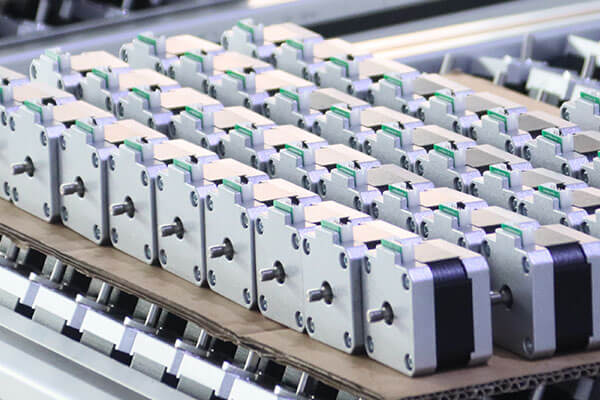

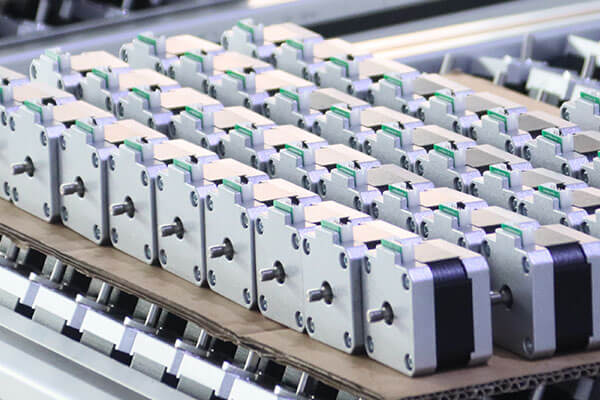

Stepper Motors are widely used in CNC machines, 3D printers, robotics, and automation systems due to their precision and reliability. However, like any electromechanical device, they can develop faults over time. When a stepper motor goes bad, it can cause serious issues such as inconsistent movement, loss of torque, vibration, or complete system failure. Understanding the causes, symptoms, and solutions can help you diagnose and prevent costly downtime.

Understanding How a Stepper Motor Works

A stepper motor operates by dividing a full rotation into a number of equal steps. Each pulse sent from the driver corresponds to one step of rotation. Unlike traditional DC motors, stepper motors move in discrete increments, making them ideal for applications requiring accurate positioning and speed control.

The motor consists of a rotor (the rotating part) and a stator (the stationary part with coils). When the stator windings are energized in sequence, a magnetic field is created that causes the rotor to align with it. This process repeats to create continuous motion.

When the motor or its control circuitry fails, this precise synchronization is lost — leading to various performance issues.

Common Symptoms of a Failing Stepper Motor

When a stepper motor begins to fail, it often shows several warning signs that indicate electrical, mechanical, or thermal issues. Recognizing these symptoms early can help you prevent costly downtime and extend the lifespan of your equipment. Below are the most common and critical signs that your stepper motor may be going bad:

1. Stalling or Missing Steps

A healthy stepper motor moves in precise, incremental steps. If your motor begins to stall, skip steps, or lose synchronization, it's a clear sign of trouble. This usually occurs when the motor is overloaded, the supply current is insufficient, or the driver signals are unstable. Stalling leads to inaccurate positioning, which can seriously affect applications that require high precision, such as CNC machinery and 3D printers.

2. Excessive Noise or Vibration

Unusual buzzing, grinding, or rattling noises often indicate bearing wear, rotor imbalance, or misalignment. Excessive vibration can also result from incorrect microstepping settings or loose motor mounts. If ignored, vibration not only reduces accuracy but can also cause long-term mechanical damage.

3. Overheating

A stepper motor that becomes too hot to touch is likely under excessive electrical or mechanical load. Overheating damages the winding insulation, weakens the magnets, and can lead to irreversible coil failure. Common causes include overcurrent, poor ventilation, or continuous high-speed operation beyond the motor's rating.

4. Reduced Torque Output

If your motor seems weaker than usual or fails to hold its position when energized, it may have lost holding torque. This can result from demagnetized rotor magnets, shorted coils, or power driver malfunction. Reduced torque not only compromises precision but also signals that the motor is nearing the end of its operational life.

5. Irregular or Jerky Motion

A stepper motor should rotate smoothly in evenly spaced steps. If it begins to move erratically, unevenly, or in unpredictable directions, this suggests signal interference, driver issues, or wiring faults. Jerky motion is a major indicator that the motor is struggling to receive or process control signals properly.

6. Motor Not Moving at All

The most obvious sign of failure is a completely non-responsive motor. If power is applied but the motor doesn't move, check for open windings, damaged cables, loose connections, or a burned-out driver. In severe cases, the coils may be electrically shorted, requiring complete motor replacement.

7. Unusual Smell or Burn Marks

A burning odor or visible discoloration on the motor casing indicates overheating or insulation failure. This is a serious issue that typically means internal components have been damaged. Continuing to operate the motor in this state can lead to total burnout or even pose a fire hazard.

Conclusion

Understanding these common symptoms of a failing stepper motor can help you detect problems before they escalate. Regular inspection, proper current limiting, adequate cooling, and careful alignment are key to keeping your stepper motor performing reliably. If you notice any of these warning signs, take immediate action to troubleshoot, repair, or replace the motor before further damage occurs.

Electrical Causes of Stepper Motor Failure

Electrical issues are among the most common causes of stepper motor failure. Since a stepper motor relies on precise electrical pulses to control its position and speed, any inconsistency or fault in the electrical system can lead to erratic performance, overheating, or total breakdown. Below are the primary electrical causes that can damage a stepper motor and how each one affects performance.

1. Overvoltage and Undervoltage Conditions

Operating a stepper motor at incorrect voltage levels is one of the fastest ways to cause damage.

Overvoltage can lead to insulation breakdown in the windings, generating excessive heat that burns the coils or driver components.

Undervoltage, on the other hand, causes insufficient torque and may lead to step loss or stalling, especially under load.

Maintaining voltage within the manufacturer's specified range ensures stable performance and prevents premature wear of electrical components.

2. Overcurrent and Improper Current Settings

Every stepper motor has a maximum rated current. When the driver supplies more current than the motor can handle, the windings overheat, leading to insulation degradation and eventual short circuits.

Improper current settings on the stepper driver, especially in constant current modes, can cause continuous overloading even if voltage levels seem correct. Using current-limiting drivers and adjusting them properly is crucial to prevent thermal and electrical stress.

3. Driver Circuit Malfunction

The stepper motor driver is responsible for delivering timed electrical pulses to each phase. If the driver malfunctions due to component failure, software bugs, or overheating, it can send incorrect or unbalanced signals to the motor.

Symptoms of a faulty driver include irregular rotation, sudden reversals, or the motor locking up. Long-term exposure to bad signals can damage the motor windings and reduce magnet strength.

4. Faulty Wiring and Loose Connections

Improper or deteriorated wiring is another frequent source of failure. Loose, corroded, or broken connections between the motor and driver can cause intermittent power supply, resulting in vibration, skipped steps, or motor stoppage.

In severe cases, short circuits can occur, damaging both the driver and the motor coils. Using shielded cables, secure connectors, and performing regular wiring inspections help prevent such electrical interruptions.

5. Incorrect Signal Timing or Pulse Frequency

A stepper motor relies on precise pulse timing to move accurately. When the control signals arrive too quickly or irregularly, the motor cannot follow them properly, causing missed steps, stalling, or loss of synchronization.

This usually happens when the controller's pulse frequency exceeds the motor's acceleration capability. Adjusting acceleration ramps and ensuring proper synchronization between the controller and driver can eliminate this issue.

6. Grounding and Electrical Noise Problems

Poor grounding and electrical interference (EMI or RFI) can distort the pulse signals that control the stepper motor. Nearby power cables, switching power supplies, or high-frequency devices can introduce noise into the signal lines.

The result is unpredictable behavior, including sudden stops, vibration, or loss of torque. Proper grounding, twisted-pair cables, and shielded wiring are effective measures to minimize noise-related failures.

7. Power Supply Instability

A fluctuating power source can cause repeated voltage spikes or drops that stress both the driver and the motor. These fluctuations can trigger overcurrent protection, reset the driver, or even damage control electronics.

Using a regulated power supply with surge protection ensures a consistent voltage feed and prevents electronic components from burning out.

8. Coil Short Circuits or Open Windings

If the motor windings develop an internal short circuit, the affected phase will draw excessive current, resulting in heat buildup and uneven rotation.

Alternatively, an open winding—where the coil wire breaks—causes the motor to lose an entire phase, drastically reducing torque and creating erratic motion.

These failures are usually permanent and require the replacement of the motor.

9. Static Discharge and Power Surges

Electrostatic discharge (ESD) or lightning-induced surges can destroy sensitive electronic components within the driver and controller. Even minor surges can weaken the insulation or damage the semiconductor switches inside the driver circuit.

To protect against these, always use surge protectors, proper grounding, and ESD-safe handling procedures when installing or maintaining stepper systems.

Conclusion

Electrical issues are often silent but destructive causes of stepper motor failure. Whether it's incorrect current settings, power supply fluctuations, or faulty connections, these problems can shorten the motor's lifespan and affect overall system performance.

Regular inspection, stable power sources, and proper grounding techniques are essential to keep your stepper motor operating reliably and efficiently. Early detection of electrical faults can save both time and costly repairs.

Mechanical Causes of Stepper Motor Failure

Besides electrical faults, mechanical problems also contribute significantly to motor degradation.

1. Bearing Wear

Stepper motor bearings endure constant stress from both radial and axial loads. Over time, they can wear out, resulting in increased friction, vibration, and noise. Once the bearings seize, the rotor cannot turn smoothly, causing performance loss.

2. Shaft Misalignment

Improper alignment between the motor shaft and the load can lead to uneven wear and excessive mechanical load. This not only damages the motor bearings but also causes the system to lose synchronization.

3. Debris and Contamination

Dust, oil, and metal particles can infiltrate the motor housing, leading to blockage or corrosion of internal parts. Contamination may also short circuit the windings if it reaches the stator.

4. Rotor Magnet Degradation

Over time, excessive heat or mechanical shock can demagnetize the rotor magnets, reducing torque output and accuracy. This issue is irreversible and requires motor replacement.

How to Diagnose a Bad Stepper Motor

Diagnosing a bad stepper motor requires a systematic approach to identify whether the problem lies in the motor itself, the driver, or the control circuitry. Because stepper motors depend on precise electrical pulses and mechanical synchronization, even small issues can lead to stalling, overheating, or erratic movement. Below is a comprehensive step-by-step guide on how to accurately diagnose a failing stepper motor.

1. Perform a Visual Inspection

Start with a thorough visual inspection of the motor and its components. Look for any burn marks, discoloration, corrosion, or melted insulation on the wiring and connectors. Check the shaft and housing for physical damage, dirt buildup, or oil contamination.

If you detect a burnt smell or visible signs of overheating, the internal windings or bearings may already be damaged. In such cases, further electrical testing is recommended to confirm the extent of failure.

2. Check for Loose or Damaged Wiring

Faulty wiring is a common cause of stepper motor malfunctions. Inspect all connections between the motor, driver, and controller for loose plugs, frayed cables, or exposed conductors.

Any damaged or intermittent connection can cause the motor to stall, skip steps, or stop functioning altogether.

3. Measure Coil Resistance with a Multimeter

Each phase (coil) of a stepper motor should have a consistent resistance value. To check this:

Disconnect the motor from the driver.

Set your multimeter to the ohms (Ω) setting.

Measure resistance between the two wires of each coil (for bipolar motors) or between common and phase wires (for unipolar motors).

If one coil reads significantly higher or lower than the others, or if it reads open circuit (infinite resistance), it indicates a broken or shorted winding.

Consistent and balanced resistance readings mean the coils are likely intact.

4. Test for Short Circuits Between Coils

A short between coils or between a coil and the motor casing can cause the motor to malfunction or overheat.

To test this:

Measure resistance between each coil and the motor frame.

A reading near zero indicates a short to ground, while a very high or infinite reading means the insulation is intact.

If a short is detected, the motor must be replaced, as internal insulation damage cannot be repaired.

5. Inspect Driver Signals

The stepper driver controls the pulses sent to the motor. If the driver fails to output the correct sequence, the motor will behave erratically.

To check the driver:

Use an oscilloscope or logic analyzer to observe the step and direction signals from the controller.

Ensure the waveform is clean, consistent, and properly timed.

Check the driver output phases for voltage consistency across all terminals.

If one phase shows no output, the driver or controller could be faulty, not the motor itself.

6. Run a Functional Test

Connect the motor to a known working driver and controller. Run it at low speed first to observe behavior:

If the motor runs smoothly, the problem may be in your original driver or wiring.

If it vibrates, stalls, or produces unusual sounds, the issue is likely internal to the motor.

Gradually increase speed to test acceleration response. Irregular movement or skipped steps during acceleration suggest weak torque or electrical imbalance.

7. Check for Excessive Heat

Operate the motor under normal load for a few minutes, then monitor its temperature.

Consistent overheating often means the motor's insulation or bearings are failing and the motor should be replaced.

8. Listen for Unusual Sounds

Healthy stepper motors emit a smooth, rhythmic sound when stepping. If you hear clicking, grinding, or high-pitched buzzing, it suggests bearing wear, rotor misalignment, or driver pulse mismatch.

Mechanical noise is often accompanied by reduced torque or erratic movement, confirming a mechanical or hybrid failure.

9. Evaluate Holding Torque

With the motor energized but not rotating, gently try to rotate the shaft by hand. A properly functioning motor should resist movement due to holding torque.

If the shaft turns easily, one or more phases may not be energizing correctly. This could result from open windings, driver failure, or demagnetized rotor magnets.

10. Swap Components to Isolate the Problem

If multiple motors and drivers are available, perform a component swap test:

Connect a known-good motor to the same driver.

If it runs normally, your original motor is faulty.

If the problem persists, the issue lies in the driver, wiring, or control signals.

This is one of the fastest ways to isolate the root cause without needing advanced diagnostic tools.

Diagnosing a bad stepper motor involves a careful combination of visual inspection, electrical testing, and functional analysis. By following these steps, you can accurately identify whether the issue lies in the motor windings, connections, or driver circuit.

Regular maintenance, proper current settings, and clean electrical connections are the best ways to prevent future failures. If the motor shows signs of burnt windings, short circuits, or demagnetization, replacement is the safest and most cost-effective solution.

How to Prevent Stepper Motor Failure

Preventive maintenance can significantly extend the lifespan of a stepper motor.

1. Maintain Proper Voltage and Current Levels

Always operate within the specified voltage and current range. Use current-limiting drivers to avoid overloading.

2. Ensure Adequate Cooling

Install heat sinks or fans to keep the motor cool during continuous operation. Overheating drastically reduces insulation life.

3. Regular Lubrication and Cleaning

Keep the motor clean and lubricate bearings periodically (if serviceable). Avoid operating in dusty or oily environments without protective enclosures.

4. Avoid Overloading

Ensure the load torque does not exceed the motor's rated capacity. Overloading can cause skipped steps and long-term mechanical wear.

5. Use Proper Mounting and Alignment

Misalignment increases mechanical stress. Always align the motor shaft precisely with the driven load using flexible couplings if necessary.

When to Replace a Stepper Motor

Even with proper maintenance, stepper motors have a finite lifespan. Replace the motor if you notice:

Persistent overheating despite corrections

Severe vibration or noise

Significant torque loss

Burnt smell or visible coil damage

Frequent missed steps after tuning

Replacing a faulty stepper motor promptly ensures optimal machine performance, reliability, and safety.

Conclusion

When a stepper motor goes bad, it can disrupt your entire automation system. Recognizing the symptoms early, performing systematic diagnostics, and maintaining proper operation parameters can prevent catastrophic failures. By understanding the electrical and mechanical factors behind motor degradation, you can take proactive measures to ensure smooth, precise, and long-lasting performance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català