In modern manufacturing, precision, efficiency, and durability are non-negotiable. Metal-cutting industries, ranging from aerospace to automotive, rely heavily on high-performance motion control systems. At the heart of these systems are servo motors, purpose-built to withstand the harsh conditions of metal-cutting applications. These motors provide not only exact control over positioning but also deliver the power and resilience necessary for continuous operations in demanding environments.

What are Servo Motors ?

A servo motor is a specialized electric motor designed to provide precise control of angular or linear position, velocity, and acceleration. Unlike regular motors that simply spin when powered, a servo motor operates within a closed-loop control system. This means it continuously receives feedback from sensors (such as encoders or resolvers) to adjust its motion in real time, ensuring exact positioning and smooth performance.

Key Characteristics of Servo Motors

Accuracy – They can move to a specific angle or position with high precision.

Feedback System – Equipped with sensors that constantly send data to the controller for corrections.

High Efficiency – Deliver strong torque even at low speeds.

Controlled Motion – Speed, torque, and position can all be managed simultaneously.

Compact and Reliable – Designed to operate continuously and withstand demanding applications.

Main Components of a Servo Motor System

Motor – Usually a DC motor, AC motor, or brushless DC motor (BLDC).

Controller – The brain of the system that sends commands.

Feedback Device – Encoder or resolver that provides position and speed information.

Drive (Amplifier) – Regulates the power supplied to the motor.

Applications of Servo Motors

Servo motors are used wherever precision and control are essential, including:

Robotics – For controlling arm joints and movements.

CNC Machines – For accurate cutting, drilling, and shaping.

Automation Systems – In packaging, labeling, and conveyor systems.

Aerospace and Defense – For navigation, control surfaces, and targeting systems.

Medical Devices – In surgical robots and imaging equipment.

In simple terms: A servo motor is not just about spinning—it's about spinning with purpose and precision.

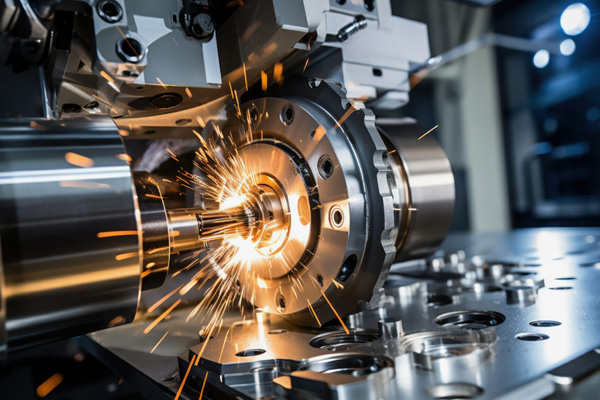

Why Servo Motors Are Crucial in Metal-Cutting Applications

Servo motors are engineered to provide precise rotational or linear movement with the ability to control torque, speed, and position accurately. In metal-cutting, where tolerances are measured in microns, servo motors deliver the level of accuracy and repeatability that traditional motors cannot achieve.

Unlike standard induction motors, servo motors operate with closed-loop feedback systems, ensuring that every movement matches the programmed path exactly. This makes them indispensable in applications such as:

CNC lathes and milling machines

Laser and plasma cutting systems

High-speed drilling machines

Precision grinding and shaping equipment

Key Challenges in Metal-Cutting Environments

Metal-cutting operations expose motors to some of the most extreme working conditions. Servo motors designed for these applications must overcome:

High temperatures generated by continuous machining and cutting processes.

Vibration and shock loads from heavy-duty equipment and tooling.

Dust, chips, and coolant contamination, requiring sealed designs.

Demand for 24/7 reliability, as downtime results in substantial production losses.

By design, servo motors for metal-cutting incorporate rugged housings, high IP ratings, thermal protection, and reinforced bearings to withstand these challenges.

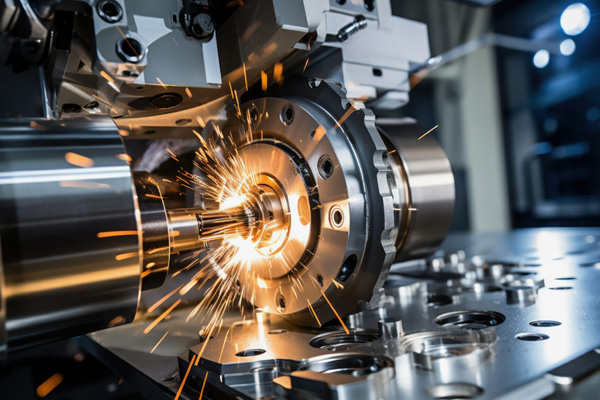

Design Features of Servo Motors for Tough Environments

Servo motors used in metal-cutting machinery are not standard units; they are specialized with features tailored for durability:

1. Robust Housing and Sealing

Metal-cutting generates dust, oil mist, and debris that can damage motor components. Servo motors often come with IP65 or higher protection ratings, ensuring complete sealing against coolant ingress and contaminants.

2. High Thermal Stability

Continuous high-speed cutting operations generate intense heat. These motors are equipped with enhanced cooling systems, advanced insulation, and built-in thermal sensors to maintain stable operation under elevated temperatures.

3. Precision Bearings and Shafts

To endure the repetitive stress of cutting, servo motors use heavy-duty bearings and hardened shafts that resist wear and reduce vibration.

4. Integrated Feedback Systems

Servo motors include encoders or resolvers to ensure exact positioning and real-time monitoring, critical for maintaining accuracy in cutting paths.

5. Energy Efficiency

Modern servo motors are optimized for low energy consumption, reducing overall operating costs while still providing high torque and speed control.

Performance Benefits in Metal-Cutting Applications

The implementation of servo motors provides measurable improvements across all aspects of machining:

Higher precision – enabling ultra-fine cuts and tight tolerances.

Increased productivity – faster cutting speeds with consistent quality.

Reduced downtime – motors are built for reliability and extended lifespan.

Flexibility – servo systems easily adapt to different cutting programs and tool paths.

Lower maintenance costs – due to robust design and advanced protective features.

Applications of Servo Motors in Metal-Cutting Machines

CNC Milling Machines

Servo motors control the spindle speed and tool positioning with extreme precision, allowing for complex 3D shapes and accurate contouring.

Laser and Plasma Cutting Systems

For high-speed sheet metal cutting, servo motors deliver rapid acceleration, exact movement control, and smooth motion, ensuring clean edges without distortion.

Turning and Lathe Machines

Servo motors allow multi-axis control with synchronized movement, essential for producing cylindrical components with perfect symmetry.

Grinding Machines

In grinding operations, where surface finish is critical, servo motors maintain stable torque and smooth rotational control for flawless results.

Industry Sectors Benefiting from Servo Motors

Servo motors play a transformative role across industries that depend on precision cutting:

Aerospace: Manufacturing turbine blades, structural components, and lightweight alloys.

Automotive: Precision cutting for engine blocks, transmission parts, and chassis components.

Medical Equipment: Fabrication of surgical instruments and implants requiring ultra-high accuracy.

Defense and Heavy Machinery: Production of armored parts, weapon systems, and large-scale machinery.

Choosing the Right Servo Motor for Metal-Cutting

Selecting the correct servo motor requires careful consideration of application requirements. Factors include:

Torque and speed ratings for the specific cutting operation.

Load capacity and duty cycle to handle heavy machining tasks.

Feedback type (encoder or resolver) for desired precision level.

Environmental protection level for coolant, dust, and temperature resistance.

Compatibility with CNC controllers and drive systems.

Manufacturers often provide customized servo motor solutions, ensuring seamless integration with existing machinery and production lines.

Future of Servo Motors in Metal-Cutting

With the rise of Industry 4.0 and smart manufacturing, servo motors are evolving into more intelligent and connected systems. The future promises:

IoT-enabled servo motors with predictive maintenance capabilities.

AI-driven motion control for optimizing cutting efficiency in real time.

Lightweight, high-torque designs for energy savings without performance loss.

Advanced cooling and insulation materials to further extend motor life in extreme environments.

These advancements will make servo motors even more critical to achieving unmatched accuracy, reduced waste, and maximum uptime in metal-cutting applications.

Top 20 Servo Motor Manufacturers in Germany

1. Siemens AG

Company Profile:

Siemens is a global leading servo motor manufacturer in industrial automation, headquartered in Munich, Germany.

Main Products:

Servo motors, industrial drives, PLCs, automation solutions.

Advantages:

Strong global presence, advanced servo technologies, integration with Industry 4.0 solutions.

2. Bosch Rexroth AG

Company Profile:

A division of Bosch Group, Bosch Rexroth is a leading servo motor manufacturer in drive and control technology.

Main Products:

Servo motors, servo drives, motion control systems, hydraulic and pneumatic systems.

Advantages:

High-performance servo systems, robust designs for harsh environments, reliable German engineering.

3. SEW-Eurodrive GmbH & Co. KG

Company Profile:

Based in Bruchsal, SEW-Eurodrive is a major servo motor manufacturer of drive technology.

Main Products:

Servo motors, gear motors, frequency inverters, automation systems.

Advantages:

Energy-efficient motors, modular drive solutions, wide application range.

4. Lenze SE

Company Profile:

Lenze is a specialist in motion control and automation systems, headquartered in Aerzen.

Main Products:

Servo motors, servo inverters, gearboxes, automation software.

Advantages:

Innovative automation solutions, flexible and scalable products, global distribution network.

5. B&R Industrial Automation GmbH

Company Profile:

Part of ABB Group, B&R focuses on automation and motion control.

Main Products:

Servo motors, servo drives, PLCs, industrial PCs, software solutions.

Advantages:

Integrated automation solutions, cutting-edge servo technology, strong ABB support.

6. Baumüller Nürnberg GmbH

Company Profile:

A Nuremberg-based servo motor manufacturer specializing in drive and automation systems.

Main Products:

Servo motors, servo drives, control systems, electric automation solutions.

Advantages:

Strong focus on sustainability, robust motor designs, decades of industry experience.

7. KEB Automation KG

Company Profile:

Headquartered in Barntrup, KEB develops drive and automation technology.

Main Products:

Servo motors, servo drives, control systems, industrial communication solutions.

Advantages:

Reliable servo solutions for demanding applications, strong focus on energy efficiency.

8. Dunkermotoren GmbH (Part of AMETEK Group)

Company Profile:

Specializes in intelligent servo motor and drive technology.

Main Products:

Servo motors, brushless DC motors, integrated servo drives.

Advantages:

Compact and integrated motor solutions, high-precision engineering, strong presence in robotics.

9. EBM-Papst Group

Company Profile:

Known globally for fans and motors, EBM-Papst also produces servo motor solutions.

Main Products:

Servo motors, EC motors, automation drive solutions.

Advantages:

Energy-efficient motors, focus on sustainability, broad industrial applications.

10. Wittenstein SE

Company Profile:

Headquartered in Igersheim, Wittenstein specializes in precision servo technology.

Main Products:

Servo motors, actuators, gearboxes, mechatronic drive systems.

Advantages:

High-precision products, innovative mechatronics, strong in aerospace and robotics sectors.

11. Hanning Elektro-Werke GmbH & Co. KG

Company Profile:

A long-established German servo motor manufacturer.

Main Products:

Servo motors, synchronous motors, asynchronous motors.

Advantages:

Custom-tailored solutions, reliable and durable motor technology.

12. Berger Lahr (Now Schneider Electric Motion)

Company Profile:

Originally a German servo motor manufacturer, now part of Schneider Electric.

Main Products:

Servo motors, stepper motors, motion control solutions.

Advantages:

Strong expertise in motion systems, global support from Schneider Electric.

13. Heidenhain GmbH

Company Profile:

Renowned for precision measurement and control systems.

Main Products:

Servo motors, encoders, CNC controls.

Advantages:

High-precision feedback systems, ideal for CNC and high-tech machining.

14. Beckhoff Automation GmbH & Co. KG

Company Profile:

Known worldwide for PC-based automation technology.

Main Products:

Servo motors, servo drives, I/O systems, motion controllers.

Advantages:

Advanced PC-based control, scalable motion solutions, Industry 4.0 ready.

15. STOBER Antriebstechnik GmbH + Co. KG

Company Profile:

Specialist in gear and drive technology from Pforzheim.

Main Products:

Servo motors, servo gear units, motion control systems.

Advantages:

Precision engineering, durable servo solutions, modular drive systems.

16. Harmonic Drive AG

Company Profile:

Expert in precision gear and motion systems.

Main Products:

Servo motors with harmonic drive gears, actuators, control systems.

Advantages:

Extreme precision, compact motor design, excellent for robotics.

17. Pilz GmbH & Co. KG

Company Profile:

A global automation and safety technology provider.

Main Products:

Servo motors, servo drives, safety controllers.

Advantages:

Strong focus on safety and compliance, integrated automation solutions.

18. Eisele Antriebstechnik GmbH

Company Profile:

Family-owned servo motor manufacturer with expertise in custom drive solutions.

Main Products:

Servo motors, synchronous motors, special drive systems.

Advantages:

Tailored servo motor solutions, high flexibility, customer-specific engineering.

19. Groschopp AG Drives & More

Company Profile:

Servo motor manufacturer of customized electric motors in Viersen.

Main Products:

Servo motors, DC motors, gear motors, drive systems.

Advantages:

Focus on customer-specific applications, robust and reliable products.

20. Jenaer Antriebstechnik GmbH (JAT)

Company Profile:

Based in Jena, specializing in precision drive technology.

Main Products:

Servo motors, linear motors, motion control systems.

Advantages:

High-precision and dynamic servo solutions, expertise in automation and robotics.

These companies represent the core of Germany's servo motor industry, with a strong focus on precision engineering, automation, and Industry 4.0 innovations.

Conclusion

Servo motors are the backbone of modern metal-cutting machinery, delivering precision, durability, and efficiency even in the harshest working conditions. Their advanced design, combined with continuous innovation, ensures that industries can achieve the highest productivity while maintaining exacting quality standards. As manufacturing environments become more demanding, servo motors built for tough conditions will continue to set the benchmark for reliability and performance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català