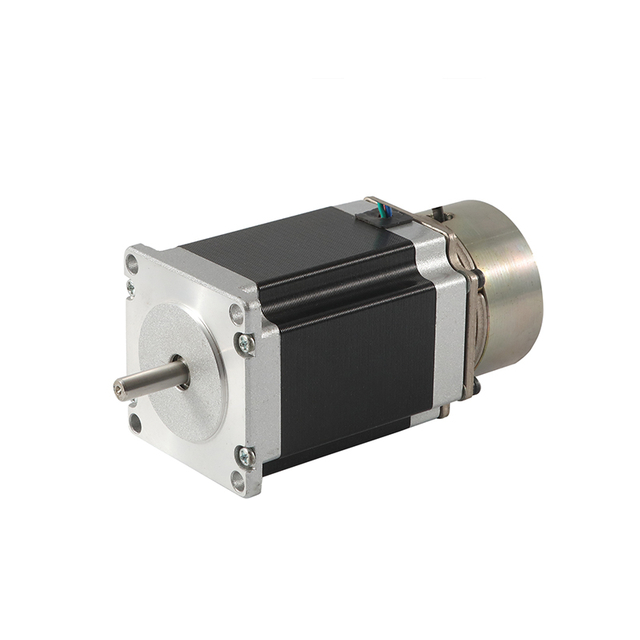

Stepper motors are essential components in automation, robotics, and precision motion control applications. One of the most frequently asked questions when designing systems with stepper motors is: “How fast can a stepper motor rotate?” The answer is not as simple as quoting a single number, as several factors—including motor type, drive voltage, current, and load conditions—significantly influence the achievable rotational speed.

In this article, we'll dive deep into the maximum speed capabilities of stepper motors, explore what limits their performance, and discuss how to optimize speed without losing torque or accuracy.

Understanding Stepper Motor Speed Basics

Stepper motors operate on the principle of electrical pulses being converted into mechanical motion. Each pulse sent to the motor corresponds to a specific movement of the shaft, known as a step. The number of these steps per revolution is determined by the step angle, which defines how precisely the motor can position itself.

For example, a 1.8° stepper motor takes 200 steps per full revolution (360° ÷ 1.8° = 200 steps). The speed of rotation depends directly on how quickly these electrical pulses are delivered to the motor.

The basic formula for calculating rotational speed is:

Speed (RPM)=Pulse Rate (PPS)×60Steps per Revolution\text{Speed (RPM)} = \frac{\text{Pulse Rate (PPS)} \times 60}{\text{Steps per Revolution}}

Speed (RPM)=Steps per RevolutionPulse Rate (PPS)×60

Where:

For instance, if a 200-step motor receives 2000 pulses per second, the motor will rotate at:

2000×60200=600 RPM\frac{2000 \times 60}{200} = 600\ \text{RPM}

2002000×60=600 RPM

This means that increasing the pulse rate (the frequency of electrical signals) directly increases the motor's rotational speed.

However, the relationship between speed and torque is not linear. As the step rate increases, torque begins to drop due to the motor's electrical and magnetic limitations. Beyond a certain frequency, the motor can no longer maintain synchronization with the pulses, resulting in missed steps or stalling.

Therefore, understanding how pulse frequency, step angle, and torque interact is crucial for designing a stable, high-performance stepper motor system. Proper selection of the driver voltage, current, and microstepping mode ensures smooth operation across the desired speed range.

Typical Speed Ranges of Stepper Motors

Stepper motors are generally categorized into low-speed and high-speed operation ranges:

| Motor Type | Typical Max Speed (RPM) | Ideal Applications |

| Permanent Magnet (PM) Stepper | 300–1000 RPM | Printers, small positioning systems |

| Hybrid Stepper | 1000–3000 RPM | CNC machines, 3D printers, robotics |

| Variable Reluctance Stepper | Up to 1500 RPM | Light-load precision equipment |

| High-Performance Closed-Loop Stepper | 3000–6000 RPM | AGVs, conveyors, high-speed automation |

While many hybrid stepper motors are designed to deliver optimal torque at 300–1000 RPM, modern closed-loop or servo-stepper systems can exceed 4000 RPM under the right conditions.

Factors That Determine Maximum Speed

1. Motor Inductance

Inductance plays a critical role in determining how quickly current can change in the motor windings. High-inductance motors resist current changes, limiting their high-speed torque. Low-inductance stepper motors, in contrast, allow faster current rise times, enabling higher rotational speeds.

Tip: For high-speed applications, choose a low-inductance motor combined with a high-voltage driver to overcome winding resistance faster.

2. Supply Voltage and Driver Capability

The higher the supply voltage, the faster the current can rise through the motor coils, allowing higher speeds. This is why high-performance stepper systems often use advanced microstepping drivers that operate at 24V, 48V, or even 80V.

The driver's ability to deliver current precisely and maintain smooth microstepping also impacts performance. Digital current control drivers minimize torque ripple, allowing smoother high-speed operation.

3. Load Torque and Inertia

Every stepper motor has a torque-speed curve, which defines how torque decreases as speed increases. When the load demands more torque than available at a given speed, the motor can lose steps or stall.

To maintain synchronization at higher speeds:

Use gearing or belt reduction systems.

Gradually accelerate to target speed using acceleration ramps.

Match the load inertia to the motor's rotor inertia for stability.

4. Microstepping and Step Resolution

Microstepping divides each full step into smaller increments, enhancing smoothness and accuracy. However, it can also reduce the torque per microstep, slightly limiting maximum speed under heavy loads.

For high-speed rotation, full-step or half-step modes may provide better torque efficiency, while microstepping is best suited for moderate speeds requiring smoother motion.

5. Drive Mode: Open-Loop vs. Closed-Loop

Open-loop stepper systems rely solely on commanded steps, making them vulnerable to missed steps at high speeds.

Closed-loop stepper motors, equipped with encoders, continuously monitor position feedback, allowing the driver to correct errors instantly.

Closed-loop designs enable much higher speed and acceleration while maintaining torque, often achieving speeds up to 6000 RPM without step loss.

Torque-Speed Relationship Explained

The torque-speed relationship is one of the most important aspects of stepper motor performance. It describes how the available torque of a stepper motor changes as its rotational speed increases. Understanding this relationship helps engineers design motion systems that balance speed, torque, and precision effectively.

1. The Inverse Relationship Between Torque and Speed

In a stepper motor, torque decreases as speed increases. This occurs because of a phenomenon known as back electromotive force (back EMF)—a voltage generated by the motor itself when the rotor spins. At higher speeds, this back EMF opposes the input voltage, making it harder for current to build up in the motor windings.

As a result, the magnetic field strength weakens, and the motor produces less torque. Therefore, stepper motors typically deliver maximum torque at low speeds and reduced torque at high speeds.

2. The Shape of the Torque-Speed Curve

Every stepper motor has a characteristic torque-speed curve, provided by the manufacturer. This curve shows how torque changes as the motor speed increases.

The curve can be divided into three main regions:

Low-Speed Region (0–300 RPM):

The motor delivers its highest torque and performs with excellent positional accuracy. This range is ideal for holding loads and slow, precise movements.

Mid-Speed Region (300–1200 RPM):

Torque begins to decline gradually. The motor can still perform well, but if acceleration is too aggressive, it may lose steps. Proper ramping and tuning are essential here.

High-Speed Region (1200–3000+ RPM):

Torque drops sharply because of high back EMF and limited current rise time. Unless compensated by higher supply voltage or closed-loop feedback, the motor might stall under load.

3. The Role of Supply Voltage and Driver Performance

A higher supply voltage can counteract the torque drop at high speeds. It allows the driver to push current through the inductive windings more quickly, maintaining stronger magnetic fields. High-performance microstepping drivers or digital servo drivers are designed to optimize this current flow, extending the motor's usable torque-speed range.

For example, a motor running at 24V might begin to lose torque beyond 1000 RPM, while the same motor powered by 48V can maintain torque up to 2500 RPM or more.

4. Mechanical Load and Inertia Impact

The load torque and rotational inertia of the mechanical system also affect the usable torque-speed range. A heavier load requires more torque to accelerate. If the load torque exceeds the available torque at a certain speed, the motor will lose synchronization or stall.

To improve performance:

Use acceleration and deceleration ramps instead of instant speed changes.

Match load inertia with the motor's rotor inertia for stability.

Implement gear reduction to maintain torque at higher speeds.

5. Resonance and Torque Dips

Stepper motors can experience resonance—a vibration that occurs when the motor's natural frequency aligns with its step frequency. This often happens in the mid-speed range (around 200–600 RPM). During resonance, torque can dip temporarily, causing rough motion or loss of steps.

To minimize resonance:

Use microstepping to create smoother motion.

Add dampers or mechanical couplings to absorb vibration.

Employ closed-loop feedback to automatically compensate for instability.

6. Closed-Loop Stepper Systems and Torque Stability

Modern closed-loop stepper motors, equipped with position encoders, can dynamically adjust current and speed to maintain torque output even at higher speeds. Unlike open-loop systems, they can detect and correct step loss instantly.

Closed-loop systems often achieve 30–50% higher effective speed and more stable torque curves, making them ideal for demanding applications such as CNC machines, robotic arms, and automated conveyors.

7. Practical Example of Torque-Speed Trade-Off

Consider a NEMA 23 Hybrid Stepper motor rated for 2.8A current and 1.2 Nm holding torque:

At 100 RPM, torque remains near its rated value (≈1.1 Nm).

At 500 RPM, torque may drop to about 0.7 Nm.

At 1500 RPM, it may fall further to 0.3 Nm or less.

This shows why torque margin planning is critical—especially when running at high speeds under varying loads.

8. Balancing Torque and Speed for Optimal Performance

To get the most out of a stepper motor system:

Use higher voltages to maintain torque at speed.

Select a low-inductance motor for faster current rise.

Avoid abrupt speed changes—always ramp up or down.

Consider closed-loop control for improved reliability.

Analyze the torque-speed curve before selecting a motor.

Conclusion

The torque-speed relationship defines the limits of a stepper motor's performance. While speed can be increased by raising the pulse rate, the available torque decreases as back EMF builds and inductance limits current flow. Balancing these forces through proper voltage, driver configuration, and feedback control ensures smooth, powerful, and reliable motion across the entire operating range.

Techniques to Increase Stepper Motor Speed

1. Use a Higher Voltage Power Supply

Raising the voltage allows current to build faster, overcoming inductance and maintaining torque at higher speeds.

2. Implement Acceleration and Deceleration Ramps

Avoid sudden speed changes. Use ramped acceleration profiles (S-curve or trapezoidal) to reach top speeds smoothly without losing synchronization.

3. Optimize Microstepping Settings

While microstepping improves smoothness, it can slightly limit torque. Experiment with 8–16 microsteps per full step for a balance between speed and precision.

4. Apply Closed-Loop Control

Adding an encoder allows feedback-driven corrections, enabling higher performance at both low and high speeds.

5. Reduce Mechanical Load

Minimize friction, use lightweight components, and balance load inertia to enhance acceleration and top-end speed.

6. Choose the Right Motor Winding

Manufacturers often offer parallel and series windings; parallel windings favor higher speeds, while series windings favor higher torque at low speeds.

Practical Examples of Stepper Motor Speeds

3D Printers: Typically operate stepper motors at 300–1200 RPM for precise filament feeding and smooth movement.

CNC Machines: Motors may reach 1000–2500 RPM, depending on the axis and mechanical reduction.

AGV/AMR Robots: Closed-loop steppers can run between 3000–5000 RPM for efficient wheel drive.

Camera Gimbals or Actuators: Require smooth low-speed performance, typically under 500 RPM, but occasionally exceed 2000 RPM when repositioning.

High-Speed Stepper Motor Innovations

In recent years, stepper motor technology has undergone remarkable advancements, transforming these traditionally low-to-medium speed devices into high-performance motion control systems capable of achieving higher speeds, smoother motion, and greater efficiency. These innovations have significantly expanded the use of stepper motors in industrial automation, robotics, CNC systems, and AGV/AMR vehicles.

Let's explore the latest high-speed stepper motor innovations that are redefining performance standards in precision motion control.

1. Integrated Servo-Stepper Technology

One of the most impactful innovations in stepper motor design is the development of integrated servo-stepper systems. These combine the accuracy of a stepper motor with the intelligence of a servo drive and an encoder for feedback control, all in a single, compact unit.

This hybrid design maintains the open-loop simplicity of traditional steppers while eliminating issues like missed steps and torque loss at high speeds. The built-in encoder continuously monitors shaft position and adjusts current in real time, allowing the motor to:

Operate smoothly across the full speed range

Deliver constant torque even at higher RPMs

Run cooler and more efficiently

Automatically correct positioning errors

As a result, integrated servo-stepper motors can reach speeds of 4000 to 6000 RPM, a level once reserved for full servo systems.

2. Digital Current Shaping and Adaptive Drive Control

Traditional stepper motor drives use basic current control methods, which can result in torque ripple and uneven motion at high speeds. Digital current shaping technology has revolutionized this process by precisely controlling the phase current waveform in real time.

Through advanced algorithms, the driver adjusts current dynamically to:

Minimize vibration and resonance

Maintain linear torque output across all speeds

Improve energy efficiency and reduce motor heating

Additionally, adaptive drive control continuously monitors load conditions and automatically optimizes performance. This ensures stable operation even under variable loads, extending both speed and torque range.

3. High-Voltage and Low-Inductance Designs

The use of high-voltage drivers (typically 48V–80V) and low-inductance winding designs has significantly increased the high-speed capabilities of stepper motors.

A low-inductance motor allows current to rise and fall more quickly, making it ideal for rapid pulse frequencies. When paired with a high-voltage driver, it can overcome the effects of back EMF—the counter voltage that limits speed in conventional steppers.

This combination enables:

Faster current response times

Greater torque at higher RPMs

Extended operating range without sacrificing accuracy

These advancements have made NEMA 17, 23, and 34 hybrid steppers capable of achieving speeds above 3000 RPM, once considered the upper limit.

4. Advanced Microstepping Techniques

Microstepping technology has evolved far beyond its early implementations. Modern drivers can divide a single step into up to 256 microsteps, delivering incredibly smooth motion and reducing mechanical vibration.

While early microstepping systems sacrificed torque for smoothness, newer methods use sinusoidal current waveforms and digital compensation algorithms to preserve torque even at high microstep resolutions.

This allows for:

Ultra-smooth acceleration and deceleration

Reduced mechanical resonance

Better synchronization with high-speed control systems

Enhanced microstepping also makes stepper motors suitable for high-precision, high-speed applications, such as laser positioning, pick-and-place machines, and semiconductor manufacturing.

5. Closed-Loop Feedback and Smart Motion Control

The introduction of closed-loop feedback systems—using encoders or Hall sensors—has transformed stepper motors into intelligent, self-correcting actuators.

Closed-loop systems monitor the actual rotor position and compare it with the commanded position, allowing the motor to instantly correct errors. This approach eliminates step loss, improves acceleration, and extends the upper speed limit.

Key benefits include:

Automatic torque compensation under dynamic loads

Instant stall detection and recovery

Higher peak speeds without losing synchronization

Energy savings by reducing current draw during light loads

These systems combine the torque density of stepper motors with the control precision of servo systems, bridging the gap between the two technologies.

6. Resonance Suppression and Vibration Reduction

Resonance has long been a challenge in stepper motor operation, particularly in the mid-speed range (200–800 RPM). Today's high-speed stepper motors use active resonance suppression techniques to combat this issue.

Modern drivers utilize:

Digital filtering algorithms to detect and neutralize resonant frequencies

Mechanical damping technologies, such as inertia dampers or vibration-absorbing couplings

Electronic anti-resonance control that adjusts current phase timing in real time

These methods reduce noise, improve positioning accuracy, and allow for stable high-speed operation without mechanical modifications.

7. High-Temperature and Low-Noise Motor Materials

Material advancements have also contributed to higher motor speeds. The use of high-temperature-rated insulation, optimized laminations, and improved bearing materials allows stepper motors to run faster without overheating or excessive wear.

In addition, new rotor designs and precision-ground shafts help minimize vibration, resulting in quieter, smoother, and more efficient operation at high RPMs. These innovations are especially valuable in industries where noise control and precision are critical, such as medical devices, laboratory automation, and consumer electronics.

8. Integration with Smart Industrial Networks

Modern high-speed stepper systems are no longer standalone devices—they are now part of smart, interconnected automation networks. Stepper motors with EtherCAT, CANopen, Modbus, or RS-485 interfaces allow seamless integration into industrial control architectures.

This connectivity enables:

Real-time monitoring of motor performance and temperature

Remote tuning and diagnostics for predictive maintenance

Synchronized multi-axis motion control across large systems

These smart communication features ensure consistent, high-speed operation even in complex automated environments.

Conclusion

The evolution of high-speed stepper motor technology has pushed the boundaries of what was once possible with open-loop systems. Through innovations like integrated servo-stepper designs, digital current shaping, closed-loop feedback, and advanced microstepping, stepper motors now rival traditional servos in performance, precision, and reliability.

These advancements enable engineers to achieve higher rotational speeds, smoother motion, and enhanced efficiency without the cost and complexity of full servo systems. As stepper motor technology continues to evolve, we can expect even faster, smarter, and more adaptable solutions driving the future of automation and robotics.

Conclusion: Balancing Speed and Performance

The maximum speed of a stepper motor depends on its type, drive voltage, load conditions, and control strategy. While typical open-loop systems may operate effectively up to 1000–2000 RPM, modern closed-loop stepper systems can exceed 5000 RPM with stable torque and precise control.

When optimizing for speed, always consider the trade-offs between torque, precision, and thermal performance. By choosing the right motor, driver, and control method, engineers can achieve the perfect balance between speed and stability—ensuring smooth, efficient motion in any automation application.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català