When identifying whether a DC motor is single-phase or three-phase, it's essential to understand how these motors are powered, wired, and constructed. While AC motors commonly use 1-phase or 3-phase systems, DC motors differ in design and operation. However, many technicians and engineers still ask this question when examining motors in mixed electrical systems. This article will help you clearly distinguish between single-phase and three-phase motors, explain how DC motors fit into the classification, and guide you through practical identification methods.

Understanding the Basics: DC Motors vs. AC Motors

Electric motors are essential for converting electrical energy into mechanical motion. The two most common types are DC (Direct Current) and AC (Alternating Current) motors. While they perform the same function, they differ in power source, construction, and control characteristics.

DC Motors

A DC motor runs on direct current, where electricity flows in one direction. It typically includes a commutator and brushes (in brushed types) or an electronic controller (in brushless types) to manage current flow.

Key Features:

Operates on DC voltage (e.g., 12V, 24V, 48V, 90V).

Offers excellent speed control and high starting torque.

Ideal for applications like robots, electric vehicles, and conveyors.

Main Components :

Stator: Produces the stationary magnetic field.

Armature (Rotor): The rotating component that carries current.

Commutator: Reverses the direction of current in the armature winding to maintain rotation.

Brushes: Conduct current between the stationary and rotating parts of the motor.

AC Motors

An AC motor operates on alternating current, where the current changes direction periodically. It creates a rotating magnetic field that drives the rotor.

Key Features:

Runs on single-phase (household) or three-phase (industrial) AC power.

Requires little maintenance and has a simple, durable design.

Commonly used in fans, pumps, compressors, and household appliances.

Main Components:

Stator: Stationary part that produces a rotating magnetic field.

Rotor: Rotating part that moves due to electromagnetic induction or synchronous interaction.

Bearings and Shaft: Provide mechanical support and transmit torque.

Key Differences Between DC and AC Motors

| Feature | DC motor | AC Motor |

| Power Source | Direct Current (DC) | Alternating Current (AC) |

| Current Direction | Unidirectional | Alternating |

| Speed Control | Easy and precise | More complex |

| Starting Torque | High | Moderate |

| Maintenance | Higher (brushes and commutator) | Lower (no brushes) |

| Efficiency | High in low-speed applications | High in constant-speed applications |

| Cost | Higher for control systems | Generally lower |

| Applications | Robotics, vehicles, automation | Fans, pumps, industrial drives |

Working Principle Comparison

DC motor Working Principle:

When DC voltage is applied to the armature winding, current flows through it. The interaction between the armature's magnetic field and the stator's magnetic field creates a torque, causing the rotor to turn. The commutator ensures that the direction of current in the armature windings reverses at the correct time, maintaining continuous rotation.

AC Motor Working Principle:

An AC motor relies on a rotating magnetic field (RMF). In a three-phase AC motor, the alternating current in each phase is 120° out of phase with the others, generating a rotating field that induces current in the rotor (in induction motors) or synchronizes with it (in synchronous motors). This field interaction produces torque and rotation.

Summary

In short, DC motors are best for speed control and high torque applications, while AC motors are preferred for continuous, reliable, and low-maintenance operation. Your choice depends on your power source and control requirements.

Step 1: Check the Motor Nameplate

The motor nameplate provides crucial information about the motor's electrical characteristics. Look for these details:

Voltage (V): A DC motor will list voltages such as 12V, 24V, 48V, 90V, or 220V DC.

Current Type: It will specifically say “DC” or “Direct Current.”

Polarity: You might see + and – terminals, indicating DC supply.

Phase Information: If the nameplate says “1 Phase” or “3 Phase”, it's an AC motor, not DC.

✅ Tip: If you don't see the word “Phase” but instead see “DC,” then you're working with a DC motor, which has no phase classification.

Step 2: Inspect the Power Supply

Look at how the motor is powered:

DC Motor: Powered by a battery, rectifier, or DC power supply. The voltage polarity remains fixed.

Single-Phase Motor: Powered by standard household AC supply (120V or 230V AC).

Three-Phase Motor: Powered by industrial 3-phase supply (commonly 208V, 380V, 415V, or 460V AC).

If your power source connects directly to positive and negative terminals, not labeled as L1, L2, L3, it's a DC motor.

Step 3: Examine the Terminal Box or Wiring

Open the terminal box or inspect the lead wires:

DC motors usually have two main terminals (positive and negative).

Some DC motors may have extra small wires for speed control or feedback (in case of servo or BLDC motors).

AC motors have three or more wires labeled as U, V, W, or L1, L2, L3 for 3-phase motors, and L1, L2 for 1-phase motors.

✅ Quick check:

If you only see two heavy terminals (labeled + and –), it's DC.

If you see three terminals labeled L1, L2, L3, it's 3-phase AC.

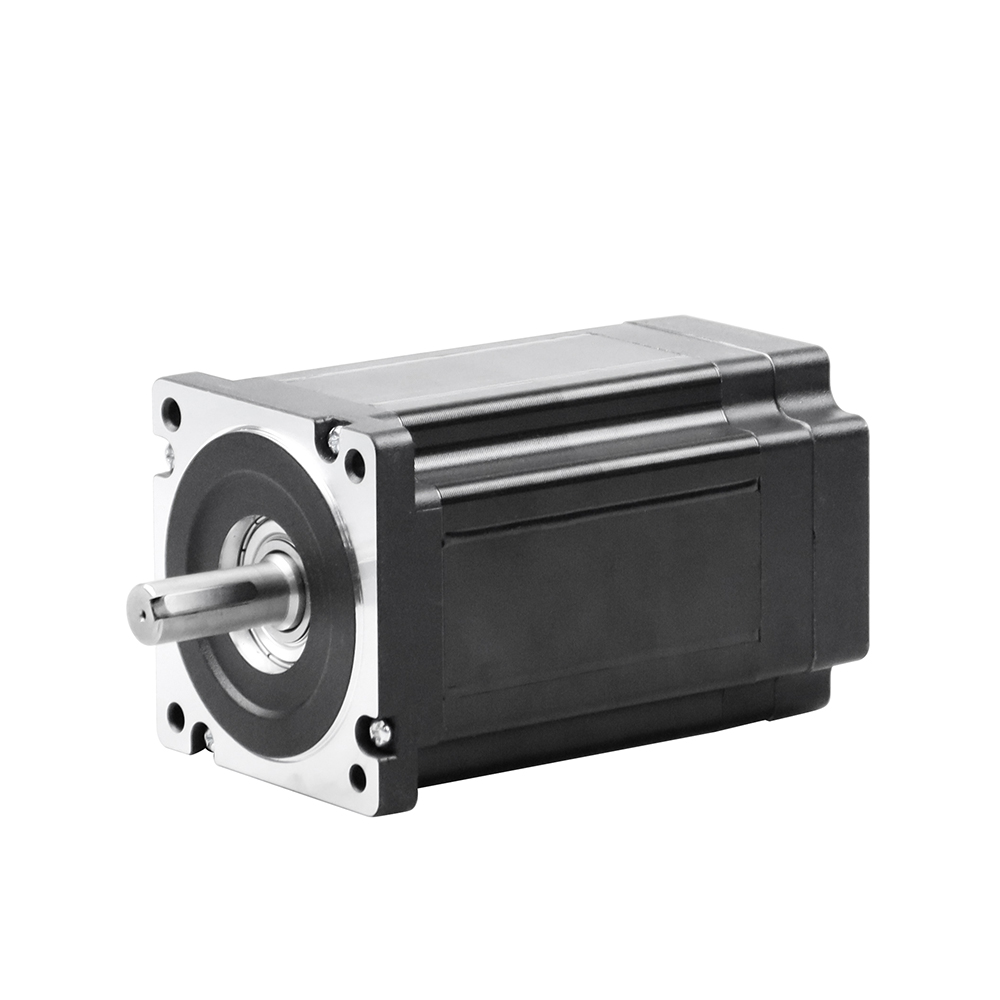

Step 4: Look for Brushes and Commutator

Another physical feature that distinguishes DC motors from AC motors is the presence of brushes and a commutator.

Brushed DC Motors have a rotating commutator and carbon brushes that transfer current to the armature.

Brushless DC Motors (BLDC) use electronic controllers instead of brushes.

AC Motors generally do not have brushes (except universal motors).

If you can see or detect a commutator and brushes, you're certainly looking at a DC motor, which means phases don't apply.

Step 5: Check the Motor Controller or Drive

If your motor is connected to a controller or driver, this can reveal its type:

If your controller mentions “PWM DC output” or “H-bridge,” it's a DC system.

If it mentions “3-phase output,” it's driving an AC motor.

Step 6: Measure with a Multimeter

You can verify the type of power feeding your motor using a multimeter:

Set your multimeter to voltage measurement.

Connect the probes to the motor supply lines.

Observe the reading:

If the voltage remains steady, it's DC.

If the voltage alternates (positive and negative periodically), it's AC.

A steady reading confirms DC power — meaning the concept of 1-phase or 3-phase doesn't apply.

Why DC Motors Don't Have Phases

In electrical engineering, you often hear about single-phase and three-phase motors — but these classifications apply only to AC (Alternating Current) motors. When it comes to DC (Direct Current) motors, the term “phase” simply doesn't apply. Understanding why DC motors don't have phases requires looking at how current flows, how magnetic fields are generated, and how motion is produced inside these motors.

Understanding What “Phase” Means

In AC systems, a “phase” refers to a sinusoidal waveform of alternating current that cycles between positive and negative polarity.

A single-phase system has one alternating voltage.

A three-phase system has three separate voltages, each 120° out of phase with the others.

These multiple waveforms allow for constant power delivery and smoother torque, which is why 3-phase AC motors are used in industrial applications.

However, DC power doesn't alternate — it flows in one continuous direction, meaning there's no phase angle, no frequency, and therefore, no phases.

How DC Motors Work Without Phases

A DC motor operates on steady direct current. When voltage is applied, current flows through the armature winding, creating a magnetic field. The interaction between this magnetic field and the stator's field produces rotational torque.

The direction of torque is maintained by mechanical or electronic switching:

In brushed DC motors, the commutator reverses the current flow in the armature coils.

In brushless DC motors (BLDC), electronic controllers perform the switching function.

This switching keeps the rotor spinning smoothly, but it does not create phases like AC systems do — it's simply changing current direction, not generating alternating waveforms.

Phases Belong to AC Power Systems

To clarify:

Thus, in a DC system, you only have positive and negative terminals — not “L1, L2, L3” phase lines. The phase concept only applies when the current alternates between directions at a frequency (like 50 Hz or 60 Hz).

The Exception: 3-Phase Brushless DC Motors

You may encounter the term “3-phase DC motor” in reference to BLDC motors, which can be confusing.

A Brushless DC Motor (BLDC) is powered by DC voltage, but its electronic controller converts that DC into three alternating signals that are 120° apart — effectively creating a three-phase AC-like output to drive the motor windings.

In other words:

The motor itself operates using three “phases” internally.

The power supply, however, remains DC.

So, a 3-phase BLDC motor doesn't receive three-phase power directly; instead, it simulates a three-phase operation electronically.

Why This Matters

Understanding that DC motors don't have phases helps prevent wiring and power-supply mistakes. For example:

When identifying a motor:

If you see + and – terminals, it's DC.

If you see L1, L2, L3, it's three-phase AC.

Summary

| Feature | DC Motor | AC Motor |

| Type of Current | Direct (steady flow) | Alternating (reversing flow) |

| Phases | None | Single-phase or three-phase |

| Power Supply Terminals | + and – | L1, L2, L3 |

| Current Flow | Constant direction | Alternates 50–60 times per second |

| Torque Generation | Magnetic interaction with commutation | Rotating magnetic field |

In Simple Terms

DC motors don't have phases because they don't rely on alternating current. The current in a DC motor flows in one direction, creating a constant magnetic field. Motion is maintained by commutation, not by alternating waveforms or phase-shifted power supplies.

If the motor uses electronic switching (as in BLDC designs), the “phases” exist only inside the controller, not in the input power. So, while you might hear about three-phase BLDC motors, the truth is — they are still powered by DC, not true multi-phase AC power.

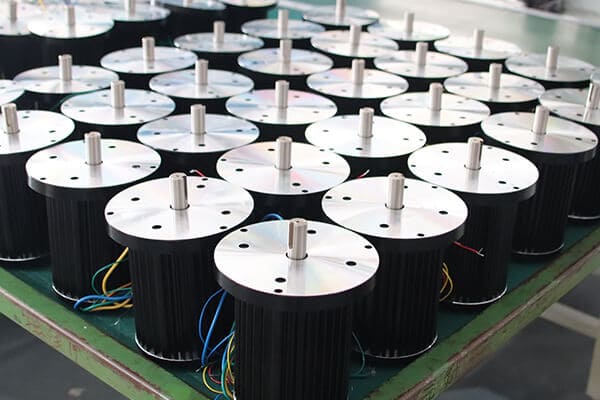

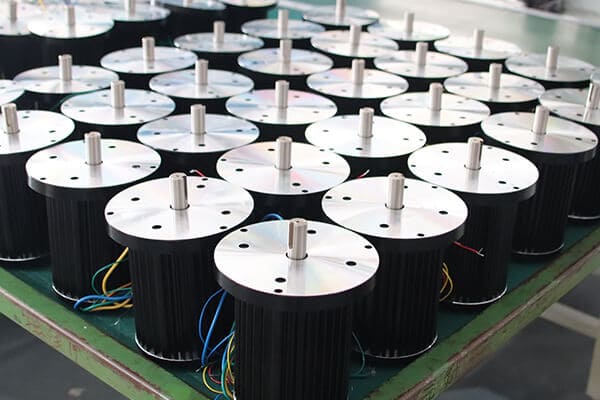

Identifying a 3-Phase Brushless DC (BLDC) Motor

This is the only type of DC motor that involves something similar to “phases.”

A BLDC motor has:

Three wires labeled U, V, W (for the three stator windings).

Electronic speed controller (ESC) or driver circuit that converts DC input into three-phase AC-like signals.

Even though it's powered by DC, the internal operation uses three electronically commutated phases. This is why BLDC motors are sometimes called “3-phase DC motors.”

✅ To identify a BLDC motor:

Look for three power wires.

Check if the driver says “3-phase output” or “BLDC controller.”

Verify that the input power is DC (e.g., 24V DC).

Summary: Quick Identification Guide

| Feature | DC Motor | 1-Phase AC Motor | 3-Phase AC Motor |

| Power Type | Direct Current | Alternating Current | Alternating Current |

| Terminals | 2 (+ and –) | 2 (L1, L2) | 3 (L1, L2, L3) |

| Power Source | Battery or DC Supply | Household AC | Industrial AC |

| Label | “DC” | “1 Phase” | “3 Phase” |

| Brushes | Yes (Brushed DC) | No | No |

| Controller | DC Driver | Capacitor/Relay | VFD/Inverter |

Conclusion

To determine if a motor is single-phase or three-phase, first confirm whether it's AC or DC.

If the motor operates on DC power, then it's not classified by phases at all — it's simply a DC motor. However, if it's a BLDC motor , it might use three internal electronic phases driven by a controller, making it somewhat analogous to a 3-phase system.

Always begin by checking the nameplate, wiring, and power source to correctly identify your motor type. Understanding these differences ensures proper installation, control, and maintenance in any electrical setup.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català