. Load inertia can vary significantly depending on arm extension and payload.

Critical considerations:

Inertia mismatch between motor and load

Dynamic torque spikes during fast moves

The need for smooth motion to prevent oscillations

Using S-curve acceleration to reduce inertial shock

In high-speed robotics, closed-loop stepper systems are often preferred to detect and correct step loss in real time.

Medical and Laboratory Equipment

Medical devices require extremely high positioning accuracy, smooth motion, and quiet operation. Loads are usually light, but precision is non-negotiable.

Key priorities include:

Low vibration and acoustic noise

Stable microstepping for smooth motion

Strict thermal limits to protect sensitive components

Long-term positional repeatability

Microstepping optimization, low-resonance drivers, and controlled current reduction during idle states are essential in these applications.

3D Printers and Desktop Manufacturing

3D printers rely heavily on stepper motors for consistent layer positioning. Step loss leads directly to layer shifts, print failure, and wasted material.

Important considerations:

Rapid acceleration on lightweight gantries

Belt tension and pulley alignment

Motor heating during long print cycles

Power supply voltage stability

Reducing acceleration, increasing motor current within safe limits, and maintaining mechanical alignment significantly reduce step loss risks.

Packaging systems often require high-speed motion with frequent start-stop cycles. Loads may vary based on product size and packaging material.

Key challenges:

High cycle rates increasing inertial stress

Variable friction due to material contact

Precise synchronization between multiple axes

Proper torque margin, synchronized motion profiles, and robust mechanical design are essential to prevent cumulative step loss.

Textile, Printing, and Conveyor Systems

These systems typically operate at constant speed with long run times, but may experience load fluctuations.

Considerations include:

Belt and roller tension consistency

Wear-related friction increase over time

Resonance at steady operating speeds

Designing for long-term torque stability and implementing preventative maintenance routines are crucial for reliability.

Summary

Each application presents unique mechanical, electrical, and dynamic challenges that influence stepper motor performance. Step loss is rarely caused by the motor alone; it emerges from the interaction between load behavior, motion profiles, thermal conditions, and mechanical design. By addressing application-specific considerations early in the design process, we can build stepper motor systems that deliver consistent, accurate, and failure-free operation across diverse industrial and precision environments.

Preventive Design Checklist

Motor torque margin ≥ 30%

Acceleration tuned to load inertia

Voltage optimized for speed

Current correctly configured

Mechanical losses minimized

Resonance actively suppressed

Applying these principles during system design eliminates step loss before it occurs.

Product & Technical FAQs

1. Why does a stepper motor lose steps under load?

Stepper motors lose steps when the applied load torque exceeds the available holding or dynamic torque, often due to improper motor sizing or acceleration settings.

2. How does load torque affect stepper motor accuracy?

Higher load torque increases the risk of missed steps, especially at higher speeds where available torque drops significantly.

3. Can increasing motor current prevent step loss?

Increasing current can improve torque, but excessive current may cause overheating and shorten motor lifespan.

4. What role does the torque-speed curve play in step loss?

The torque-speed curve shows how torque decreases with speed, helping engineers avoid operating points where step loss is likely.

5. Does acceleration setting impact stepper motor stability?

Yes, overly aggressive acceleration can cause the motor to stall or skip steps under load.

6. Is microstepping effective in reducing missed steps?

Microstepping improves smoothness and vibration control but does not significantly increase maximum torque.

7. When should a closed-loop stepper motor be used?

Closed-loop stepper motors are recommended when load variations are unpredictable and step accuracy is critical.

8. How does encoder feedback help prevent losing steps?

Encoder feedback detects position errors in real time and corrects them before step loss occurs.

9. Can a larger frame size motor solve step loss issues?

A larger frame size usually provides higher torque, reducing the risk of losing steps under heavy loads.

10. Are integrated stepper servo motors better for high-load applications?

Yes, integrated stepper servo motors combine high torque, feedback, and compact design for demanding applications.

Factory Customization & OEM FAQs

11. Can stepper motors be customized for higher load capacity?

Yes, torque can be increased through custom winding, optimized magnetic circuits, or larger motor frames.

12. Is it possible to customize motor current ratings?

Factories can adjust winding parameters to match specific voltage and current requirements.

13. Can you customize stepper motors for continuous heavy-load operation?

Thermal design, insulation class, and cooling options can be customized for long-duty cycles.

14. Do you offer integrated motor and driver solutions?

Yes, integrated solutions reduce wiring complexity and improve system reliability under load.

15. Can encoder type be customized for closed-loop stepper motors?

Different encoder resolutions and types can be selected based on accuracy and budget needs.

16. Is gearbox integration available for load-heavy applications?

Planetary or worm gearboxes can be integrated to increase output torque.

17. Can stepper motors be optimized for low-speed high-torque output?

Yes, custom pole design and winding optimization support low-speed, high-torque performance.

18. Do you support OEM or ODM stepper motor projects?

Factories provide full OEM/ODM services including mechanical, electrical, and performance customization.

19. Can vibration and noise be reduced through customization?

Damping design, rotor balancing, and drive tuning help minimize vibration and noise.

20. How does factory testing help prevent step loss issues?

Load testing, thermal testing, and dynamic motion simulation verify performance before delivery.

Conclusion

Stepper motor losing steps under load is not a single-parameter failure—it is a system-level imbalance between torque demand and torque availability. By addressing electrical, mechanical, and dynamic factors together, step loss can be fully eliminated.

Correct motor sizing, optimized motion profiles, proper power delivery, mechanical efficiency, and advanced control strategies form a robust and reliable motion system capable of handling demanding loads with absolute precision.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català