Linear motors have become a central technology in today's high-precision automation, semiconductor manufacturing, CNC machines, robotics, and advanced transportation systems. A common question that arises when selecting or integrating these systems is: Are linear motors AC or DC? Understanding this distinction is essential for designing efficient motion systems with optimal performance, accuracy, and reliability.

This comprehensive guide explores the electrical nature of linear motors, their operating principles, types, control requirements, and real-world applications. With detailed explanations and technical depth, this article answers the question thoroughly while giving engineers and decision-makers practical insights.

What Defines a Linear Motor's Electrical Type?

A linear motor's electrical type—whether it is classified as AC or DC—is determined by the type of electrical power used to energize its coils and create the magnetic field that produces linear motion. The same principles that classify rotary motors apply directly to linear motors.

1. Type of Current Supplied to the Windings

If the motor operates using alternating current, where the polarity of voltage changes over time, it is an AC linear motor.

If the motor operates using direct current, where the polarity remains constant, it is a DC linear motor.

2. Motor Construction and Magnetic Field Generation

A linear motor's design plays a major role in determining which current type it requires:

AC linear motors (e.g., linear induction and linear synchronous motors) rely on a three-phase AC supply to generate a traveling electromagnetic field along the stator.

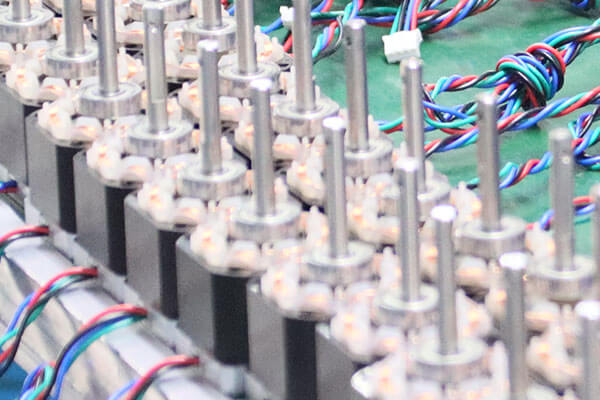

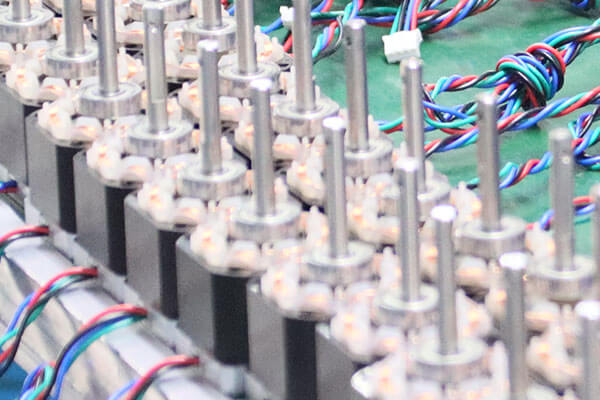

DC linear motors (e.g., voice coils and linear stepper motors) rely on steady or pulsed DC to energize coils in a controlled sequence.

3. Control Method / Drive Electronics

Modern drive systems also influence classification:

4. Behavior of the Magnetic Field

The electrical type is directly tied to how the magnetic field is produced:

AC creates a continuously moving magnetic wave, ideal for long stroke and high-speed applications.

DC creates static or stepwise shifting fields, ideal for short stroke, high-precision motion.

In Summary

A linear motor's electrical type is defined by:

Type of power supplied (AC or DC)

Coil energizing method

Drive electronics

Magnetic field behavior

This classification determines how the motor operates, how it's controlled, and which applications it is best suited for.

Are Linear Motors AC or DC?

Most linear motors are AC motors.

In modern industrial systems, linear motors are predominantly AC, especially the widely used linear induction motors (LIMs) and linear synchronous motors (LSMs). These motors rely on alternating current to produce a traveling electromagnetic field that drives the mover along a straight path.

However, there are also DC-based linear motors, though they are less common. These include linear stepper motors, voice coil actuators, and certain custom DC linear drive systems.

So, the correct and complete answer is:

Linear motors can be either AC or DC, but industrial high-force and high-speed linear motors are mostly AC.

Types of Linear Motors and Their Electrical Classification

1. Linear Induction Motors (LIMs) — AC Motors

Linear induction motors operate on the same principle as traditional rotary induction motors. They use a three-phase AC supply to generate a traveling magnetic field across the stator.

Key Characteristics

Powered by three-phase AC

High speed and high force capability

No contact or wear between primary and secondary

Common in transportation systems (e.g., maglev trains), conveyors, and high-speed automation

Why AC?

LIMs rely on alternating current to continuously create a moving electromagnetic wave that pushes the secondary conductor forward. DC cannot generate this traveling wave.

2. Linear Synchronous Motors (LSMs / PMLSMs) — AC Motors

Linear synchronous motors are powered by AC supply and utilize permanent magnets or excitation windings to generate synchronous motion.

Key Characteristics

Extremely high precision and accuracy

High efficiency, quiet operation

Used in semiconductor fabrication tools, CNC machining, pick-and-place systems

Why AC?

AC allows precise phase control and synchronism between the magnetic field and the mover, enabling ultra-accurate positioning.

Technically, stepper motors are powered using DC, but they operate through digitally controlled pulses.

Key Characteristics

Why DC?

Stepper drivers convert DC power into sequential coils energization. This creates discrete movement steps without requiring an encoder.

4. Voice Coil Actuators — DC Motors

Voice coils (also called moving-coil linear actuators) operate similarly to loudspeakers and are strictly DC motors.

Key Characteristics

Extremely smooth motion

High acceleration

Not suitable for long distances (short stroke only)

Used in optics, autofocus systems, precision testing

Why DC?

A steady or variable DC current directly controls force output—perfect for analog precision and closed-loop systems.

5. Brushless Linear Motors — AC or DC (Depending on Drive Method)

Brushless linear motors may resemble rotary BLDC motors expanded into a straight configuration. Their electrical classification can be nuanced:

Electrically AC, because the stator is fed with three-phase AC

Powered by DC, because drives typically convert DC supply into controlled AC output

Common Applications

AC Linear Motors vs DC Linear Motors: A Detailed Comparison

AC and DC linear motors are both designed to produce straight-line motion, but they differ significantly in power type, performance characteristics, and suitable applications. Understanding these differences helps engineers choose the right motor for precision, speed, force, and control requirements.

1. Power Source

AC Linear Motors

Powered by alternating current, typically three-phase.

Drive units convert supply power into controlled AC waveforms.

Required for generating a traveling electromagnetic field.

DC Linear Motors

Powered by direct current, either constant or pulsed.

Includes stepper-driven linear motors and voice coil actuators.

Uses DC voltage to create force or discrete steps.

2. Control Method and Complexity

AC Linear Motors

Require servo drives or inverters to precisely control frequency, phase, and amplitude.

More complex electronic control, enabling high dynamic response.

DC Linear Motors

Use simpler control methods such as DC amplifiers or stepper drivers.

Easier to set up, especially for low-power or short-stroke applications.

3. Motion Characteristics

AC Linear Motors

Deliver smooth, continuous motion.

Ideal for high speed, long travel, and high precision.

Capable of extremely high acceleration and deceleration.

DC Linear Motors

4. Speed and Acceleration

AC Linear Motors

DC Linear Motors

Typically lower speed unless very lightweight.

Voice coil actuators excel at fast, short-stroke acceleration.

5. Force Output

AC Linear Motors

Capable of high continuous and peak forces.

Suitable for heavy loads, machine tool axes, and transportation systems.

DC Linear Motors

Lower overall force compared to AC types.

Voice coils provide precise but limited force.

Stepper-based linear drives offer moderate force but not suitable for heavy dynamics.

6. Precision and Positioning

AC Linear Motors

Exceptional precision when combined with encoders.

Perfect for semiconductor equipment, laser cutting, and ultra-accurate automation.

DC Linear Motors

7. Stroke Length

AC Linear Motors

Designed for long travel distances, often several meters.

No mechanical contact between primary and secondary, enabling long life.

DC Linear Motors

8. Efficiency and Heat Management

AC Linear Motors

DC Linear Motors

9. Maintenance Requirements

AC Linear Motors

DC Linear Motors

10. Application Suitability

AC Linear Motors Ideal For:

DC Linear Motors Ideal For:

Summary Comparison Table

| Feature | AC Linear Motors | DC Linear Motors |

| Power Type | Alternating Current | Direct Current / Pulsed DC |

| Speed | Very High | Moderate / Short-stroke fast |

| Force | High | Low to Moderate |

| Travel Length | Long | Short |

| Control Complexity | High | Low to Medium |

| Precision | Very High | High (short range) |

| Applications | Industrial automation, CNC, maglev | Optics, small robotics, instrumentation |

How to Choose Between AC and DC Linear Motors

Selecting the correct motor type depends on application requirements. Below are the primary considerations.

Choose an AC Linear Motor When You Need:

High speeds (5–15 m/s)

High force (hundreds to thousands of Newtons)

Long stroke lengths

Extremely high accuracy and repeatability

Superior efficiency for demanding industrial applications

Examples:

Semiconductor wafer handling

High-speed automation lines

CNC machine axes

Maglev propulsion systems

Choose a DC Linear Motor When You Need:

Short strokes (0.5–100 mm)

Very smooth, analog force control

Compact size and quick response

Simpler electronics and lower cost

Examples:

Why Modern Industry Prefers AC Linear Motors

Modern industrial automation increasingly relies on AC linear motors because they deliver superior performance, higher throughput, and greater long-term reliability than most DC-based linear motor designs. Their ability to convert electrical energy into smooth, continuous linear motion makes them the preferred choice for demanding applications across manufacturing, robotics, machining, and transportation.

Below are the key reasons AC linear motors dominate today's industrial landscape.

1. Superior Speed and Acceleration

AC linear motors excel in applications requiring high speed, rapid acceleration, and fast settling times.

They can reach speeds of 5–15 m/s, far beyond most DC linear actuators.

The traveling electromagnetic field produced by three-phase AC enables seamless continuous motion without step losses or mechanical limits.

This makes them ideal for:

2. Exceptional Precision and Repeatability

Modern AC linear motors—especially linear synchronous motors (LSMs)—offer submicron positioning accuracy when combined with high-resolution feedback.

Their smooth electromagnetic travel eliminates mechanical backlash, enabling:

Ultra-precise stage positioning

Perfect repeatability for hundreds of millions of cycles

Zero mechanical wear in motion-generating components

Such characteristics are crucial in industries like semiconductor manufacturing, where accuracy directly affects product quality.

3. Higher Efficiency With Lower Heat Generation

AC linear motors are engineered for high electromagnetic efficiency, making them more energy-efficient under continuous duty cycles.

Their optimized magnetic field control reduces:

Copper losses

Iron losses

Thermal buildup

Lower heat generation results in:

4. Long Travel Capability Without Mechanical Limits

AC linear motors support virtually unlimited stroke lengths, unlike voice coil or stepper-based DC linear systems, which are limited by physical constraints.

Benefits include:

Scalability for large-format machines

No mechanical transmission components like screws or belts

Reduced maintenance and increased uptime

This makes AC linear motors ideal for long-travel industrial axes and transportation systems like maglev trains.

5. Maintenance-Free Motion Generation

Because AC linear motors contain no brushes, belts, or ballscrews, they experience almost no wear in the force-producing components.

This leads to:

Minimal scheduled maintenance

Higher system availability

Lower total cost of ownership

Only the guideways or linear bearings require periodic service.

6. Greater Force Density and Load Capacity

AC linear motors deliver high continuous and peak forces, far exceeding those achievable with DC linear motors.

Examples:

Heavy machine tool axes

High-force robotic transfer systems

Pressing, machining, and forming equipment

Industries choose AC motors because they support both high loads and high dynamics simultaneously, something DC solutions cannot match.

7. Smooth, Vibration-Free Motion

With perfectly controlled sinusoidal AC waveforms, AC linear motors provide:

These characteristics improve product quality in:

8. Advanced Control Capabilities

AC linear motors work with sophisticated servo drives that offer:

High-bandwidth current control

Adaptive tuning

Integrated safety functions

Real-time diagnostics

Field-oriented control (FOC)

Ethernet-based communication

These capabilities align with the needs of Industry 4.0 and smart factories, supporting seamless integration with modern automation systems.

9. Better Long-Term Reliability

AC linear motors are engineered for continuous-duty industrial performance.

Their lack of mechanical wear points and efficient thermal management allow them to run:

24 hours a day

At high speeds

With minimal maintenance

For manufacturers, this translates into higher productivity and lower downtime.

10. Ideal for High-End Automation and Future Manufacturing

Industries that require precision, speed, and cleanliness—such as electronics fabrication, medical device production, and cleanroom operations—depend heavily on AC linear motors.

They are becoming fundamental to:

Semiconductor lithography and inspection

Large-format CNC systems

High-speed robotic stages

Automated warehouses

Maglev and smart transport systems

Their performance aligns with modern manufacturing's demand for fast, accurate, flexible, and low-maintenance motion solutions.

In Summary

Modern industry prefers AC linear motors because they offer:

Higher speed and force

Better precision and efficiency

Longer travel and lower maintenance

Advanced control and adaptability

These advantages make AC linear motors the dominant technology in today's high-performance industrial automation and motion control applications.

Conclusion: Are Linear Motors AC or DC?

Linear motors can be either AC or DC, but the majority of industrial-grade linear motors are AC-powered, especially linear induction and synchronous types. DC linear motors—such as stepper-based linear actuators and voice-coil actuators—serve specialized applications requiring precision but typically offer shorter travel and lower forces.

Understanding the differences allows engineers to choose the correct linear motor technology for their system requirements, optimizing performance, reliability, and machine efficiency.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català