Brushless electric motors have become the performance benchmark across modern industries—power tools, drones, EVs, HVAC systems, robotics, and countless precision-driven applications. When comparing brushless electric motors (BLDC motors) to traditional brushed motors, the question is not merely whether they are better, but how deeply they redefine efficiency, longevity, and control. In this guide, we deliver a comprehensive, high-authority breakdown that clarifies exactly why brushless motors are now the preferred choice for engineers, manufacturers, and performance-centric applications worldwide.

What Sets Brushless Electric Motors Apart?

Brushless electric motors stand out because they eliminate the mechanical brushes and commutator used in traditional DC motors. This single design shift dramatically transforms how the motor performs, making brushless motors more efficient, quieter, longer-lasting, and far more precise.

At the core, brushless motors replace mechanical switching with electronic commutation, which allows current to flow through the motor’s windings with precise timing. Instead of relying on friction-based contact, the rotor’s position is detected by sensors—or inferred sensorlessly—and controlled using an intelligent driver or ESC.

This architecture gives brushless motors several key advantages:

Higher Efficiency: No brush friction means more power is converted into rotational motion, reducing energy loss and heat.

Longer Lifespan: With no brushes to wear out, the motor can operate for tens of thousands of hours.

Smoother, Quieter Operation: Electronic switching eliminates sparking, vibration, and electrical noise.

Higher Power Density: Brushless motors achieve more torque and speed for their size and weight.

Precision Control: Integrated electronics allow advanced speed, torque, and position control, ideal for automation and robotics.

Low Maintenance: No brushes mean fewer parts to replace, less downtime, and overall lower operating cost.

These combined benefits make brushless electric motors the preferred choice for modern systems that demand performance, reliability, and efficiency, from drones and EVs to CNC machines and smart appliances.

Superior Efficiency Through Electronic Commutation

One of the key advantages that makes brushless motors decisively better is significantly improved energy efficiency.

Why Brushless Motors Are More Efficient

Brushless electric motors are significantly more efficient than traditional brushed motors because of the way they convert electrical energy into mechanical power. Their design eliminates multiple sources of loss, resulting in higher performance, cooler operation, and improved overall energy utilization.

1. No Brush Friction or Mechanical Contact

Brushed motors rely on brushes rubbing against a commutator to deliver current. This constant contact creates:

Friction losses

Mechanical wear

Heat generation

Electrical arcing

Brushless motors remove this contact entirely. With no brushes, there is no friction, no sparking, and far less energy wasted as heat. More of the electrical input becomes usable rotational torque.

2. Precise Electronic Commutation

Brushless motors use a sophisticated electronic controller to switch current through the windings. This allows perfectly timed commutation, resulting in:

Optimal magnetic field alignment

Maximum torque production

Higher efficiency across all speeds

Smooth, controlled motion

This electronic optimization ensures that the motor always operates in its most efficient magnetic state.

3. Reduced Heat Generation

Because brushless motors eliminate friction from brushes and reduce electrical losses, they run much cooler. Lower heat levels translate directly to:

Cooler operation allows BLDC motors to maintain high performance even during continuous-duty cycles.

4. Better Power-to-Weight Ratio

Brushless motors typically use:

This enables them to produce more torque and power relative to their size. A higher power density means the motor works more efficiently for its weight and footprint.

5. Superior Speed Control and Torque Delivery

The controller continuously monitors motor position and speed, adjusting current as needed. This results in:

The motor only uses the power it needs at any given moment, preventing unnecessary energy consumption.

6. No Energy Loss from Brush Arcing

In brushed motors, electrical arcing during commutation leads to:

Brushless motors eliminate arcing completely, improving electrical efficiency and performance stability.

Summary

Brushless motors achieve higher efficiency because they combine zero mechanical commutation losses, advanced electronic control, and superior thermal performance. These advantages allow them to convert a greater percentage of electrical input into mechanical output, making them the clear choice for high-performance and energy-sensitive applications.

Extended Lifespan and Unmatched Reliability

Brushless electric motors are widely recognized for their exceptionally long lifespan and industry-leading reliability. Their design eliminates several inherent weaknesses found in traditional brushed motors, allowing them to operate longer, withstand harsher conditions, and deliver consistent performance over years of continuous use.

1. No Brushes Means No Wear-and-Tear Parts

The most important reason brushless motors last longer is the complete removal of carbon brushes and commutators. In brushed motors, these components are the first to degrade due to:

Constant friction

Heat generation

Electrical arcing

Carbon dust accumulation

As the brushes wear out, performance declines and maintenance becomes unavoidable. Brushless motors eliminate these wear-prone parts entirely, dramatically increasing their operational lifespan.

2. Minimal Internal Friction Improves Durability

Because there are no brushes pressing against the rotor, brushless motors experience:

Lower friction means the motor can run for thousands of hours with minimal degradation. This significantly extends the life of bearings, windings, magnets, and the rotor assembly.

3. Cooler Operating Temperatures Protect Components

Brushless motors are inherently more efficient, and therefore generate far less heat. Excess heat is a major contributor to motor failure, especially in:

Bearings

Electronic insulation

Permanent magnets

By running cooler, brushless motors preserve these components and maintain long-term stability and performance.

4. No Carbon Dust or Contaminants

Brushed motors produce fine carbon dust as the brushes wear down. This dust can:

Brushless motors keep their internal environment clean, which helps maintain reliability over years of service.

5. Advanced Electronic Control Enhances Longevity

Brushless motors rely on an electronic controller that intelligently manages:

Current flow

Torque output

Speed regulation

Overload protection

This controlled operation prevents:

Over-current conditions

Excessive torque stress

Rapid thermal cycling

All of which preserve the motor's internal structure and increase service life.

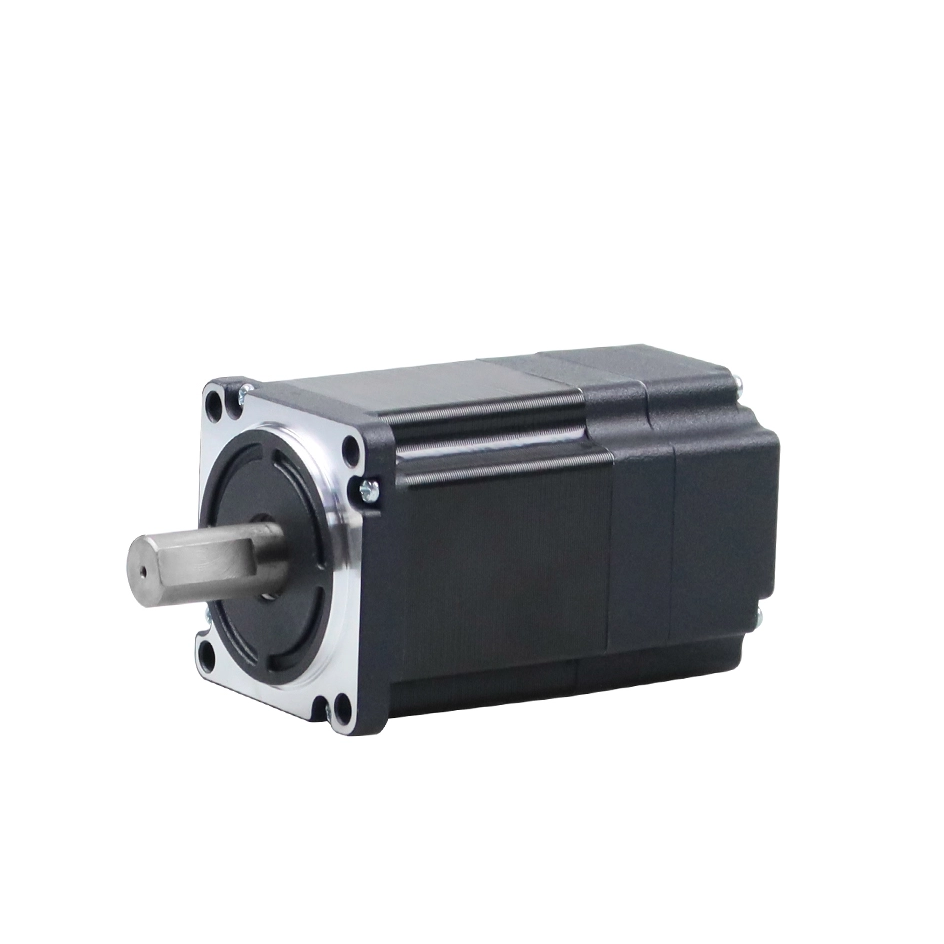

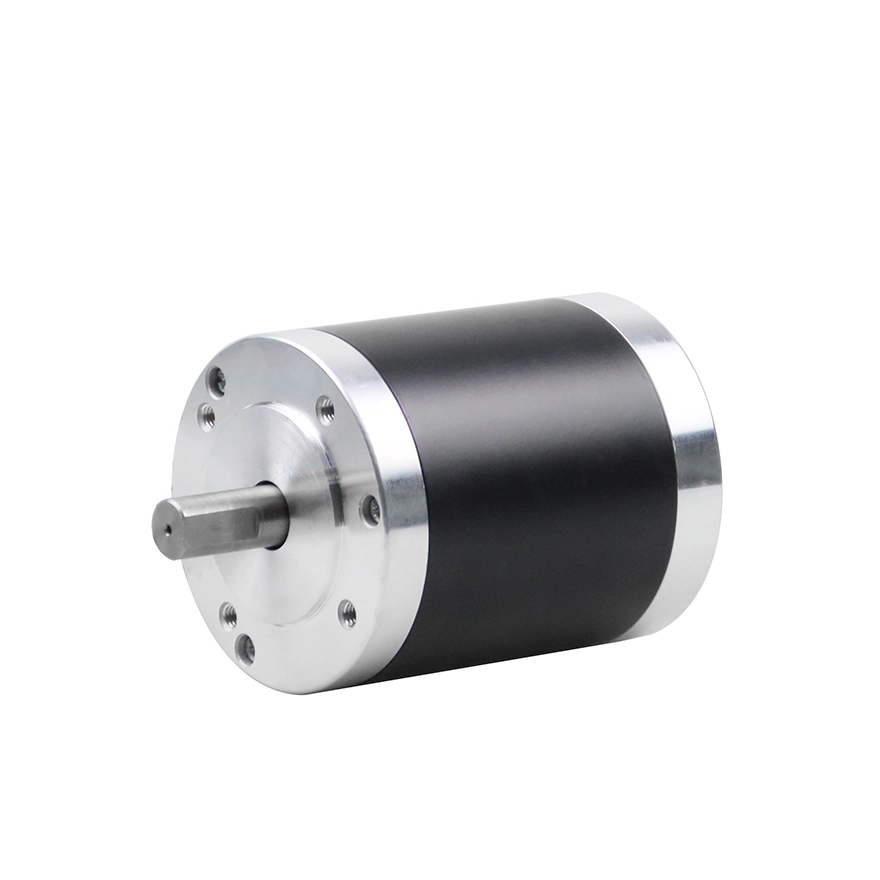

6. Higher Structural Integrity and Superior Engineering

Brushless motors are often built with:

High-grade permanent magnets

Precision-machined rotors

Advanced insulation materials

Better heat dissipation designs

These enhancements make them more durable in demanding environments, including industrial automation, aerospace, continuous-duty fans, and robotics.

7. Significantly Longer Operating Life

While a brushed motor may last 1,000–3,000 hours, a high-quality brushless motor can typically operate for 10,000–20,000 hours or more, depending on design and usage. Some industrial-grade BLDC motors exceed 50,000 hours of service when properly maintained.

Summary

Brushless motors deliver unmatched reliability and extended lifespan because they eliminate brush wear, reduce internal friction, run cooler, avoid contaminant buildup, and benefit from precise electronic control. These improvements make them ideal for applications requiring long-term, maintenance-free, and highly dependable performance.

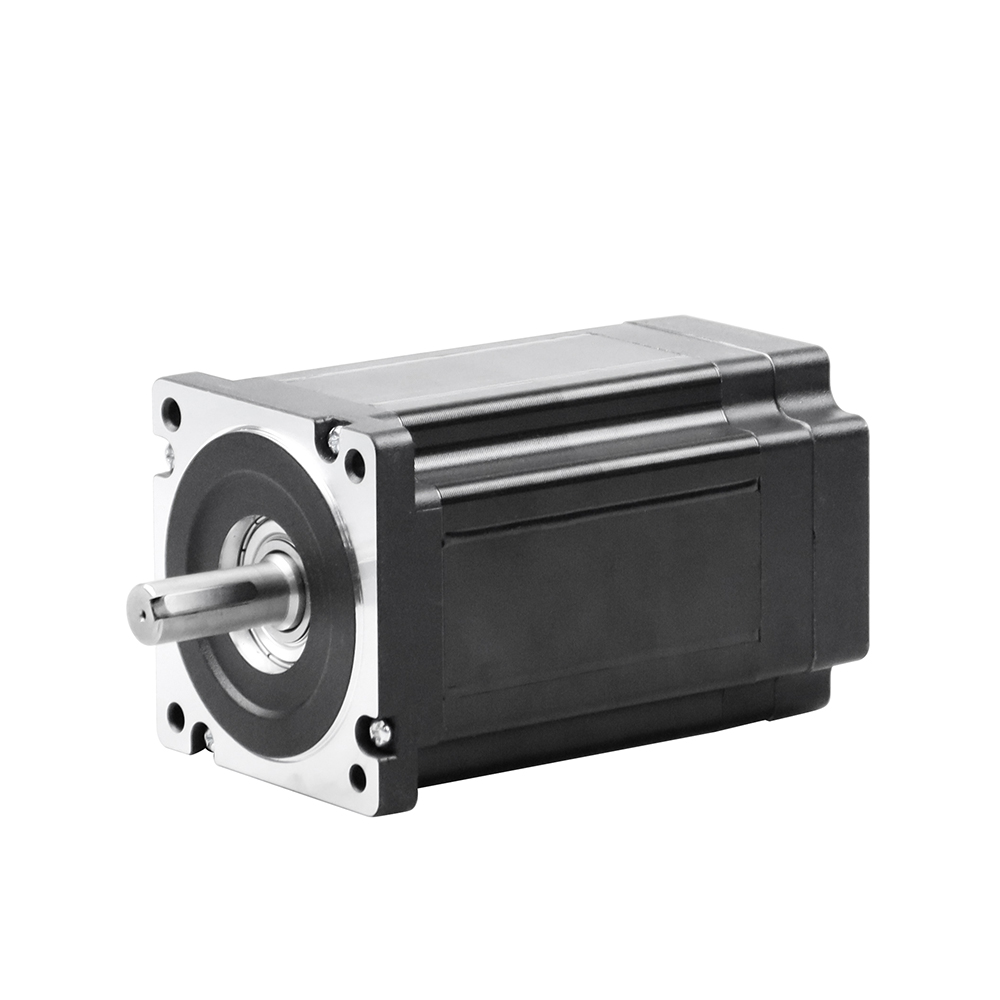

Higher Power Density and Performance Consistency

Brushless electric motors deliver more usable torque and power relative to their size compared to brushed motors.

Performance Characteristics That Make BLDC Motors Superior

High torque-to-weight ratio

Faster and smoother acceleration

Consistent torque across wide speed ranges

Improved thermal stability for sustained high power output

Brushed motors lose torque rapidly as speed increases, while brushless motors maintain a flatter and more stable torque curve, ideal for precise motion control.

Industries that rely on this advantage include:

Quiet, Smooth, and Stable Operation

Brushless motors are renowned for delivering remarkably smooth and quiet performance, making them essential in noise-sensitive applications.

Why Brushless Motors Operate More Quietly

Brushless electric motors are known for their exceptionally quiet operation, and this advantage is one of the primary reasons they are used in high-precision, noise-sensitive, and professional-grade applications. Their low-noise performance is the result of a combination of mechanical, electrical, and magnetic design improvements over traditional brushed motors.

1. No Brush Contact or Friction Noise

Traditional brushed motors rely on physical contact between carbon brushes and a rotating commutator. This contact naturally produces:

Rubbing and scraping sounds

Electrical crackling noises

Vibration and mechanical chatter

Brushless motors completely eliminate brushes. With no physical contact inside the rotor, there is no friction-generated noise, resulting in much quieter operation.

2. No Electrical Sparking or Arcing

Brushes not only create friction—they also cause electrical arcing as they switch current between commutator segments. This produces:

Brushless motors have silent electronic commutation, meaning zero sparking and no high-frequency noise produced by electrical discharge.

3. Smoother Torque Output

Brushless motors generate torque using precisely controlled magnetic fields. This leads to:

Lower torque ripple

Reduced vibration

More consistent rotation

Less torque ripple means the motor produces smoother rotation, which reduces both mechanical vibration and the noise associated with it.

4. Better Rotor Balance and Reduced Vibration

Brushless motors generally have:

These design features help the rotor spin with exceptional balance. Lower vibration equals less structure-borne noise, especially important in:

Drones

Gimbal systems

Medical devices

Home appliances

5. Cooler Operation Reduces Noise

Heat can quickly introduce noise in electric motors as materials expand, bearings wear, and components stress. Brushless motors run cooler due to their higher efficiency, which leads to:

Cooler components remain quieter and more stable over time.

6. More Precise Electronic Control

BLDC motors are driven by an electronic controller that continuously manages:

Speed

Current

Magnetic timing

Torque demand

This results in very accurate rotation with fewer sudden changes or mechanical shocks. Smoother electronic control means less acoustic noise at all operating speeds.

Summary

Brushless motors operate more quietly because they remove the biggest sources of sound found in brushed motors—brush friction, mechanical contact, and electrical arcing. Combined with improved balance, smoother torque production, and sophisticated electronic control, brushless motors offer an exceptionally low-noise performance ideal for modern, high-precision systems.

Precision Control for Advanced Motion Systems

Brushless motors excel in environments requiring fine movement accuracy, dynamic feedback, and real-time torque control.

Control Benefits That Outperform Brushed Motor Systems

Precise speed regulation

Instantaneous torque adjustments

High-resolution position sensing when paired with encoders

Closed-loop control capabilities

Because BLDC motors rely on electronic commutation, they integrate seamlessly with:

This technological synergy makes them foundational in advanced industries such as automation, robotics, and aerospace engineering.

Low Maintenance and Reduced Total Cost of Ownership

While brushless motors may cost more upfront, they dramatically reduce lifetime operating expenses.

Maintenance Advantages

This results in:

Organizations seeking long-term reliability find brushless motors to be far more cost-effective over the full lifecycle of a machine.

Enhanced Thermal Management and Cooler Operation

Heat is the primary enemy of motor longevity and performance. Brushless systems manage heat far more effectively.

Why BLDC Motors Stay Cooler

These thermal advantages improve:

Are Brushless Electric Motors Better Overall?

Considering all aspects—efficiency, control, longevity, noise reduction, power density, and maintenance—the conclusion is clear:

Yes, Brushless electric motors are unequivocally better for nearly all modern applications.

The only areas where brushed motors still hold relevance are:

Ultra-low-cost consumer products

Low-duty-cycle mechanisms

Simple systems requiring no electronics

However, for any application demanding performance, reliability, and efficiency, Brushless electric motors are undeniably the superior choice.

Final Verdict

Brushless electric motors have transformed today's mechanical and electronic systems. Their combination of precision, durability, and performance makes them the leading technology across industries that rely on speed accuracy, operational efficiency, and longevity.

As advancements in electronic control systems continue, BLDC motors will only grow more dominant, shaping the future of motion control across every sector—from consumer electronics to aerospace.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català